Transcription

MIGATRONICCONSUMABLES

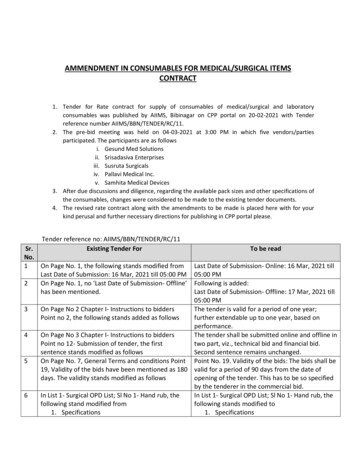

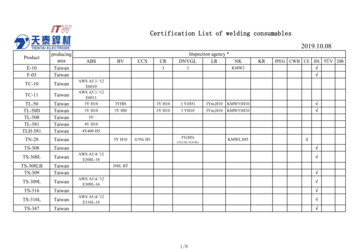

CONTENTMIG/MAGSolid wire - mild steelSG2 Precision Layer Wire - Copper-free. 6SG2 Random wire - Copper-coated . 6SG2 Precision Layer Wire - Copper-coated. 7SG3 Precision Layer Wire - Copper-coated. 7Solid wire - othersMIGAWIRE HTS for high-tensile steel. 8MIG 80S NI for fine-grained steel and high-tensile steel. 8MIGA SG CU for corten steel. 8MIGA SG1 Galva Wire for galvanised plates and workpiecesfor galvanising. 9MIGA HARD 600 for hardfacing. 9Stainless steelMIG 309 LSi. 10MIG 316 LSi. 10Aluminium wireALU MIG AlSi5. 11ALU MIG AlSi12. 11ALU MIG AlMg 4.5Mn. 11ALU MIG AlMg 5. 12Wire for MIG brazingMIGA MIG CuSi 3. 12MIGA MIG CuAl 8. 122

Flux-cored wire - FCWMIGA FCW Innershield for mild steel. 13MIGA FCW115 for mild steel. 13MIGA FCW215 for mild steel . 13MIGA FCW217 for mild steel . 14MIGA FCW Hard 5CR for hardfacing. 14TIGMild steelMIGA KV2 TIG for mild steel. 15Stainless steelTIG 309 LSi. 15TIG 316 LSi. 16Aluminium wireALU TIG AlSi 5 . 16ALU TIG AlMg 4.5Mn. 16ALU TIG AlMg 5. 17Tungsten electrodesTungsten electrode WP - Green. 17Tungsten electrode WL10 - Black. 17Tungsten electrode WL20 - Blue. 18Tungsten electrode WS2 - Super Blue. 18Tungsten electrode WL20 - pointed 20 degrees. 183

MMABasic / Rutile-coated electrodesMIGA R 100 rutile-coated electrode. 19MIGA B 120 basic electrode. 19MIGA NI nickel electrode. 20MIGA 600B for hardfacing. 20RB86 double-coated basic (rutile-basic). 20Stainless electrodes316L stainless electrode. 21GougingGouging electrode DC. 21Backing materialAluminium tape for backing. 22Ceramic backing on tape. 22Magnet til ceramic backing. 22ContactIf you have any questions relating to our consumable products,please do not hesitate to contact us by sending an e-mail to:Consumables@Migatronic.com4

CLASSIFICATION LEGENDEXAMPLE: G 42 2 M 3Si1G Solid wire42 Yield strength / Tensile strength2 Temperature for minimum average impact energyM/C Shielding gasM2 : Mixed gas without HeM21: Mixed gas Ar 15 to 25% CO2C1 : Active gas 100 % CO23Si1Chemical composition SPOOL TYPES:D200 plastic spoolD300 plastic spoolUse adapter 45050333 on machinesprepared for 300mm spools.K300 steel spoolBS300 steel spool with hubUse adapter 81899017 on K300 spools.5

MIG/MAG CONSUMABLESSolid wire - mild steelSG2 Precision Layer Wire - Copper-freeClassification according toEN ISO 14341-A: G 42 4 M21 3Si1 / G 42 2 C1 3Si1AWS A5.18: ER 70S-6Copper-free solid wire for mild steel. PLW quality.QualitySpool typeSG2BS300/15 kgSG2BS300/15 kgSG2BS300/15 kg0.6 mm0.8 mm1.0 mm1.2 mm818405628184056481840565SG2 Random wire - Copper-coatedClassification according toEN ISO 14341-A: G 46 4 M21 3Si1 / G 42 2 C1 3Si1AWS A5.18: ER 70S-6Copper-coated solid wire in SG2 quality for mild steel. Random wire quality.QualitySpool type0.6 mmSG2D200/5 kg81840611SG2D300/15 kg81840621Classification according toQualitySpool typeSG2D200/5 kgSG2D200/5 kgSG2D200/5 kg0.8 mm1.0 mm1.2 mmEN ISO 14341-A: G 42 4 M21 3Si1 / G 42 2 C1 3Si1AWS A5.18: ER 70S-60.6 mm0.8 mm1.0 mm1.2 mm8184070281840704818407056

Solid wire - mild steelSG2 Precision Layer Wire - Copper-coatedClassification according toEN ISO 14341-A: G 42 4 M21 3Si1 / G 42 2 C1 3Si1AWS A5.18: ER 70S-6Copper-coated solid wire in SG2 quality for mild steel. PLW quality.QualitySpool typeSG2BS300/15 kgSG2BS300/15 kgSG2BS300/15 kgSG2300 kg fustageSG2300 kg fustage0.6 mm0.8 mm1.0 mm1.2 mm8184076281840764818407658184077481840775SG3 Precision Layer Wire - Copper-coatedClassification according toEN ISO 14341-A: G 46 4 M21 4Si1 / G 42 3 C1 4Si1AWS A5.18: ER 70S-6Copper-coated solid wire in SG3 quality for mild steel. PLW quality.QualitySpool typeSG3BS300/15 kgSG3BS300/15 kgSG3BS300/15 kgSG3300 kg fustageSG3300 kg fustageSG3300 kg fustage0.6 mm0.8 mm1.0 mm1.2 7

Solid wire - othersMIGAWIRE HTS - Precision Layer WireClassification according toEN ISO 16834-A: G 69 4 M Mn3Ni 1CrMoAWS A5.18: ER 100 S-GSolid wire for welding of high-tensile steel with tensile strength up to755N/mm². Applicable for cranes, pressure-carrying equipment and similarstatically and dynamically influenced structures. PLW quality.Spool type0.6 mm0.8 mmD300/15 kg1.0 mm1.2 mm81841408D300/15 kg81841410D300/15 kg81841412MIG 80S NIClassification according toEN ISO 14341-A: G 46 5 M21 3Ni1AWS A5.28: ER 100 S-GManganese-nickel-alloy wire for welding of fine-grained steel tolow-temperature steel and high-tensile steel.Spool type0.6 mm0.8 mmD300/15 kg1.0 mm1.2 mm81843000MIGA SG CU - Precision Layer WireClassification according toEN ISO 16834-A: G Mn3Ni1CUAWS A5.28: ER 80 S-GEN ISO 14341-A: G504M21ZSolid wire for welding of corten steel, which is a corrosion-slow steel type.Copper-coating ensures fine current transfer. PLW quality.Spool type0.6 mm0.8 mmD300/15 kg1.0 mm81843208D300/15 kg8184321081.2 mm

Solid wire - othersMIGA SG1 Galva Wire - Precision Layer WireClassification according toEN ISO 14341-A: G 422M21ZAWS A5.18: ER 70 S-GSolid wire in SG1 quality for welding of workpieces for subsequent galvanising.Also applicable for welding of galvanised, alu-coated or primed surfaces.PLW quality.Spool type0.6 mmD200/5 kg818451060.8 mmD200/5 kg81845108D300/15 kg81845008K300/15 kg1.0 mm1.2 mm81845010MIGA HARD 600 - Precision Layer WireClassification according toEN ISO 14700: S FE8AWS A5.14: MSG 6-6Z-60Solid wire for hardfacing. Applicable for rebuilding surfaces of heavily wornconstruction equipment shovels and the like. PLW quality.Spool type0.6 mm0.8 mmD300/15 kg1.0 mm1.2 mm81845310D300/15 kg8184531281010027 Wire liner18480040 Screw connection18480041 Nut81921020 Plastic top81840XXX Drum9

Stainless steelMIG 309 LSiClassificationaccording toEN ISO 14343-A: G 23 12 LSiAWS A5.9: ER 309L (Si)Applicable for welding of joints between mild steel and stainless steel.Also applicable for welding on unalloyed steel if you want an 18 Cr/8Ni steelsurface. Recommended for buffer coating.Spool type0.6 mmBS300/15 kg0.8 mm1.0 mm1.2 mm1.6 mm81841708BS300/15 kg81841710BS300/15 kg81841712MIG 316 LSiClassificationaccording toEN ISO 14343-A: G 19 123 LSiAWS A5.9: ER 316L (Si)Applicable for welding of acid-proof low-carbon austenitic stainless steel.High silicon content provides fine flow properties. Operating temperatureranging from -196 C to 350 C.Spool type0.6 mm0.8 mmD200/5 kg81841805BS300/15 kg818438081.0 mmD200/5 kg81841803BS300/15 kg81843810BS300/15 kg1.2 mm81843812101.6 mm

Aluminium wireALU MIG AlSi5Classificationaccording toEN ISO 18273: S AL 4043AWS A5.10: ER 4043Aluminium wire with 5% silicon is the most common AlSi wire. Provides a nicesurface. Ideal for the auto business and welding of common structures.Not seawater-proof and not suitable for workpieces which are subsequentlyanodised.Spool type0.6 mm0.8 mm1.0 mmD300/6 kg1.2 mm1.6 mm81846110D300/6 kg81846112ALU MIG AlSi12Classificationaccording toEN ISO 18273: S AL 4047AWS A5.10: ER 4047Aluminium wire with 12% silicon is softer than AlSi5 and light-fluid.Not seawater-proof and not suitable for workpieces which are subsequentlyanodised.Spool type0.6 mm0.8 mm1.0 mmD300/6 kg1.2 mm1.6 mm81846212ALU MIG AlMg 4.5MNClassificationaccording toEN ISO 18273: S AL 5183AWS A5.10: ER 5183Aluminium wire with 4.5% magnesium plus manganese. Seawater-proof.Allows subsequent anodising of workpieces. Typically used for ship-building.Spool type0.6 mm0.8 mm1.0 mmD300/6 kg1.2 mm81846610D300/6 kg81846612111.6 mm

Aluminium wireALU MIG AlMg 5Classification according toEN ISO 18273: S AL 5356AWS A5.10: ER 5356Aluminium wire with 5% magnesium is the most common and versatile fillermaterial for aluminium. Seawater-proof. Allows subsequent anodising ofworkpieces.Spool type0.6 mmD200/2 kg0.8 mm1.0 mm1.2 mm1.6 mm81846700D200/2 kg81846701D200/2 kg81846702D300/5 kg81846708D300/6 kg81846710D300/6 kg8184671280 kg drum8184672580 kg drum81846732Wire for MIG brazingMIGA MIG CuSi 3wire for MIG brazingClassification according toEN ISO 18273: S CU 6560/SUSi3MN1AWS A5.7: ER CuCi ACopper-silicon wire for MIG brazing. Typically used in the auto business forjoining high-tensile steel or coated workpieces.Spool type0.6 mm0.8 mmD300/15 kg81846808D200/5 kg818468091.0 mmD300/15 kg81846810D200/5 kg818468111.2 mm1.6 mmMIGA MIG CuAl 8 wire for MIG brazingClassification according toEN ISO 18273: S CU 6100/CUAL7AWS A5.7: ER CuAl-A-1Copper-aluminium wire for MIG brazing. Typically used in the auto business forjoining aluminium or coated workpieces.Spool typeD200/5 kgD200/5 kg0.6 mm0.8 mm1.0 mm8189005512818900561.2 mm1.6 mm

Flux-cored wire - FCWMIGA FCW Innershield for mild steelEN ISO 17632-A: T 46 Z Y N 1AWS A5.20: E 71-T11Classification according toSelf-protective seamless cored wire for all welding positions.For unalloyed and low-alloy steel.Spool type0.9 mmD200/5 kg818411041.0 mm1.2 mmD200/5 kg81841109K300/16 kg81841110MIGA FCW115 for mild steelEN ISO 17632-A: T 46 6 MM1H5AWS A5.18: E 70C-6 MH4Classification according toCopper-coated seamless metal-cored wire. For single-pass and multi-pass weldingof carbon-manganese steel and fine-grained steel.Spool type0.9 mm1.0 mm1.2 mmD200/5 kg81841211K300/16 kg81841215MIGA FCW215 for mild steelEN ISO 17632-A: T 46 2 PM1H5AWS A5.20: E 71T-1 MH4Classification according toSeamless rutile flux-cored wire for welding of carbon steel and carbonmanganese steel. Applicable for all welding positions.Spool type0.9 mm1.0 mmD200/5 kg1.2 mm81841242D200/5 kg81841220K300/16 kg81841222K300/16 kg8184122513

Flux-cored wire - FCWMIGA FCW217 for mild steelEN ISO 17632-A: T 50 6 1NiPM1H5AWS A5.29: E 81T1-Ni1Classification according toSeamless rutile flux-cored wire for single-pass and multi-pass welding oflow-temperature steel.Spool type0.9 mm1.0 mmK300/16 kg1.2 mm81841235MIGA FCW Hard 5CR for hardfacingEN 14700: T FE 8DIN 8555Classification according toChromium-molybdenum-alloy metal-cored wire for hardfacing. HRC 57-62.Spool type0.9 mm1.0 mmK300/16 kg1.2 mm8184141314

TIG CONSUMABLESMild steelMIGA KV2 TIG for mild steelEN ISO 636-A: W MoSiAWS A5.28: ER 805-D2Classification according toTIG wire for welding of 0.5% molybdenum steel and pressure-carrying equipment. Prevents cold cracks in the welding metal. Applicable for boilers, pressuretanks, pipings if operating temperature 550 C.Art. no.DiameterLengthPacking818501161.6 mm1000 mm5 kg818501202.0 mm1000 mm5 kg818501242.4 mm1000 mm5 kg818501323.2 mm1000 mm5 kgStainless steelTIG 309 LSiEN ISO 14343-A: W 23 12 LSiAWS A5.9: ER 309LSiClassification according toApplicable for welding of joints between mild steel and stainless steel. Alsoapplicable for welding on unalloyed steel if you want an 18 Cr/8Ni steel surface.Recommended for buffer coating.Art. no.DiameterLengthPacking818517121.2 mm1000 mm5 kg818517161.6 mm1000 mm5 kg818517202.0 mm1000 mm5 kg818517242.4 mm1000 mm5 kg818517323.2 mm1000 mm5 kg15

TIG 316 LSiEN ISO 14343-A: W 19 12 3 L SiAWS A5.9: ER 316LSiClassification according toApplicable for welding of acid-proof low-carbon austenitic stainless steel. Highsilicon content provides fine flow properties. Operating temperature rangingfrom -196 C to 35

AWS A5.10: ER 5183 Aluminium wire with 4.5% magnesium plus manganese. Seawater-proof. Allows subsequent anodising of workpieces. Typically used for ship-building. Spool type 0.6 mm 0.8 mm 1.0 mm 1.2 mm 1.6 mm D300/6 kg 81846610 D300/6 kg 81846612. 12 Aluminium wire ALU MIG AlMg 5 Classification according to EN ISO 18273: S AL 5356 AWS A5.10: ER 5356 Aluminium wire with 5%