Transcription

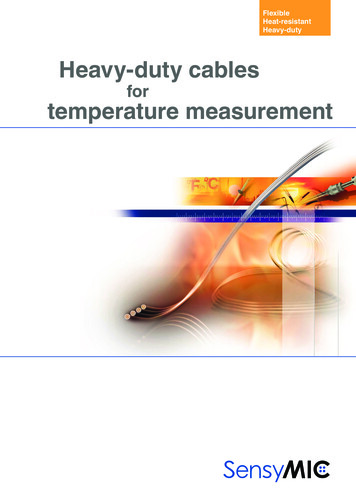

FlexibleHeat-resistantHeavy-dutyHeavy-duty cablesfortemperature measurementSensy IC

Pioneer intemperaturemeasurementfor over 50 yearsSensyMIC is one of the world‘s most experienced suppliersof mineral-insulated cables for temperature measurement.SensyMIC represents a long tradition in the production ofsheathed cables. Founded by Degussa in the 1960s, thedivision was part of the ABB Group for 18 years and hasbeen part of the WIKA Group since the beginning of 2017.SensyMIC is synonymous with outstanding quality ofproducts and modern manufacturing processes.On the basis of this know-how, we continuously promote thefurther development and improvement of our product rangefor reliable temperature measurement. Thus we are also ableto offer suitable solutions for individual applications.2Globally presentOur demandOur focus is on establishing close co-operation inpartnership with our customers from the widest range ofindustries and with the widest range of applications. We donot just offer high-quality technical solutions, but alsocomprehensive support, with which we contribute to thecontinuous improvement of our customers‘ businessprocesses.SensyMIC manufactures products to the highest qualitylevel. Custom-tailored solutions for our OEM partners forthese industries: Chemical and petrochemical industriesEnergy and steam generationFood and beverageOil and gasBasic materials industryPharmaceutical industryMachine building and automation

Mineral insulated metal sheathedcables for MIMS thermometersin accordance with IEC 61515Due to rational processing methods, MIMS cables can beused in a wide range of applications, in particular in the fieldof industrial measurement and control, as an example, insensor technology for chemical or petrochemical plants, formachine building and also for applications in hazardousareas.MIMS cables are suitable for use in extreme temperatureranges. They are used wherever particularly high demandsexist in relation to mechanical, chemical and electricalstability.Sensy IC3

Outstanding quality features ofSensyMIC MIMS cablesReproducible long-termstable EMF values byagingSensyMICPremium classThrough additional temperature processes, an aging orwith the already-proven SensyMIC premium class as thestabilisation of thermoelectric EMF values of the most-frequently used type K is achieved. The EMF values certifiedin the calibration protocol can be reproduced at any timeIn addition to the standardised tolerance classes ofinternational standards, we supplement our product rangestarting material for sensors that meet the requirements ofthe AMS 2750E or CQI-9 specifications.with proper handling of the MIMS cable.Very high insulationresistanceThe insulation material from highly compressed magnesiumor aluminium oxide (ceramic capillaries) exhibits very goodinsulation characteristics, even at high temperatures. Inthe ‚as-delivered‘ condition, the insulation resistance of allMIMS cables is 30 GOhm at room temperature.Ductility testAt SensyMIC, all final MIMS cables undergo a ductility test inwhich the bending diameter is three times the outsideHomogenous surfacestructurediameter of the sheathed cable. Through this even strongerAn additional polishing process, as the last production step,standard, the SensyMIC MIMS are particularly suitable forlayer created during this surface treatment delays thetest in comparison to the international DIN EN 61515ensures a homogeneous surface structure. The passivationuse in cramped installation situations.formation of corrosion and intrusion of pollutants from theend-user process into the MIMS cable and decisivelyincreases the reliability.4

Long-term stabilityA longer service life and long-term stability in the field ofsensors for aggressive environmental conditions is achievedthrough double-sheath technology. Due to the doublegrain boundary layers of the two tube materials, processedone above the other, a higher process reliability and delayedcorrosion processes in use are achieved.Homogenous outerdiametersHomogenous outer diameters are achieved through the useof drawing dies made of industrial diamond. This means, forexample, tolerance range 0 in the positive range of theoutside diameter is part of our standard, unless otherwisespecified by the customer.5

The right metal sheathed cable foreach application areaThe sheathThe conductor materialsCommon to all MIMS cables is the metal sheath, whichmakes it mechanically and chemically resistant to theinfluences of the medium to be measured. Sheathed cablesare produced with a jacket of cold-workable metals, inparticular from the entire range of austenitic stainless steels.For the vast majority of applications, nickel-based alloys areused. Special sheath materials are available on request.MIMS thermocouple cables have inner leads of thermomaterial in accordance with the international DIN EN, IEC,ASTM, BS, JIS standards. Noble metal thermocouples areideal for high-temperature applications under oxidisingconditions. MIMS cables for resistance thermometers haveinner leads of copper, copper-nickel alloy, nickel, nickel-chrome or nickel-plated copper.The insulationThe standard materials for the ceramic capillaries arehigh-temperature-resistant magnesium oxide (MgO) andalso aluminium oxide (Al2O3). For the manufacture of MIMSthermocouple cables, ceramic capillaries with a purity ofbetter than 99 % are used. These insulate the inner leadsagainst electrical short circuits and keep them in the desiredgeometry.6

The productrangeSensyMIC offers a wide programme of MIMS cables for themanufacture of sheathed thermocouples and sheathedresistance thermometers. All standardised thermocouples ofthe types K, J, L, T, U, E and N, as well as the noble metalthermocouples types R, S and B can be delivered as MIMSthermocouple cables. Also, various sheathed cables withCu, CuNi, Ni and NiCr inner leads are available from stock.The MIMS cables can be manufactured in a number ofcombinations. The selection of the base materials dependson various criteria (operating temperature range, requiredheat treatment during drawing process, etc.). Sheathedcables are available in outer diameters between 0.25 to12.7 mm and can be delivered in production lengthsbetween 20 and 2,000 m, depending on the diameter.For reasons of occupational safety and better processability,however, production lengths are divided into manageablestock sizes.Temperature *MIMS thermocouple cablesIEC 584, ASTM E230, DIN 43710-200 1,300 CType ** ***K, N, J, L, E, N, R, S, BSheath(as well asdouble-sheath)Alloy 75, 600, 601, 800, TDAISI 316TI, 316L, 321, 347, 446, 310SPt10Rh* The maximum operating temperature is directly correlatedto the outer sheath material and the inner lead material.These are indicated in the order documents.** All MIMS type K thermocouples are converted into the“K” state through a defined temperature process, so thata stable, reproducible and reliable temperature measurement is ensured.MIMS cables forresistance thermometers (RTD)-200 1,100 CCu, Ni-coated Cu,NiCr, Ni, CuNiAlloy 600, 800AISI 316TI, 316L, 321*** A dditionally to the standard tolerance class 1 inaccordance with DIN EN 60584-2, the K and Nthermocouple types are also supplied in SensyMICpremium class which is defined with a positive tolerancedeviation of max. 2 C between 700 and 1,000 C.The range 700 C lies in class 1.7

Thermocouple and compensating cablesThe connecting cables between the thermocouple and thecold junction must have the same thermoelectricalproperties as the thermocouple. This connection can be acompensating, extension or thermocouple cable.Original or substitute materialsWe differentiate between original materials for thermocouplecables and substitute materials for compensating cables.Thermocouple cables from original materials consist of thesame material as the thermocouple in application.Compensating cables of substitute materials are made fromcheaper alloys which are not identical to the associatedthermocouple. However, they have the same thermoelectricproperties as the thermocouple in the temperature rangepermitted for compensating cables.Insulated thermocouple wiresInsulated thermocouple wires are used for the manufactureof thermocouples which correspond to the recognisedstandards. The temperature limit values depend on variousparameters (ambient atmosphere, installation location, etc.)and should therefore be considered as guideline values. Thedelivery is made in reels or coils of up to 500 m.Thermocouple cables inaccordance with DIN 43722(original material)Temperature *-25 200 CCompensating cables inaccordance with DIN 43722(substitute material)0 200 C- 200 1,200 C**TypeKX, EX, JX, NXShieldBraid made of galvanised or stainless steel wires or aluminium foil with drainwireSheathPVC, silicone, fibreglass, Teflon-FEP/PFA/PTFEInsulated thermocouplewires in accordance withDIN EN 60584,DIN 43712, IEC 584KCA, KCB, NC, RCA/SCA, RCB/SCB K, J, E, N, LPVC, silicone, fibreglass, Teflon-FEPPVC, silicone, Teflon, fibreglass,ceramic fibre* The maximum operating temperature is directly correlated to the outer sheath material and the inner lead material.These are indicated in the order documents.** Upper temperature limit for short-term use.SensyMIC GmbHBorsigstraße 2 / 63755 Alzenau / GermanyPhone 49 9372 132-58005info@sensymic.com / www.sensymic.com14302645 10/2020 ENSensy IC

the AMS 2750E or CQI-9 specifications. Very high insulation resistance The insulation material from highly compressed magnesium or aluminium oxide (ceramic capillaries) exhibits very good insulation characteristics, even at high temperatures. In the ‚as-delivered' condition, the insulation resistance of all