Transcription

5-13Lab Ventilation Safety & Energy EfficiencyHelping Facilities EnsureSafe, Energy Efficient & Sustainable Laboratory BuildingsFran BoucherNational omas C. SmithExposure Control Technologies, Inc.919-319-4290tcsmith@labhoodpro.comSafe, Dependable and Energy Efficient Laboratories

5-13Agenda & Topics IntroductionLaboratory Safety & RisksLaboratory Hoods & Ventilation SystemsLab Ventilation - Energy Use & Costs2012 ANSI/AIHA Z9.5 StandardRequirements & RecommendationsLab Ventilation Safety & Energy Survey– A National Grid ProgramRecommended for Owners, EH&S Personnel, Building Managers,Facility Engineers, and Energy Engineers associated withLaboratory Ventilation Systems in Research Laboratory Buildings.Safe, Dependable and Energy Efficient Laboratories

5-13Goal: High Performance LaboratoriesChemistry LabsRadiological LabsBiology Labs (high containment)Nanotechnology LabsCleanrooms Animal VivariumsSafe Compliant with Codes & Standards Productive (Flexible) Energy Efficient SustainableSafe, Dependable and Energy Efficient Laboratories

Laboratory HazardsRisk of Adverse Health EffectsInhalation Hazards Airborne Materials Toxicity Generation Rate & Concentration Duration of ExposurePhysical Hazards Contact - Dermal Exposure Fire & ExplosionDose Concentration x DurationSafe, Dependable and Energy Efficient Laboratories5-13

5-13Laboratory Hoods &Ventilation SystemsProper Performance ProtectionProper Performance ComplianceOperation 60% Utility CostsSTACKCost 3 to 9 per ICESafe, Dependable and Energy Efficient Laboratories

5-13Laboratories & Fume Hoods Laboratories are rated one of the highest energy users by building type Fume hoods are the primary means of protecting lab personnel Fume hood performance can be affected by numerous factors Average Annual Energy Cost of a Traditional Fume Hood 5,000–Equivalent to Three 2500 sq. ft. Houses–Estimated lifetime cost of operation 150,000 (30 yrs)Building TypeAverage UtilityCostCommercial/Office 1 / ft2Hospital 3 / ft2Laboratory 7 / ft2Specialty Labs &Cleanrooms 15 / ft2Lights10%HVAC60%Safe, Dependable and Energy Efficient Laboratories30%Plug/Misc.

5-13Evaluating Fume Hood SafetyANSI/ASHRAE 110 “Method of Testing Performance of Laboratory Fume Hoods”MannequinDetermine Operating Conditions TracerGasEjectorHood and Lab InspectionComputer&DAQFace Velocity MeasurementsCross Draft Velocity TestsVAV Response and StabilityDetermine Performance (Containment ) TracerGasDetectorFlow Visualization Smoke TestsFaceVelocityProbeCross DraftProbeTracer Gas Containment TestsMethods to Evaluate Containment Performance and Ensure Safe HoodsSafe, Dependable and Energy Efficient Laboratories

5-13Laboratory Hood Safety & PerformanceECT, Inc. has conducted more than 30,000ASHRAE 110 Tracer Gas Containment TestsTest Results Demonstrate 15% FailurePrimary Factors Affecting Performance Hood design - 20% Lab Design System Operation Work practices - 25%Safe, Dependable and Energy Efficient Laboratories

5-13Causes of Inadequate PerformanceImproper: DesignOperationMaintenanceUseSafe, Dependable and Energy Efficient Laboratories

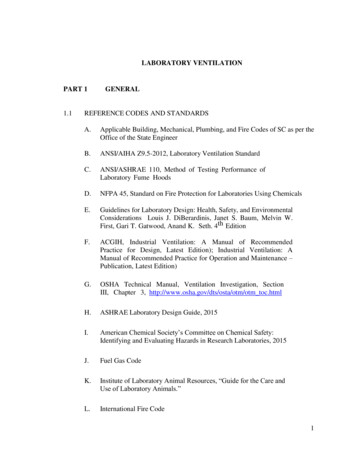

5-13ANSI/AIHA –Z9.5 - 2012American National Standard for Laboratory Ventilation Newly Revised & Published September 2012 Minimum Requirements and Best Practices –Protect People–Ensure Dependable Operation–Operate Energy Efficient LabsRecommendations & Specifications for New andRenovated Laboratories– Hood Design & Operation– Laboratory Design– Ventilation System Design– Commissioning and Routine Testing– Work Practices and Training– Preventative MaintenanceSafe, Dependable and Energy Efficient Laboratories

5-13Specifications for Safe & Energy Efficient Labs Laboratory Hood Operation– Monitors & VAV Controls– Construction Specs & Performance CriteriaTypes, Accuracy and Operating ModesLaboratory Design & Operation–ACH & Air Change Effectiveness–Diffuser Type and Location–Temperature & Humidity ControlVentilation Design & Operation–Duct Velocity & Static Pressure–Stack Discharge–Recirculation & Energy RecoveryCommissioning and Routine Tests–ASHRAE/ANSI 110 “Method of TestingPerformance of Laboratory Fume Hoods”–Lab Environment Tests–System Operating Mode TestsSafe, Dependable and Energy Efficient Laboratories

5-13Types of Laboratory Fume Hoods Bench-Top– Traditional Bypass– Low Velocity / High Performance– VAV – Restricted Bypass DistillationFloor Mounted (Walk-in)Safe, Dependable and Energy Efficient Laboratories

5-13Fume Hood Operation and SpecificationsSupply FlowExhaust FlowSash Opening Configuration 100% Full Open Design Opening User OpeningAverage Face Velocity 100 fpm (0.51 m/s) – Traditional 60 fpm (0.3 m/s) – High PerformanceAirflow Controls CAV VAVSafe, Dependable and Energy Efficient Laboratories

5-13High Performance Fume Hoods Full Open Sash Face Velocity: 60 - 70 fpm Equivalent or Better Containment thanTraditional Fume Hoods @ 100 fpm Safe & Proven Technology Numerous Hood Manufacturers– Lab Crafters– Fisher Hamilton– Kewaunee Scientific– Labconco– Air Master– Others EPA Tested & ApprovedSafe, Dependable and Energy Efficient Laboratories

5-13Retrofit-Upgrade Traditional Fume HoodsUpgradeCriticalComponents Airfoil Sill Renew/Refurbish Inefficient Hoods Improve Safety & ContainmentSash Handle Reduce Flow and Energy UseBaffle Typical Reduction 20% to 40%Safe, Dependable and Energy Efficient Laboratories

5-13Upgrade & Retrofit Fume HoodsBeforeAfterSafe & Sustainable TechnologySafe, Dependable and Energy Efficient Laboratories

5-13Flow Monitors and VAV Controls Hood Monitors (Flow Measuring Device)– Flow– Velocity– Pressure Monitors arerequired on allfume hoodsFlow Control Types– Through the Wall Velocity– Sash Position– Occupancy– Manual VAV Modes– Two State– Full VAV– VAV HybridSafe, Dependable and Energy Efficient LaboratoriesTTWVelocitySensorandHoodMonitor

5-13VAV Flow Response & ntEscapeMeasureSlot VelocityorExhaust FlowSafe, Dependable and Energy Efficient Laboratories

VAV Flow Response and StabilitySash OpenSash ClosedGood Control & ContainmentVAVTerminalPoor Control & ContainmentSafe, Dependable and Energy Efficient Laboratories5-13

Minimum Flow for VAV Fume Hoods Containment Dilution1990s - EPA – 50 cfm / ft of WhRemovalDuct Conc. (Cd)2004 - NFPA 4525 cfm / sq. ft. ws2010 - Defers to ANSI Z9.52012 - ANSI Z9.5 (must be appropriate)Internal ACH (150 ACH to 375 ACH)150 ACH 10 cfm / sq. ft. wsInternalConc.(Ci)375 ACH 25 cfm / sq. ft. wsBench-TopFume HoodSize - ftInternalVolume (Vh) ft3429.618018070648.2300300120866.9410410160Min Flow cfm ANSI Flow cfm ANSI Flow cfm(NFPA)(375 ACH)(150 ACH)Caution: ECT finds 150 ACH too lowSafe, Dependable and Energy Efficient Laboratories5-13

Laboratory Airflow Specifications Qe - ExhaustOperating ModeMin and Max FlowTemperature ControlDilution – ACHAir Change EffectivenessRoom PressureTransfer VolumeQt Qe – QsQt ConstantRoom Pressure 5-13Safe, Dependable and Energy Efficient Laboratories

5-13Typical ACH GuidelinesAgencyVentilation RateOSHA 29 CFR Part 1910.14504-12 ACHASHRAE Lab Guides4-12 ACHUBC – 19971 cfm/ft2IBC – 20031 cfm /ft2IMC – 20031 cfm/ft2U.S. EPA4 ACH Unoccupied Lab - 8 ACH Occupied LabAIA4-12 ACHNFPA-45-20044 ACH Unoccupied Lab - 8 ACH Occupied LabNRC Prudent Practices4-12 ACHACGIH 24th Edition, 2001Ventilation depends on the generation rate and toxicity of thecontaminant and not the size of the room.Prescriptive ACH is not appropriate.ANSI/AIHA Z9.5Rate shall be established by the owner.Dilution is seldom effective – source capture preferredSafe, Dependable and Energy Efficient Laboratories

5-13Emissions in Labs Requiring Dilution Escape from Lab HoodsImproper Bench Top ProceduresUnventilated EquipmentFugitive Emissions–Chemical Bottles & Containers–Gas CylindersAccidental SpillsTypical Generation Rates 0.1 lpm to 10 lpmCatastrophic Failure of a Gas Cylinder1400 lpmSafe, Dependable and Energy Efficient Laboratories

5-13Specifying Airflow Rates for LabsAir Change Rate (ACH)? Evaluate hazardous emissions Ensure appropriate laboratory hoods Capture hazards at the source Ensure air change effectiveness Base airflow rates on:– Hood Exhaust Requirements– IAQ Requirements– Comfort (Temperature)– Pressurization/IsolationSafe, Dependable and Energy Efficient Laboratories

5-13Ventilation System Operating Specifications Max and Min Flows Exhaust ManifoldsEnergy SavingsRequire ReducingTotal Building Flow Fan Redundancy Emergency Power System Static Pressure Duct Transport Velocity Exhaust Stack Discharge VAV Control Capabilities Diversity SensitivitySafe, Dependable and Energy Efficient Laboratories

5-13Stack Discharge and Plume DispersionRe-entrainmentStack Height 10 ft.Stack Velocity 3000 fpmBetter DesignSafe, Dependable and Energy Efficient Laboratories

5-13Laboratory Ventilation Management Program(LVMP) Required By ANSI Z9.5 System Management and Sustainability Plan–Organization and Responsibilities–Effective Collaboration/Integration–SOP’s for Testing and Maintenance–Metrics and Monitoring–BAS Utilization Management of Change Personnel TrainingCognizant PersonSafe, Dependable and Energy Efficient Laboratories

5-13Critical Elements of a LVMP Building Information - Documentation and SpecificationsManagement and Personnel (Roles and Responsibilities)Test and Maintenance Tasks Schedule of Activities Preventive & Repair Maintenance AHUs /Exhaust Fans Control Components (Flow Terminals, Sensors, dP Transducers) System, Environment & Hood Performance Tests System Operating Mode Tests (SOMTs) Lab Environment Tests (LETs) Lab Hood Tests BAS Utilization (Monitoring and Reports)Management of Change (MOC)Record KeepingTraining ProgramsSafe, Dependable and Energy Efficient Laboratories

Training of PersonnelEnsure Proper Work Practices Lab Personnel Facility Maintenance Building OperatorsSafe, Dependable and Energy Efficient Laboratories5-13

National Grid’sLab Ventilation Safety and Energy Survey Meet With Key Stakeholders Review Building Documentation Survey Laboratories and Exposure Control Devices Inventory Devices Assess the Demand for Ventilation Evaluate State of the Systems Assess Conformance with ANSI/AIHA Z9.5 Identify Performance Improvement Measures Identify Potential Energy Conservation Measures Provide Written Report & RecommendationsSafe, Dependable and Energy Efficient h ValueReport5-13

Lab Ventilation Safety and EnergySurvey Report Description of Building and Lab Ventilation SystemsSummary of UtilitiesIdentify Ventilation Safety RisksTypically Recommended PIMs and ECMs Replace or upgrade inappropriate hoods Optimize airflow specifications (ACH) Relocate / Replace air supply diffusers Ensure proper space pressurization Install monitors and upgrade/replace VAV controls Improve exhaust configuration and optimize fan stacks Install Variable Speed Drives Develop a Lab Ventilation Management Plan & Train Laboratory PersonnelSafe, Dependable and Energy Efficient Laboratories5-13

5-13National Grid’s Laboratory Building ProgramsSafe, Dependable and Energy Efficient Laboratories

5-13National Grid’sLab Safety and Energy ProgramsCustomerState University in MAPrivate University in MA*State University in RI*Private University in RI*Pharmaceutical Research*Biomedical Research*ConductedLab BuildingSurvey(s)Identified/ResolvedSafety IssuesIdentified/ReducedEnergy 15%Developed/ImplementedLVMP * Projects in ProgressAverage Annual Energy Reduction 15%Safe, Dependable and Energy Efficient Laboratories

5-13ENDQUESTIONS?Fran BoucherThomas C. SmithNational GridExposure Control Technologies, alGrid.comtcsmith@labhoodpro.comSafe, Dependable and Energy Efficient Laboratories

22.05.2013 · 2012 ANSI/AIHA Z9.5 Standard. Requirements & Recommendations. Lab Ventilation Safety & Energy Survey. – A National Grid Program. Recommended for Owners, EH&S Personnel, Building Managers, Facility Engineers, and Energy Engineers associated with Laboratory Ventilation Systems in Research Laboratory Buildings.