Transcription

KitchenVentilationHood Types and Testing Procedures

A Must-have Resource forIndustry Professionals!The AABC National Standards for Total System BalanceWe are pleased to introduce the AABC National Standards for TotalSystem Balance, 2002 Edition, which has been completely rewrittenand reorganized to reflect the latest advancements in the test andbalance industry.This comprehensive manual details the minimum standards for totalsystem balance. Each chapter covers a specific area in the test andbalance process, enabling the design professional to select thoseitems that are best suited for a particular project.Additionally, the Standards will assist the design professional inachieving design intent, provide a better understanding of the scope ofwork required of the TAB agency, and ensure that proper methods andprocedures are followed in the test and balance process.New features of the Standards include: Illustrative tables and charts New technologies, such as DDC Equations and examples Updated testing procedures Sample specifications Appendix with equations in both Expanded section of sampleEnglish and Metric formatsreport formsAABC believes that by promoting the concept of Total System Balance,the industry will be encouraged to adopt more consistent practices,thus ensuring greater success for all parties involved in the design,installation, start-up, operation and testing of HVAC systems.Over 350 pages of standards for totalsystem balancing. Order your copy ofthe new AABC National Standards forTotal System Balance today!For additional information on the Associated Air Balance Council or thenew AABC Standards, visit our website at www.aabc.com, or contactAABC National Headquarters at 202-737-0202.Non-Member Cost: 75.00AABC National Standards 2002 @ 75 each x Payment InformationPayment Type (Check one) Check Enclosed MasterCard VisaNameCard NumberCompanyName on CardShipping AddressSignatureCityStatePhoneFaxEmail3Zip American ExpressExpiration DatePlease complete order form and return along with payment to:Associated Air Balance Council1518 K Street, N.W., Suite 503 Washington, D.C. 20005Credit card purchasers may fax orders to: (202) 638-4833or order online at www.aabc.com/publicationsAABC

CONTENTSTABJournalAssociated Air Balance CouncilBoard of Directorsand OfficersPresidentMike YoungTest and Balance CorporationExecutive Vice PresidentJoseph E. Baumgartner, III, P.E.Baumgartner, Inc.Secretary/TreasurerMichael RenovichRS Analysis, Inc.Vice President/Eastern Zone-1Daniel J. AcriFlood and SterlingVice President/Central Zone-2Jay A. JohnsonThermal Balance, Inc.Vice President/Western Zone-3Michael DelcampPrecisionaire of TexasImmediate Past PresidentRobert A. ConboyAmerican Air Balance Co., Inc.Director, Canadian ChapterMarc Desjardins, P.EngKanata Air Balancing &Engineering ServicesExecutive DirectorKenneth M. SufkaKitchen Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Gilles Tremblay, TBE, Gregor Hartenhoff, Inc.Kitchen Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6AABC National Standards ExcerptTech Talk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Phased Projects, TAB Checklists, Accuracy vs. TolerancesCooperation: An Important Tool. . . . . . . . . . . . . . . . . . . . . . 15Gayla Davis, TBE, Texas Precisionaire Ltd.Modified Curbs Can Cause Low Exhaust Flow. . . . . . . . . . . 16Bobby Standridge, TBE, Southeast Test and Balance, Inc.Balancing an AIRWAY system at the University of Memphis. . . 17Chuck Fant, P.E., TBE, Environmental Test and Balance Co.Carrier Moduline Air Terminals . . . . . . . . . . . . . . . . . . . . . . 19Mike Demchuk, TBE, Precision Air BalanceProper Balance Valve Sizing and Branch Balancing Valves . . . . 20Harry Gaines, TBE, Testing & Balancing Co. of the OzarksFee for Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21Charles W. Kaupp, TBE, Southern Independent Testing Agency, Inc.TAB Journal EditorRay BertEditorial Office1518 K Street, N.W., Suite 503Washington, D.C. 20005(202) 737-0202 FAX: (202) 638-4833E-mail: info@aabc.comWebsite: www.aabc.comTAB Journal is published quarterly bythe Associated Air Balance Council. It isdistributed free to AABC members andby subscription to non-members at 24per year. TAB Journal is an open forumfor the free expression of opinions andinformation. The views expressed arenot necessarily those of AABC, itsofficers, directors, or staff. Letters,manuscripts, and other submissionsare welcome. However, TAB Journalaccepts no responsibility forunsolicited material.All rights reserved. Copyright 2008by the Associated Air Balance Council.TAB JournalFrom the PublisherThe latest issue of TAB Journal examines the test and balance of kitchen ventilationsystems, which are vital to the safe operation of many buildings. Gilles Tremblayof Gregor Hartenhoff Inc. provides an in-depth examination of different types ofexhaust hoods and grease removal devices; different styles, sizes, and flow ratesof those hoods; and information about proper balancing of these systems. Alsoincluded is a chapter from the AABC National Standards covering Kitchen Systems.Other articles in this issue include proper balance valve sizing and branch balancingvalves, information on balancing a specific type of air system, balancing an oldertype of air terminal unit that is still in use in the industry, the role of cooperation insolving problems in the field, and thoughts on “fee for services.”This issue’s edition of “Tech Talk” answers questions on phased projects, TABchecklists, and accuracy versus tolerances. AABC test and balance engineers (TBEs),the most qualified experts in the industry, lend their expertise to Tech Talk and writemost articles that appear in TAB Journal. If you have a question about test andbalance, or an idea for an article, please submit them to us at info@aabc.com.1

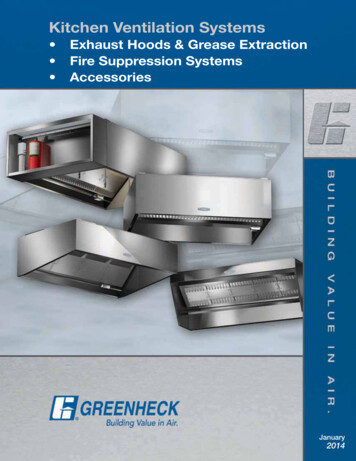

Kitchen VentilationG i l l e s Tre m b l a y, T B E , Gregor Hartenhoff, Inc.Kitchen ventilation is a complex application ofHVAC systems. The design of kitchen ventilationsystem includes aspects of air conditioning, firesafety, ventilation, building pressurization, refrigeration,air distribution, food service equipment and systemscommissioning. Kitchen ventilation systems are providedin buildings for at least two reasons: first to provide acomfortable environment and second to enhance the safetyof personnel working in the kitchen and of other buildingoccupants. Obviously, the kitchen ventilation systemcan affect the temperature and humidity conditions inthe kitchen. “Comfortable” in this context has differentmeanings because depending on the local climate, somekitchens are not air-conditioned. The ventilation system canalso affect the acoustical conditions of a kitchen.The centerpiece of almost any kitchen ventilation systemis an exhaust hood, which is used primarily to removeeffluent from kitchens. Effluent includes the gaseous,liquid and solid contaminants produced by the cookingprocess. These contaminants must be removed for bothcomfort and safety. The effluent can range from simplyannoying to potentially life threatening and under certainconditions, flammable. Not only is the exhaust hood itselfvery important to the efficient operation of the kitchen,2but the way the food service equipment is arranged andcoordinated with the hood(s) greatly affect the operatingcost of the kitchen.HVAC system designers are frequently involved incommercial kitchen applications, those in which largeamounts of grease or water vapor are produced in thecooking effluent. Residential kitchens typically use atotally different type of hood. The amount of greaseproduced in residential applications is significantly lessthan in commercial applications, making the health andfire hazard much lower.Many types, categories and styles of hoods are available,and hood selection depends on many factors. Hood typesare classified based on whether or not they are designed forgrease-handling applications. The model codes distinguishbetween grease-handling and non grease-handling hoods.Although not all model codes use Type I or Type IIterminology, Type I refers to hoods designed for removal ofgrease and smoke and Type II refers to all other foods.A Type I hood is used for collection and removal ofgrease and smoke. It includes both listed grease filters,baffles or extractors for the removal of the grease andfire suppression equipment. This type of hood is requiredTAB Journal

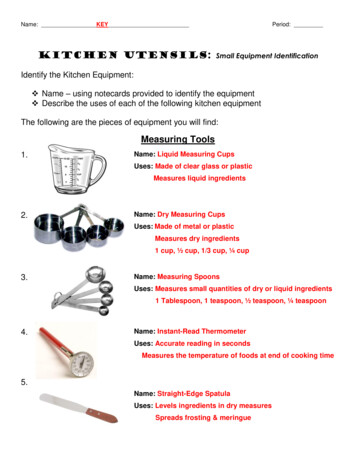

over restaurant equipment such as ranges, fryers, griddles,broilers, ovens and steam kettles that produce smoke orgrease-laden vapors.A Type II hood is a general hood for collection andremoval of steam, vapor, heat and odors where greaseis not present. The Type II hood may or may not havegrease filters or baffles and typically does not have a firesuppression system. It is typically used over dishwashers,steam tables and so forth. The Type II hood is sometimesused over ovens, steamers or kettles if they do not producesmoke or grease laden vapors and if the authority havingjurisdiction allows it.Most grease removal devices in Type I hoods operate onthe same general principle. The exhaust passes througha series of baffles in which a centrifugal force is createdas the exhaust air passes around the baffles to extract thegrease. Mesh filters cannot meet the requirements of ULStandard 1046 and therefore cannot be used as primarygrease filters. Grease removal devices generally fall into thefollowing categories:1. Baffle Filters. The baffle filter is a series of verticalbaffles designed to capture grease and drain it awayto a container. The filters are arranged in a channelor bracket for ease insertion into and removal fromthe hood for cleaning. Each hood usually has two ormore baffle filters. The filters are usually constructed ofaluminum, steel or stainless steel and come in variousstandard sizes. Filters are cleaned by running themthrough a dishwasher or by soaking and rinsing. NFPAStandard 96 requires grease filters to be listed. Listedgrease filters are tested and certified by a nationallyrecognized test laboratory under UL Standard 1046.2. Removable Extractor. Removable extractors are anintegral component of listed exhaust hoods designedto use them. They are typically constructed of stainlesssteel and contain a series of horizontal baffles designedto remove grease and drain it away to a container.Removable extractors come in various sizes. They arecleaned by running them through a dishwasher or bysoaking and rinsing.3. Stationary Extractor. The stationary extractor (alsocalled a water wash hood) is an integral component oflisted exhaust hoods that use them. They are typicallyconstructed of stainless steel and contain a seriesof baffles that run the full length of the hood. Thebaffles are not removable for cleaning. The stationaryextractor includes one or more water manifolds withspray nozzles that upon activation, wash the greaseextractor with hot, detergent injected water, removingthe accumulation of grease from the extractor.The wash cycle is typically activated at the end of the day,after the cooking equipment and fans have been turned off(although it can be activated at more frequent schedules).It runs for five to ten minutes depending on the hoodmanufacturer, the type of cooking, the number of hoursTAB Journalof operation and the water temperature and pressure.The average water consumption varies between 0.50 and1.50 gpm per linear foot of hood, depending upon thehood manufacturer. Some manufacturers of water washhoods provide continuous cold water mist as an option.The mist runs continuously during cooking operationand may or may not be recirculated, depending on themanufacturer. The advantage of continuous cold watermist is that it improves grease extraction and removal.Many hood manufacturers recommend continuous coldwater mist in hoods that are located over solid fuel burningequipment, as the mist will also extinguish hot embers thatmay be drawn up into the hood and help cool the exhauststream. UL Standards 1046 and 710 do not include greaseextraction tests because at present no industry-acceptedtests are available in the United States. Grease extractionrates published by filter and hood manufacturers areusually derived from tests conducted by independent testlaboratories retained by the manufacturer. Because of this,the test methods and results vary greatly.Types of Hoods – Styles. There are six basic styles ofhoods for both Type I and Type II applications. These stylenames are not universally used in all standards and codes,but are well accepted in the industry:Wall-mounted Used for all types of cooking equipmentcanopyagainst a wall.Single IslandcanopyUsed for all types of cooking equipmentin a single line island configuration.Double IslandcanopyUsed for all types of cooking equipmentmounted back to back in an islandconfiguration.BackshelfUsed for counter height equipmenttypically located against a wall but couldbe freestanding.EyebrowUsed for direct mounting to ovens andsome dishwashers.Used for counter height equipment whenPass-over style pass-over configuration (from the cookingside to the serving side) is required.Type I Hoods – Sizing. The size of the exhaust hood inrelation to cooking appliances is an important aspect ofhood performance. Usually the hood must extend beyondthe cooking appliances (overhang) on all open sidesof canopy style hoods and over the ends on backshelfand pass-over hoods to capture the expanding thermalcurrents rising from the appliances. This overhang varieswith the style of the hood, the distance between the hoodand the cooking appliance and the characteristics of thecooking equipment.With backshelf and

exhaust hoods and grease removal devices; different styles, sizes, and flow rates of those hoods; and information about proper balancing of these systems . Also included is a chapter from the AABC National Standards covering Kitchen Systems . Other articles in this issue include proper balance valve sizing and branch balancing valves, information on balancing a specific type of air system .