Transcription

Supply Chain Risk and Visibility inthe Movement of GoodsOctober 2014

About Transport IntelligenceTransport Intelligence’s products and services include: Daily and weekly newsletters Market and competitor monitoring Market reports including trend analysis, market sizing, market share, forecasting and ranking Ti Dashboard – a selection of economic and industry data/charts Unparalleled access to TI’s entire research output through the Global Supply Chain Intelligence websitewww.gscintell.com Dedicated research and client surveys Acquisition/agent/partner search and marketing due diligenceFor more information about these services and to sign up to the free Transport Intelligence newsletter go towww.transportintelligence.comAll rights reserved. No part of this publication may be reproduced in any material form including photocopying or storing it byelectronic means without the written permission of the copyright owner, Transport Intelligence Limited.This report is based upon factual information obtained from a number of sources. Whilst every effort is made to ensure that theinformation is accurate, Transport Intelligence Limited accepts no responsibility for any loss or damage caused by reliance uponthe information in this report.

About KewillKewill, a Francisco Partners portfolio company, is a global leader in multimodal transportation management software, providingorganizations with a comprehensive end-to-end platform for managing the complexities of transportation, logistics and tradecompliance. The Kewill MOVE platform helps companies reduce costs, manage volatility and gain greater visibility across thelogistics value chain. Trade, transport, store, comply, manage and integrate – the Kewill transportation management platform givesyou the insight, agility and tools you need to deliver better customer service and streamline global supply chain execution forstrategic advantage.The Kewill platform supports supply chain execution activities for in excess of 7,500 companies in more than 100 countries. To learnmore about the company, visit www.kewill.com, follow us on Twitter @Kewill Ltd or check our LinkedIn page for company updates.www.kewill.com

Supply Chain Risk & Visibility in the Movement of GoodsAs supply chains have become more globalised and complexover recent decades, so too have the challenges and risksthreatening their safe and efficient operation. However, it can bemisleading to suggest that more threats to supply chains exist intoday’s world, or that the risks are more severe than in the past.Rather, as a result of the way supply chains have evolved,disruptions are pushed further through the system and variousrisks have the potential to cause more intense disruptions.One such example of this evolution is the adoption of lean andjust-in-time techniques over recent decades. Such methods offermanufacturers and retailers the ability to operate with vastlyreduced inventories. Operating this way, however, cuts themargin for error in supply chains and means a range of naturaland man-made disasters at all operational levels can havewidespread consequences for production schedules andcustomer service levels.Overcoming such challenges is a tricky proposition for supplychain professionals. While the temptation may be to attempt toinsulate the supply chain from the myriad threats and risks,logistics managers must take a wider and more holistic view ofhow the supply chain fits into their organisation and the costsdisruptions could cause across the overall organisation. Ratherthan ‘insulation’, effective risk management strategies requirescenario planning and putting processes in place, as well asimplementing the technology to sense and respond to events as October 2014 Transport Intelligencethey happen. In summary, it requires placing risk and visibility atthe core of a company’s supply chain strategy to achieve an agileresponse to risk.Creating such a risk-agnostic supply chain is a global challenge,and the emergence of new logistics markets is introducing anumber of additional variables to the equation. Ti’s CEO andauthor of the book Supply Chain Risk: Understanding EmergingThreats to Global Supply Chains, John Manners-Bell, characterisedthe challenge thus; “Modern supply chains reach deep into manyemerging markets where social and environmental practices areless sophisticated and under much less scrutiny than in thedeveloped world. Multinational enterprises are starting to realisethat there is a huge reputational risk to their companies if theyare not seen to be treating their employees, or more often theirsuppliers’ employees, in a fair and equitable fashion. Likewisethey understand that their suppliers must behave in a sustainableway to the environment, otherwise the implications of bad presswill rebound on their brand. Consequently we mustn’t just thinkof supply chain risk in terms of the disruption to the flow ofproducts; there are much wider issues and costs at stake.”Stakeholders throughout the supply chain must be engaged inunderstanding and overcoming risk; this survey examines theoperational and strategic approaches taken by manufacturers,retailers and logistics service providers the world over to createsuch risk-agnostic supply chains.Supply Chain Risk & Visibility in the Movement of Goods4

Executive Summary Levels of outsourcing are increasing, but it’s unclear ifresponsibility for risk is outsourced alongside physicaltransportation.collaborate with key partners to increase visibility in thesupply chain, more than one in four indicated that their ownorganisation formed the boundary of what could be ‘seen’. Customers are becoming more exacting in their standards andlook for a range of service options to suit their individualneeds. These include sophisticated track & trace capabilities,increased speed, value-added services and cost reductions. The visibility to measure own and partner performanceagainst SLAs, and to identify performance by trade lane, areall required to overcome threats to revenue and profitability. Shipments are moving to less expensive, ocean-based modes.Inter-modal shipments that balance speed and lower costsare increasingly popular. Providing supply chain visibility is a significant challenge.Achieving the required degree of visibility is a complex taskand necessitates working with partners throughout the supplychain to understand and share salient information in a timelyfashion. While a general economic downturn would have a significantimpact, more pervasive risk is posed by a sudden increase incosts, poor schedule compliance from transportation partnersor the failure of a key supplier. Respondents suggested overcoming supply chain risk isviewed primarily as a visibility challenge to be tackled withbetter and more transparent data and reporting capabilitiesenabled by sophisticated operational procedures and ITsystems. While over a third of those surveyed had managed to Respondents viewed their capacity to improve supply chainvisibility as a function of their capacity for data collection,interpretation and distribution, with IT systems playing a keyrole in the process. Warehouse management systems, transport managementsystems and freight management systems ranked as the mostimportant operational IT systems. Providing systems whichenable visibility and the tracking and tracing of shipments area primary concern for LSPs aware of the emphasis theircustomers place on this information. A single software system managing across all modes is thepreferred option. IT provision is generally satisfactory for most functions, butroom for improvement remains. Adaptability andcustomisation are highly sought, suggesting a system’s abilityto manage change and complexity is highly prized.

The ParticipantsBetween June and September 2014, Ti undertook an electronicsurvey of 271 industry professionals from across the globeexamining supply chain risk and visibility in partnership withKewill. The survey aimed to investigate operational and strategicapproaches to managing supply chain risk and visibility at theworld’s leading logistics service providers (LSPs), as well as atretailers and manufacturers.The majority of respondents (47.7%) operate on a global scalewhile more than one quarter (26.2%) were drawn from the highgrowth emerging markets of Asia.Respondents: Logistics Services3PL/4PL33.8%Warehousing4.4%Freight Forwarder34.8%Ocean Carrier3.9%Customs Broker2.9%Distributor9.8%Road Transport10.3%More than three quarters of those surveyed (77.0%) are involvedin the provision of logistics services, with respondents drawnfrom a broad base and represent all major areas of the widerlogistics sector, including its customer base. October 2014 Transport IntelligenceA significant majority of those surveyed (57.3%) representedorganisations with annual revenue exceeding 100m.Supply Chain Risk & Visibility in the Movement of Goods6

Business & Operational LandscapeSurvey respondents indicated that levels of outsourcing in theglobal logistics industry are expanding. While the majority(51.7%) have seen outsourcing levels remain stable over the lastthree years, those seeing higher rates of outsourcingoutnumbered those bringing logistics processes back in-housenearly 2-to-1.Outsourcing presents logistics service providers and theircustomers with a potentially tricky proposition. Whileoutsourcing the physical transportation of goods has clearparameters and boundaries as an economic exchange, it is notalways so clear whether the less tangible aspects of supply chainmanagement, including risk, are outsourced as well. While forsome the opportunity to outsource is a means to push the morecomplex and often costly elements of managing risk to otherstakeholders, for others the loosening of control associated withtransferring responsibility will represent added risk itself.manufacturers, as well as management at operational andstrategic levels of LSPs, to view risk as a whole organisationundertaking and reveals the need to more closely partner withthe various stakeholders throughout the supply chain. Anydecision to outsource fundamentally involves relinquishing acertain degree of control, with partnership having the potentialto prove the best way for many to mitigate the risk of loosenedcontrol.When relating to risk specifically, responsibility can bestraightforward at lower levels – late delivery of shipments canbe subject to specific contract provisions, for example – but ithas the potential to become far more complex at higher, morestrategic levels, and especially in terms of indirect risks. Apple,for example, is widely cited as having a strong supply chain, butfound itself at the centre of a storm over arrangements at itsChinese partner, Foxconn. This type of risk is representative ofthe need for supply chain managers at retailers and October 2014 Transport IntelligenceSupply Chain Risk & Visibility in the Movement of Goods7

Business & Operational LandscapeSurvey responses suggest that more detailed tracking andreporting measures are highly sought by customers, with nearlyone fifth (18.1%) seeking improvements in the data provided.This places an emphasis on sophisticated systems which canprovide such services, with respondents noting that expectationsof inventory data management particularly were ever increasing.for lower cost solutions seems opposed to this however, butsuggests that customers are having to balance of the benefits ofspeed with cost. Importantly, it should be noted that slower andcheaper doesn’t mean demand for added risk and visibilityfeatures is sacrificed, but that customers expect these featuresacross all product ranges, regardless of cost to the provider.That respondents grouped five different demands relativelyclosely to suggest that customers are seeking a broad base ofconsistently high performance from their shippers with toleranceof poor service provision low. Respondents commented too, thatexpectations were increasingly set out at the tender stage, andthat these expectations were beginning to push LSPs to offerincreasingly tailored and specific services, including the ability tomonitor and report at a customer and even transactional level.This presents several opportunities for LSPs to push theirservices throughout customer’s operations and increase control– a way to reduce risk and improve visibility – particularly asdemand for value-added services grows.Low levels of ‘in-housing’ tallies with increasing rates ofoutsourcing seen elsewhere in the survey, while the lower levelsof demand seen for parcel handling capability suggests theimpact of e-commerce is limited. This may be due to themajority of online sales falling within national markets, withshippers able to consolidate orders by on an international level.The increase in required speed is likely driven in part by thecontinued evolution of Just-in-Time and Just-in-Sequencemanufacturing techniques and the reduction of inventories inthe retail sector which both place an emphasis on timelytransportation. This in turn requires robust supply chains thatcan adapt and overcome potential disruptions, with visibility andrisk awareness as an enabler of such. The increasing preference October 2014 Transport IntelligenceSupply Chain Risk & Visibility in the Movement of Goods8

Business & Operational LandscapeAcross all transportation geography, more than 80% ofrespondents indicated that shipments were either stable orincreasing, highlighting that providers are operating in a positivesum environment. More than half (51.5%) of those surveyed areseeing global shipments increase, the largest of any geography,while just 17.2% of respondents were seeing a decreasingamount of global shipments – the lowest of any geography andsuggesting that demand is originating across multiple regions. October 2014 Transport IntelligenceEmerging markets – particularly Asia – seem likely to be drivingat least some of the growth across most transport geographies.Demand will continue to expand in these markets as middleclasses grow, but also as infrastructure is improved andproduction capabilities increase. Moreover, as costs rise in themore advanced emerging markets, including China, productionwill shift to other, cheaper markets. The growth in intra-regionaltransits points to this trend as emerging markets that were oncestrictly export-only experience growing domestic demand.Supply Chain Risk & Visibility in the Movement of Goods9

Business & Operational LandscapeSurvey participants revealed a shift towards less expensive,ocean-based modes. This is perhaps not surprising as such atrend has been witnessed for much of the period since the 2008recession as pressure has been exerted on rates and marginssqueezed. The shift, however, is harder to reconcile with thegrowing demand for speed in transportation that respondentscited elsewhere in the survey. Several respondents commented,however, that modal shifts had resulted in increased intermodaltransportation and the introduction of a second mode ratherthan a straightforward switch, which is perhaps an attempt totrade balance reduced costs with the demand for increasedspeed.Given the widespread growth of e-commerce driven volumes, itcould perhaps have been expected that parcels would be a muchmore in demand shipment method in 2014, however, withrespondents indicating unchanged volumes it appears likely thate-commerce is having a much less significant impact on theinternational market.Increased container usage supports the increased usage of seafreight and suggests consolidation is being used to leverageeconomies of scale in order to drive down prices – indeed, itappears as if this is where the lost pallet volumes have gone, andindicates shippers are scaling up rather than down to save costsand ease margin pressure. October 2014 Transport IntelligenceSupply Chain Risk & Visibility in the Movement of Goods10

Supply Chain RiskRespondents indicated that providing supply chain visibility is asignificant challenge. Achieving the required degree of visibility isa complex task and necessitates working with partnersthroughout the supply chain to share information. In addition,investment in IT is required to allow for remote monitoring ofvarious measurables, some of which are central to customerrequirements, such as the preservation of the cold chain in thepharmaceutical & healthcare sector. Moreover, a visible supplychain requires the capability to make the accurate data availableand accessible to customers in real-time, as well asimplementing systems and procedures that allow forinterventions to be made when something goes wrong.schedule. For those providers, failure to adhere to schedulesholds the risk that additional charges will be levied, potentiallyerasing already thin margins.Transportation reliability was also cited as a key issue, and onethat is likely to grow in significance as rates of outsourcingincrease. There can be an increased risk associated withloosening control over transportation, and customers areincreasingly likely to place more exacting demands on LSPs asthey seek the capability to track, trace and monitor the shippingenvironment. This places emphasis on collaboration throughoutthe supply chain.The prevalence of Just-in-Time, Just-in-Sequence and other lowinventory manufacturing methods makes keeping schedulesvital. For customers, loosing the schedule is a risk in and of itself,regardless of the cause, and respondents indicate this hastranslated into pressure on deliveries occurring on time and to October 2014 Transport IntelligenceSupply Chain Risk & Visibility in the Movement of Goods11

Supply Chain RiskWhile nearly half (43.4%) of those surveyed concluded thateconomic downturn would have a very significant impact onrevenue and profitability, respondents indicated that three otherpotential risks were likely to have a wider, if perhaps less intense,impact.Some 73.9% noted that a sudden increase in costs would impactor significantly impact revenue and profitability across the sector,while 72.7% rated poor schedule compliance fromtransportation partners as likely to have that same level ofimpact. The highest rating risk by impact, however, was thepotential failure of key suppliers at 74.0%. The implication is thatstakeholders throughout the supply chain need effective internaland external monitoring processes in place as well ascontingency plans should any of the events occur.The two most pertinent threats relate back to key themesalready cited in the survey – at 74.0%, the failures of keysuppliers drives the need for closer, more collaborativepartnerships throughout the supply chain, while the threat of asudden rise in costs hints at the margin pressure so keenly feltacross much of the logistics sector. At the other end of the scale,changes to trade compliance regulations appeared to be the riskrespondents felt most able to overcome, with 40.8% rating theimpact of such changes as neutral or slight.The importance of visibility in the supply chain was noted by onesurvey respondent who cited the interrelated nature ofoperations; “If you have robust visibility mechanisms yourforecasting accuracy will improve and you will be able to reactproactively to the advent of other risks and minimise the impactto your business.” October 2014 Transport IntelligenceSupply Chain Risk & Visibility in the Movement of Goods12

Supply Chain RiskWhile it is clear that many organisations are looking at variousoptions to minimise their exposure to and mitigate the impact ofrisks in their supply chains, respondents suggested overcomingsupply chain risk is viewed primarily as a visibility challenge to betackled with better and more transparent data and reportingcapabilities enabled by more sophisticated operationalprocedures and IT systems. Indeed, some 27.9% said increasingvisibility was their primary route to reducing risk, and 22.2%pointing out that additional IT capabilities were required.The inclusion of risk management in KPIs and the introduction ofadditional compliance procedures rated highly, as opposed to October 2014 Transport Intelligencethe appointment of a Chief Risk Officer with just 2.8% ofrespondents indicating their organisations had plans to makesuch a move. Indeed, several comments pointed out that riskmanagement was being added to existing executiveresponsibility rather than having a strategic-level role of its own.The implication appears to be that the majority of thosesurveyed believed the strategic capability to overcome supplychain risks was already present in their organisations, with thenecessary improvements needing to be made at the operationallevel where emphasis can be placed on proper implementationof systems and the monitoring of risks.Supply Chain Risk & Visibility in the Movement of Goods13

Supply Chain VisibilityMore than one third (37.6%) of those surveyed have been ableto collaborate with partners to expand the boundaries ofvisibility beyond their own company’s walls. According to theresponses of this survey, achieving such a level of visibility is akey step along the road to better understanding and managingrisk. October 2014 Transport IntelligenceStill, more than one in four (28.7%) of those surveyed said theircompany formed the boundary of what they could effectivelysee, and therefore exercise direct influence over. This can placethe management of both shipments, and of supply chain riskinto the hands of others. This may be a strategic move tooutsource the responsibility for risk and visibility, however.Supply Chain Risk & Visibility in the Movement of Goods14

Supply Chain VisibilityThe generally balanced outcome across the three visibilitychallenges suggests that the ability to collect, manage andinterpret data from various operational activities is neededthroughout the supply chain.The placement of accurately identifying performance by tradelane/mode of transport at the top of the list is likely a reflectionof the increased demands customers are placing on providers todeliver real-time performance data across a range ofmeasurements which may affect their shipments. October 2014 Transport IntelligenceIt was noted by several respondents that such data allowed bothproviders and their customers to make better decisions andgenerate better outcomes across the business. Meeting suchdemands can, therefore, become a competitive advantage, andone LSPs appear to be pursuing in order to win business. Theability to measure partners performance reinforces the messagethat end-to-end supply chain visibility is a collaborative effort,requiring partnership and integrated working patterns ifprocesses to identify and overcome risks are to be effective.Supply Chain Risk & Visibility in the Movement of Goods15

Supply Chain VisibilityRunning parallel with the strategies employed tomitigate risk are the actions being taken to increasevisibility. It appears respondents view their capacity toenable better supply chain visibility in improving theircapacity for data collection, interpretation anddistribution, with IT systems playing a key role in theprocess. These improvements occur on the operationallevel, just as the risk management practices cited earlierin the survey. October 2014 Transport IntelligenceSupply Chain Risk & Visibility in the Movement of Goods16

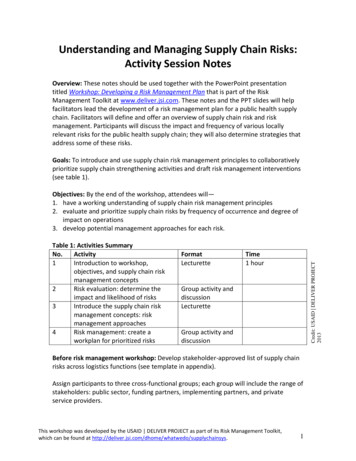

The Role of TechnologyParticipants were asked to rank the various software types in terms of their importance in assisting with the management ofoperations on a scale of 1 to 5, where 1 equalled the least important and 5 the most important. In order to rank the software types,ranking points were awarded according to each rating – 5 points for a ‘most important’ rating, through to 1 for a least importantrating.H o w imp o rta nt d o y o u fe e l the fo llo wing s o ftwa re s y s te msa re in a s s is ting the ma na g e me nt o f o p e ra tio ns ?Warehouse management systemTransport management systemFreight management systemFinance softwareOrder management softwareEnterprise resource planningCustoms and compliance softwarePlanning and optimisation softwareCustomer relationship management softwareParcel shipping softwareR a nk12245677910Warehouse management systems ranked highest, while transport management systems and freight management systems rankedjointly in second place. This suggests that systems which allow for visibility and the tracking and tracing of shipments is a primaryconcern for LSPs who are aware of the emphasis their customers place on this information. These are also systems that allow formanagement of shipments at the tactical/operational level, while those which eek out a strategic advantage for providers – CRMsoftware, for example – rate more lowly. October 2014 Transport IntelligenceSupply Chain Risk & Visibility in the Movement of Goods17

The Role of TechnologySurvey respondents indicated that one software system managing across all modes is the preferred option. This can reduce thecomplexity by managing multiple transportation modes and shipments with a single integrated platform. However, it exposesproviders to several risks – disruptions take on the potential to be perpetuated throughout the supply chain. October 2014 Transport IntelligenceSupply Chain Risk & Visibility in the Movement of Goods18

The Role of TechnologyWhen asked to rate the performance of their current softwareacross a variety of functions, it is perhaps understandable thatthe ratings given by respondents produced a bell curve, withthe majority of answers falling in the mid-range to indicate thatsoftware is generally satisfactory but room for improvementexists. Indeed, approximately half of all respondents rated theircurrent functional software in either the ‘meets expectations’or ‘meets expectations ’ category. Of the software typessurveyed, freight forwarding software and warehousemanagement systems were the only two which peaked in the‘meets expectations ’ rating. Warehouse managementsystems scored best when ‘meets expectation ’ and ‘exceedsexpectations’ scores were combined with 39.2% indicating October 2014 Transport Intelligencethey were highly satisfied with the performance of theircurrent software. Some 37.5% of respondent rated theirfreight forwarding software across those same two categories.Respondents did, however, reveal a clear need forimprovement in software that facilitates integration withtrading partners – at 32.3%, nearly one third of respondentscategorised their current software as either ‘not meetingexpectations’ or ‘meets expectations –’. Nearly as concerning isthe 29.6% who ranked BI/tools for management dashboardsand reporting in the same two categories. Similarly, nearly onefifth (19.6%) reported unsatisfactory performance from theircustoms & compliance software. This reveals a clear demandfor improved solutions.Supply Chain Risk & Visibility in the Movement of Goods19

The Role of TechnologyAdaptability and the ability to customise software is a clearlysought after feature. The demand to tailor software to meetindividual needs is likely a direct link to the desire of eachprovider to serve the individual demands of their owncustomers.Scalability is important for one fifth (20.5%) of respondents. Thismay relate to respondents’ desire to manage shipmentstravelling on domestic, regional and global trade lanes, or withspecialised requirements, at any one time from a single system. October 2014 Transport IntelligenceThe difference between initial cost and return on investmentsuggests that high initial cost isn’t always prohibitive, but only solong as the value of a system is evident. This is also perhapslinked to speed of deployment rating near the bottom of the list– similar to ROI, it seems the correct solution over the long-termis prioritised. The implication is clear; software must facilitatethe efficient and effective operation of the business model, notdictate what capabilities an LSP can offer customers.Supply Chain Risk & Visibility in the Movement of Goods20

Contact Transport IntelligenceFor more information about the information contained within this report or about anyof Ti’s products and services contact :Global Head Office: 44 (0)1666 519902Mike Nordmann, Business Development DirectorT: 44 (0)1793 850025E: mnordmann@transportintelligence.comJoel Ray, Head of Consulting:T: 44 (0)1666 519910E: gence.com

About Kewill Kewill, a Francisco Partners portfolio company, is a global leader in multimodal transportation management software, providing organizations with a comprehensive end-to-end platform for managing the complexities of transportation, logistics and trade compliance.