Transcription

OPC in SmartManufacturing 4.0John WeberFounder, Software ToolboxOur Asean Partner

New to Automation? - Terminology OPC – Open Platform Communications. A standard for software to software communications within theindustrial automation space. Created in 1995/96 and is the leading means of sharing data betweensoftware applications in automationOPC DA – the original Data Access part of the OPC Standards – used for real-time dataOPC UA – the modern name for the latest OPC standards which address real-time, alarming, historical dataand more. UA Unified ArchitectureODBC – Open DataBase Connectivity – a Microsoft standard for connecting to different databasesDDE – Dynamic Data Exchange – the first way Microsoft ever offered, in Windows 2.0, in 1988, for sharingdata between software applications.MQTT - Message Queuing Telemetry Transport – a standard for sharing data through a publish subscribemethodology that is widely adopted in IoT ApplicationsIOT – Internet of ThingsWant to learn more?––Download our OPC 101 guide at estions-guideVisit our Automation 101 blog at 101

The Software Toolbox Difference Variety of Offerings Interoperability Knowledge Trusted Support Since 1996 14,000 Users 115 Countries Success Assurance throughRisk reduction

Why Software Toolbox Technical team focused ondevice and data integration Test Lab with Hardware We deal with protocols allthe time We deal withcommunicationstroubleshooting every day

Our clients are in every industry

Our Products Help Our Clients ToGetconnectedTo theRight DataSourcesSo theRightPeopleCan MakeReal-TimeDecisionsAnd address problems before they ruin theirday, week, month, quarter, year, or career

Where we fit in IoTWithout Data fromthe Edge, NothingHappens

What is TOP Server?Most ClientConnectionsOne InstallOne *.EXEMany types ofdriverssoftwaretoolbox.com/topserverMost IndustryStd ProtocolsAdvancedFunctionalityAggregate fromother software8

TOP Server Gets You Connected – 100 Drivers! AB Bulletin 1609 UPSAB Bulletin 900 Temp. ControllersABB Totalflow SerialAB Micro800 Serial & EthernetAB ControlLogix Ethernet & GatewayAB ControlLogix Unsolicited EthernetAB PLC5,SLC5/05 EthernetAB DF1 Full/Half-Duplex/Radio SerialAB Data Highway Plus (DH )Alstom Redundant EthernetAdvanced SimulatorAnalog Devices 6BAromat Serial & EthernetAutomation Direct DirectNet SerialAutomation Direct K-Sequence SerialAutomation Direct ECOM EthernetAutomation Direct P3000Automation Direct EBC EthernetBACnetBailey Fisher & Porter Micro-DCIBeckhoff TwinCATBristol/IP EthernetBUSWARE Ethernet I/OCODESYS EthernetContrex/Fenner CX1000Contrex/Fenner M SeriesCustom Interface Driver (CID)Cutler Hammer D50/100Cutler Hammer ELC Danfoss AKC55 SerialDataforth IsoLynxDDE Server to OPC Client BridgeDeviceNet/Profibus (Hilscher Universal)DNP3 Serial EthernetEnron Modbus SerialEUROMAP 63Fisher ROC & ROC PlusFuji Flex PLCsGE Focas1 EthernetGE SRTP EthernetGE EGD EthernetGE CCM SerialGE SNPGE SNP-X SerialHoneywell UDC & HC900Idec MicroIEC 60870-5-101 Master SerialIEC 60870-5-104 Master EthernetIEC 61850 MMS ClientIntelligent Actuator SuperSELIOTech PointScan EthernetKeyence KV EthernetKraussMaffei MC4 EthernetLufkin Modbus SerialMettler Toledo Scale SerialMitsubishi FX Serial Programming PortMitsubishi FX-Net Multidrop SerialMitsubishi A Series Serial Mitsubishi A Series EthernetMitsubishi Q/QnA Series EthernetModbus RTU & ASCII Serial MasterModbus RTU Serial RTU SlaveModbus PlusModbus Ethernet Master & SlaveMQTT ClientMTConnect ClientODBC Client DriverOmni Flow ComputerOmron Hostlink & FINS SerialOmron Process SuiteOmron FINS EthernetOmron NJ/NX EthernetOPC DA / UA / XML-DA ClientOptimation OptiLogic I/OOpto 22 EthernetOracle Connectivity SuitePartlow ASCII SerialPhilips PC8/PC20Red Prairie Logistic SystemsSattbus & Sattbus EthernetScanivalve EthernetSiemens S5 AS-511Siemens 3964RSiemens S7-200 PPI & ModemSiemens S7-300/400 MPISiemens S7-200/300/400 EthernetSiemens S7-300 Ethernet SlaveSiemens Plus (OPC UA Client for S71500) Simatic/TI 5x5 EthernetSimatic/TI 5x5 SerialSimatic/TI Unilink TIWAY Host AdapterSixnet UDR & Ethertrak Ethernet I/OSimulator SuiteSquareD SerialSystem Monitor (WindowsPerformance)Telemecanique UnitelwayThermowestronics Serial EthernetTorque Tool EthernetToyopuc PC2 Serial & PC2/PC3EthernetToshiba PLCs Serial EthernetTriconex TSAA EthernetUser Configurable Driver (UCON)Wago 750 Ethernet I/OWeatherford 8500 SerialWITS Level 0 (Active & Passive)Wonderware Intouch ClientYaskawa MemoBus PlusYaskawa MP Serial & EthernetYokogawa CXYokogawa DX100/200 & Darwin SerialYokogawa DX(P)100/200Yokogawa Darwin EthernetYokogawa DXPYokogawa HRYokogawa MWYokogawa MXYokogawa YS100 SerialPlug-Ins Advanced Tag Connection Sharing Data Logger Local Historian Media-Level Redundancy OPC Alarms & Events Real-Time Scheduler SNMP Agent Security PoliciesVertical Industry Suites Building Automation IT & Infrastructure Manufacturing Oil& Gas Power DistributionEFM Suite (Electronic FlowMeasurement) EFM Exporter Plug-In Omni Flow Computer Enron Modbus Serial Fisher ROC Suite ABB Totalflow Serial EFM Simulator

CompatibilityInTouchSystemPlatformHistorianWindows 7, Windows 8, 8.1, Windows 10Windows Server 2008, 2008 R2Windows Server 2012, 2012R2, 2016Windows 7 Standard Embedded32 and 64-bit OS SupportVirtualized Environment SupportRemote Desktop/Terminal Services/ACP ThinMan SupportedMarathon and Stratus High Availability Supportedsoftwaretoolbox.com/topserver10

TOP Server Security Out-of-the-Box TOP Server SecureDeployment ConsiderationsGuide Current OS and OPC UACapabilities & Security Project File Encryption Administrator Passwordduring Installation Back-end Security Updates

TOP Server – What & Why? 100 000 Tags - 1 Second Scan update 7% – 10% for Top Server 33% for Entire Wonderware System Highly Scalable 350 000 Tags 50% Total CPU Usage (WW TopServer) Water & Wastewater / Oil & Gas Apps 1 000 000 Tags with over 1000 devices

TOP Server Performance Empowered By User controllable threading Thread-safe application Multi-core and multi-CPU machines fullysupported Processor affinity settings Processor priority settings Runs as service

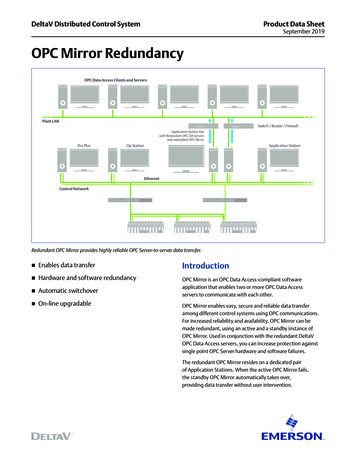

Redundancy Support Redundant AppServers Single TOP Server Single PLCnetwork Non-RedundantPLCs

Redundancy Support Redundant App ServersRedundant TOP ServersSingle PLC networkNon-Redundant PLCs

Redundancy Support Redundant AppServers Redundant TOPServers on AppServer machines Single PLC network Non-Redundant PLCs

Redundancy Support Redundant AppServers Redundant TOPServers RedundantCommunicationPaths Non-RedundantPLCs

Redundancy Support Redundant AppServers Redundant TOPServers RedundantCommunicationPaths Redundant PLCs

TOP Server Modbus Offerings Modbus Suite – 1 solution many drivers––––Modbus RTU Master & SlaveModbus ASCII MasterModbus TCP GatewayModbus Plus Modbus Variant Drivers––––Enron Modbusbe used to make an HMI/SCADA look like aLufkinCanELAMModbus Device with full Modbus Register memoryOmnimap!FlowComputersExcellentway to integrate to other systemsthatUDCwant 3000/3300/HC900to be a Modbus TCP Master!Honeywell

TOP Server Modbus Differentiators Flexibility, flexibility, flexibility5/13/201921

TOP Server DNP Suite DNP 3.0 Master in Level 3 Implementation– Serial– Ethernet Uses Timestamps from DEVICE! Buffered event playback in order Used as a reference by Wonderwaredevelopment in their Historian improvementsas an example data source Field experience since 2006 enables us toknow when a device is following DNP specs . And when it isn’t and how to deal with it 5/13/201922

Water Industry Experience

TOP Server Oil & Gas Suite TOP Server OPC & Suitelink Server Core Drivers for–––––––––––ABB TotalFlowBristol/IPEnron ModbusFisher ROC & ROC Plus SerialLufkin Modbus (ELAM)Modbus ASCII, RTU, & TCP/Ethernet w/highly flexibleoptionsOmni Flow ComputerWITS Level 0 Active & PassiveWeatherford 8500 protocol serialUser Configurable DriverCustom Interface Driver (CID)

TOP Server EFM Suite Also Oil & Gas Oriented EFM Exporter – Flow-Cal,PGAS, CSV, SQL formats Drivers supporting EFM––––Enron ModbusOmni Flow ComputerABB TotalFlowFisher ROC/ROC EFM Simulator

IEC61850 IEC61850 Master– IEC 61850-6 (SCL)– IEC 61850-7-3 and 7-4 (all logical node anddata object templates)– IEC 61850-8-1 (MMS) Item timestamps from devices Buffered data playback SCL file import for auto-configuration– Filter import by device and functionalconstraints Report Block (RCB) support Control command capability5/13/201926

IEC 60870 Driver Anywhere power distributionand substations are involved –not just for utilities Connect to IEDs, RTUs such asABB, SEL, Siemens, GE,Schneider Found more in existingapplications Part 101 & 104 supported Great companion to ourexisting IEC61850 driver5/13/201927

TOP Server EUROMAP 63 Driver Add OPC to Injection MoldingMachines (IMMs) Integrates EUROMAP 63enabled IMMs including:–––––––Cincinnati MilacronFanucEngelSumitomo DEMAGToyoKraussMaffeiMore

Great way to learn eos

Keep Up with TOP erver30

Connecting The Rest of Your DevicesTypical Solutions1.2.Historian3.4.Linear Scalesi.e. Mitutoyo,DigimaticCustom Code/ApplicationsHardwired Interfaces to controller if possibleInTouchChoose different hardware with standard I/FDon’t IntegrateEthernet: TCP/IP, UDP, Telnet, RS-232, RS-422, RS-485Bar CodeScannersi.e. Intermec,Symbol, Z-TronWeigh ScalesInBatchAll of these areMessagePrinters1.BarcodeCostlyDisplays &Scoreboards2. Risky3. Suboptimal forOperations SystemsGasChromatographsGas analyzersLaser MarkingSystemsSystemPlatform

OmniServer Connects Them Proven solution No Coding orDevelopmentRequired Field proven since 1995 Over 7000 InstalledLicenses l-guide

Food Packaging Proof Point Global MESImplementation Standardized onOmniServer for allconnectivity to thesedevice types Can Printers Barcode printers Weigh bridges Weigh Scales Barcode readers

How? - Typical Implementer Journey Step 1 Implement DeviceSpecific Protocol– Point & clickconfiguration– One time step per deviceprotocol type the you’redone, forever– Done by SI or ourprofessional services– 12 sample protocolsincludedSoftware Toolbox Confidential

Typical Implementer Journey Step 2 Device Physical Connection– RS-232/422/485 Serial– USB provided it presents asvirtual com port– TCP/IP, UDP, Telnet overEthernet – wired, wireless,including terminal server(serial/ethernet converters) Done by user or integrator CSV Import for MassConfigurationSoftware Toolbox Confidential

Typical Implementer Journey Step 3 Connect Protocols to Devices to makeTopics – One Per Field Device Up to 1000 devices in a single Omniserverinstance – CSV import for mass configurationSoftware Toolbox Confidential

Typical Implementer Journey Step 4 Connect your Client application––––OPC DAOPC UA (DA profile)SuitelinkPlug-Ins Log to CSVLog to DBEmailKeyboard wedgeFuture: MQTT clientSoftware Toolbox Confidential

OPC DataLogger – OPC DA/UA to SQL, CSV, Text,AzureSQL, MySQL, Oracle Log on data change Start/stop logging onother tag condition(s) Scheduler based logging(i.e by shifts, etc) Handshake withPLC/device once datawritten to data store

Cogent DataHub Ultimate dataintegrationmiddleware New ConnectionsOPC DA& UAAny other OPCDA or UAServerWatch thisspace ideos– MQTT– Azure IoT Hub– Amazon IoT– Google IoT

Proof Point - Award Winning Solutions SetBrewing in a Desert! & Green Manufacturing TOP Server & Cogent DataHubWonderware om/wonderware-brewmaxx-sap-integration

DataHub Connects – OPC UA OPC UA Clientand Server Easy OPC UA SSLCertificateManagementAny other OPCUA Data AccessData Source

DataHub Connects – OPC DA Data AccessClient and Server Flexible optionsto deal withabout any DAserverAny other OPCDA Data AccessData Source

DataHub Connects - Databases Log To Extract From Connect to OPC SQL serverOracleMySQLAny ODBCCompliant DB

Proof Point: First Gas New Zealand Integration of FoxboroSCADA History DB Move data to Wonderwarehistorian for fasterreporting OPC DA, ODBC, & ScriptingFeatures Used

DataHub Connects - Excel

Non-Windows Data Sources

Data BridgingRockwell ControlLogixController Type 1Controller Type 2

Proof Point: Database to OPC Integration Oracle MES DB onLinux Wonderware OPC DataSources Custom C applicationto be replaced DataHub as -opc-database-integration

OPC DA/UA Gateway & Tunneling

Proof Point: Trans Anatolian Natural Gas Pipeline 1 DataHub V92.1 mm pointsTunnelingBridgingRedundancyOPC Alarms &Events Honeywell and ABBsystems

Modbus

DataHub IoT Gateway If you can getit intoDatahub You can usewith the IoTGateway

MQTT Client Publish anyDataHub Data Subscribe to 1-NMQTT brokers Flexibleconfigurationoptions

MQTT Broker Premise hostedsecure broker Integrate OPC DA,UA, ODBC,Modbus HighlyConfigurable Hierarchical DataSets

IoT Destinations - Azure

IoT Destinations – Amazon IoT Core

IoT Destinations – Google IoT

Stay In Touch – blog.softwaretoolbox.com Tech tips Productannouncements Training videos Subscribe now!jweber@softwaretoolbox.com

Wonderware Intouch Client Yaskawa MemoBus Plus Yaskawa MP Serial & Ethernet Yokogawa CX Yokogawa DX100/200 & Darwin Serial Yokogawa DX(P)100/200 . Oracle MES DB on Linux Wonderware OPC Data Sources Custom C application to be replaced