Transcription

XRD-6100 XRD-6100 OneSightC141-E004KX-ray DiffractometerXRD-6100XRD-6100 OneSight

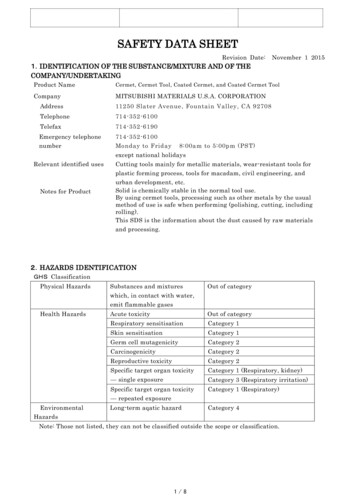

Ease of Use and Abundant Functions Herald a New Era of AnalysisThe Windows-supported application software ushers this compact, multi-functional,general-purpose X-ray Diffractometer into the networking era of analysis.X-Ray DiffractometerXRD-6100 / XRD-6100 OneSightTMIn addition to its basic ease of use and abundant functions, the XRD-6100 boasts an integrated design featuring a vertical goniometer anddata processing software supporting the Windows user interface.The XRD-6100 offers solutions encompassing wide-ranging analysis requirements, from routine qualitative and quantitative analysis to statechange analysis, including stress analysis, residual austenite quantitation, crystallite size/lattice strain, crystallinity calculation, materialsanalysis via overlaid X-ray diffraction patterns, enhanced material evaluation and sample heating analysis. Of course, crystalline structuralanalysis, including precise lattice constant determination, is also supported.

A General-Purpose X-ray Diffractometerto Address Your Various Analytical NeedsFe a tu resHi g h -Prec i s i o n a nd Re lia ble Built -in Ve r t ica l G oniom e t e rThe goniometer mounted on the XRD-6100 is compact and simple.All the components in the X-ray optical system are precisely assembled and adjusted at thefactory and have been designed to ensure that accuracy is maintained.Thus, there is absolutely no need for users to make any adjustments in the future.Wi n d o ws 10 Em ploy e d a s S of t w a re P la t f or mThe main unit control and data processing software support the widely used Windows 10 userinterface. For this reason, data can be exported to marketed software. Network support andmulti-user accessibility are easily achieved.Multi-Functional Auto-Search/Match Software (Qualitative Analysis)and Quantitative Analysis Software Equipped as StandardThe XRD-6100 is equipped with auto-search / match software as standard to aid qualitativeanalysis - the important analysis task of X-ray diffraction. The detailed search parametersettings, second search function, and the comparison display of candidate substances on araw data profile make analysis easy to understand - even for beginners. What’s more, agreater success ratio in results can be achieved with the system. In addition, a simplifiedquantitative calculation function using the RIR method* and a function that allows users tocreate their own database are included in the system as standard.*RIR (Reference Intensity Ration)Safe, C o mp ac t a nd S ophist ica t e d BodyThe main body (W900 D700 H1600 mm) has been massively slimmed. As the rear is a sheerflat surface with no superfluous protrusions, the device can be placed up against walls, whichmeans it does not take up room when installed on site or in the lab. Furthermore, the unit isdesigned to save energy; the X-ray is OFF when the door is open and the power is turned ONonly at the start of measurement (only the filament is always ON; Shimadzu patent). Inaddition, the door lock mechanism works when sample measurements are taken (when X-raysare emitted) to provide a safe operating environment for protection against X-ray exposure.O n eSi g h t Wi d e-Ra nge H igh-S pe e d D e t e ct or Av a ila bleThe OneSight is a wide-range high-speed detector that consists of a number of semiconductordevices. It is able to achieve an intensity more than 100 times higher than a scintillationdetector.

Applications of X-ray DiffractometryF e rro u s Meta lsSteelQualitative analysis of steel sheet, measurement ofresidual austenite and residual stress, analysis of friction and wear test samples,measurement of iron oxide films and nitride layers, evaluation of plating andtexture.Cast IronQualitative analysis of precipitates and additives in cast iron, etc.Surface-Treated SteelEvaluation of characteristics of surface-treated areas, quality control, residualstress measurement.N o n - F e rro u s Meta lsCopper and ZincQualitative analysis of alloys, orientation measurementsof foil samples, evaluation of texture, qualitative analysis of plated areas, etc.AluminumQualitative analysis (aluminum, aluminum alloys, oxides and nitrides), evaluationof texture in rolled material.Other MetalsQualitative analysis (metallic compounds, oxides and nitrides), characteristicevaluation of surface-treated areas, residual stress measurement.M a c h in ery, A u to mo b iles and ShipbuildingMachineryQualitative analysis of tool steels, surface condition analysis ofmachined parts, analysis of austenite layers, qualitative analysis of surfaceplating, residual stress measurement.Automobiles and ShipbuildingQualitative analysis of structural parts, surface quantitative analysis of austenite,residual stress measurement, qualitative analysis of exhaust gas catalysts, etc.C h e m icals a n d C ata lystsChemicalsQualitative analysis of organic and inorganic chemicals, impurity analysis.CatalystsQualitative analysis and measurement of crystalline, measurement of crystallitesize to check final product.C e ra m icsPorcelain and CeramicsQualitative analysis of raw materials, final productevaluation, analysis of crystal structures during heating (crystal system, crystallitesize, lattice constant).Cement and GlassQualitative and quantitative analysis of clinker and cement (free lime, etc.),qualitative analysis of raw materials. Qualitative analysis and orientationmeasurements of thin film layers formed at the glass surface.4

Pharmac eutic als and M edic al Treat m en tPharmaceuticalsQualitative analysis of pharmaceutical raw materials and identification ofimpurities. Crystal polymorphism analysis and crystallinity measurements, qualitycontrol during pharmaceutical manufacture using crystallite size measurement,final product quality check, crystal polymorphism analysis related to patents.Dental MaterialsQualitative analysis of dental materials such as apatite, etc.Electrical and Electronic MaterialsElectrical ComponentsQualitative analysis of corrosion and adhering matter onelectrical contacts. Stress measurements in structural parts, qualitative analysisof plated parts, etc.Electronic ComponentsQualitative analysis and orientation measurements of thin-film electronicmaterials. Measurement of substrate crystal orientation for magnetic heads andelectronic elements.Battery MaterialsCrystal structure analysis of battery materials.Construction and Civil EngineeringQualitative/quantitative analysis of asbestos in construction materials, qualitativeanalysis of construction materials such as tiles and bricks.Environment and Industrial WastesEnvironmentQualitative/quantitative analysis of asbestos and free silicic acids in the workenvironment. Qualitative analysis of dust.Industrial WasteQualitative analysis of residual matter in plating liquids, combustion ash, coalash, and furnace slag.Resourc es and EnergyCoal, Oil and Natural GasPlant-scale qualitative analysis, evaluation of carbonmaterials, evaluation of catalysts during petroleum refining.Rocks and MineralsQualitative analysis of raw materials and identification of impurities.Qualitative/quantitative analysis of asbestos minerals (compatible with PRTRmethod).XRD-6100X-ray Diffractometer5

Polycapillary Optical SystemPrinciple of the Polycapillary Optical SystemSchematic Diagramof the Polycapillary Optical SystemThe fine glass capillaries in the order of several microns are arranged in asolid as guides to multiple X-rays. The X-rays pass along each capillary whilerepeating total internal reflection and exit from the opposite end of thepolycapillary system. The capillaries are curved so that repeated total internalreflection is allowed, and the X-rays from the point X-ray source exit the unitas a parallel beam with a large solid angle.Output divergence angle0.22 Intake angle4.1 Several hundredOutput beam sizethousands of capillaries 10 10 mmPoint X-ray sourceF e a tu res o f th e P o lyca p illary Optic al SystemCompared with the conventional focused-beam system and the normalparallel-beam system, the polycapillary optical system more efficientlyexploits the beam from the X-ray tube, resulting in higher diffraction X-rayintensity. A displacement of the sample in a Bragg-Brentano optical systemcan move it outside the focus, causing a significant displacement in height indiffraction angle and a dramatic drop-off in diffraction X-ray intensity.Conversely, a displacement of a few millimeters in a parallel-beam systemhas no effect on the diffraction angle and a small decrease on the diffractionX-ray intensity. Consequently, incorrect loading of the upper and lowersample faces or an irregular surface causes no angular displacement andaccurate measurement is possible. The parallel-beam system also allowsanalysis of curved surfaces, something not possible with conventional opticalsystems.Configuration of PolycapillaryParallel-Beam Optical SystemParallel-beam optical systemFlat crystal monochromatorPolycapillaryDetectorSoller slit forparallel beamPoint X-ray sourceSampleConfiguration of Bragg-Brentano Optical SystemDivergence slit (DS)Curved crystal monochromatorReceiving slit (RS)Scattering prevention slit (SS)SampleS a m p le Mea su reme n t U singth e P o lyca p illary Op tica l System20000.0016000.00Intensity (CPS) CUnits per secondThis example shows measurements of the raw drug acetaminophen and itstablets during the process of manufacturing. Tablets can be directly analyzedto evaluate the degree of crystallinity and crystal polymorphism. TheXRD-6100 is able to perform accurate, highly sensitive measurements onirregular surfaces or curved surfaces like this.Tablet-Formed Acetaminophen12000.008000.00Tablet 24000.00Tablet 10.0010.00Ingredient20.0030.002 θ- θ640.00

Qualitative and Quantitative Analysis of Asbestosand Free Silicic AcidsThe content of asbestos in construction materials is measuredusing phase dispersion microscopes and X-ray diffractometers.After pulverizing the sample acquired from the site in a pulverizer,a phase dispersion microscope and X-ray diffractometer are usedrespectively to qualitatively analyze the sample. If the sample isdetermined to contain asbestos at this stage, then it isquantitatively analyzed using the X-ray diffractometer. In actualpractice, asbestos analysis (JIS A 1481-3) requires sensitivitysufficient to determine 0.1 % content by weight in 100 mg ofacquired sample. To increase sensitivity so that such trace asbestoslevels can be detected, formic acid is used to dissolve matrixcomponents in the pulverized sample. Then the residue afterformic acid treatment is recovered in a fluorocarbon polymerbinder filter using a suction filtration system for use in quantitativeanalysis. The quantitative analysis is performed using an X-raydiffractometer, where the absorption of diffracted X-rays must becorrected to compensate for the asbestos itself and theundissolved matrix components. This correction process (basestandard absorption correction method) involves first measuringthe metal plate (base plate) for a blank filter, placing the filter withthe formic acid-treated asbestos in the diffractometer, andmeasuring the asbestos together with the metal base plate todetermine a correction factor from the diffraction intensity ratio ofthe metal plate. Then that correction factor is used to determinethe corrected asbestos diffraction intensity. Note that this methodwas originally developed for measuring the free silicic acid contentin mineral particulates during work environment measurements.The XRD-6100 X-ray diffractometer environmental measurementpackage includes a filter holder and rotational sample stage foruse in the base standard absorption correction method, andenvironmental quantitation software for performing quantitativecalculations that correct for absorption. This environmentalquantitation software incorporates Shimadzu's proprietarymeasurement expertise cultivated from many years in this field,which is especially valuable when quantitating particularly tracelevels of asbestos.In addition, this XRD-6100 X-ray diffractometer environmentalmeasurement package is compliant with methods specified in theNotification No. 0828001 by the Director of the Chemical HazardsControl Division, Industrial Safety and Health Department, LabourStandards Bureau, Ministry of Health, Labour and Welfare ofJapan, such as for analyzing asbestos in natural minerals ormeasuring the free silicic acid content in mineral particulatesduring work environment measurements.Typical X-ray Diffraction Pattern of AsbestosThe major types of asbestos are serpentine asbestos (chrysotile) and amphiboleasbestos (amosite and crocidolite). The characteristic peaks of these types canbe quantitatively analyzed by X-ray diffractometry.Qualitative Analysis Results for AsbestosScreenshot of Environmental Quantitation SoftwareNote: Please obtain the ICDD database separately for analysis ofasbestos and free silicic acids.XRD-6100X-ray Diffractometer7

P ri n c ip le o f O p e ra tio nCons truc tionThe XRD-6100 analyzes crystalline states under normalatmospheric conditions. Furthermore, this method isnon-destructive. X-rays hit a sample loaded in the center of thegoniometer and are diffracted by the sample. The changes inthe diffracted X-ray intensities are measured, recorded andplotted against the rotation angles of the sample. The result isreferred to as the X-ray diffraction pattern of the sample.Computer analysis of the peak positions and intensitiesassociated with this pattern enables qualitative analysis, latticeconstant determination and/or stress determination. Qualitativeanalysis may be conducted on the basis of peak height or peakarea. The peak angles and profiles may be used to determinecrystalline size and degree of crystallization, and are useful inconducting precise X-ray structural analysis.Incident X-rays(λÅ)Diffracted X-raysθθθθCompact, X-ray-Protected HousingThe compact construction (W900xD700xH1600mm) minimizesinstallation space requirements.The front door is mounted on guide rollers, enabling light andsmooth opening of the door. Therefore, it is easy to facilitatethe installation/exchange of samples and attachments. Amagnet latch assures the door closes; to further ensure safety,a door interlock mechanism is automatically activatedwhenever X-rays are generated.High-Precision, Vertical θ -θ GoniometerHigh-speed rate (1000 /min) and high-precision anglereproducibility ( 0.001 ) provide fast measurement and highlyreliable data. The θ-θ Vertical goniometer unit allows analysisof samples in various states, substantially widening theapplication range. The drive mechanism features anindependent dual axis θ -2θ linkage drive, and independent 2θand θ axis drives, freely selectable for efficient thin film andvarious other types of analysis.dÅdÅλ 2d · sinθCounter monochromator(option)A p p l icatio n sFerrous metals, non-ferrous metals, machinery, shipbuilding,welding, automobiles, ceramics, cement, glass, catalysts,electrical parts, electronic materials, magnetic materials,battery materials, fibers, paper, pulp, food products, chemicals,agricultural chemicals, dies, pigments, paints, pharmaceuticals,dental materials, biological matter, petroleum, coal, powergeneration, natural gas, mining ore, soil, rocks, clay, minerals,construction, civil engineering, environment, and industrialwaste.Rotational sample stage(option)Vertical GoniometerHigh-Voltage Transformer forHigh Output X-ray TubeThe high-voltage transformer supports either the 2.2kW highoutput fine focus X-ray tube or 2.7kW high output broad focusX-ray tube.8

X-ray TubesHighly Stable X-ray GeneratorThe XRD-6100 will accept various types of X-ray tubes,including the normal focus (NF) 2kW type and broad focus (BF)2.7kW type, which are standard accessories, as well as theoptional long fine focus (LFF) 2.2kW type. By attaching theoptional counter monochromator, all types of samples,including Fe samples, can be analyzed using the standard CuX-ray tube.Shimadzu's extensive experience in producinghigh-performance X-ray generators has enabled the productionof a highly stable X-ray generator, with tube voltage and tubecurrent both stable to within 0.01% with respect to 10%voltage fluctuation. This stability is unaffected duringfluctuation of source voltage or ambient temperature, ensuringhigh reliability of data even during prolonged periods of dataacquisition.DetectorGoniometerMonitorAAngle ofdiffraction2θBBABθSampleX-ray tubeHigh-voltagetransformerX-ray controlGoniometer controlDetectorhigh-voltage PHAStandard dataprocessing systemcompatible with WindowsXRD-6100 Relational DiagramXRD-6100X-ray Diffractometer9

Providing a Complete Analysis SystemAnalysis SystemStandard SoftwareX-ray generator controlOptical path adjustmentX-ray ON/OFF, tubevoltage/current settingGoniometer adjustmentDetector adjustmentMeasurementSingle scan, multi-scanFile maintenanceASCII data conversionASCII data to XRD-6100 data conversionXD-D1 data to XRD-6100 data conversionBasic data processingGraphic displaySmoothing, backgroundelimination, Kα1-Kα2 separation,peak search, system errorcorrection, internal/externalstandard correction, operationsbetween dataVertical display, horizontaldisplayOverlay display (3D)Log displayQualitative analysisAuto searchUser database creationQuantitative analysisCalibration curve generationQuantitative calculationOptionsQualitative analysisCounter monochromatorICDD database PDF-2, PDF-4Quantitative analysisResidual austenite quantitation softwareRotational sample stageEnvironmental quantitation analysis systemPeak processingProfile fitting software (overlapping peak separation)Crystalline structural analysisPrecise lattice constant determination softwareState analysisCrystallite size/lattice strain calculationCrystallinity calculationAttachmentsThin film measurement attachmentFiber sample attachment(with orientation evaluation software)Stress measurement attachment(with stress analysis software)Sample heating attachmentMicro-measuring attachmentAuto Search Results and Thin Film Sample Overlay Display10

Automatic Measurement, Easy OperationMeasurement DisplaySample measurement conditions can be set easily.The scheduling and the progress condition of themeasurement can be confirmed in one view bythe analysis & spooler.Measurement ScreenMultitasking for Enhanced Analysis EfficiencyBasic Data ProcessingThe multitasking capability provided with theWindows operating environment allowsmeasurement and data processing to beconducted simultaneously, enhancing theefficiency of analysis operations.Basic Data Processing ScreenXRD-6100X-ray Diffractometer11

Comfortable Data Processing EnvironmentGraphic DisplayData can be freely zoomed with a click of the mouse, so profilecomparison of thin film data or heating measurement data canbe easily accomplished using a combined 2-dimensional or3-dimensional display. The software also features a variety ofother useful graphic functions, such as intensity Log conversiondisplay and hidden-line processing on the 3-dimensional display.Each type of data can be output to a color printer, sodifferences between samples can be recognized at a glance.3-Dimensional Screen of Thin Film Sample2-Dimensional Output of Thin Film SampleAddition/Subtraction OperationsData manipulation functions such as deletion of unnecessarypeak profiles and addition of duplicate measurement data toobtain a summed profile are some of the invaluable toolsavailable for conducting efficient data analysis. Profilecalculations are conducted in the window displayed on theright.Profile Calculation Window12

File Maintenance Data Format Conversion With the XRD-6100, digital data measured by other x-raydiffractometers can be converted into files to enable analysisusing this data processing software. In the case of other x-raydiffraction data, 2θ angle and x-ray intensity text files (ASCIIdata) can be converted into XRD-7000 data format. In reverse,raw data measured by the XRD-6100 also can be convertedinto text files or files formatted to enable Rietveld analysis.Furthermore, processed data including peak data, as well asraw data, can be converted to text format, facilitating dataprocessing in customized formats.File Conversion WindowOptical System AdjustmentsThe XRD-6100 system makes fully automatic opticaladjustments to the goniometer from the computer screen,even for optional attachments. In addition to completelyautomatically adjusting all settings, such as the zero angle forthe θ and 2θ axes, the x-ray detector high-voltage settings,the PHA baseline and window width settings, it automaticallysaves the settings information. This feature can be utilized forroutine maintenance.The PHA (Pulse Height Analysis)Adjustment ScreenHV (High-Voltage) Adjustment Screenθ-Axis Adjustment ScreenXRD-6100X-ray Diffractometer13

Enhanced Auto Search System[ Auto Search, General Quantitation Software Provided as Standard ]I d e n t ificatio n wo rk can be performed effic iently on s c reen.Detailed search parameters c an be set.To obtain correct results with automatic search/match, searchparameters that conform to each sample must be set. TheXRD-6100 enables the setting of detailed search parameterssuch as selection of files to be used in the search and threelevels of element data input.Replete with second search function forauthoritative identification of a small amountof components.Identifying a small amount of components with a primarysearch is difficult; a second search is often needed after themaior components have been identified. The XRD-6100 isequipped with a second search function to provide easyidentification of a small amount of components.Search Parameter Setting ScreenVarious search result data can be displayed.Search results can be stack-displayed with each standard datadisplay over raw data. Also, for easy comparison, standardsubstance names, chemical equations, ore names, Millerindices, and ICDD numbers can be displayed on each peak.Furthermore, an easy quantitative calculation function using acorundum ratio for candidate substances (Intensity ratio for theα-Al2O3 strongest peak) is included in the equipment.*If the system has a PDF-2 or PDF-4 database, PDF-2 or PDF-4detailed data for candidate substances can be displayed on aseparate window.* When using this function, please obtain the ICDD database separately.Search Result ScreenD e d i cate d u ser d ata b ase c an be c reated.The user's own database file - separate from the sub-filesupplied by ICDD (International Center for Diffraction Data ) can be created. Data obtained through measurements by theXRD-6100 and manually entered data can be registered in thedatabase file, which means that the user's basic samples can beregistered, and comparisons made with those substances toprovide an extra dimension to quality control.User Database Creation Screen14

Sophisticated Quantitation SoftwareS a ti s fie s yo u r a n aly sis objec tives .Creating Calibration CurvesCalibration curves are created with a standard sample ofknown concentration, based on the fact that the massconcentration and X-ray diffraction intensity of a crystal areproportional. Three methods are available for creatingcalibration curves: the external standard method, in which nomatrix absorption correction is made; the internal standardmethod in which absorption correction is made; and thestandard addition method. The software supports all threemethods.With the software, intensity (X-ray diffraction line height),integrated intensity, or intensity ratio modes can be selectedfor the axis displayed. The mass concentration unit can beswitched between mg and %.In addition, displaying the correlation coefficient (R) allows theaccuracy of the calibration curve to be evaluated.Calibration Curve Screen for Integrated IntensityQuantitative AnalysisThe three methods indicated above are available to satisfy mostof the application needs.Further, up to 5 peaks may the specified for quantitation and upto 10 sets of data may be calculated simultaneously.Integrated Intensity Quantitation Results ScreenNote: Residual austenite quantitation and environmental quantitation software packages are optional.XRD-6100X-ray Diffractometer15

OneSight Wide-Range High-Speed Detector forHigh-Speed and High-Sensitivity MeasurementThe OneSight is a wide-range high-speed detector consisting ofa number of semiconductor devices. It is able to achieveintensity more than 100 times higher than a scintillationdetector. The wider angle of acquiring diffraction lines allowsmeasurement to be performed with the goniometer fixed. Byoffering high-speed, high-sensitivity measurements, the timerequired for qualitative and quantitative analysis can besignificantly reduced. The OneSight can be mounted onexisting XRD-6100/7000 units installed at customers' sites.Wide-range array detector with 1280 channelsAdvanced user interface enhances operational efficiency.A conventional scintillation detector has only one channel at one pointThe measurement software for the OneSight has been redesigned. Thewhereas the OneSight has 1280 channels on a wide-range array.analytical profile is located in the center, the analytical conditions list andThus, compared with scintillation detectors, this detector can acquireinstrument status display are indicated on the left, the analysis schedule isdiffraction lines over a wide angle at one time.displayed on the bottom center, and the detailed analysis conditionsdisplay is shown on the right. The window layout can also be changed. ByConventional detectordisplaying necessary information in one window, the new design makes itWide-range high-speed detectoreasy for a user to understand the measurement status at a glance.ScanninGoniometeranctigdon1280 in-line channelschannelninireOne point, one ffraction angleangle2θ2θθDiffraction angle2θAnalytical Conditions DetailedDisplay and Setting WindowDisplays the profilewindow. Allows bothzoom in and out.Allows users to edit the detailedconditions of the analytical conditionsfile. Displayed when editingconditions.Allows analytical conditions to be read,edited and new conditions to be created.Instrument Status Display WindowDisplays the status of the X-ray generator,goniometer, and other units.SampleSamplSampleSamplAnalytical Conditions File Displayand Editing WindowAnalysis ProfileDisplay WindowAnalysis Progress Status WindowX-ray tubeX-ray tubeDisplays the OneSight status and analysisprogress. An analysis progress bar isdisplayed so that users can check thestatus at a glance.Analytical Conditions Registration WindowDisplays the registered analyticalconditions file. Users can check or changethe analysis schedule based on this file.High-speed quantitative analysis usingthree measurement modesONE SHOT mode achieves simultaneous measurement ofdiffraction profiles at a specific angle range.The OneSight features three kinds of measurement modes: HighThe OneSight can perform a simultaneous diffraction profileresolution, Standard, and Fast. It enables measurement speeds that are 10measurement over a range of more than 10 deg. with a fixed-positiontimes faster (High resolution), 15 times faster (Standard), and 25 timesgoniometer.faster (Fast) than those attained with a conventional scintillation detector.This is useful in quantitative analysis using a specific diffraction peak.Multi-plotConventionalDetector5mgHigh Resolution ModeAbout 1/103mgStandard ModeAbout 1/15FastAbout 1/251mgMeasurement TimeSample: Silicon0.5mg0.3mg0.1mgBlankStandard Sample Data of Asbestos (Chrysotile)(30 sec. measurement time per sample)16

OptionsOneSight Wide-Range High-Speed Detector(FD-10 01 1D hi gh- s peed det ec t or P/ N S 2 1 5 - 2 4 3 2 0 - 9 3 )It is an optional detector that can be mounted on existingXRD-6100/7000 units. The wide-range detector consists of1280 semiconductor devices, and achieves an intensity at least100 times greater than conventional scintillation detectors,thus allowing high-speed measurements to be made. It alsofeatures a ONE SHOT mode that takes advantage of the widemeasurement angle to perform analysis with a fixedgoniometer. Operability is improved by using software thatsupports measurements made using the OneSight.Number of Channels1280Strip Width50 µmSensor AreaW64 L8 mmDimensionsW70 D22 H62 mmQ u a l ita tiv e A n a ly sisCounter MonochromatorInstalled in the X-ray detector unit, the countermonochromator transforms X-rays which have passed throughthe entrance slit into monochromatic X-rays, allowing only thecharacteristic X-rays (Kα X-rays) to be detected. Exclusion of allother X-rays from the sample, including continuous X-rays andKß X-rays as well as fluorescent X-rays, ensures diffractionpatterns with a high signal-to-noise ratio.Part DescriptionApplicationP/NCounter Monochromator CM-3121Cu X-ray tube215-22360-02Counter Monochromator CM-3131Co X-ray tube215-22360-03Counter Monochromator CM-3141Fe X-ray tube215-22360-04Counter Monochromator CM-3151Cr X-ray tube215-22360-05Note: It is not possible to be used in combination with OneSightwide-range high-speed detector.(please use Kß X-ray cut filters as a substitute.)XRD-6100X-ray Diffractometer17

OptionsQ u a l itativ e A n a ly sisICDD PDF-2This is the powder X-ray diffraction database (DVD) provided byICDD. PDF-2 contains substance name, chemical formula, d-Idata. Furthermore, it also contains miller indices, latticeconstants, space groups and other crystallographic information.Using the special PDF-2 Automatic Search Software, unknownsubstances can be easily identified via the registeredcrystallographic information.ICDD PDF-2P/N for Educational InstitutionsP/N for Other UsesSingle License239-50002-12239-50002-11Note: The license (before 2017) is valid for five years. It can beextended for five more years for free at the time the licenseperiod end

The main unit control and data processing software support the widely used Windows 10 user interface. For this reason, data can be exported to marketed software. Network support and multi-user accessibility are easily achieved. Multi-Functional Auto-Search/Match Software (Qualitative Analysis) and Quantitative Analysis Software Equipped as Standard