Transcription

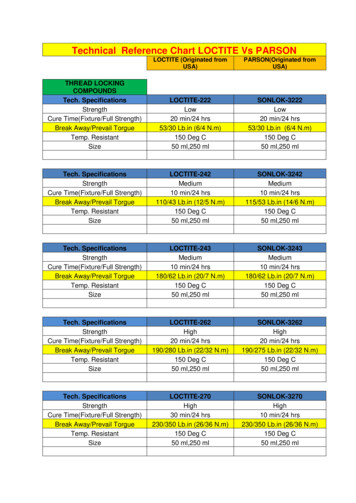

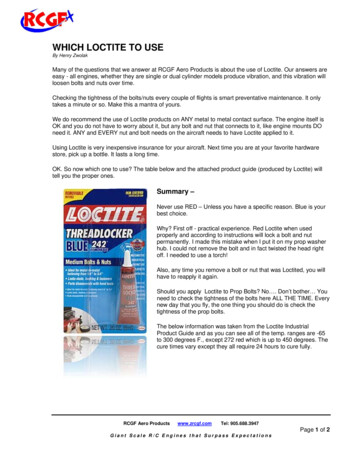

WHICH LOCTITE TO USEBy Henry ZwolakMany of the questions that we answer at RCGF Aero Products is about the use of Loctite. Our answers areeasy - all engines, whether they are single or dual cylinder models produce vibration, and this vibration willloosen bolts and nuts over time.Checking the tightness of the bolts/nuts every couple of flights is smart preventative maintenance. It onlytakes a minute or so. Make this a mantra of yours.We do recommend the use of Loctite products on ANY metal to metal contact surface. The engine itself isOK and you do not have to worry about it, but any bolt and nut that connects to it, like engine mounts DOneed it. ANY and EVERY nut and bolt needs on the aircraft needs to have Loctite applied to it.Using Loctite is very inexpensive insurance for your aircraft. Next time you are at your favorite hardwarestore, pick up a bottle. It lasts a long time.OK. So now which one to use? The table below and the attached product guide (produced by Loctite) willtell you the proper ones.Summary –Never use RED – Unless you have a specific reason. Blue is yourbest choice.Why? First off - practical experience. Red Loctite when usedproperly and according to instructions will lock a bolt and nutpermanently. I made this mistake when I put it on my prop washerhub. I could not remove the bolt and in fact twisted the head rightoff. I needed to use a torch!Also, any time you remove a bolt or nut that was Loctited, you willhave to reapply it again.Should you apply Loctite to Prop Bolts? No . Don’t bother Youneed to check the tightness of the bolts here ALL THE TIME. Everynew day that you fly, the one thing you should do is check thetightness of the prop bolts.The below information was taken from the Loctite IndustrialProduct Guide and as you can see all of the temp. ranges are -65to 300 degrees F., except 272 red which is up to 450 degrees. Thecure times vary except they all require 24 hours to cure fully.RCGF Aero Productswww.zrcgf.comTel: 905.688.3947Page 1 of 2Giant Scale R/C Engines that Surpass Expectations

222 - Purple - Low strength thread locker, designed for precision metal fasteners under3/4". Protect threads from rust and corrosion. Removable with hand tools. Temp range 65 to 300 degrees F. Cure Speed 20 min. Full 24 hrs.242 - Blue - Medium strength thread locker for fasteners up to 3/4". Cures reliably evenon stainless steel. Tolerant of oil and other contamination. Protects threads from rust andcorrosion. Parts can be disassembled with hand tools. Temp range -65 to 300 degrees F.Cure speed 15 min. Full 24 hrs.262 - Red - Permanent strength thread locker for fasteners up to 3/4". Designed forextreme environmental/chemical conditions. Especially useful for holding tight Grade 5and 8 fasteners. Protects threads from rust and corrosion. Localized heating and handtools required for disassembly. Temp range -65 to 300 degrees F. Cure speed 30 min.Full 24 hrs.272 - Red - Hi-temp/hi-strength formula. Suited for temperatures up to 450 degrees F.Fast cure on most surfaces including "as received" fasteners. Recommended for bolts upto 1 1/2" in diameter. Heat and hand tools required for disassembly. Temp range -65 to450 degrees F. Cure speed 60 min. Full 24 hrs.277 - Red - High strength for locking fasteners up to 1 1/2". Prevents fasteners fromloosening due to shock, heat or vibration . Protects threads from rust and corrosion.Removable with heat and hand tools. Temp range -65 to 300 degrees F. Cure speed 60min. Full 24 hrs.290 - Green - Medium strength thread locker for pre-assembled bolts up to 1/2".Penetrates threads by capillary action: simplifies preventive maintenance. Secures setscrews and other assemblies after settings are completed. Used to seal welds and porousmetal parts. Protects threads from rust and corrosion. Temp range -65 to 300 degrees F.Cure speed 10 min. Full 24 hrs.RCGF Aero Productswww.zrcgf.comTel: 905.688.3947Page 2 of 2Giant Scale R/C Engines that Surpass Expectations

LT 3722 v7 MRO F.qxp2/12/079:03 AMPage 2ThreadlockingLocking of Threaded Fasteners Prevents loosening from shock and vibration Single component – clean and easy to apply Can be used on various sizes of fasteners – reduces inventory costs Seals threads Stops rust and corrosionARE THE PARTS ALREADY ASSEMBLED?YesNoWicking GradeWhat strength do you require?Helpful Hints: Clean parts with Loctite ODC-Free Cleaner & Degreaser beforeapplying the adhesive If the threadlocker will be applied below 40 F, pre-treat withLoctite 7649 Primer N What strength do you require?Low – PurpleMedium – BlueHigh – Red If the parts were in contact with aqueous washing solutionsor cutting fluids which leave a protective layer on the surface,wash with hot water before useMedium – BlueMedium/High – GreenLiquid ProductLiquid ProductSemi-Solid ProductLiquid ProductSemi-Solid ProductSolutionLoctite 220 ThreadlockerLoctite 290 ThreadlockerLoctite 222MS ThreadlockerLoctite 2440 ThreadlockerLoctite QuickStix 248 Threadlocker –Medium StrengthLoctite 2760 ThreadlockerLoctite QuickStix 268 Threadlocker –High Strength#2 to 1 2"Medium#2 to 1 2"HighUp to 1 4"LowUp to 1"Up to 1"6 min./24 hr.20 min./24 hr.10 min./24 hr.Fastener SizeStrengthCure Time (Fixture/Full Strength)*Breakaway/Prevail Torque (lb./in.)Temperature Resistance for Continuous ServiceCommon Sizes / Part Number* Typical value @ 70 F (22 C)1 "4to 3 4"1 4"to 3 4"MediumMediumHighHigh3 min./24 hr.10 min./24 hr.4 min./24 hr.20 min./24 hr.20/25090/26053/30215/53110/43325/320220/4300 F (150 C)300 F (150 C)300 F (150 C)300 F (150 C)300 F (150 C)300 F (150 C)300 F (150 C)10 ml bottle – 3738850 ml bottle – 39186250 ml bottle – 2204110 ml bottle – 2902150 ml bottle – 29031250 ml bottle – 2904110 ml bottle – 2222150 ml bottle – 22231250 ml bottle – 2224110 ml bottle – 3394650 ml bottle – 33947250 ml bottle – 339489 g stick – 3768419 g stick – 3708710 ml bottle – 3252650 ml bottle – 32525250 ml bottle – 325279 g stick – 3768519 g stick – 37686Additional Loctite brand ThreadlockersName StrengthBreakaway/PrevailFeaturesTorque (lb./in.)242 Medium110/43243 Medium180/62262 High272 277 Part #Package SizeFasteners 4" to 2"2423150 ml bottleOil Tolerance2407850 ml bottle189/275Fasteners up to 3 2"2623150 ml bottleHigh200/220High Temp up. to 11 2"2724050 ml bottleHigh275/275Fasteners up to 11 2"2773150 ml bottle4/2Plastic Fasteners4254020 g bottle9700198414250 ml bottle50 ml bottle425 Assure Low13Loctite Bottle Hand Pump – Fits Loctite 50 or 250 ml bottlesUse Loctite 7649 Primer N to:1.2.3.4.5.2Activate inactive surfaces.Speed cure times for faster return to service.Speed curing through larger gaps and deep threads.Substantially speed cure times on cold parts.Act as a cleaning agent.Primer is optional with: Active surfaces: Brass, copper, bronze,iron, soft steel, nickel.Primer is required with: Inactive surfaces: Aluminum, stainlesssteel, magnesium, zinc, black oxide, cadmium, titanium, others.Package Size/Part Number: 1.75 fl. oz. bottle– 384024.5 oz. aerosol – 21348Loctite 220 Threadlocker –Medium Strength/Wicking/BlueLoctite 290 Threadlocker –High Strength/Wicking/GreenA low viscosity threadlockingadhesive that allows theproduct to wick along thethreads of preassembledfasteners. Perfect forfasteners up to 1 4"diameter (6 mm).Recommended for lockingpre-assembled fasteners,i.e. instrumentation screws,electrical connectors, andset screws. Also sealsporosities in welds andmetal parts. Mil Spec(S-46163A) Type III,Grade R. NSF/ANSI 61.Loctite 222MS Threadlocker –Low StrengthRecommended forlow-strength threadlockingof adjustment screws,countersunk head screws,and set screws; on collars,pulleys, tool holders, andcontrollers. Also for lowstrength metals such asaluminum or brass.Mil-Spec (S-46163A)Type II, Grade M.NSF P1.Loctite 2440 Threadlocker –Primerless/Medium StrengthParticularly fast curing,reducing or eliminating theneed for primers. Effectiveon all types of metalthreaded fasteners.Prevents loosening onvibrating parts such aspumps, motor mountingbolts, gear boxes, orpresses. Removable withhand tools.Loctite QuickStix 248 Threadlocker –Medium StrengthSemi-solid stick form isconvenient, portable, andgreat for hard-to-reachapplications. Loctite QuickStix 248 Threadlocker is theideal general-purposethreadlocker for all nutand bolt applications,especially fastenersbetween 1 4" and 3 4".Removable with handtools. NSF/ANSI 61.Loctite 2760 Threadlocker –Primerless/High StrengthParticularly fast curing,reducing or eliminatingthe need for primers. Foruse on all metal fastenerswhere regular removal formaintenance is notrequired. Recommendedfor permanently lockingstuds on engine blocksand pump housings.CFIA Approved.Loctite QuickStix 268 Threadlocker –High StrengthThis convenient semi-solidstick form is portable andless messy. Its highstrength prevents looseningof threaded fasteners.Well suited for heavyduty applications.3

ThreadlockingTechnical GuideWhat you need to know to ensurea reliable threaded assembly

Loctite Threadlocking Guide Table of ContentsLoctite – Finding a Better Way Old WayTHREADED FASTENERSMechanical Locking DevicesMechanical locking devices (e.g., split washers, nylon nuts)were invented to solve the common problem of loosening thatoccurs in most threaded assemblies. Although they were madefor this purpose, they have several shortcomings.Functions of a threaded assembly. 2Why do threaded assemblies fail?. 2Shortcomings of Mechanical Locking Devices Loosen under vibration, thermal expansion and/orimproper torque Do not seal threads Require extensive inventory of several shapes and sizes Prone to rustLOCKING METHODSShortcomings of locking devices. 3Why use Loctite threadlockers. 3 LOCTITE THREADLOCKING SOLUTIONS How does a Loctite threadlocker work?. 4 How to use a Loctite threadlocker. 4 Why should I use a primer?. 5Better WayLoctite ThreadlockersInvented fifty years ago by Loctite Corporation, now Henkel Corporation,this revolutionary method to lock and seal threaded fasteners withliquid anaerobic adhesives has found worldwide acceptance. Suited fora wide range of applications, from delicate electronic components toheavy industrial equipment, Loctite threadlockers have dramaticallyincreased the reliability of threaded assemblies.Key selection factors. 5 HOW TO SELECT THE RIGHT LOCTITE THREADLOCKER Decision tree. 6, 7 Benefits of Loctite Threadlockers Lock nuts and bolts against vibration and thermal expansion Seal against corrosion and leakage Reduce inventory costs Suitable for all shapes and sizes of fasteners Act as a thread lubricant Maintain critical adjustments of the assembly No on-torque adjustments needed High chemical resistance LOCTITE INNOVATIONS. . 8 LOCTITE THREADLOCKER PROPERTIES CHART. 9 1

Threaded FastenersLocking MethodsFunctions of a threaded assemblyShortcomings of locking devices1. Create clamp forceSplit ring or spring washersTab washers, split pins, castle nuts2. Maintain clamp forceIncreased friction reduces clamp load; willnot ensure reliable threadlocking underdynamic loads.Expensive and time consuming methods,they often impose challenges to line up theircomponents appropriately (i.e., tabs, cotterpins).Tooth or ribbed flanged boltsNylon nutPrevent self-loosening, but are expensive;need larger flange-bearing surfaces andmay damage the surfaces.More expensive than a standard nut, nyloninserts increase friction, which results ininaccurate torque.3. Allow disassemblyClampForceWhy do threaded assemblies fail?Clamp force is not maintainedThreaded assemblies loosen because of:Why use Loctite threadlockers A. Gaps: In order to make the assembly possible, nuts andbolts must have some tolerance, which creates gapsbetween the threads.Loctite performance Superior to all mechanical locking devices:Clamp Load Retention Loctite threadlockers are the most versatile andinexpensive option to ensure a reliable assembly.Parts toleranceB. Vibration & side-to-side movement: These gapsallow the parts to move from side-to-side whenexposed to vibration.Loctite benefits C. Expansion/contraction & loosening: Expansion andcontraction can also cause side-by-side movement. This,in addition to vibration, lead to loosening and ultimatelydisassembly of parts.Stretching of the bolt beyond its yield point and thermal expansion/contraction ofparts leads to lack of structural rigidity and relaxation of partsDisassembly is not always possible2Standard bolt w/ Loctite threadlockerBolt w/ saw-toothed flangeNylon nutBolt w/ DIN 6797 A tooth lock washerBolt w/ DIN 127 A spring washerUnsecured standard boltSuperior vibrationresistance Locks and seals in any position Resists vibration and torque down to zero bolt tensionIncreasedreliability Joints withstand vibration, shock and thermal cycling Threads are sealed to prevent corrosion Clamp load is maintained Prevents loosening Controlled clamp loadLonger endproduct life Assembly remains locked and leak-proof for its fullservice life Clamp load retention and higher off-torque provideadditional safetyCost savings.which can lead to broken bolts.Number of load cyclesLoctite cost Prevention ofgalling andcorrosion Liquid film prevents friction welding or galling Sealing effect prevents corros

Loctite QuickStix 248 Threadlocker – Medium Strength Semi-solid stick form is convenient, portable, and great for hard-to-reach applications. Loctite QuickStix 248 Threadlocker is the ideal general-purpose threadlocker for all nut and bolt applications, especially fasteners between 1 4" and 3 4 ". Removable with hand tools. NSF/ANSI 61. Loctite 2760 File Size: 2MBPage Count: 10