Transcription

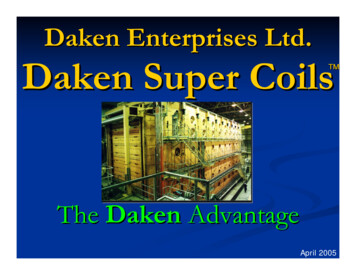

Daken Enterprises Ltd.Daken Super Coils The Daken AdvantageApril 2005

Who is Daken Enterprises Ltd.? Celebrating 40 years, Daken EnterprisesLtd. is the world's leading innovator forimproving the operation and efficiency ofFlakt Pulp Dryers.Daken Enterprises Ltd. is a privately ownedcompany located in Port Coquitlam, BritishColumbia, Canada.

Daken Enterprises Ltd. - What we do For over 40 years Daken has manufacturedproducts for the pulp industry. Daken'sextensive knowledge and expertise in the fieldhas led to the development of thirteen patentsin addition to other patent pending designsand products for Flakt Pulp Dryers

Steam CoilsThe most common misconception regardingsteam coils is that leaving air temperatures (out ofthe steam coil) is the only component equating tosuperior drying.While temperature plays an important part, it isthe BTUH generated and air velocity out putthat is the true measure to your Flakt dryersperformance.

The importance ofBTUH’s and Air VelocityThink of clothes drying on a clothesline.Even in the shade, they dry on a daywhen the humidity is low, especially inthe wind!. Dry air has a powerfultendency to draw water out of anyaccessible source: puddles, the garden,wet clothes or a wet pulp sheet. The onlynecessary action is to maintain a steadysupply of fresh dry air. Air velocity is a key component indetermining dryer performance.Daken Super Coils are designed todeliver superior drying performanceto your Flakt Airborne Dryer

The importance ofBTUH’s and Air Velocity BTUH (British Thermal Units per Hour)determines the amount of drying heat deliverAir velocity is the speed in which it is deliveredBTUH 1.085 x CFM x TRCFM Cubic Feet per minute (air velocity)TR Air Temperature Rise Leaving Dry Bulb (LDB) – Entering Dry Bulb (EDB)

Daken Super Coils Series 3000 In kind CoilsDesign ComparisonO.E.M.DakenEntering Air Temperature285 F285 F357 F363 F438,002 BTUH495,653 BTUH9,800 cfm10,251 cfm960 fpm1,004.6 fpm562 lb/hr588 lbs/hr.010” aluminum.010” aluminumFin Patternwaffle rippleflatFin Space2 mm2 mm½”OD x .035 Cu.5/8” OD x .049 Cuinlinestaggeredsingle serpentinetriple parallel tubesflatsloped (to drain) ilsor C theeup rmSn rfo n byekoeDa ut p etitio mp %12coLeaving Air TemperatureHeat OutputAir VolumeAir VelocityCondensate LoadFinsTubesTube Arrangement to Air FlowTube RoutingDrainageThe above values shown are based upon best information determined by Daken Enterprises Ltd. and may be subject to change.

Problems with Other Steam Coils Steam Leaks caused by– Erosion At bends in horizontal tubing In steam headers– Corrosion Condensate pooling in tubes and headers– Stress (tubes & piping) Shop fabricated flanges (cup) warp Fractured coil tube connections Thermal stresses Limited Air Flow– Inefficient design of existing coil

Other Replacement CoilsErosionMost steam header tubing achieveequalization by restricting flow inthe various tubes. This isaccomplished by increasing thepressure drop through orifices ineach tubeOne problem plaguing most other tubing issome of the orifices tilt during theassembly & brazing process consequentlyredirecting the steam flow off centre. Thiscauses erosion on the tube walls resultingin premature failureCenterCenter LineLine ofof tubetubeTypical OEM Steam Header TubingTiltedTilted orificeorificeCenterCenter LineLine ofof thethe tiltedtiltedtubetube orificeorifice

Other Replacement CoilsThin wallstypical ofall u-bendsErosionExistingExisting replacementreplacement coilscoilshavehave U-bendsU-bends resultingresulting ininsignificantlysignificantly thinnerthinner wallswalls atatthethe bendbendProne tosteam leaks

Daken Super Coils The Daken SOLUTIONSteamHeaderDistributionTubeSteamSteam equalizationequalization isisaccomplishedaccomplished inin Daken’sDaken’spatentedpatented SteamSteamDistributorDistributor locatedlocated ininthesteamheader.the steam header.DakenDaken equalizesequalizes steamsteamflowflow toto thethe tubestubesthroughthrough aa seriesseries ofofsteamventsoppositesteam vents oppositethethe tubes,tubes, graduallygraduallyreducingreducing thethe steam’ssteam’svelocity.velocity.Tube erosion iseliminated !SteamHeaderDistributionTubeSteam VentsSteam FlowSteam Vents

Other Replacement CoilsNo tube slopeCorrosionOrifice plateCondensate level asa function of pressuredifferentialflowAccumulationAccumulation ofof corrosivecorrosive carboniccarbonic acidacid isis aa heuseproblem with other coils. This is a result of the use rifice plates at the condensate connections used tocontrolcontrol flowflow andand waterwater hammerhammer butbut endsends upup holdingholdingbackback condensatecondensate inin thethe coils.coils. ThereforeTherefore tubestubes areare moremoreproneprone toto stressstress failurefailure causedcaused byby corrosioncorrosionOrifice

Daken Super Coils NOITULOSnakeThe DSiphon . Eliminates theneed for an orifice plateCondensate levelNotNot onlyonly byby controllingcontrolling flowflow andand waterwaterhammerbutbycompletelydraininghammer but by completely draining thethe coilcoiltubesthe DakenDaken SiphonSiphontubes ofof allall condensatecondensate thepreventsprevents thethe accumulationaccumulation ofof corrosivecorrosivecarbonicacid.carbonic acid.

Daken Super CoilsThe Daken SOLUTION TubeTube slopeslope providesprovidespositivepositive drainagedrainage totothethe condensatecondensate headerheadertoto drydry thethe condensingcondensingsurfacesurface inin orderorder totoavoidavoid corrosioncorrosion andandincreaseincrease efficiencyefficiency

Daken Super CoilsFin width 3.875”Air flowFin width 3.875”loir fAAiAir flowOtherOther coilscoils parallelparallel tubetube patternspatterns promotepromotelaminarlaminar flowflow reducingreducing airair flowflow pastpast secondsecondandand thirdthird tubestubes withwith embossedembossed finsfins toto g,heat transfer. Embossed fins tend to clog, andandplugthefinsurfacethereforereducingairplug the fin surface therefore reducing air flowflowtoto thethe blowblow boxboxwAir flowrflowDaken’sDaken’s staggeredstaggered tubetube patternspatterns ulent tube flow for superior heat dwith flat fins to reduce lint clogging and totomaintainmaintain highhigh pressurepressure toto thethe blowblow boxbox

Other Replacement CoilsOEM tube construction usewaffled fins in an endeavorto optimize airflow.The problem this results in istwo fold:1. Fins tend to clog2. Air flow is reducedbetween tube rowsmeaning less pressureto the blow box.

Daken Super CoilsThe Daken AdvantageDaken’sDaken’s staggeredstaggered tubetube patternspatternspromotepromote turbulentturbulent tubetube flowflow forforsuperiorsuperior heatheat transfertransfer withwith flatflat finsfinstoto reducereduce lintlint cloggingclogging andand totomaintainmaintain highhigh pressurepressure toto thethe blowblowboxesboxes toto liftlift andand drydry thethe sheetsheetfAirA irf lolo wAir floww

Other Replacement CoilsPipingCupping & poorbolt alignmentAA commoncommon problemproblem withwith otherotherreplacementreplacement coilcoil flangesflanges andand flangeflangeadaptersadapters isis “cupping”.“cupping”. CuppingCuppingoccursoccurs duringduring bolt-upbolt-up andand resultsresults ininlooseloose fitsfits proneprone toto leaks.leaks.

Daken Super Coils The Daken SOLUTIONTheseThese featuresfeatures uniqueuniquetoto thethe DakenDaken designdesignpreventprevent cuppingcupping andandensureensure tighttight leakleak freefreejointsjointsDakenDaken LapLap JointJoint FlangeFlange AdaptersAdaptersarefabricatedfromhighgradeare fabricated from high grade(99.9%(99.9% pure)pure) coppercopper c/wc/w extraextra thickthickringsringsPerfectPerfect boltboltalignmentalignmentDaken’sDaken’s ASAASA standardstandard forgedforgedsteelsteel laplap jointjoint flangesflanges areare 28%28%thickerthantheOEMstandardthicker than the OEM standard andandarehubreinforced.are hub reinforced.

Other Replacement CoilsA problem with OEM coils isdamage (bending) to thecondensate headers.This damage is caused by thefact that the bottom edge ofthe flange is in line with thebottom of the coil framemaking it difficult to walk thecoil in during storage, handlingand installation.This causes fractures in thelower tubes even before theyare installed.Short spigots haveto take the load ofclimbing operators

Daken Super Coils The Daken SOLUTIONDakenDaken tubestubes andand headersheaders arearearrangedarranged withwith sufficientsufficient clearanceclearancetoto minimizeminimize damagedamage duringduringstorage,storage, handlinghandling andand installation.installation.

Other Replacement CoilsOnly one tube is connected perrow. Therefore this tube has toabsorb all the stress of expansionresulting in greater potential tocrack and leak (steam leaks)Leakingu-bendTheThe coilcoil shownshown inin thisthis photophoto isis ananactualactual coilcoil takentaken fromfrom Tembec,Tembec,SkookumchukSkookumchuk

Daken Super Coils The Daken SOLUTIONExpansionExpansion stressstress isis evenlyevenly distributeddistributedacrossacross threethree tubestubes connectedconnected perper row.row.ThereforeTherefore thethe chanceschances ofof crackscracks andandleaksleaks areare virtuallyvirtually eliminatedeliminatedPLAN VIEW

Daken Super Coils Flange AdaptersThe Daken AdvantageFabricatedFabricated fromfrom highhigh gradegrade(99.9%(99.9% pure)pure) coppercopper withwithextraextra thickthick facesfaces toto preventpreventcuppingcupping causedcaused byby bolt-upbolt-upstressstress

Daken Super Coils FlangesMOEThe Daken AdvantageDnekaA.S.A.A.S.A. forgedforged steelsteel flangesflanges arearethickerthicker andand hubhub reinforcedreinforced totopreventprevent cuppingcupping causedcaused bybybolt-upbolt-up stressstressTheThe DakenDaken AdvantageAdvantage9Thicker9Thicker99ForgedForged99 HubHub ReinforcedReinforced99PrecisePrecise

Daken Super CoilsBrazed JointsThe Daken Advantage Note: this shows the.049 wall thickness ofthe Daken tubingAllAll DakenDaken brazingbrazing usesuses 50%50%silversilver brazingbrazing spelterspelter andand jointjointlapslaps thatthat exceedexceed acceptedacceptedindustryindustry standardsstandards

Daken Super Coils TubingThe Daken AdvantageAllAll DakenDaken tubingtubing isis 99.9%99.9%coppercopper andand wallwall thicknessesthicknessesareare thethe heaviestheaviest availableavailableTheThe DakenDaken AdvantageAdvantage9Thicker WallWall TubingTubing9Thicker

Daken Super Coils The Daken Advantage Superior replacement coils. Customized to meet the specific requirements ofeach customer

Daken Super Coils Series 3000Type L Flakt DryerSteam CoilReplacement

Daken Enterprises Ltd.894 Citadel DrivePort Coquitlam, B.C.Canada V3C 5Y1Phone: 604.941.0888Fax:604.941.0258Email: info@daken.cawww.daken.ca

Daken Super Coils Steam Header Distribution Tube Steam equalization is accomplished in Daken's patented Steam Distributor located in the steam header. Daken equalizes steam flow to the tubes through a series of steam vents opposite the tubes, gradually reducing the steam's velocity. Tube erosion is eliminated ! Steam equalization is