Transcription

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS1000 RWTrapezoidal163InsulatedKS1000 LP/CRLo-Pitch - Curved255KS1000 TSSlate & Tile Support305KS1000 RT Roof Tile351KS1000 SF Secret Fix371Roof Systems161Insulated RoofSystemsKS500/1000 ZIPStanding Seam - Kingzip 229

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.info162

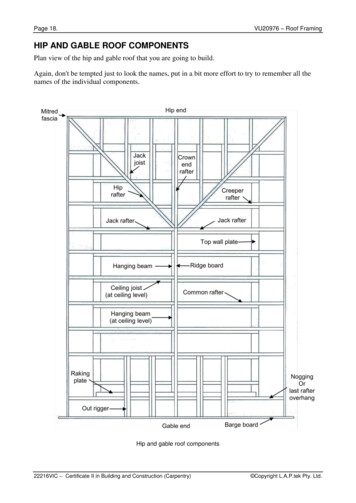

Product Data165Model Specifications169Fastener Selection187Construction Details189 Panel DimensionsFastener LocationsSide & End LapRidgeMono RidgeCurved Mono RidgeEavesCurved EavesVergeValley GutterHipValley HipLean-to RoofExpansion JointChange in Roof SlopeRidge VentilatorRooflight VentilatorBarrel Type VentilatorVelux RooflightRoof ExtractorKS1000 Safespan 80Rooflight SystemTrapezoidalInsulated Roof 3214215216217218219221KS1000 RWTrapezoidalRoof SystemFor more information on Kingspan Insulated Panels visit www.barbourproductsearch.info

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.info“Kingspan systems provide certaintyof specification and construction performanceover the building’s lifetime”164

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS1000 RW Roof SystemTrapezoidalApplicationProduct ReferenceApplication DescriptionThe KS1000 RW Roof system is suitable for building applicationswith roof slopes of 4 and above.KS1000 RWStandard trapezoidal roof panel.KS1000 RW-FMTrapezoidal roof panel with Factory Mutual(FM) approval for roof applications.KS1000 RW-LPCBTrapezoidal roof panel with LossPrevention Certification Board (LPCB)approval for roof applications.Ref. No. 260a/06to LPS 1181SystemDimensions & Weight1000mm cover width333mm333mm333mmABA - Core Thickness (mm)4050607080*B - Overall Dimension (mm)758595105115100*135Weight kg/m2 0.5/0.4 steel9.910.310.711.011.512.3Weight kg/m2 0.63/0.4 steel11.812.212.612.913.414.2Weight kg/m2 0.7/0.5 alum.†5.66.06.46.77.28.0*These panel thicknesses comply with Part L2 (England & Wales) and Part J (Scotland)†Aluminium faced panels are not LPCB and FM certified.Product TolerancePanel End Cut BackCut to Length-0.05% 0.1%Liner Sheet Length-0.1% 0.1%Cover Width-0mm 3mmThickness-2mm 2mmEnd Square-3mm 3mmAll panels are normally produced with a minimum cut back of10mm. Cut backs up to 175mm can also be manufactured.If flush ended panels (no cut back) are required they can bemanufactured with one end flush and a 10mm cut back on theopposite end, based on panels exceeding 1.8m in length.The recommended cut back for panel end lapping is 150mm.Panels less than 1.8m long which require a cut back can beprovided, but will be charged at full 1.8m price, plus cutting cost.Available LengthsStandard lengths 1.8 to 12 metres. 12 to 22 metres can besupplied but may be subject to a transport surcharge. Panels lessthan 1.8m long which require a cut back can be provided, but willbe charged at full 1.8m price, plus cutting cost.Panel lengthCut back165KS1000 RW RoofProduct DataInsurer Approved

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS1000 RW Roof SystemTrapezoidalMaterials - SteelMaterials - AluminiumSubstrateSubstrate HPS200/Celestia: ZA255 Galvalloy hot-dip zinc-aluminium Aluminium substrate, Grades 3003/4/5 series. Standard external sheet thickness 0.7mm, standard internalalloy coated steel ( 95% Zn/ 5% Al) to BS EN 10214: 1995,Grade Fe E220G with a Z275 zinc coating. PVDF: Galvatite, hot-dipped zinc coated steel to BS EN 10147:1992. Grade Fe E220G with a Z275 zinc coating. Standard external sheet thickness 0.5mm, standard internalsheet thickness 0.4mm. Other thicknesses can be supplied tospecial order.sheet thickness 0.5mm.Coatings - External Weather Sheet PVDF: 25 micron thick stoved fluorocarbon coating which hasexcellent colour stability even at temperatures as high as 120 C. ARS Abrasion Resistant: 28 micron thick polyester orpolyurethane resin reinforced with polyamide high durabilitycoating with exceptionally good handling characteristics. Silicone Polyester: An economical coating with medium termlife for worldwide use. Alternatively the weather sheet can be supplied in mill finish,stucco embossed.Coatings - External Weather Sheet HPS200 Plastisol: 200 micron thick high performance coating applied to the weatherside of the panel. Designed to achievehigh levels of durability and colour stability, is highly resistant todamage in transit and on-site.PVDF: 27 micron thick stoved fluorocarbon coating which hasexcellent colour stability even at temperatures as high as 120 C.Celestia: 120 micron thick Plastisol coating. 16 metalliccolours.Silicone Polyester: An economical coating with medium termlife for worldwide use.Reverse side of sheet coated with a light grey polyester coating.The sheet is available in either plain or stucco embossed finish.Coatings - Internal Liner Sheet Standard internal facing is white polyester coated, plain orstucco embossed.Insulation Core Polyisocyanurate (PIR): with zero ozone depletion (Zero ODP).Available in LPCB and FM insurer approvedcertified product range, please contact Kingspan TechnicalDesign Bureau.Coatings - Internal Liner Sheet Lining Enamel: 15 micron thick coating developed for use for Sealsthe internal lining of insulated panels. Standard colour is “brightwhite” with an easily cleaned surface.HPS200 Plastisol: 200 micron thick coating used in areaswhere there is high internal humidity, or a corrosive environment.Stelvetite Food & Hygiene Safe: This is a 120 micron thickchemically inert polymer film bonded to steel suitable forcladding the interior of cold stores, food processing buildingsand other hygiene applications.Reverse side of sheet coated with a light grey polyester coating.The sheet is available in either plain or stucco embossed finish.Factory Applied Side Lap TapeAll side laps have a factory applied anti condensation tape.Additionally a specially developed side lap tape is factory appliedto panels for low-temperature chill stores at extra cost.Factory Applied Side & End Lap ProtectionIf specifiers require additional under lap corrosion protection, thiscan be factory applied at extra cost.166

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS1000 RW Roof SystemTrapezoidalPerformanceQuality & DurabilityKingspan Insulated Panels are manufactured from the highestquality materials, using state of the art production equipment torigorous quality control standards, complying with ISO 9001: 2000standard, ensuring long term reliability and service life.Thermal InsulationPanel Thickness (mm)U value tees & WarrantiesKingspan will provide external coating and product warranties andguarantees on an individual project basis.U - Thermal transmittance W/m2K* U-Value calculated in accordance with the method required by the BuildingRegulations Part L2 (England & Wales) and Building Standards Part J (Scotland)Standard PackingKS1000 RW panels are stacked weather sheet to weather sheet(to minimise pack height). The top, bottom, sides and ends areprotected with foam and timber packing and the entire pack iswrapped in plastic.The number of panels in each pack depends on panel thicknessand length. The table below is shown as a guide. Quantities arereduced for exceptionally long panels. Typical pack height is1100mm. Maximum pack weight is 1500kg.BiologicalKingspan panels are normally immune to attack from mould, fungi,mildew and vermin. No urea formaldehyde is used in theconstruction, and the panels are not considered deleterious.FireSteel and aluminium outer and inner facings have Class 1 surfacespread of flame to BS 476: Part 7: 1987, and are Class 0, asdefined by Building Regulations. The panel surfaces are ratedFAA/SAA to BS 476: Part 3: 1975. KS1000 RW insurer approvedpanels are available with FM and LPCB certification,with steel facings.Panel Core Thickness4050607080100No. panel/pack (max.)17151311117Sea FreightFully timber crated packs are available on projects requiringdelivery by sea freight shipping, at additional cost. Alternatively,steel containers can be used. Special loading charges apply.AcousticsKS1000 RW panels comply with Building Regulations Part E fornon-domestic buildings. For residential, domestic, educationand healthcare building applications, BB93 and HTM 2045solutions, consult Kingspan Technical Design Bureau.DeliveryAll deliveries (unless indicated otherwise) are by road transport toproject site. Off loading is the responsibility of the client.All KS1000 RW panels have a single figure weighted soundreduction Rw 25dB.Sound Reduction Index (SRI) TestedFrequency Hz1252505001k2k4kSRI dB17.220.023.223.423.240.5Site Installation ProcedureSite assembly instructions are available from theKingspan Technical Design Bureau.Building Regulations & StandardsKingspan insulated roof and wall systems conform to the followingBuilding Regulations and Standards (Non-domestic buildings):i) Approved Document A: Structure (England & Wales)ii) Approved Document B: Fire (England & Wales)iii) Approved Document E: Resistance to the Passage of Sound(England & Wales)iv) Approved Document Part L2: Conservation of Fuel & Power(England & Wales)v) Building Standard Part D: Structural Fire Precautions (Scotland)vi Building Standard Part H: Resistance to the Transmission ofSound (Scotland)vii) Building Standard Part J: Conservation of Fuel & Power (Scotland)viii) Building Standard Part L: Conservation of Fuel & Energy (Ireland)167KS1000 RW RoofProduct DataPacking

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS1000 RW Roof SystemTrapezoidalStructuralUnfactored Load/Span Table (use calculated design windload values unfactored)SPANCONDITIONCoreThickness(mm )SINGLE SPAN40Outer Sheet0.5mm steelInner Sheet0.4mm steel506070L80100DOUBLE SPAN40Outer Sheet0.5mm steelInner Sheet0.4mm steel506070LL80100LoadType1.6Uniformly Distributed Loads (kN/m2)Span L in 21.371.891.442.151.502.341.562.631.65Notes:1. Values have been calculated using the limit state method described in the“European Recommendations for the Design of Sandwich Panels”(ECCS document No.115 2001), taking imposed loads, temperature andcreep into account.6. The standard fastener pattern is shown in the construction details. When thepanels are valley fixed to 1.6mm thick cold rolled steel purlins at 2m centresthe allowable suction load is 1.8kN/m2. For other fastener and purlinarrangements the allowable suction load can be calculated using theprocedure shown in the design example under “Structural Performance”in the Building Design Section.2. For each value individual and combined load cases with appropriate loadfactors and temperatures have been considered. These are detailed under“Structural Performance” in the Building Design Section.7. The allowable steelwork tolerance between bearing planes of adjacentpurlins is L/600, where L is the purlin spacing.3. The table is for medium and light coloured panels, as recommended byKingspan for roofs.8. Load span tables for panel specifications not shown are available fromthe Kingspan Technical Design Bureau.4. The following deflection limits have been used:Downward loadingSuction loading9. FM approved panels spans must be limited to a maximum of 2 metres insingle or double span conditions./200/150LL5. For intermediate values linear interpolation may be used.168

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoSystems”KS1000 RW RoofModel Specifications“Kingspan Insurer Approved169

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoConstruction ApplicationStandard Environment - Roof - LPS 1181 Grade BKS1000 RW/Zero ODP/LPCB Trapezoidal Roof SystemRef No: 1/5.71/LPS-BApplicationSeals & FillersThe following specification is for KS1000 RW/Zero ODP/LPCBcertified Trapezoidal Insulated Roof Panel used for buildings withroof slopes of 4 and above with internal humidity classenvironments 1-4 inclusive.Side LapAll external side laps to be weather sealed along the full length byan unbroken bead of Scapa Tape 4mm diameter butyl rubbersealant tape, Ref: 0311.KS1000 RW is Loss Prevention Certification Board (LPCB) certifiedto LPS 1181 Grade B.In addition all side laps have a factory applied anti condensationtape.Materials & CoatingsEnd LapAll external end laps to be 150mm long, and weather sealed alongthe full width using three unbroken runs of Scapa Tape 4mmdiameter butyl rubber sealant tape Ref: 0311.External Weather SheetSubstrate to be 0.5mm thick steel S220GD ZA eutectic Galvalloyhot-dip zinc coated steel to BS EN10214: 1992.Profiled FillersWhere flashings are fixed across the profile of the insulated panel,EPDM faced closed cell polyethylene foam fillers should be usedto seal and close the profile. Seal the top, bottom and sides ofeach profiled filler with non-curing gun-grade sealant, Scapa Tapes,Ref: 0100.External coating to be Corus UK Limited Colorcoat HPS200Plastisol, 200 microns thick.Colour – standard SC.Reverse to have a light grey polyester coating.Insulation CoreTo consist of 80mm thick, closed cell, with zero ozone depletion(Zero ODP) and LPCB certified polyisocyanurate (PIR) insulation.JunctionsJunctions between the roof panel system and walls / penetrationsinsulated with PIR board insulation any gaps filled with AlfasbondFR fire rated gun applied canister urethane insulation.The auto adhesive properties of the core bond the external andinternal sheets together, and control the panel thickness achievedduring manufacture.Internal face of panel to be air sealed along the full length by anunbroken Scapa Tape 6mm diameter butyl rubber sealant tape.Internal Liner SheetSubstrate to be 0.4mm thick hot-dip zinc coated Steel toBS EN10147: 1992.FastenersPrimaryAll primary fasteners must be the high threaded typemanufactured from carbon steel, anti-corrosion coated, and fittedwith a 19mm diameter bonded stainless steel washer and integralcolour matched heads.Internal coating to be Lining Enamel, 15 microns thick.Colour - White.Reverse to have a light grey polyester coating.PerformanceAll fasteners to be located through every valley of the profile.Thermal InsulationThe panel must have a thermal transmittance (U value) of0.25 W/m2K calculated using the method required by the BuildingRegulations Part L2 (England & Wales) and Building StandardsPart J (Scotland).To comply with the requirements of BS 6399: Part 2: 1997, it maybe necessary to provide additional fixings in areas of high localsuction.SecondarySide laps and flashings to be stitched at 450mm centres(maximum) with carbon steel stitching screws, complete with14mm diameter bonded stainless steel washers and integralcolour matched heads.FireThe external and internal faces of the panel to be Class 0 inaccordance with the Building Regulations when tested to BS 476:Parts 6: 1989 and Part 7: 1987.The panel must be rated SAA when tested to BS 476: Part 3: 1975.The system has passed all the requirements of LPS 1181: Issue 3ceiling Lining Test.AirtightnessOverall airtightness for complete envelope less than 10m3/hr/m2at 50Pa.170

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoConstruction ApplicationStandard Environment - Roof - LPS 1181 Grade BKS1000 RW/Zero ODP/LPCB Trapezoidal Roof SystemRef No: 1/5.71/LPS-BConstruction DetailsNBS Format SpecificationFlashingsAll external flashings to be made from 0.63mm thick coated steelto the same specification as the outer sheet of the panel. Colour standard SC.H43 - Metal Composite PanelsCladding/CoveringTo be read with Preliminaries/General conditions. Drawing reference(s): Supports: Cold rolled purlinsBearing width: 50mmPitch: minimum 4 Manufacturer and reference: Kingspan roof cladding systemfor standard internal and external environments and LossPrevention Certification Board certified to LPS 1181 Grade B. Test results: LPS 1181 Issue 3, ceiling lining tests: Passed allrequirements Panels:Profile reference:KS1000 RW/Zero ODP/LPCB - Trapezoidal Insulated Roof Panel.External facings: Material: Galvalloy hot-dip ZA255 coated steel to BS EN10214, Grade S220GD ZA. Thickness: 0.5mm Finish/Colour: Colorcoat HPS200 Plastisol with Scintillafinish, Standard colour.Internal facings: Material: Hot-dip zinc coated steel to BS EN 10147. Thickness: 0.4mm Finish/Colour: Lining Enamel, colour White.Core insulation: s and LPCB certified.Panel thickness: 115mm overall (80mm core) End laps: 150mm. End lap sealant: Triple line of 4mm diameter Scapa Tapes,Ref: 0311, site applied at lap in external facings. Side lap sealant: Single line of 4mm diameter Scapa Tapes, Ref: 0311,site applied at lap in external facings. Anti-condensation tape, factory applied at buttjoint between panels. Fasteners: As determined by Clause 220A.Number and location: Primary fasteners: As determined by Clause 197A, but witheach panel fixed to each support using not less than threefastenings. Fix through every valley of profile, asrecommended by cladding manufacturer. Secondary fasteners: Stitch external side laps at 450mmmaximum centres.All flashings to have butt straps and sealed with two unbrokenruns of Scapa Tape 9mm wide x 3mm thick butyl rubber sealanttape, Ref: 0311.All internal flashings to be made from 0.4mm thick steel substrate,to the same specification as the liner sheet of the panel.All internal flashings to be air sealed at laps and along the fulllength by an unbroken bead of Scapa Tape 6mm diameter butylrubber sealant tape, Ref: 0311. End laps to be air sealed withVapourflex or gun-grade sealant.Panel LengthsExact lengths to be determined by the cladding contractor fromthe steelwork drawing, but typically using 9000mm lengths.Construction RequirementsSteelwork ToleranceThe steel frame must be made and assembled to an accuracy ofL/600 between fixing planes of adjacent purlins, where L. is thepurlin spacing, and generally to BS 5950: Part 2: 1992.InstallationAll fasteners, seals and fillers to be of correct specification andinstalled as indicated on the project construction drawings.Site cut panels must provide accurate, true lines with no distortion.Panels to be cut with powered reciprocating type saw and allexposed site cut panels to be treated with a suitable edgeprotection lacquer.Cut openings for outlets, vents, flues etc. to be the minimumsize necessary.Remove all swarf and any foreign matter immediately from theexternal surface of panels.Fasteners to be checked and adjusted if necessary to ensure theyare weather tight and external panel facing is not distorted.SafetyThe contractor is to determine and use a safe method of workingthroughout the installation and construction period, whichcomplies with HSE & CDM requirements.171KS1000 RW RoofModel Specifications121S - Metal Composite Panels Roof CladdingAll flashings to be weather sealed at laps and along the full lengthby an unbroken bead of Scapa Tape 9mm wide x 3mm thick butylrubber sealant tape, Ref: 0311.

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoConstruction ApplicationStandard Environment - Roof - LPS 1181 Grade BKS1000 RW/Zero ODP/LPCB Trapezoidal Roof System Accessories: Profiled fillers as Clause 300A. Thermal Transmittance (U Value) calculated using the methodrequired by the Building Regulations Part L2 (England & Wales)and Building Standards Part J (Scotland): 0.25 W/m2K Air leakage rate of 10m3/hr/m2 at 50 Pa. Other requirements: Internal face of panel to be air sealed along the full length byan unbroken run of 6mm diameter Scapa Tapes, Ref: 0311.Ref No: 1/5.71/LPS-B275 - Continuity Thermal Insulation Junctions between the roof panel system andwalls/penetrations insulated with PIR board insulation anygaps filled with Alfasbond FR fire rated gun applied canisterurethane insulation. Placement: Secure and continuous with cladding/coveringinsulation300A - Profiled Fillers Drawing reference(s): Manufacturer and reference: Hartington Conway 0730, typeto suit cladding profile.Material: EPDM faced polyethylene foam.Colour: Black. Fixing: Seal the top, bottom and sides of each profile filler witha non-setting gun-grade sealant, Scapa Tapes, Ref: 0100. Locate where shown on drawings and wherever necessary toclose off corrugation cavities from the inside and outside of thebuilding. Ensure a tight fit and leave no gaps.197A - Attachment Determine the number and location of cladding fastenersrecommended by the cladding manufacturer to resist windloads calculated in accordance with BS 6399: Part 2 StandardMethod and BS 5427: Part 1. Calculate wind loads on roof and wall cladding appropriate tolocation, exposure, roof height, building shape and size inaccordance with BS 6399: Part 2 Standard Method andBS 5427: Part 1.Basic wind speed (Vb): m/sAltitude factor (Sa):Direction factor (Sd):Seasonal factor (Ss): 1Probability factor (Sp): 1Terrain and building factor (Sb):External and internal size effect factors (Ca): 1External pressure coefficients (Cpe): As determined fromBS 6399: Part 2, Clauses 2.4 and 2.5.Internal pressure coefficients (Cpi): As determined fromBS 6399: Part 2, Clause 2.6.Dominant opening:310A - Purpose Made Cold Formed Metal Accessories External Drawing reference(s): Material/finish: As external face of cladding.Thickness: 0.63mmColour: To match external face of cladding.Workmanship as section Z11. Fixing: Stitch to external face of panels at max. 450mmcentres using secondary fasteners as specified for the claddingsystem. Sealing: Single line of 6mm diameter butyl rubber sealant TapeRef: 0311, site applied between flashing and panel.220A - Fasteners Manufacturer: One of the following:SFS Intec Ltd, tel. 0113 208 5500Ejot Ecofast Ltd, tel. 0113 247 0880 Primary fasteners:High threaded screws with bonded washers.Type(s), size(s) and drilling capacity: As re-commended byfastener manufacturer to suit type and thickness of supports,and thickness of cladding panels.Screw material: Anti-corrosion coated carbon steel.Washer material: Grade 304 austenitic stainless steel.Washer size: 19mm diameter.Heads: Integral colour matched heads Secondary fasteners: Stitching screws with bonded washers.Screw/washer material: As primary fasteners.Washer size: 14mm diameter.Heads: As primary fasteners.311A - Purpose Made Cold Formed Metal Accessories Internal Drawing reference(s): Material/finish: As internal face of cladding.Thickness: 0.4mmColour: White.Workmanship as section Z11. Fixing: Stitch to internal face of panels at max. 450mm centresusing secondary fasteners as specified for the cladding system. Sealing: Single line of 6mm diameter Scapa Tapes, Ref: 0311butyl rubber, site applied between flashing and panel. End laps to be air sealed with Vapourflex or gun-grade sealant.172

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoConstruction ApplicationStandard Environment - Roof - LPS 1181 Grade BKS1000 RW/Zero ODP/LPCB Trapezoidal Roof SystemDetail 1 - Side LapAnti-condensation tape(Factory applied)Ref No: 1/5.71/LPS-BDetail 2 - End LapStitching screws at450mm centresFixing screw150mmmNominal 10mMax. 20mm50mmMin.10mm3 runs of 4mm Øbutyl rubber sealant(Site applied)Detail 3 - Fastener LocationsNote: Main fixing every valleyDetail 4 - Ridge DetailSite applied Alfasbond fire rated (FR) canister insulationRidge flashing with 150mmsealed butt strapsKS1000 RW/LPCB insulated roof panelProfiled filler set back 80 to100mm to prevent bird attackProfiled filler sealed top andbottom with gun-grade sealantAir seal - 8mm Øbutyl rubber sealantPurlinInternal ridge flashing with150mm overlap sealedwith air seal, Vapourflex orgun-grade sealant173KS1000 RW RoofModel Specifications4mm Ø butyl rubbersealant (site applied)

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoConstruction ApplicationStandard Environment - Roof - Factory Mutual CertificateKS1000 RW/Zero ODP/FM Trapezoidal Roof SystemRef No: 1/5.71/FMApplicationSeals & FillersThe following specification is for KS1000 RW/Zero ODP/FMcertified Trapezoidal Insulated Roof Panel used for buildings withroof slopes of 4 and above, internal humidity class environments1-4 inclusive and where a Factory Mutual (FM) insurer approvedcertified system is required.Side LapAll external side laps to be weather sealed along the full length byan unbroken bead of Scapa Tape 4mm diameter butyl rubbersealant tape, Ref: 0311.In addition all side laps have a factory applied anti-condensationtape.Materials & CoatingsEnd LapAll external end laps to be 150mm long, and weather sealed alongthe full width using three unbroken runs of Scapa Tape 4mmdiameter butyl rubber sealant tape Ref: 0311.External Weather SheetSubstrate to be 0.5mm thick steel S220GD ZA eutectic Galvalloyhot-dip zinc coated steel to BS EN10214: 1992. External coatingto be Corus UK Limited Colorcoat HPS200 Plastisol, 200 micronsthick.Profiled FillersWhere flashings are fixed across the profile of the insulated panel,EPDM faced closed cell polyethylene foam fillers should be usedto seal and close the profile. Seal the top, bottom and sides ofeach profiled filler with non-curing gun-grade sealant, Scapa Tapes,Ref: 0100.Colour – Standard.Reverse to have a light grey polyester coating.Insulation CoreTo consist of 80mm thick, closed cell, with zero ozone depletion(Zero ODP) and FM insurer approvedcertifiedpolyisocyanurate (PIR) insulation.JunctionsJunctions between the roof panel system and walls / penetrationsinsulated with FM approved board insulation any gaps filled withAlfasbond FR fire rated gun applied canister urethane insulation.The auto adhesive properties of the core bond the external andinternal sheets together, and control the panel thickness achievedduring manufacture.Internal face of panel to be air sealed along the full length by anunbroken Scapa Tape 6mm diameter butyl rubber sealant tape.Internal Liner SheetSubstrate to be 0.4mm thick hot-dip zinc coated Steel toBS EN10147: 1992.FastenersPrimaryAll primary fasteners must be the high threaded typemanufactured from carbon steel, anti-corrosion coated, and fittedwith a 19mm diameter bonded stainless steel washer and integralcolour matched heads.Internal coating to be Lining Enamel, 15 microns thick.Colour - White.Reverse to have a light grey polyester coating.PerformanceAll fasteners to be located through the every valley of the profile.To comply with the requirements of BS 6399: Part 2: 1997, andthose of Factory Mutual it may be necessary to provide additionalfixings in areas of high local suction.Thermal InsulationThe panel must have a thermal transmittance (U value) of0.25 W/m2K calculated using the method required by the BuildingRegulations Part L2 (England & Wales) and Building StandardsPart J (Scotland).SecondarySide laps and flashings to be stitched at 450mm centres(maximum) with carbon steel stitching screws, complete with14mm diameter bonded stainless steel washers and integralcolour matched heads.FireThe external and internal faces of the panel to be Class 0 inaccordance with the Building Regulations when tested to BS 476:Parts 6: 1989 and Part 7: 1987.The panel must be rated SAA when tested to BS 476: Part 3: 1975.The System has the following FM test results ASTM E-180 Spreadof Flame Test-Pass Class A, Class 1 Test (Calorimeter)-PassClass 1, Wind uplift Test-Pass 1-90.AirtightnessOverall airtightness for complete envelope less than 10m3/hr/m2at 50Pa.174

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoConstruction ApplicationStandard Environment - Roof - Factory Mutual CertificateKS1000 RW/Zero ODP/FM Trapezoidal Roof SystemRef No: 1/5.71/FMConstruction DetailsNBS Format SpecificationFlashingsAll external flashings to be made from 0.63mm thick coated steelto the same specification as the outer sheet of the panel.Colour - Standard.H43 - Metal Composite PanelCladding/CoveringTo be read with Preliminaries/General conditions. Drawing reference(s): Supports: Cold rolled purlins. Maximum centres 2000mm.Bearing width: 50mmPitch: minimum 4 Manufacturer and reference: Kingspan roof cladding systemfor standard internal and external environments and FactoryMutual ìnsurer approvedcertified FM test results: ASTM E-108 spread of flame test: Pass,class A.Class 1 test (calorimeter): Pass, class 1.Wind uplift test: Pass, 1-90. Panels:Profile reference:KS1000 RW/Zero ODP/FM - Trapezoidal Insulated Roof Panel.External facings: Material: Galvalloy hot-dip ZA255 coated steel to BS EN10214, Grade S220GD ZA. Thickness: 0.5mm Finish/Colour: Colorcoat HPS200 Plastisol with Scintillafinish, Standard colour.Internal facings: Material: Hot-dip zinc coated steel to BS EN 10147. Thickness: 0.4mm Finish/Colour: Lining Enamel, colour White.Core

Insulated Roof Systems KS1000 RW Trapezoidal 163 KS500/1000 ZIP Standing Seam - Kingzip 229 KS1000 LP/CR Lo-Pitch - Curved 255 KS1000 TS . Valley Gutter 209 Hip 209 Valley Hip 210 Lean-to Roof 211 Expansion Joint 213 Change in Roof Slope 214 Ridge Ventilator 215