Transcription

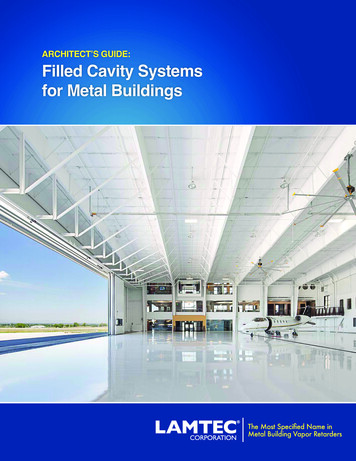

ARCHITECT’S GUIDE:Filled Cavity Systemsfor Metal Buildings1The Most Specified Name inMetal Building Vapor Retarders

THE COMPANYLAMTEC’S 260,000 square foot facility is situatedon a 45-acre site in Northeastern Pennsylvania,convenient to all New York metropolitan areaports and major north-south and east-westinterstate highways.LAMTEC CORPORATION IS ACTIVELY INVOLVEDWITH THE FOLLOWING ORGANIZATIONS:Proud Member ofTMEstablished in 1975, LAMTEC has grown intoa leadership role in the industry. Our philosophyis simple: “Design and manufacture the verybest in laminated insulation facings, offer themat competitive pricing, deliver them on time andfollow-up with comprehensive technical support.”LAMTEC is ready to help you meet the challengesof today.and tomorrow.LAMTEC products are proudlymanufactured in the USA.

Table of ContentsPage 4Introduction to Lamtec and Vapor RetardersPage 5Lamtec’ s Metal Building Product Line / Application GuidePage 6Insulation Solutions for Metal Building RoofsPage 7Filled Cavity (FC) / Long Tab Banded Tested U-ValuesPage 8Insulation Solutions for Metal Building WallsPage 9Filled Cavity Metal Building Wall Insulation Systems Hot Box Test ResultsPage 10IECC 2018 / ASHRAE 2016 Fiberglass SolutionsPage 11IECC 2015 / ASHRAE 2013 Fiberglass SolutionsPage 12IECC 2012 / ASHRAE 2010 Fiberglass SolutionsPage 13IECC 2009 / ASHRAE 2007 Fiberglass SolutionsPage 14Frequently Asked Questions3

Don’t spec without LamtecFor 40 years, Lamtec has been developing and manufacturing insulation facingsand vapor retarders for Pre-Engineered Metal Buildings.Lamtec offers the largest line of Underwriters Laboratories (UL) Classified and Factory Mutual (FM)Approved insulation facings for the Metal Building industry. The entire WMP series of products havebeen specifically designed for Metal Building applications.Metal building insulation facing and vapor retarders are an integral part of an aesthetic and functionalbuilding envelope.About Lamtec ProductsCondensation ControlMoisture PermeanceWater vapor passing through insulation to the coldexterior surfaces of the building can condense, degradingthe thermal performance of the insulation system aswell as contributing to corrosion, mold, mildew, andodor. Left unchecked, condensation will degrade theeffectiveness of the insulation system and reduce theservice life of the building components.Lamtec’s insulation facings are designed to reducecondensation and its damaging effects by controllingmoisture movement through the insulation system.With permeance ratings as low as 0.02 Perm, Lamtec’sfacings are tested, effective vapor retarders.Air PermeanceAir leakage has the potential to transport significantquantities of moisture though the insulation to the coldexterior cladding resulting in wintertime condensation.Controlling air leakage with an effective air barrier isan important aspect in reducing condensation and itsdamaging effects.With an air permeance rating well below the codespecified air barrier requirements of 0.004 cfm/ft2 at1.57 psf, Lamtec’s WMP Metal Building facings aretested, effective air barriers. Lamtec facings are bothlow permeance air barriers and low permeance vaporretarders.Fire PerformanceLamtec’s insulation facings are tested in accordancewith ASTM E84 and have Flame Spread Ratings 25and Smoke Developed Ratings 50. In addition, manyof Lamtec’s metal building facings are UL Classified,and FM Approved for use with fiberglass insulation inaccordance with FM 4880 (a full-scale room fire test).Aesthetics and FunctionalityLamtec’s facings protect the insulation from physicaldamage as well as water vapor intrusion.Lamtec’s proprietary white facings provide a cleanwhite interior surface with outstanding light reflectivity,which may allow for reduced lighting loads.Lamtec’s foil based vapor retarders provide radiantbarrier properties for use in applications requiring lowemittance surfaces, such as Ice Rinks and HockeyArenas.For buildings with extreme artificial and natural lightingconditions, Lamtec offers WMP-UV HD with enhancedUV resistance.For architectural open ceiling designs, many of Lamtec’sfacings are also available in an attractive black finishthat is UL Classified.“LAMTEC” AND “WMP” ARE TRADEMARKS OF LAMTEC CORPORATION4ARCHITECT’S GUIDE: Filled Cavity Systems for Metal Buildings

Lamtec’s Metal Building Product LineMost Popular Facings - General PurposeWMP-VR - Low Cost Standard Duty (Excellent for Most Chemical Environments)WMP-VR-R PLUS - Low Cost Standard Duty (Excellent for High Humidity Environments)WMP-10 - Standard DutyWMP-30 - Heavy DutyWMP-50 - Premium Heavy Duty with Added Abuse ResistanceSpecialty FacingsWMP-UV HD - Premium Heavy Duty with Added UV ResistanceGYMGUARD - Athletic Facilities and High Traffic Areas (Highly Abuse Resistant)Low (0.03) Emissivity FacingsARENASHIELD - Ice Arena Roofs (Highly Abuse Resistant)RADIANT ICE - Ice Arena and General Purpose (Double Sided Foil with Tear Resistance)R-3035 HD - Heavy Duty Foil/Scrim/Kraft (FSK)Facings Available in BlackWMP-VR, WMP-VR-R PLUS, WMP-10, and WMP-50

Insulation Solutions forMetal Building Roofs:Filled Cavity systems are the preferred option forinsulating Metal Building roofs in order to meet today’sstringent energy codes. The two most accepted FilledCavity systems are Long Tab Banded (LTB) and Liner,with the Long Tab Banded option typically being themost cost effective. Both systems provide comparableenervgy performance.The primary advantage of LTB is easier access tothe purlins for installation and maintenance of electrical,HVAC, and sprinkler systems without unsightly penetrations which compromise the integrity of the vaporretarder and the insulation system. In addition, mostof the scheduling complexities associated with othersystems are eliminated.LTB provides the building owner and design professional the most design flexibility with respect to the exposedvapor retarder. The designer can match the right vaporretarder with the application. The specifier can choosefrom one of Lamtec Corporation’s fully engineered vapor retarders including: WMP-VR, WMP-VR-R Plus,WMP-10, WMP-30, WMP-50, WMP-UV HD, etc In addition, the designer can match the roof and wallvapor retarder / facing for a continuous and finishedappearance. Alternate High R-Value Systems typicallyoffer only one or two vapor retarder options.Key Benefits of a Long Tab Banded System: Proven, cost effective High R-Value insulation system Meets or exceeds specified U-Values outlined intoday’s energy codes and standards Easier, unobstructed access to purlins for electrical,HVAC, sprinkler installation, and maintenance, whichreduces the number of penetrations in the vaporretarder Match roof and wall facing for a more finishedappearance Lamtec’s bright white WMP facings provide anattractive installed appearance and may reducecosts associated with lighting requirements Wide selection of Lamtec’s vapor retardersspecifically engineered for Metal Building applications Lamtec is the most trusted and specified name ininsulation vapor retarders with the most completeline of UL Classified and FM Approved Metal BuildingfacingsInstallation Guide Can Be Downloaded at LAMTEC.COM6ARCHITECT’S GUIDE: Filled Cavity Systems for Metal Buildings

Filled Cavity (FC) / Long Tab BandedTested U-ValuesThermal testing of Filled Cavity / Long Tab Bandedsystems, with Lamtec facing, was conducted inOctober 2010 and January 2011 at the ButlerManufacturing Research Center located in Grandview,MO, an independent certified laboratory.Testing was conducted in accordance with ASTMC1363, “Standard Test Method for Thermal Performance of Building Materials and Envelope Assembliesby Means of a Hot Box Apparatus”.Finite Element Analysis Modeling was conducted byEngrana LLC.Filled Cavity / Long Tab Banded systems results:(Based on standing seam roof panels with thermal spacer block)ASSEMBLY DESCRIPTIONSU-VALUER19 Faced / R11 Unfaced0.037R25 Faced / R11 Unfaced0.035*R25 Faced / R19 Unfaced0.029*Results based on Finite Element Analysis ModelingReports can be downloaded at the following links:Faced R19 / Unfaced DFFaced R25 / Unfaced R11http://www.lamtec.com/cdocs/LTBRoofFEM.pdfFaced R25 / Unfaced dfUsing COMcheck to Meet Energy CodesToday’s stringent energy codes offer prescriptivesolutions for compliance. Other more cost effectiveand / or better performing options can easily besubstituted by following some simple steps:1. Go to www.energycodes.gov and click on theDOE link to download the free COMcheck codecompliance program.72. Insert U-Value for a Filled Cavity / Long TabBanded system shown above into COMcheck byclicking on:Envelope / Roof Assembly / Other / Metal BuildingRoof. This allows you to replace the default valuesin the prescriptive path with the above alternateU-Value.3. Generate the Envelope Compliance Certificateand submit to the building official along withsupporting test or modeling documentation.

Insulation Solutions forMetal Building Walls:While today’s stringent energy codes prescribeContinuous Insulation (CI) for Metal Building walls,there are other options that are tested, code-acceptable, and more cost effective.Filled Cavity insulation systems, with either a singlelayer or a double layer of fiberglass, are a cost effectiveway to meet today’s demanding energy codes forMetal Building walls. These systems can achieveU-Factors as low as 0.035. Tested systems areavailable for every climate zone and energy code.Filled Cavity insulation systems featuring Lamtecfacings provide the building owner and designprofessional the most design flexibility in terms of theexposed vapor retarders. The specifier can choosefrom one of Lamtec’s industry leading vapor retardersincluding WMP-VR, WMP-VR-R Plus, WMP-10, WMP-30,WMP-50, WMP-UV HD, etc In addition, the designercan match the roof and wall vapor retarder / facing fora continuous and finished appearance.Single Layer Wall SystemDouble Layer Wall SystemKey Benefits Include: Proven, cost effective High R-Value insulation system Meets or exceeds prescribed U-Values as outlinedin today’s energy codes and standards Match roof and wall facing for a more finishedappearance Lamtec’s bright white WMP facings provide anattractive installed appearance and may reducecosts associated with lighting requirements W ide selection of Lamtec’s vapor retarders specificallyengineered for Metal Building applications Lamtec is the most trusted and specified name invapor retarders with the most complete line of ULClassified and FM Approved Metal Building facingsAlternate High R-Value systems typically offer only oneor two vapor retarder options.Installation Guide Can Be Downloaded at LAMTEC.COM8ARCHITECT’S GUIDE: Filled Cavity Systems for Metal Buildings

Filled Cavity Fiberglass Wall Insulation Systems results:Filled Cavity Metal Building Wall Insulation SystemsHot Box Test ResultsThermal testing of the Filled Cavity FiberglassWall Insulation Systems was conducted at the ButlerFilled Cavity Fiberglass Wall Insulation Systems results:Manufacturing Research Center located in Grandview,ASSEMBLY DESCRIPTIONS*MO, an independent certified laboratory.R-25 with 1/8” FoamThermal Break Strip:Testing was conducted in accordance with ASTMC1363, “Standard Test Method for Thermal Performanceof Building Materials and Envelope Assemblies byMeans of a Hot Box Apparatus”.U-VALUE*0.059R-30 with 1/4” FoamThermal Break Strip:0.052R-25 / R-10:0.047R-25 / R-16:0.042R-30 / R-16:0.039* Per ASHRAE 90.1-2016, Appendix Table A3.2.3Using COMcheck to Meet Energy CodesToday’s stringent energy codes offer prescriptivesolutions for compliance. Other more cost effectiveand / or better performing options can easily besubstituted by following some simple steps:1. Go to www.energycodes.gov and click on theDOE link to download the free COMcheck codecompliance program.92. Insert U-Value for a Filled Cavity Wall systemshown above into COMcheck by clicking on:Envelope / Exterior Wall Assembly / Other / MetalBuilding Wall. This allows you to replace thedefault values in the prescriptive path with theabove alternate U-Value.3. Generate the Envelope Compliance Certificateand submit to the building official along with supporting test or modeling documentation.

IECC 2018 / ASHRAE 2016Fiberglass SolutionsIECC 2018 Building Envelope Requirements, Table C402.1.4Metal Building WallsCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1IECC 2018 Building Envelope Requirements, Table C402.1.4Metal Building RoofCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1ᵃ0.0790.059*2Single Layer, Filled Cavity FiberglassSystem - R-25 with 1/8” FoamThermal Break Strip0.037**Filled Cavity / Long Tab BandedInsulation System - Faced R-19 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof0.0350.035**Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof0.029**Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-19 with Thermal Blocksand Standing Seam Roof2ᵃ33ᵃ4450.044560.0520.052*Single Layer, Filled Cavity FiberglassSystem - R-30 with 1/4” FoamThermal Break Strip67788* Use with COMcheck - Other Metal Building Wall0.0310.029** Use with COMcheck - Other Metal Building Roofᵃ Metal Building roofs with a slope less than 2:12, installed directly above cooled conditioned spacesin Climate Zones 1, 2, and 3 shall comply with one or more of the following options; 3 year aged SolarReflectance of 0.55 and a 3 year aged Thermal Emittance of 0.75 or a 3 year aged Solar Reflectance Indexof 64, see C402.3 for a list of exceptions.ASHRAE 90.1-2016 Building Envelope Requirements, Table 5.5Non-Residential Metal Building WallsCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1ASHRAE 90.1-2016 Building Envelope Requirements, Table 5.5Non-Residential Metal Building RoofCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1ᵇ20.094340.059*Single Layer, Filled Cavity FiberglassSystem - R-25 with 1/8” FoamThermal Break Strip0.042*Double Layer, Filled Cavity FiberglassSystem - R-25 plus R-16 (If both fiberglass layers are faced with a vaporretarder, the vapor retarder towardthe cold side of the building MUST beperforated)0.039*Double Layer, Filled Cavity FiberglassSystem - R-30 plus R-16 (If both fiberglass layers are faced with a vaporretarder, the vapor retarder towardthe cold side of the building MUST beperforated)0.06050.050670.039* Use with COMcheck - Other Metal Building Wall100.041340.04482560.037***Filled Cavity / Long Tab BandedInsulation System - Faced R-19 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof0.029***Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-19 with Thermal Blocksand Standing Seam Roof--------0.0370.03170.02980.026*** Use with COMcheck - Other Metal Building Roofᵇ Metal Building roof panels installed directly above cooled conditioned spaces in Climate Zone 1, shallcomply with a minimum 3 year aged Solar Reflectance value of 0.55 and a minimum 3 year aged ThermalEmittance of 0.75 or a minimum 3 year aged Solar Reflectance Index of 64, if not, the roof insulation mustbe increased by installing a system with a maximum U - Factor of 0.028.ARCHITECT’S GUIDE: Filled Cavity Systems for Metal Buildings

IECC 2015 / ASHRAE 2013Fiberglass SolutionsIECC 2015 Building Envelope Requirements, Table C402.1.4Metal Building WallsCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1IECC 2015 Building Envelope Requirements, Table C402.1.4Metal Building RoofCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1ᵃ0.0790.059*2Single Layer, Filled Cavity FiberglassSystem - R-25 with 1/8” FoamThermal Break Strip0.037**Filled Cavity / Long Tab BandedInsulation System - Faced R-19 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof0.0350.035**Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof0.029**Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-19 with Thermal Blocksand Standing Seam Roof2ᵃ33ᵃ4450.044560.0520.052*Single Layer, Filled Cavity FiberglassSystem - R-30 with 1/4” FoamThermal Break Strip67788* Use with COMcheck - Other Metal Building Wall0.0310.029** Use with COMcheck - Other Metal Building Roofᵃ Metal Building roofs with a slope less than 2:12, installed directly above cooled conditioned spacesin Climate Zones 1, 2, and 3 shall comply with one or more of the following options; 3 year aged SolarReflectance of 0.55 and a 3 year aged Thermal Emittance of 0.75 or a 3 year aged Solar Reflectance Indexof 64, see C402.3 for a list of exceptions.ASHRAE 90.1-2013 Building Envelope Requirements, Table 5.5Non-Residential Metal Building WallsCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1ASHRAE 90.1-2013 Building Envelope Requirements, Table 5.5Non-Residential Metal Building RoofCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1ᵇ20.094340.059*Single Layer, Filled Cavity FiberglassSystem - R-25 with 1/8” FoamThermal Break Strip0.042*Double Layer, Filled Cavity FiberglassSystem - R-25 plus R-16 (If both fiberglass layers are faced with a vaporretarder, the vapor retarder towardthe cold side of the building MUST beperforated)0.039*Double Layer, Filled Cavity FiberglassSystem - R-30 plus R-16 (If both fiberglass layers are faced with a vaporretarder, the vapor retarder towardthe cold side of the building MUST beperforated)0.06050.050670.039* Use with COMcheck - Other Metal Building Wall110.041340.04482560.037***Filled Cavity / Long Tab BandedInsulation System - Faced R-19 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof0.029***Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-19 with Thermal Blocksand Standing Seam Roof--------0.0370.03170.02980.026*** Use with COMcheck - Other Metal Building Roofᵇ Metal Building roof panels installed directly above cooled conditioned spaces in Climate Zone 1, shallcomply with a minimum 3 year aged Solar Reflectance value of 0.55 and a minimum 3 year aged ThermalEmittance of 0.75 or a minimum 3 year aged Solar Reflectance Index of 64, if not, the roof insulation mustbe increased by installing a system with a maximum U - Factor of 0.028.

IECC 2012 / ASHRAE 2010Fiberglass SolutionsIECC 2012 Building Envelope Requirements, Table C402.1.2Metal Building WallsCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1IECC 2012 Building Envelope Requirements, Table C402.1.2Metal Building RoofCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1ᵃ0.07920.059*Single Layer, Filled Cavity InsulationSystem - R-25 with 1/8” FoamThermal Break Strip0.037**Filled Cavity / Long Tab BandedInsulation System - Faced R-19 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof0.0350.035**Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof0.029**Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-19 with Thermal Blocksand Standing Seam Roof2ᵃ33ᵃ4450.044560.0520.052*Single Layer, Filled Cavity InsulationSystem - R-30 with 1/4” FoamThermal Break Strip67788* Use with COMcheck - Other Metal Building Wall0.0310.029** Use with COMcheck - Other Metal Building Roofᵃ Metal Building roofs with a slope less than 2:12, installed directly above cooled conditioned spacesin Climate Zones 1, 2, and 3 shall comply with one or more of the following options; 3 year aged SolarReflectance of 0.55 and a 3 year aged Thermal Emittance of 0.75 or an initial Solar Reflectance of 0.70and an initial Thermal Emittance of 0.75 or a 3 year aged Solar Reflectance Index of 64 or an initial SolarReflectance Index of 82, see C402.2.1.1 for a list of exceptions.ASHRAE 90.1-2010 Building Envelope Requirements, Table 5.5Non-Residential Metal Building WallsCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description10.0930.093Single Layer, Faced R-16 FiberglassBlanket2ASHRAE 90.1-2010 Building Envelope Requirements, Table 5.5Non-Residential Metal Building RoofCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description1ᵇ0.0650.065Single Layer, Faced R-19 FiberglassBlanket with Thermal Blocks andStanding Seam Roof0.0550.055Double Layer, Faced R-13 plusUnfaced R-13 Fiberglass Blanketwith Thermal Blocks and StandingSeam Roof0.0490.049Double Layer, Faced R-13 plusUnfaced R-19 Fiberglass Blanketwith Thermal Blocks and StandingSeam Roof0.0350.035**Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof234560.0840.084Single Layer, Faced R-19 FiberglassBlanket0.0690.059*Single Layer, Filled Cavity InsulationSystem - R-25 with 1/8” FoamThermal Break Strip3456770.0578* Use with COMcheck - Other Metal Building Wall0.052*Single Layer, Filled Cavity InsulationSystem - R-30 with 1/4” FoamThermal Break Strip8** Use with COMcheck - Other Metal Building Roofᵇ Metal Building roof panels installed directly above cooled conditioned spaces in Climate Zone 1, shallcomply with a minimum 3 year aged Solar Reflectance of 0.55 and a minimum 3 year aged Thermal Emittance of 0.75 or a minimum 3 year aged Solar Reflectance Index of 64, if not, the roof insulation must beincreased by installing a system with a maximum U - Factor of 0.028.12ARCHITECT’S GUIDE: Filled Cavity Systems for Metal Buildings

IECC 2009 / ASHRAE 2007Fiberglass SolutionsIECC 2009 Building Envelope Requirements, Table C502.1.2Metal Building WallsCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description10.0930.059*Single Layer, Filled Cavity FiberglassSystem - R -25 with 1/8” FoamThermal Break Strip2IECC 2009 Building Envelope Requirements, Table C502.1.2Metal Building RoofCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description10.0650.065Single Layer, Faced R-19 FiberglassBlanket with Thermal Blocks andStanding Seam Roof0.0550.055Double Layer, Faced R-13 plusUnfaced R-13 Fiberglass Blanketwith Thermal Blocks and StandingSeam Roof0.0490.049Double Layer, Faced R-13 plusUnfaced R-19 Fiberglass Blanketwith Thermal Blocks and StandingSeam Roof0.0350.035**Filled Cavity / Long Tab BandedInsulation System - Faced R-25 plusUnfaced R-11 with Thermal Blocksand Standing Seam Roof2340.0840.059*Single Layer, Filled Cavity FiberglassSystem - R-25 with 1/8” FoamThermal Break Strip0.0690.059*Single Layer, Filled Cavity FiberglassSystem - R -25 with 1/8” FoamThermal Break Strip567345670.05780.052*Single Layer, Filled Cavity FiberglassSystem - R -30 with 1/4” FoamThermal Break Strip* Use with COMcheck - Other Metal Building Wall8** Use with COMcheck - Other Metal Building RoofASHRAE 90.1-2007 Building Envelope Requirements, Table 5.5Non-Residential Metal Building WallsCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly DescriptionASHRAE 90.1-2007 Building Envelope Requirements, Table 5.5Non-Residential Metal Building RoofCompliance OptionsPrescriptiveClimate ZoneMaximum U-FactorU - FactorAssembly Description11ᵃ22ᵃ30.11340.113Single Layer, Faced R-13 FiberglassBlanket3ᵃ4556670.0650.065Single Layer, Faced R-19 FiberglassBlanket with Thermal Blocks andStanding Seam Roof0.0490.049Double Layer, Faced R-13 plusUnfaced R-19 Fiberglass Blanketwith Thermal Blocks and StandingSeam Roof70.0578* Use with COMcheck - Other Metal Building Wall130.052*Single Layer, Filled Cavity FiberglassSystem - R -30 with 1/4” FoamThermal Break Strip8ᵃ For Metal Building roof panels installed directly above conditioned spaces that are not cooled, wherethe exterior surface has a Solar Reflectance of 0.70 and a minimum Thermal Emittance of 0.75 or a SolarReflectance Index of 82, the roof insulation shall comply with a maximum U - Factor of 0.084 for ClimateZone 1, U- Factor of 0.078 for Climate Zone 2, and a U-Factor of 0.076 for Climate Zone 3.

Frequently Asked Questions1. Energy Codes and Standards use the termprescriptive path. Does prescriptive path mean itis the only option available to demonstrate energycode compliance?No, alternate systems can easily be substituted usingCOMcheck or other compliance programs.2. Can systems not listed in the ASHRAE tablesbe used to comply with the energy codes?Absolutely, there are many higher performing andlower cost systems not listed in the tables. As long asthere is supporting test or modeling data, the designprofessional can use alternative systems to satisfycompliance requirements for the building envelope.3. Is there an advantage to using a higherperforming system than prescribed by code?Yes, the trade-off option allows the specifying anddesign professional to trade an energy efficient component or assembly in one area with a less energyefficient component in another area, using COMcheckto verify conformity. An example of this approach wouldbe to enter a higher performing roof system intoCOMcheck, which could offset a lesser performingsystem for the walls or other areas. The trade-off optioncan be less restrictive than the prescriptive approach.You are able to modify the components and assemblies of the building design and still satisfy the compliance requirements of the building envelope.144. What is a Filled Cavity system?A Filled Cavity system is one that fills the cavitybetween the purlins / roof panel or girts / wall panelwith insulation. There are two types of FilledCavity systems: Long Tab Banded and Liner.5. Today’s stringent energy codes appear veryrestrictive and costly with the prescribed insulationoptions. Do I have any flexibility to value engineermy insulation system design?Yes, by using the COMcheck trade-off option processand selecting the “Other, Metal Building roof / wall”category, a filled cavity roof or wall insulation systemcan be substituted to demonstrate compliance. Thisoption allows the specifying and design professionalsto trade an energy efficient component or assemblyin one area with a less energy efficient component inanother area, using COMcheck to verify conformity.An example of this option would be to enter a higherperforming roof insulation system which could offsetmore costly windows, skylights, doors, or other assemblies. This value engineering design approach can beless restrictive than the prescriptive path. You are ableto utilize less costly components and assemblies inthe building design while still satisfying the compliancerequirements of the building envelope. Currently theCOMcheck program does not allow trade-offs betweenthe building envelope and lighting or HVAC equipment.ARCHITECT’S GUIDE: Filled Cavity Systems for Metal Buildings

6. What is the difference between Long TabBanded and Liner Systems? Is one system betterthan the other?A. Both can be considered Filled Cavity systems.Both systems fill the cavity, the only difference is theorientation of the facing tabs.C. B oth systems will provide comparable U-Factor results. Long Tab Banded facing tabs are installed tightagainst the purlin and over-lapped on top of theflange to maintain the continuity of the vapor retarder,see Figure 1. Liner facings are installed under the purlins,see Figure 2.B. Both when properly installed, fill the cavity betweenthe purlins.D. Both systems, when installed properly, canprovide a continuous vapor retarder.E. Long Tab Banded systems allow for much easieraccess to the purlins for installation andmaintenance of electrical, HVAC, and sprinklersystems without the unsightly penetrationsassociated with Liner systems. These penetrationscan compromise the integrity of the vapor retarderand insulation system.Figure 1 - Long Tab BandedFigure 2 - Liner SystemNOTE: The Vapor Retarders have been illustrated in blue for emphasis.11/201615

well as contributing to corrosion, mold, mildew, and odor. Left unchecked, condensation will degrade the effectiveness of the insulation system and reduce the . Filled Cavity Fiberglass Wall Insulation Systems results: Filled Cavity Fiberglass Wall Insulation Systems results: *ASHRAE 90.1-2016, Appendix Table A3.2.3Per :