Transcription

Distributed Acoustic Sensing fiber optic pipeline monitoringJJ WilliamsRegional Director – AmericasOptaSense - Houston Copyright OptaSense Ltd. 2018

Agenda What is Distributed Acoustic Sensing?Typical system architectureInstallationApplications:– Leak detection– ROW intrusion monitoring– PIG tracking and others Notable projects Fiber Optic Sensing Association2 Copyright OptaSense Ltd. 2018

About DASConvert a fiber optic cable into a listening device every 30ft over long distanceStandard commercial cable –up to 25 miles with 1 unitOptaSense Interrogator Unit Oil & GasBorders & PerimetersDefenseTransportUtilities Copyright OptaSense Ltd. 2018

20,000 miles proven performance on pipelines3,000 km Turkey40km N AlbertaCalgary1,000km KazakhstanUKSan FranciscoDubaiHouston5,000 km India120 km Tunisia1,000km USA4,00km Iraq550km Mexico250km Yemen250km NigeriaApplication AreasOil & Gas230km ColombiaTransportDefence & SecurityTelecommunicationsOptaSense Offices4 Copyright OptaSense Ltd. 2018

Principals of DASThe fiber is the sensorStandard SingleMode optical fiberA1A2A3 OptaSense employs a Coherent reflection techniquewhich uses the Rayleigh backscatter phenomenon oftelecoms cable to convert the fiber into a highlysensitive acoustic sensor.A4 . Changes in the reflected light are reactions to the acoustic activities presentat each 30ft increment along the pipeline, railway, border etc Pulse of lightA4,995A4,996A4,997A4,998A4,9995 Copyright OptaSense Ltd. 2018

Quick Demo6 Copyright OptaSense Ltd. 2018

System overviewOptaSense can be deployed stand alone or integrated into existing systems7 Copyright OptaSense Ltd. 2018

Typical pipeline architectureExample: 230 mile pipeline230 ne50 milesCoverage perequipment siteCentral Monitor of 1000’sof miles of cableBlock Valve Station1Gbit CAT5 EthernetInterrogation Unit100Mbit CAT5 EthernetProcessingUnit1(with local storage)Telecomm optical fiber2 (used for sensing)Network Attached Storage1Telecomm optical fiber2 (used for comms)Ethernet network switch1Note:1. Can be supplied as an option2. Both telecom optical fibers can be fromthe same fiber-optic cableOperator Workstation18This deployment requires:10 Interrogation Units6 Processing Units1 Network Attached Storage2 Operator Workstations Copyright OptaSense Ltd. 2018

Fiber optic cable installation Copyright OptaSense Ltd. 2018

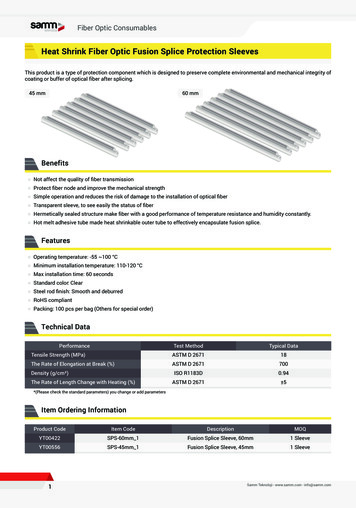

Cable and installation overviewMore suited to new pipeline construction – optimizing an open trenchFiber located in close proximity for Leak DetectionStandard single mode fiber optic cableDuctPipe Direct buried or in a HDPE conduit Single mode fiber optic cable Position is not as important as proximity Certain cables preferred but not specialized 2 o’clock position within 1ft is common Off the shelf HDD – 2 x conduits often pulled through thesame bore as the pipe, then fiber blown Cost effective Fiber optic infrastructure is highly reliable Installation considerations are available fromthe industry (FOSA)10 Copyright OptaSense Ltd. 2018

Cable installation example Recent example from WestTexas Cable both directly buried(armored) and installed inconduit (unarmored) Multiple crossings – HDDs andbores Aggressive constructionschedule with no delays11 Copyright OptaSense Ltd. 2018

Cable RetrofitCurrently challenging but R&D in progress A focus of industry and government R&DCurrent project with Southwest Research and PRCIFiber Optic Sensing Association ready to supportOpen trench less challenging than crossingsSolution must be safe and cost effective12 Copyright OptaSense Ltd. 2018

Typical pipeline architectureExample: 230 mile pipeline230 ne50 milesCoverage perequipment siteCentral Monitor of 1000’sof miles of cableBlock Valve Station1Gbit CAT5 EthernetInterrogation Unit100Mbit CAT5 EthernetProcessingUnit1(with local storage)Telecomm optical fiber2 (used for sensing)Network Attached Storage1Telecomm optical fiber2 (used for comms)Ethernet network switch1Note:1. Can be supplied as an option2. Both telecom optical fibers can be fromthe same fiber-optic cableOperator Workstation113This deployment requires:10 Interrogation Units6 Processing Units1 Network Attached Storage2 Operator Workstations Copyright OptaSense Ltd. 2018

Applications of DAS forpipeline monitoring Copyright OptaSense Ltd. 2018

Applications of DASFocused on leak detection and third party intrusion detectionPipeline LeakDetectionThird e HeatTrace MonitoringTemperature Copyright OptaSense Ltd. 2018

DAS multi-signature Leak Detection16 Copyright OptaSense Ltd. 2018

Leak Case Study17 Copyright OptaSense Ltd. 2018

Recorded DataLeak Detection via Acoustics Copyright OptaSense Ltd. 2018

Leak detection Case StudyCPM system took 3 hours to detect Copyright OptaSense Ltd. 2018

Leak detection performanceConsult experts for specific pipeline analysis Typical performance for DAS is around0.1% leak size detectable (of pipelineflow) So for a 100,000 bpd pipeline, this is aleak size of 100 barrels This is detected 1-5 minutes, with alocation accuracy of 10m or 30ft Traditional leak detection performancetypically floors at around 1% For 100,000 bpd pipeline, this would be1,000 barrels, detected in hours withless location accuracy 1% leak size 1-5 mins detection time 10m or 30ft locationRepresents a 10Ximprovement ontraditional methods Copyright OptaSense Ltd. 2018

Third Party IntrusionReal time detection with high locational accuracy21 Copyright OptaSense Ltd. 2018

What about false alarmsThe ability to classify activity using acoustic signal processing22 Copyright OptaSense Ltd. 2018

Damage prevention and early leak detectionAvoid costs altogether or minimize leak impactsCPMsystemsIntrusion DetectionFiber opticLeak Detection23 Copyright OptaSense Ltd. 2018

Earthquake MonitoringMagnitude 3.8 earthquake in Turkey During a routine deploymentat a customer pipeline amagnitude 3.8 earthquake wasobserved and recorded OptaSense provided earlywarning of potential pipelinedamage in a seismicallysensitive location Before and after analysis waspreformed in order to focus oninspections35 km24 Copyright OptaSense Ltd. 2018

Flow monitoringSlack Lines25 Copyright OptaSense Ltd. 2018

Pig TrackingAutomated detection and tracking of pig in oil pipeline The interaction of a cleaning pig / scraperwith the side walls and butt welds creates amoving series of pressure pulses– Long used for very precise PIG location ID26 Copyright OptaSense Ltd. 2018

Notable projects Copyright OptaSense Ltd. 2018

Largest fiber optic sensing system in North America1,100 miles (initially) Details:– 730 miles NGL and Crude line fromthe Permian to the Coast Applications:– Leak detection and ROW intrusiondetection Benefits:– Has detected a leak on separatepipeline that crosses the ROW– Has detected multiple excavators onthe ROW– Kept up with aggressiveconstruction schedule Copyright OptaSense Ltd. 201828

TANAP – Caspian gas to Europe1,100 miles Details:– 1,800km gas pipeline– 164 units in a networked system Applications:– Leak detection and securitymonitoring– Scope includes in-line facilityperimeter security– Scope includes a 30km water crossing Benefits:– Combines pipeline and facilitymonitoring in one system Copyright OptaSense Ltd. 201829

Los Ramones SUR Mexico200 miles Details– Gas pipeline Applications:– Leak Detection– Intrusion– Land slides Benefits:– Multiple functions– ONE cable– ONE system30 Copyright OptaSense Ltd. 2018

Bicentennial Colombia150 miles Details:– Oil pipeline– Installed in 2014 Applications:– Intrusion Benefits:– “Since installation, OptaSense DAS hasdetected multiple intrusions on thepipeline, reducing incident rates andoverall pipeline risk.”Operations Director, OBC Won an ASME global pipelineaward 201531 Copyright OptaSense Ltd. 2018

Copyright OptaSense Ltd. 2018

FOSAA fantastic resource for all things related to distributed fiber optic sensing FOSA is a non-profit industry association formed in 2017 in Washington D.C.Promoting Distributed Fiber Optic Sensing (DFOS) across many marketsProviding education on the benefits of DFOS technology, through:––– Technology Awareness CampaignsPromotion of DFOS SolutionsTechnology best practice developmentMembership is open to companies globally who make, install, support and use distributed/quasidistributed fiber optic sensors.Hands-on activities – members organize, manage, and collaborate regularly www.fiberopticsensing.org33 Copyright OptaSense Ltd. 2018

FOSA memberswww.fiberopticsensing.org34 Copyright OptaSense Ltd. 2018

SummaryWhat can DAS technology provide? Long reach – spans greater than 50 miles (80 km) possibleQuick scan – entire length scanned in seconds – real time reportingHigh spatial resolution – thousands of sensing points, detect every few feetPrecise event location detection – know quickly and accurately when problemsoccurVery low maintenanceAdd additional fiber to the sensor cable – built-in communications capability alongrights-of-way / broadband delivery35 Copyright OptaSense Ltd. 2018

THANK YOU! QUESTIONS?JJ Williams713 825-9909John.Williams@optasense.com36 Copyright OptaSense Ltd. 2018

Leak detection performance Typical performance for DAS is around 0.1% leak size detectable (of pipeline flow) So for a 100,000 bpd pipeline, this is a leak size of 100 barrels This is detected 1-5 minutes, with a location accuracy of 10m or 30ft Traditional leak detection performance typically floors at around 1%

![Fiber Optic - Perimeter Intrusion Detection System [Fopids]](/img/57/foss-presentation.jpg)