Transcription

HYDRAULICMAINTENANCE &SAFETYTIPS TO PREVENT DOWNTIME AND SAVE YOU MONEYTM

TABLE OF CONTENTSWHY PREVENTIVE MAINTENANCE?. 3CHOOSING THE RIGHT COMPONENTS. 4AGENCY SPECIFICATIONS. 9COUPLING IDENTIFICATION.10HOSE ROUTING.15HOSE CLEANLINESS.18ASSEMBLY INSTALLATION.19PERIODIC INSPECTIONS.23HOSE TROUBLESHOOTING.25SAFE HYDRAULICS .272

WHY PREVENTIVE MAINTENANCE?Hydraulic preventive maintenance and safety are important foranyone who operates hydraulically powered equipment. Improperlymaintained assemblies can cause premature hose failure andblowouts, resulting in equipment downtime, possible equipmentdamage, personal injury and even death. Safe Hydraulics trainingcan lead to not only safety, but safe production.At Gates, we believe following proper preventive maintenanceprocedures is time well spent. Shown below are some of thenumerous benefits provided by preventive maintenance.Let’s take a look at some preventive maintenance and safetyprocedures. They’ll put you on the right track to safe and longlasting hydraulic assemblies.BENEFITS› Reduce downtime› Improve production› Increase efficiency of maintenance personnel› Enhance control of spare parts inventory› Decrease safety hazards and accidents› Extend equipment service life› Reduce capital outlays for new equipment3

CHOOSING THE RIGHT COMPONENTSDON’T MIX ‘N’ MATCHSafe, long-lasting hydraulic assemblies begin by choosingthe right components. The “right” components are couplings,hoses, crimping equipment and accessories that are alldesigned to work together. Not all manufacturers offer safe,high-quality components. Mixing and matching couplings fromone manufacturer with hoses from another manufacturercan lead to premature or catastrophic assembly failure.That’s because hoses, couplings, assembly equipment and crimpingtolerances vary from one manufacturer to another, and they’re notinterchangeable. When components from different manufacturersare mixed together, coupling retention can be adversely affected.Mixing components can not only cause unnecessary downtime,it can result in personal injury as well. In addition, the thread orflange ends of couplings must be properly matched to their matingcomponents to create leak-proof connections.SAE J517 — “SAE J517 hose from one manufacturer isusually not compatible with SAE J516 fittings suppliedby another manufacturer.”Gates offers a complete line of hoses, couplings, crimpers andrelated equipment, all designed to work together as a system.4

Gates components meet stringent test requirements and areengineered to provide the highest-quality, longest-lasting, safestassemblies available. Your Gates distributor is specially trained tomake sure you get the hose assemblies that best meet your needs.THE CRITICAL DESIGN FACTORHydraulic system performance is determined by the weakestcomponent, which can be the hose/coupling interface, reassuringthat Gates assembly procedures are crucial. Controlling how thecoupling is connected to the hose and their interaction is criticalto designing effective, reliable and safe hydraulic hose assemblies.CHOOSING THE RIGHT HOSEChoosing the right hose is the first step to long and safe assemblyservice life. But before we look into how to select the proper hosefor the job, let’s first take a look at the benefits of using rubberhose in fluid power applications. Unlike rigid tubing, rubber hoseoffers several advantages:›› Less susceptible to vibration and movement.›› Requires no brazing or specialized bending.›› Easier to obtain in the aftermarket.›› Faster to route around obstacles.›› Absorbs sound and impulses.›› Dampens pressure surges.Given its superior availability and routing advantages, rubber hoseis preferred over metal tubing by most maintenance personnel.In fact, it’s not uncommon for maintenance technicians to replacemetal tubing with a hose assembly.HOSE CONSTRUCTIONCoverHydraulic hoses have three parts:the cover, tube and reinforcement.TubeThe cover protects the tubeand reinforcing material fromenvironmental conditions likeReinforcementadverse weather, ozone, abrasion,heat, chemicals, etc. Choose a hose with a cover that can meet thedemands of your system, especially in abrasive situations or if thehose will be exposed to chemicals or extreme temperatures.The tube is the part of the hose that comes in contact with thehydraulic fluid. Reinforcement allows the hose to withstandinternal pressures, or in the case of suction/vacuum hose, externalpressures. Hoses generally have braided, spiraled or helicalreinforcement. The type of reinforcement depends on the intendeduse of the hose.5

The three basic types of reinforcement are:Braided reinforcement can be wire or textile and can have singleor multiple layers.Spiraled reinforcement on hydraulic hose is typically wire ortextile and has four or six layers (plies). Spiral-reinforced hosecan typically handle more severe applications with longer impulseservice life.Helical coil reinforcement keeps the hose from collapsing duringsuction (vacuum) and tight bending.When choosing a hose, it’s crucial that the cover, tube andreinforcement are all compatible with the type of fluid conveyedin the system. This is an important point to remember becausemany hoses are not compatible with all of the hydraulic fluids onthe market today, including petroleum-based, phosphate ester,water-based and diester fluids.Other variables, such as elevated temperatures, fluidcontamination and fluid concentration, will also affectcompatibility. When in doubt, consult the hose manufacturer.6

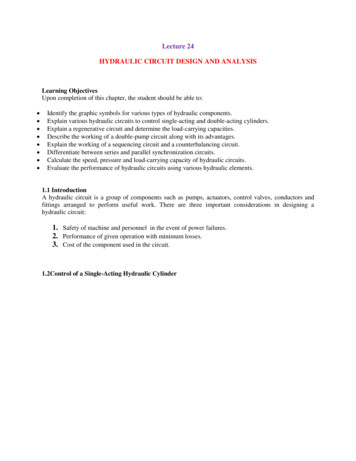

THE “STAMPED” ialEDDelivery (Volume)Ends/CouplingsStudies by fluid power manufacturers indicate that the threemost common causes of hydraulic hose failure are abuse,misapplication and improper plumbing. Equipment operatorsand technicians can reduce, if not eliminate, premature hydraulichose failure by giving maximum consideration to hose assemblyselection and installation.Yet, with all of the different types of hoses on the market, choosingthe right one can be difficult.Gates suggests using the “STAMPED” method to ensure you getthe right hose assembly for the job. “STAMPED” stands for Size,Temperature, Application, Material to be conveyed, Pressure, Endsor Couplings, and Delivery (Volume).Here’s how it works:Size — Choose a hose with an inside diameter that is adequate tominimize pressure loss and to avoid hose damage caused by theheat generated by excessive fluid turbulence.Temperature — The hose must be able to withstand the system’sminimum and maximum fluid and ambient temperatures.Application — Determine where or how the hose will be used.You’ll need to know the equipment type, working and impulsepressures, fluid to be used, bend radius, static conductivity, etc.Material to be conveyed — The hose, including the hose tube andcover, along with the couplings and O-rings, must be compatiblewith the type of fluid being conveyed.Pressure — Know the system pressure, including pressurespikes. The hose’s published working pressure must be equal to,or greater than, the normal system pressure and any pressuresurges it will encounter.Ends or Couplings — Identify the type of threads the system usesand select couplings that are compatible with those thread types.Delivery (Volume) — How much fluid must go through the hose?This will determine the size of hose that must be used. Undersizinga hose leads to increased pressure loss. Oversizing the hose addsunnecessary cost, weight and bulk.7

HOSE SIZE (DASH NUMBERS)Hose I.D. (Inches)Nominal Industry Standard DimensionsAll except C5 Series,C14 and AC134a8C5 Series,C14 and AC134aDash 115.2——

AGENCY SPECIFICATIONSINDUSTRY AGENCIESABS — American Bureau of ShippingAS — Australia StandardDIN — Deutsche Industrial Norme, GermanDNV — Det Norske Veritas for North Sea Floating VesselsEN — European Norm/StandardGL — Germanischer LloydIJS — Industrial Jack SpecificationsRCCC — Regular Common Carrier Conference for Fleet Truck and BusSAE — Society of Automotive EngineersGOVERNMENT AGENCIESDOT/FMVSS — U.S. Department of Transportation/Federal Motor Vehicle Safety StandardsMSHA — U.S. Mine Safety and Health AdministrationUSCG — U.S. Coast Guard9

COUPLING IDENTIFICATIONIdentifying couplings is as easy as 1-2-3.1. Determine seat type:›› Thread interface›› O-ring›› Mated angle or mechanical joint›› Mated angle with O-ring2. Visually identify3. Measure threadsA hydraulic coupling consists of two functional ends:1. The hose end for hose attachment2. The thread end for port attachmentHose EndThread EndThe hose end is identified by the hose size and type to whichit is attached. Serration patterns are specified by the couplingmanufacturer to meet performance requirements.The thread end of a coupling (or adapter) can be identified bycomparing it with the coupling being replaced or by measuringthe port or thread end to which it will be attached. The threadend may also come in different configurations.10Straight45 90 Block

Hose ends and thread ends are measured by industry standarddash sizes. The hose end dash size refers to the inside diameterin 1/16" (except for PolarSeal hose, SAE 100R5 and SAE 100R14which are based on tube O.D. and are one size smaller than thedash size implies), e.g., –8C5C hose is actually 13/32" I.D.Tools used for coupling identification include calipers, seatgauges (English and metric), thread gauges, thread ID manualsand coupling templates. Gates offers several tool kits that makecoupling identification fast and easy.COUPLING AND ADAPTEREND-STYLE NOMENCLATUREGates couplings feature a meaningful description by combiningend-style codes shown below that make thread identification fastand easy. Always refer to Gates Crimp Data Charts when selectinghose and coupling combinations.The following image shows the Gates 8G-8MP wire braidcoupling, a MegaCrimp male pipe coupling for -8 (1/2") hosesize and -8 (1/2") stem size.8 G-8MP1/2" MegaCrimp Male PipeCoupling1/2" NominalThread Size11

THREAD END lessIInverted FlareABAir BrakeJJIC (37 Flare)APIAPI UnionsBO-Ring BossJISJapanese IndustrialStandardBJBanjoKBKHDBulkheadKomatsu Style(Japanese 30 Seat)BLBlockLHLong HexBSBite SleeveLNLong NoseBritish StandardPipe ParallelMMaleBSPPMBAXBSPTBritish Standard PipeTaperedMale BossAdapterless SwivelMFACCaterpillar FlangeDimensionMale FlarelessAssembly (Ermeto)MKBMetric KobelcoCCClamping CollarMLSPDHDIN HeavyMetric LightStand PipeDLDIN LightMMMetric MaleFFemaleMNMetric NutFBFFORFemale BritishFlat-Face O-RingMPGMale SpecialGrease FittingFemale Braze-OnStemMSPMetric Stand PipeFBONASPFFFlat-FaceNorth AmericanStand PipeFemale FrenchGAZ SwivelORO-RingFFGXPFFNFemale Flareless NutPipe Thread(NPTF or NPSM)PLPress-Lok FFSFemale FlarelessSleevePTPortFGFemale Grease ThreadPWXFKXFemale KomatsuStyle SwivelPressure WasherSwivelRField AttachableFLCode 61 O-RingFlangeSSAE (45 Flare)SPSpecialFLCCaterpillar-StyleO-Ring Flange(Code 62)TSTube SleeveTSNTube Sleeve NutXSwivelFLHCode 62 O-RingFlange HeavyZParker Triple ThreadFLOSFlange O-RingSpecial (Code 62)2222-1/2 Drop30 DropFORFlat-Face O-Ring30Female SAE Tube4545 DropFT60 DropHLEHose Length Extender6067-1/2 DropHLECHose Length Extender(Caterpillar)679090 DropHMHose Mender110110 Drop135135 Drop12

MEASURING THREADS AND SEAT ANGLESMeasuring ThreadsWith a caliper, measure the thread diameter at the largest point(O.D. of male threads or I.D. of female threads).Read “Out”DimensionRead “In”DimensionUsing the pitch gauge, determine the number of threads per inch.Comparison of gauge and coupling threads against a lightedbackground will ensure an accurate reading.Measuring Seat AnglesWhen the centerline of the seat gauge points straight out of thecoupling, the angles of the gauge and seat match.CenterlinesAre ParallelRIGHTCenterlinesAt An AngleWRONGCompare the measurements taken to the coupling specificationtables that appear in Gates Hydraulic Hose, Couplings & EquipmentCatalog 35093 or the specifications in Gates Hydraulic CouplingInternational Thread Identification Manual 435-0998.NOTE: Thread binding will occur when different threadconfigurations are used. DO NOT mix thread configurations.13

HOW TO MAKE HOSE ASSEMBLIESOF SPECIFIC LENGTHSSelect the hose and couplings required to make the desiredhydraulic assembly. Measure the entire length of the assembly.Then use the formula below to calculate the required hose cutlength for the assembly.Hose Length Assembly Overall Length Minus (C1 C2)Female JIC 37 Flare Swivel — 90 Bent TubeLCTH2Cut-off value “C” is the length of that part of the coupling notdirectly in contact with or applied to the hose. Therefore, subtractthe two “C” values from the total length of the assembly and youwill have the approximate hose length to be replaced.Assembly Overall LengthCut Hose LengthC1C2Hose Length Assembly Overall Length Minus (C1 C2)SAE Length Tolerances for

Safe Hydraulics training can lead to not only safety, but safe production. At Gates, we believe following proper preventive maintenance procedures is time well spent. Shown below are some of the numerous benefits provided by preventive maintenance. Let’s take a look at some preventive maintenance and safety procedures. They’ll put you on the right track to safe and long-lasting .