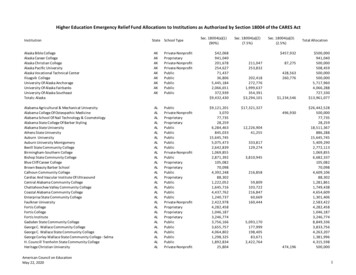

Transcription

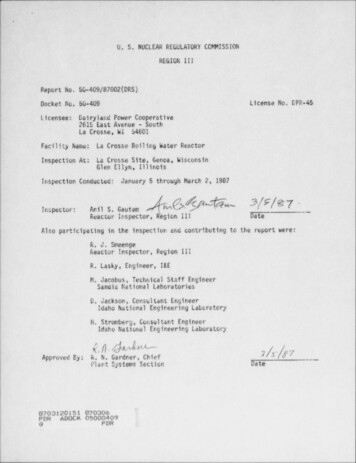

.,QU. S. NUCLEAR REGULATORY CCPNISSIONREGION IIIReport No. 50-409/87002(DRS)License No. DPR-45Docket No. 50-409Licensee: Dairyland Power Cooperative2615 East Avenue - SouthLa Crosse, WI 54601Facility Name: La Crosse Boiling Water ReactorInspection At: La Crosse Site, Genoa, WisconsinGlen Ellyn, IllinoisInspection Conducted: January 5 through March 2, 1987Inspector:Anil S. GautamMM*/5P""Reactor Inspector, Region III3!&7 'DateAlso participating in the inspection and contributing to the report were:R. J. SmeengeReactor Inspector, Region IIIR. Lasky, Engineer, I&EM. Jacobus, Technical Staff EngineerSandia National LaboratoriesD. Jackson, Consultant EngineerIdaho hational Engineering LaboratoryH. Stromberg, Consultant EngineerIdaho National Engineering Laboratory[, A, MAAk&hApproved By:R. N. Gardner, ChiefPlant Systems Section87031201S1 070306PDH0ADOCK 05000409PDR"87Date

.OInspection Summary8. Inspection on January 5 thru February 27,1987 (Report No. 50 4,09/870 02JDRSRAreas Inspected: Special announced safety inspection of the environmentalqualification The inspection included licensee action cn SER/TER connitinents; EQ programof EQ docunientation; and a plantphysicalcceplianceto10CFR50.49;adequacy (ModulesNo.30703andNo.25576).inspection of EQ equipmentResults: The licensee has implemented a program to meet the requirementsof 10 CTR 50.49. Deficiencies in the areas inspected are sumarized below:Potentially Enforceable / Unresolved I t e mDescriptionItem Number50-409/67002-03(DRS)EQ file for the GE RTV scalantsReport Section4anot in an auditable form due to thelack of a similarity analysis forthe sealing compounds RTV-615,RTV-11, and RTV-106.Open ItemsDescriptionItem NumberReport Section50-409/87002-01(DRS)Lack of study to evaluate postulatedfailures of containtrent cooling unitson the qualification of EQ equipment.3b(1)50-409/87002-02(DRS)Lack of adequate participation ofQA personnel in plant EQ training3eprogram.2

'.DETAILS1.Persons Contacteda.Dairyland Power Cooperative (DPC)-*J. W. Taylor, General Manager *J. Parkyn, Plant Supe. intendent*J. Leifer, Assistant General Manager*R. Brimer, Electrical Engineer*B. Wery, QA Supervisorb.Consultants*P. A. Di Benedetto, Di Benedetto Associatesc.USNRC*I.V111alva, Senior Resident Inspector, LACBWR* Denotes those attending the interim site exit interview onJanuary 9,1987. Denotes those attending the exit interview on March 2, 1987,at the conclusion of the inspection.2.Licensee Action on SER/TER CommitmentsThe NRC inspection team evaluated the implementation of the licensee'sEQ corrective action commitments made as a result of EQ deficienciesidentified by the NRC in the LACBWR June 25, 1982, FRC/TER; December 21,1982, SER; and April 18, 1985 final SER for the environmental qualificationof safety related electrical equipment.The majority of the deficiencies identified in the FRC/TER and SERsaddressed documentation, similarity, aging, qualified life and replacementschedules. All open items identified in the FRC/TER and the SERs werediscussed with the NRC staff, and the licensee's proposed resolutionsto these items were found acceptable by the NRC, as stated in theirApril 18, 1985 SER. The primary objective of the Region III EQ auditin this area was to verify that appropriate analyses and necessarydocumentation to support the licensee's proposed and accepted resolutionsto NRR were contained in the licensee's EQ files.During this review, the NRC inspection team reviewed EQ documentationrelevant to prior discrepancies identified in the SERs. This includedlicensee corrective action on Limitorque actuators, ASCO solenoid valves,Allis Chalmers electric motors, General Atomic radiation monitordetectors, and level transmitters.No violations of NRC requirements were identified.Ii :i3

'.' v3.Pj ;t '!-it,.j'EQ Program Compliance to 10 CFR 50.49. 'The inspectors reviewed. selected areas of the licensee's EQ program toverify compliance to 10.CFR 50.49. The licensee's EQ program identifiedmethods-for equipment; qualification; provides for evaluation andmaintenance of EQ documentation in an auditable form, including-maintenance records; provides for updating of replacement equipment, and .control of. plant modifications. Based on their review, the-inspectors1 determined that the licensee had established an adeouate EQ program in' compliance'with.the requirements'of 10 CFR 50.49. '' v licensee's methodsfor establishing and maintaining the environmentalLc 'ification of.electrical equipment were reviewed in the following nas:a.EQ Program ProceduresThe inspectors examined the' adequacy'of the licensee's' policiesand procedures for establishing and maintaining the environmentalqualification of equipment within the scope of 10 CFR 50.49. Thelicensee's EQ program was reviewed for procurement of qualifiedequipment;' maintenance of qualified equipment; modifications tothe plant that could affect qualified equipment; updating of theEQ master list; and review and approval of EQ documentation.Procedures reviewed included the following documents:*ACP*ACP*ACP.03.4, " Environmental Qualification of ElectricalEquipment Important-to Safety Program," Issue 3,dated August 18, 1986.04.3, " Substitution Request," Issue 8, dated*ACP.05.1, " Procurement Document Control," Issue 10,.02.13, " Operations Review Committee (ORC),"Issue 3, dated August 28, 1986.March 13, 1985.dated December 26, 1985.*I&E48-02, " Repair or Adjustment of EnvironmentallyQualified Electrical Equipment," Issue 7, datedDecember-16, 1986.*LACBWR Preventive Maintenance Cross Reference Listing,Issued December 18, 1986.Specific areas reviewed in these procedures included definitionsof harsh and mild environments, equipment qualified life, serviceconditions, periodic testing, maintenance and surveillance, andupgrading of replacement equipment purchased'after February 22, 1983.One deficiency was identified and is noted below:(1) During review of Procedure I&E 48-02, Revision 7, theinspectors noted that torquing requirements for housingcovers on transmitters, switches, ASCO valves and junctionboxes did not include tolerances. The inspectors wereconcerned that without tolerances the covers may be!:iiI[4

.Ii!.J-inadvertently under or over torqued, thereby affecting theenvironmental seal the covers provided. The licensee tookimmediate corrective action during this inspection, andrevised the procedure to identify appropriate tolerances'for the torque values.No violation of NRC requirements were identified.b.10 CFR 50.49 Master Equipment List (MEL) of EQ EquipmentIE Bulletin No. 79-01B required licensees of all power reactorfacilities with an operating license to provide a MEL thatidentified each Class IE electrical equipment item relied uponto perform a safety function during a design basis event.10 CFR 50.49, Paragraph (d), requires licensees to prepare alist of electric equipment important to safety and within thescope of the rule. The NRC inspectors reviewed the LACBWRMEL for compliance to 10 CFR 50.49. Areas reviewed includedadequacy of the MEL, technical justifications for removal ofitems from the MEL, and licensee reviews of the MEL for changesdue to field modifications.The inspectors verified the completeness / adequacy of the listin terms of equipment needed under accident conditions throughreview of Piping and Instrumentation Drawings (P& ids), EmergencyProcedures, Technical Specifications and FSARs. The inspectorsreviewed equipment needed to function under accident conditions,including equipment used during a primary system leak, scrams,and a complete loss of electric power. Equipment needed for theseaccidents were identified in the Plant Emergency Procedures 4.3,4.1, and 4.2 respectively. All applicable equipment in theprocedures were reviewed for applicability and inclusion in theMEL. The following exception was identified.(1) The LACBWR containment building is maintained at a normaloperating temperature of 70 F to 80*F by means of two airconditioning units in the containment, and an independentblower fan that exhausts through a vent. The inspectors notedthat neither the air conditioning units nor the blower were onthe MEL. The licensee stated that during an accident none ofthis equipment was required to perform a safety function andthat the FSAR did not assume operation of this equipment forthe safe shutdown of the plant. The licensee also statedthat postulated failures of this equipment during normaloperation would cause a temperature rise in the containment,if the equipment was not restored within an hour.Since the above equipment had adequate redundancy, andsufficient margins existed in the licensee's qualificationspecifications for EQ equipment in the containment, no concernsregarding plant operability were identified. The licensee! 5

--,:.-,n:; s,4Yc.Lwas informed, however,:that any effacts on the-aging .of EQ :equipment in;the containment due to failures of the aboveequipment during normal operation must be addressed in their.EQ files.1: The licensee. agreed to perform an onsite review / studyin summer to simulate postulate failures of the above equipmentunder worst ' case ambient conditions. This study will identify-temperature rises in the containment during normal operationand during and after an accident, as applicable. Pending NRC.review of this study, this is an Open Item (50-409/87002-01(DRS)).EQ Maintenance and Surveillance Program-The inspectors reviewed. specific maintenance, replacement,surveillance tests, and inspections necessary to preserve theenvironmental qualification of EQ equipment identified on the MEL.The NRC inspectors found the licensee s methods for schedulingmaintenance and surveillance adequate.No violations of NRC requirements were identified.d.Plant Procurement and Upgrading of Replacement EquipmentLicensee procedures adequately addressed upgrading of replacementequipment purchased after February 22, 1983. Procurement proceduresand documents adequately addressed appropriate quality and regulatory.requirements regarding the environmental qualification of equipmentwithin the scope of 10 CFR 50.49. Checklists were used to provideevidence of reviews and approvals. For example, procurement packagesfor the replacement of Foxboro transmitters, ASCO solenoid valves,NAMCO limit switches and General Atomic radiation monitoring equipmentwere found to properly address upgrading of replacement equipment torequirements of IEEE 323-1974.No violations of NRC requirements were identified.e.Quality Assurance (QA) and Training ProgramDuring this review, the inspectors determined that the licenseehad implemented a program to monitor the quality of EQ activitiesthrough surveillance, audits, and the reviews of the records andfiles for plant modifications and equipment procurement. NRCinspectors reviewed Audit 60-85-1, conducted in March 1985, and foundthe methodology, results and follow-up of corrective action relativeto this QA audit acceptable. :jThe inspectors also reviewed the licensee's staff training programand associated training records relevant to the performance ofEQ activities. Training records indicated that the licensee hadimplemented a training program for key personnel responsible forEQ activities, including management and operations and maintenancepersonnel, and that the training program addressed key aspects of10 CFR 50.49 requirements. The NRC inspectors noted that personnelfrom the QA department had not attended the plant EQ training;L, t-6-

;r.,,.-. .m- '. h. .,- however, the plant QA personnel did exhibit a consistent; awareness 'of. environmental qualification requirements.of 10 CFR 50.49. 'The.-licensee agreed to increase the participation'of all appropriatepersonnel in the EQ training program. Pending further NRC review ofthe plant's EQ training' program, this.is an Open Item;'- (50-409/87002-02(DRS)).- Detailed Review of Qualification Files- 4.iThe licensee qualified their EQ equipment.to the requirements of the,DOR Guidelines (10 CFR 50.49, Paragraph K). -The inspectors reviewed 29equipment qualification files for evidence of the environmentalqualification of-equipment within the scope of 10 CFR 50.49 and evidenceof equipment qualification to the DOR Guidelines. Files were found toinclude a full description of-the equipment; similarity analysis of testedequipment to that installed in the plant; allowed mounting methods andi'orientation; qualification of interfaces (conduit housing, seal, etc.);,evaluation of aging effects on equipment; description of test' sequenceand methodology; environmental conditions for the equipment during anaccident; qualification for submergence of applicable equipment;resolution of test anomalies; and maintenance / surveillance criteriafor the preservation of the qualified status of the equipment.:;,;':The inspectors selectively reviewed the above areas, as applicable,including special reviews for the required duration of operability ofequipment; licensee evaluation of tested materials and configurationsL!,'relative to actual plant installations; adequacy of test conditions;!aging calculations for qualified life and replacement intervals; effects[of decreases in insulation resistance on equipment performance; adequacyof demonstrated accuracy of equipment and interfaces; and licensee.-evaluations of discrepancies identified in IE Notices and Bulletins.EQ files were reviewed for Electrical Cables, Cable Splices, Terminations,Terminal Blocks, Electric Motors, Solenoid Valves, Electrical Penetrations,Seals, Lubricants, Transmitters, Detectors, Radiation Monitors, LimitSwitches and Switch Gear. The inspectors found that in almost all casesthe files allowed verification of equipment qualification to a specifiedperformance for accident conditions. Exceptions are noted below:jia.;,General Electric (GE) RTV Sealant'LACBWR uses two kinds of RTV potting compounds, RTV 11 and RTV 615,as a moisture intrusion seal at the connections of mineral insulatedcables to EQ devices. Both kinds of compounds are used insidenon-EQ gasketed condulets in their appropriate appitcations. Duringthis review the inspectors noted that the licensee did not haveadequate documentation in their EQ files to justify the use of these;i!,'compounds in a steam environment.L1ili!.i7)iT*.w-ww,,w,we--- wewe.wmw-mw--.-n.c-m,,e-,,,,,- -p.mm,-yene,y y ,m-mw- - --- .w'

w,,s'* '13,; N.-At the site exit meeting.the licensee provided an additional existingtest report of research conducted at Wyle Laboratories relative tothe sealing of.in-containment electrical, equipment. This test report(Research Project RP 1707-12)' indicated that a similar sealing,compound, GE RTV 106, had been tested at 300'F, 60 psig,'and exposed1to-steam and chemical spray with no anomalies. The NRC-inspectorsfound this test acceptable in terms of the environmental conditionstested and the similarity of tested sealant to the installed sealants;however,:the licensee did not have a similarity analysis in theirfile to permit proper verification.Based on their review of the test data on RTV 106, the inspectorsdetermined that sufficient qualification documentation had beenavailable at the site to mitigate concerns regarding the qualificationof the installed RTV. sealants. 10 CFR-50.49 Paragraph (j) states. that a record of qualification, including documentation, must be.maintained in an auditable form for the entire period during which,the covered item is installed in the plant to permit verificationthat the equipment is qualified for its application and meets itsperformance requirements during an accident. Contrary to theabove, the EQ file for the RTV sealant was not auditable to permitappropriate verifications, in that a similarity analysis of theabove sealants was missing. - The licensee's failure to maintain anauditable EQ file for the RTV sealant past the November 30, 1985 EQdeadline is considered a violation of 10 CFR 50.49, and pendingfurther review this is a Potentially Enforceable / Unresolved Item(50-409/87002-03(DRS)).b.Containment Flood Level-During review of the EQ files, the inspectors noted that there wasno positive statement in the files to identify the plant containmentflood level, and that the files did not include any qualificationfor submergence.The licensee identified the cause of the worst flood condition tobe a line break below the core level. In such an event the licenseeconfirmed that the containment flood level would reach elevation 630'in approximately three hours. The NRC inspectors reviewed calculations done by the licensee regarding the time and elevation at whichthe appropriate EQ equipment would be submerged, and the time andsequence at which the EQ equipment would perform their safety .)function. The licensee's evaluation stated that all EQ equipmentwould perform their safety functions prior to submergence; however,statements regarding submergence had not been included in the files.!j'[ijThe licensee was informed that appropriate flood levels needed to beaddressed in their EQ files. The licensee took immediate correctiveaction to include appropriate statements in their EQ files and toclarify requirements for submergence. No violations of NRC requirements were identified.!i!!!