Transcription

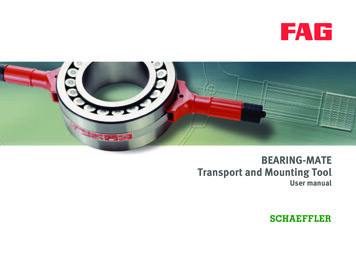

BEARING-MATETransport and Mounting ToolUser manual

ContentsPageAbout the user manual.General safety regulations .Scope of delivery .Application.Inspection and maintenance .Appendix.2BA 1359122123Schaeffler Technologies

About the user manualThe purpose of this user manual is to assist the userto become acquainted with the transport and mountingtool BEARING-MATE and use it for the intendedpurpose.This user manual describes the construction and useof the transport and mounting tool BEARING-MATE andhelps in avoiding hazards and extending the life ofthe device.This user manual is part of the device and containsimportant information. It applies exclusively tothe transport and mounting tool BEARING-MATE.Schaeffler TechnologiesWarning and hazard symbolsThe warning and hazard symbols are defined alongthe lines of ANSI Z535.6-2006.The meaning of the guidelines and symbols isas follows:WarningIn case of non-compliance, death or serious injury mayoccur.CautionIn case of non-compliance, damage or malfunctionsin the product or the adjacent construction will occur.BA 13

AvailabilityThis user manual is supplied with each device andcan also be ordered retrospectively.If the user manual is absent, incomplete or illegible,the user may lack important information relating to safeuse of the device and this may lead to incorrect usage.It must be ensured that this user manual is alwayscomplete and legible and that any persons usingthe device have the user manual available.Legal guidelinesThe information in this manual corresponded tothe most recent status at the close of editing.The illustrations and descriptions cannot be used asgrounds for any claims relating to devices that havealready been delivered. Schaeffler TechnologiesAG & Co. KG accepts no liability for any damage ormalfunctions if the device or accessories have beenmodified or used in an inappropriate manner.Original user manualThis user manual is the original user manual inaccordance with the Machinery Directive 2006/42/EC.4BA 1Schaeffler Technologies

General safety regulationsThis chapter brings together all the important safetyregulations. Any person working with the transport andmounting tool BEARING-MATE must read this chapterand observe the guidelines.PrinciplesThe transport and mounting tool BEARING-MATEcorresponds to the current level of technology andthe recognised rules of safety practice.If the safety guidelines are not observed, risks to lifeand limb for the user or third parties and extensivedamage to other material assets may neverthelessarise during use.Schaeffler TechnologiesMarkingThe transport and mounting tool BEARING-MATE ismarked by means of a nameplate with a unique serialnumber.Usage for the intended purposeThe transport and mounting tool BEARING-MATE mayonly be used for the transport and mounting of heavy,rotationally symmetrical (round) parts such as rollingbearings.The transport and mounting tool BEARING-MATE mayonly be used in accordance with the technical data,see Technical data.Weights of more than 25 kg may only be lifted by2 persons or by means of a lifting aid (crane).The maximum lifting weight is 500 kg.BA 15

Further specifications: cylindrical outside surface non-separable bearing width of outer ring at least 60 mm width of outer ring no more than 270 mm.In the case of spherical roller bearings and selfaligning ball bearings, use long retaining brackets.Usage for the intended purpose also includesthe following: All safety guidelines in the user manual must beobserved All maintenance work must be implemented All relevant specifications on occupational safetyand accident prevention must be observed.6BA 1Usage not for the intended purposeThe transport and mounting tool BEARING-MATEmust not be used for the transport and mountingof separable bearings. It must not be used for thehandling of other workpieces.The steel strips must not be replaced by shorteror longer strips for use with bearings of a differentdiameter range.The transport and mounting tool BEARING-MATE mustnot be used for the handling of bearings with an oilyouter ring. Bearings with an oily outer ring may slip outof the tool when lifted.Schaeffler Technologies

WarrantyThe manufacturer shall assume liability for warrantiesin relation to operational security, reliability andperformance only under the following conditions: Mounting, connection, maintenance and repairsmust be carried out by authorised and skilledpersonnel. The transport and mounting tool BEARING-MATEis used in accordance with the explanations inthe technical datasheets. The limit values indicated in the technical data maynot be exceeded under any circumstances. Conversion and repair work on the transport andmounting tool BEARING-MATE may only be carriedout by the manufacturer.The following points must therefore be observed: Only authorised personnel should use the BEARINGMATE. Before use, this manual should be read. This user manual must always be followed precisely. The transport and mounting tool BEARING-MATEmay only be used for non-separable rolling bearings.It must not be used for the handling of otherworkpieces. Before any use, the transport and mounting toolBEARING-MATE must be checked for damage.If damaged, it must no longer be used. The transport and mounting tool must not be usedfor the lifting or handling of bearings with a weight ofmore than 500 kg.Safety guidelinesIncorrect use of the transport and mounting toolBEARING-MATE represents a potential risk.Schaeffler TechnologiesBA 17

When using the transport and mounting tool,suitable protective or safety equipment must beworn (safety boots, gloves and helmet). The bearing may only be lifted as high as is requiredby the application. If the bearing must be rotatedfrom the horizontal to the vertical or vice versa,this must always be carried out at the smallestpossible distance above the floor. Never stand under the bearing or place feet under it.Avoid all similar hazardous situations. The transport and mounting tool must not be usedwith accessories, such as a carrying sling, that aredesigned for a weight of less than 500 kg. If the transport and mounting tool is lifted by hand,this must always be carried out by two persons.In this case, the maximum weight must not be morethan 50 kg.8BA 1 Lifting with the transport and mounting tool mustnot be carried out using chains. No modifications may be made to the transport andmounting tool. The transport and mounting tool must be checkedin accordance with the local regulations at regularintervals. If you have any questions about the useof the transport and mounting tool, or if any uncertainties arise, please contact Schaeffler CustomerServices. The transport and mounting tool must not under anycircumstances be used for the handling of bearingswith an oily outer ring. Bearings with an oily outerring may slip out of the tool when lifted. The outerring must be thoroughly cleaned using a solvent orcleaning agent. For transport with the aid of a crane and usingcarrying slings, additional means of support(securing belt) must be used.Schaeffler Technologies

Schaeffler Technologies121400016B71Scope of deliveryThe scope of delivery comprises: transport and mounting tool BEARING-MATE two short inner ring holders one tube of grease user manual.The transport and mounting tool BEARING-MATEcomprises: two retaining grips with rotating handles two clamping strips (steel strips) two inner ring holders pictogram label.3BA 19

10BA 1500016B72Basic operationThe transport and mounting tool BEARING-MATE wasdeveloped in order to allow easier transport andmounting of heavy, rotationally symmetrical parts suchas rolling bearings. The transport and mounting toolBEARING-MATE is wrapped around the outer ring,with the two handles facing each other.Within the specified diameter ranges, the transport andmounting tool can be adjusted to the various bearingdiameters.After mounting, the bearing and BEARING-MATE form aunit . The two opposing handles allow secure liftingand transport of the bearing.In order to transport the unit comprising the bearingand BEARING-MATE by means of a crane, two suitablecarrying slings of equal length must be used.Schaeffler Technologies

Schaeffler TechnologiesL min1,5 45 D00016B73The carrying sling length (L) must correspond to at least1,5 times the bearing diameter (D).Before mounting, the unit can be rotated while it is suspended in the carrying slings. In this case, the handlesform the axis of rotation. The BEARING-MATE canthus be used for the whole handling procedure,from transport through to mounting.If the bearing is to be heated using an inductionheating device, it is not necessary to remove theBEARING-MATE.If heating is to be carried out using a flexible inductorand a medium frequency generator, the BEARING-MATEmust be removed.DBA 111

Suitable bearings00016B76ApplicationWarningObserve the maximum mass (m) and the permissibleoutside diameter of the rolling bearing (D), see label.Ensure that the outer ring is clean and free from greaseand oil.Further specifications of bearings: cylindrical outside surface non-separable bearing width of outer ring at least 60 mm width of outer ring no more than 270 mm.In the case of spherical roller bearings and selfaligning ball bearings, use long retaining brackets.12BA 1Schaeffler Technologies

00016B77Checking and cleaning the transport andmounting toolWarningIf the transport and mounting tool BEARING-MATEis damaged, it must not be used. Check whether all labels are present and easilylegible, see page 24. Before each use, inspect the steel strips andhandles for cracks, fractures, deformation, bends,notches, corrosion and wear. If the steel strips or handles are damaged,the complete tool must always be sent to CustomerServices. E-mail, see page 25. Extend the steel strips to maximum length andclean them thoroughly.CautionThe steel strips must be clean and free from grease andoil.Schaeffler TechnologiesBA 113

Cleaning of bearingsBefore applying the steel strips, the bearing outer ringmust always be cleaned.Clean the bearing outer ring: Remove grease and oil as well as any foreign matterfrom the outer ring. Dry the outer ring.14BA 100016BA5WarningA bearing with an oily outer ring may slip out ofthe transport and mounting tool BEARING-MATE.Ensure that the outer ring is dry.Schaeffler Technologies

00016B781200016B79UtilisationAfter cleaning the BEARING-MATE and outer ring,use the BEARING-MATE as follows: Place the steel strips centrally on the outer ring,see label . The bearing can be lying horizontally ormounted vertically on a shaft. Rotate the ends of the handles uniformly ina clockwise direction by hand until the steel stripsare firmly in contact with the bearing and are pulledin to the same extent. Observe the distancesbetween the labels and the ends of the handles. Tighten the screw heads on the ends of the handles,observing the correct tightening torque,see label . Use a torque wrench to check whether the finaltightening torque is between 14 Nm and 20 Nm.Schaeffler TechnologiesBA 115

00016B7AMounting the retaining bracketsIn the case of spherical roller bearings and self-aligningball bearings, the inner ring must be secured in place toprevent rotation.CautionThe retaining brackets must not extend beyondthe inner ring and must both be fitted on the sameside.Secure the inner ring: The bearing outer ring is marked on one side.Insert both retaining brackets on this side. Align the retaining brackets parallel until they arein contact with the inner ring. Tighten the retaining brackets.16BA 1Schaeffler Technologies

00016B7BFitting the carrying slingsWarningFor transport by means of a crane, use two carryingslings of equal length. Ensure that each carrying slinghas a carrying force of at least 1000 kg. Chains mustnot be used, see label.00016B7C Position the carrying slings between the contact faceand the flange, . The carrying sling length (L)must correspond to at least 1,5 times the bearingdiameter (D). Suspend the carrying slings on the crane hook.Before mounting of the bearing, the unit can be rotatedwhile it is suspended in the carrying slings.In this case, the handles form the axis of rotation.The transport and mounting tool BEARING-MATE canthus be used for the whole handling procedure,from transport through to mounting.1Schaeffler TechnologiesBA 117

WarningApply additional means of support (securing belt,carrying force at least 1000 kg), .Ensure that nobody is underneath the bearing at anytime during transport.Secure the hazard area.Transport the bearing without shocks or vibration.100016B7DTransport Transport the bearing to the mounting location.18BA 1Schaeffler Technologies

00016B7EMounting of bearings Rotate the bearing at the mounting location ifnecessary, . The handles serve as the axis whenrotating the bearing.CautionEnsure that the retaining brackets do not protrudebeyond the inner ring. Mount the bearing. Remove the retaining brackets. Loosen the handles and remove the transport andmounting tool BEARING-MATE.Schaeffler Technologies2BA 119

Place the bearing, with the BEARING-MATE stillmounted, on the induction heater. Heat the bearing inner ring to a maximum of 120 C. Before lifting the bearing off the heating device,check the tightening torque using a torque wrench(14 Nm to 20 Nm). Move the inner ring retainers into the correctposition.20BA 1000B6E18Heating of bearingsThe transport and mounting tool BEARING-MATE can besafely heated by means of induction heating devicesHEATER. The inner ring retainers must not be in contactwith the inner ring of the bearing, since this allows heatto be conducted to the outer ring.Schaeffler Technologies

Inspection and maintenanceInspectionThe transport and mounting tool must be inspectedat least once per year. The first inspection should becarried out one year after manufacture. If the relevantregulations require more frequent inspection, matchthe inspection period to the relevant regulations.Schaeffler Technologies0008741F Inspection must only be carried out by authorisedpersonnel. Check the date of manufacture, .13.06 indicates the year 2013, week 6. Before each use, inspect the tool for damage andin accordance with local regulations. Prepare and archive an inspection record:date of inspection, results (free from defects ordescription of any defects), name and position ofthe inspector.BA 121

MaintenanceRegular maintenance prevents excessive wear andincreases the expected life. Every 6 months, lubricate the clamping strips atthe 4 entry points using Arcanol MULTI2, .22014 2015 201622BA 1000874432Schaeffler Technologies

AppendixTechnical dataShort170 mmBEARING-MATELong270 mmLoad carrying capacityInner ring retainer (length)500 kgBEARING-MATE250-450Minimum diameter250 mmMaximum diameter450 mmMass6,3 kgBEARING-MATE450-650Minimum diameter450 mmMaximum diameter650 mmMass6,5 kgBEARING-MATE650-850Minimum diameter650 mmMaximum diameter850 mmMass6,7 kgBEARING-MATE850-1050Minimum diameter850 mmMaximum diameter1050 mmMassSchaeffler TechnologiesConversion, repairAny modifications such as conversion or incorrectrepair of the transport and mounting tool BEARINGMATE can lead to hazards for the user.WarningThe transport and mounting tool BEARING-MATEmust not be modified; conversion and repair are notpermissible.Repairs may only be carried out by SchaefflerCustomer Services.CertificatesThe transport and mounting tool BEARING-MATEhas been inspected by TÜV Product Service GmbH.A copy is available on request.6,9 kgBA 123

2000B486C183BEARING-MATE250-450 FAG BEARING-MATE250-450Schaeffler Technologies AG & Co. KGGeorg-Schäfer-Straße 3097421 SchweinfurtGermanyFAG BEARING-MATE450-6504BEARING-MATE450-650 Accessories and spare partsSchaeffler offers accessories and spare parts forthe BEARING-MATE.Accessories: Two long inner ring retainers, Ordering number: BEARING-MATE.LOCKBAR270.Spare parts: Two short inner ring retainers, Ordering number: BEARING-MATE.LOCKBAR170. Service kit:Ordering number: BEARING-MATE.SERVICE-KIT– One 20 g tube of Arcanol MULTI2, (can also be ordered separately:ARCANOL-MULTI2-20G)– Two pictogram labels each forBEARING.MATE250-450 BEARING.MATE450-650 BEARING.MATE650-850 BEARING.MATE850-1050 – Four labels End of strip pull-in.Schaeffler Technologies AG & Co. KGGeorg-Schäfer-Straße 3097421 SchweinfurtGermany5BEARING-MATE650-850Schaeffler Technologies AG & Co. KGGeorg-Schäfer-Straße 3097421 SchweinfurtGermany6BEARING-MATE850-1050 FAG BEARING-MATE850-1050Schaeffler Technologies AG & Co. KGD 850-1050 mm24BA 1Georg-Schäfer-Straße 3097421 SchweinfurtGermany7000AA0F2 FAG BEARING-MATE650-850Schaeffler Technologies

Declaration of ConformityA copy of the EU Declaration of Conformity in originalsize is available on request.000B6E43ContactE-mail: industrial-services@schaeffler.comSchaeffler TechnologiesBA 125

MATNR 035819995-0000 / BA 01 / 01 / GB-D / 201809 / pdf onlySchaeffler Technologies AG & Co. KGGeorg-Schäfer-Straße 3097421 SchweinfurtGermanyInternet www.schaeffler.com/servicesE-mail industrial-services@schaeffler.comIn Germany:Phone 0180 5003872Fax0180 5003873From other countries:Phone 49 9721 91-0Fax 49 9721 91-3435Every care has been taken to ensure thecorrectness of the information containedin this publication but no liability canbe accepted for any errors or omissions.We reserve the right to make technicalchanges. Schaeffler Technologies AG & Co. KGIssued: 2018, SeptemberThis publication or parts thereof may notbe reproduced without our permission.BA 01 GB-D

mounting tool BEARING-MATE must read this chapter and observe the guidelines. Principles The transport and mounting tool BEARING-MATE corresponds to the current level of technology and the recognised rules of safety practice. If the safety guidelines are not observed, risks to life and limb for the user or third parties and extensive