Transcription

X-ray Inspection Systemsfor ensuring product safety, integrity and qualityX-ray inspection systems from Minebea Intec support compliance with industry standards such as HACCP,IFS and BRC, protect brand reputation and avoid costly product recalls.

// 2X-ray Inspection SystemsWe make daily life saferMinebea Intec, formerly known as Sartorius Intec,provides products, solutions and services to theindustry for increasing the reliability, safety andefficiency of production and packaging lines. Thiswe give evidence through our promise to ourcustomers and consumers:‘We make daily life safer.’Our core market position, that of a leadingglobal product and solution provider together withour aim to set strong standards in all areas of ourbusiness, are both reflected in our company motto:‘The true measure’.We have almost 70 years experience in supportingthe industry to ensure that manufactured goodshave the right quality and do not contain anyforeign bodies. Our ability to do this is based onthe ‘German Quality’ of our products and servicescombined with our continuous investment indeveloping leading technology. As a result, tensof thousands of customers put their trust in ourcompany, having allowed us to supply them withmillions of products and solutions during our longhistory.Via our world-wide presence, we stand beside ourcustomers around the globe and through the wholelife cycle of our products and solutions; fromassistance with selecting the right equipment,design-in support, installation & calibration andmaintenance & repair services, up to realisingequipment upgrades and refurbishments andproviding user trainings.The Minebea GroupThe Minebea Group is a global precisionelectromechanical components manufacturer,providing products for various industries. Minebeawas founded in 1951 in Japan and today has morethan 70,000 employees as well as production andsales & service facilities in 20 countries around theglobe. For many products, The Minebea Group isNo. 1 in terms of global market share.For more information on Minebea Intec, our productsand services or for locating our office and partners inyour country, please visit www.minebea-intec.com.Minebea Intec Sales - ServiceMinebea Intec Production - Sales - ServiceDistribution Partners

// 4X-ray Inspection SystemsInvesting in an X-ray system pays off‘Minebea Intec X-ray inspectionsystems help me protect thereputation of our brand andavoid costly product recalls.’The use of X-ray inspection systems in the food industry has significantly increased over the lastyears as they have proven to be a good investment for ensuring product safety, integrity andquality. Their ability to detect products containing foreign bodies and remove these reliably from theproduction or packaging line, supports compliance with industry standards such as HACCP, IFS andBRC, protects brand reputation and avoids costly product recalls.While identifying products contaminated with metal, glass, rubber, stone, dense plastics orcalcified bone, X-ray inspection systems can simultaneously perform in-line quality checks,including measuring mass, counting components, identifying missing or damaged products,monitoring fill levels and inspecting seal integrity.Minebea Intec offers a wide range of X-ray inspection systemsfor different applications. All systems feature: Intuitive operator control through an icon based user interface. Products can easily beset up or adjusted by line operators without requiring special training or previous X-rayknowledge and without the involvement of an engineerScan the QR code and watch the video to convince yourself of ourintuitive user interfacewww.minebea-intec.com/en/videos/interface Outstanding detection performance while ensuring maximum line speeds Multi-lane solutions for up to eight lines through one detector Integrated network compatibility, allowing remote access by techniciansfor quick error diagnosis and support Powerful interfaces, including USB and Ethernet, allow an easy integration into data networksTo learn more about X-rayinspection in general, downloadour White Paper here!Quick and tool-less belt release for ensuring minimum down time whencleaning or changing belts. Scan the QR code and see how it .x-ray-inspection.info/en

// 6X-ray Inspection SystemsX-ray inspection systems forpackaged food productsDylightMinebea Intec offers a complete portfolio of X-ray systems for inspecting packagedproducts. Typical applications include cartons, boxes, pouches, bags, trays andsachets that can contain a wide variety of dry or liquid food products. The modelsDylight and Dymond are specifically designed for these applications and feature:The Dylight X-ray inspection system is a true ‘Plug andPlay’ solution, combining all functions in one compactunit. It is perfectly suited for the inspection of smallproducts such as snacks, energy bars and sweets.Further features include: Hygienic Extremely small width of only 1 metre, allowingdesign, following EHEDG principles featuring sloped surfaces andcurved edges allowing easy inspection and cleaning, resulting in considerabletime and cost savings Combining high detection sensitivity with low power consumption 15” colour touchscreen display Covering belt widths from 200 mm up to 800 mm A wide range of standard possibilities for ensuring productintegrity and quality, including:Hygienic Designyou to integrate the unit in your packagingline, even when only very limited floor space isavailable Complete with integrated reject mechanism andcollection container for contaminated or faultyproductsDylightDymond 80/120/160Checking completenessDetermining product massThe Dymond Series of X-ray inspection systems is extremelyversatile. Featuring 3 models it is able to cover the majorityof applications for inspecting packaged products. With beltwidths up to 800 mm it is ideal for multi-lane applications ofup to 8 traces.Determining compartment mass Are you looking to check specific quality attributes on your products?Please ask us. Through our Engineering Support services we offer individualsoftware solutions for this.For more information on Minebea Intec, our productsand services or for locating our office and partners inyour country, please visit www.minebea-intec.com.Dymond 80Dymond 120Dymond 160

// 8X-ray Inspection SystemsX-ray inspection systemsfor large packagesX-ray inspection systems for tall containerssuch as bottles, cans and jarsWith increasing product size and material density, high energy systems are requiredto ensure a reliable detection of foreign bodies. This is what the Dyxim FB Series offers.With the Dymond S, Dyxim S and Dyxim D, Minebea Intec offers a comprehensive product portfoliofor inspecting tall containers. Next to reliably identifying products contaminated with foreign bodies,these systems can simultaneously perform in-line quality checks, e.g. monitoring of fill-levels.Dyxim FB For inspecting large packages such as sacksand boxes up to a size of 700 mm x 360 mmcontaining dry or liquid food products While identifying product contaminations, theFB Series can simultaneously perform in-linequality checks, including measuring mass,counting components and identifying missingor damaged productsDymond SThe Dymond S combinines high detectionsensitivity with low power consumption. Theunit is optionally available with a so-calledchicane belt. Ideal for those situations whereonly very limited space is available.Dyxim SThe Dyxim S is a high power system for reliablyinspecting tall containers at very high speeds.Dyxim DThe Dyxim D is a dual beam X-ray inspectionsystem that produces two X-ray images at a90 angle. This improves the ability to detectcontaminations in plastic and glass containers,jars and bottles particularly in comparison tosingle beam systems. Below pictures showsome of the situations in which the Dyxim Dproves its value.Raised bottomsLarge thin foreign bodiesInspection along the glass wallThe dual beam X-ray inspection systemprevents blind areas when inspectingglass jars.Reliable detection of a thin glass sliver,most likely not detected with a singlebeam system.Small foreign bodies near the glass arereliably detected with a dual beam system.Dyxim FB

// 10 X-ray Inspection SystemsConfiguration options andcomplementary productsCustomer individual solutionsToday’s wide variety of different food products are being offered in an evenlarger variety of packagings, each having individual requirements when itcomes to product handling, contamination detection and the checking of qualityattributes.Rejector systemsAlthough our standard systems offer extreme flexibility, in some cases bespokesolutions or in-depth consultancy are required. Our in-house EngineeringSupport team offers both. They can also provide you with design-in support forintegrating our machines or solutions into your production or packaging line.Specifically for foreign body detection applications, they can run tests with yourproducts, advising you of achievable detection sensitivities.As part of our X-ray inspection solutions we offer a widerange of high-speed rejector systems for guaranteeinga reliable and effective removal from the line in case of adetected contamination or a non-compliance of a productattribute. The rejector systems include the followingpossibilities: pusher, blower, swivel arm, flap/trapdoor,telescopic retract conveyors and multi-lane rejection systems.Test piecesMost quality management systems require a regular testing ofthe detection performance of your X-ray inspection system.We can provide you with a comprehensive range of certifiedtest pieces that ensure that you collect accurate andconsistent validation data. The test pieces are available in avariety of materials and sizes for use in any X-ray inspectionapplication. All Minebea Intec test pieces are of course madeof FDA approved materials.SPC@EnterpriseThe statistical process controlsoftware SPC@Enterprise helps yousecure product quality, food safetyand productivity.The proven software offersconfigurable interfaces for recordingdata from a wide variety ofmachines, equipment and sensors inthe processing or packaging line. Ittransforms this data into informationvia powerful and comprehensivereporting functions, making itpossible to react instantly if andwhen required.

// 12 X-ray Inspection SystemsOur product portfolioBulk material receipt & storageGoods inPiece goods receiptAccurate control of incomingand stored materialsAutomated ProductionAchieving totalprocess controlManual ProductionErgonomic solutions ensuringaccuracy and traceabilityEnsuring product qualityand food safetyGoods outGuaranteeing finalproduct qualityMetal DetectionBatching SolutionsTruck Scale Components and SolutionsPackagingFloor ScalesPortioning & CheckweighingSilo Weighing SolutionsCheckweighingBulk Material Metal Detection SystemsFloor ScalesWe provide products, solutions and services to theindustry for increasing the reliability, safety and efficiencyof production and packaging lines. Our portfolio coversapplications from goods-in to goods-out, includingautomated as well as manual processes and filling andpackaging.Process Vessel Weighing(standard/digital solutions)Formulation & Manual Recipe WeighingX-ray InspectionFilling SolutionsProcess Vessel Weighing(hygienic solutions)Statistical Process ControlHigh Capacity Checkweighing

// 14 X-ray Inspection SystemsMaintenance and repair – ensuringequipment availability and performanceOur services Equipment calibration or verification to legalmetrology and measurement standards Preventative maintenance safeguarding continuedavailability and performance Repair services, including emergency servicecontracts for a guaranteed response timeVia our world-wide presence, we stand beside our customersaround the globe and through the whole life cycle of ourproducts and solutions: from assistance for selecting the rightequipment up to realising upgrades and refurbishments andproviding user trainings. Remote servicesUpgrades – prolonging equipment lifetime and boosting performance Hardware and software upgrades Equipment refurbishmentEngineering Support – ensuring optimal solutions Consultancy assistance for selecting optimal products or solutions in terms ofTraining – enhancing staff capabilitiesrequired performance, accuracy and cost Design-in support for integrating our products and solutions into your Customisation: products or solutions designed to suit your individual needsequipment, installation or production lineStart-up – ensuring equipmentperformance and on timeproduction commencement Mechanical and/or electrical installation,commissioning, set-up and user instruction Equipment calibration or verification to legalmetrology standards Equipment qualification (IQ/OQ) User trainings covering daily operation and/or repair Seminars providing knowledge on regulationsand technologies

We make daily life saferPublished bySartorius Mechatronics C&D GmbH & Co. KG Am Gut Wolf 11 52070 Aachen, GermanyPhone 49.241.1827.0 Fax 49.241.1827.210 Email info@minebea-intec.comwww.minebea-intec.com

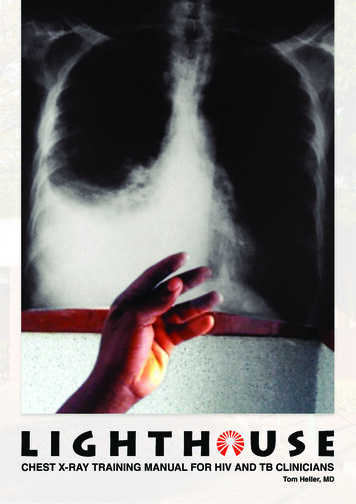

The Dyxim D is a dual beam X-ray inspection system that produces two X-ray images at a 90 angle. This improves the ability to detect contaminations in plastic and glass containers, jars and bottles particularly in comparison to single beam systems. Below pictures show some of the situations in which the Dyxim D proves its value. X-ray .

![[AWS Black Belt Online Seminar] AWS X-Ray](/img/17/20200526-blackbelt-x-ray.jpg)