Transcription

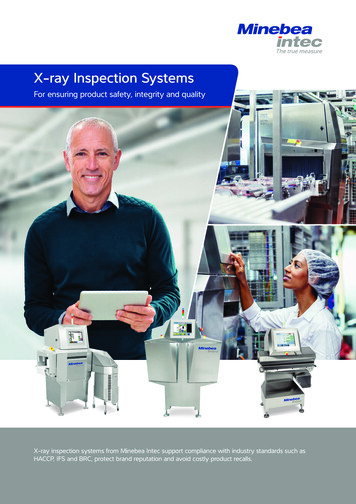

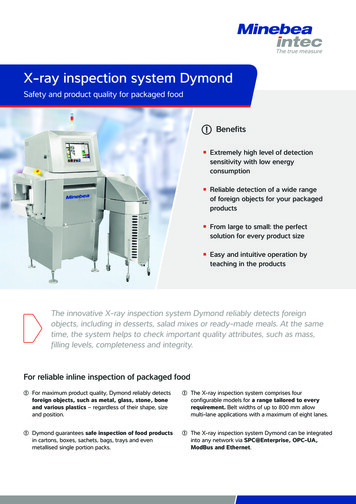

X-ray inspection system DymondSafety and product quality for packaged foodBenefits Extremely high level of detectionsensitivity with low energyconsumption Reliable detection of a wide rangeof foreign objects for your packagedproducts From large to small: the perfectsolution for every product size Easy and intuitive operation byteaching in the productsThe innovative X-ray inspection system Dymond reliably detects foreignobjects, including in desserts, salad mixes or ready-made meals. At the sametime, the system helps to check important quality attributes, such as mass,filling levels, completeness and integrity.For reliable inline inspection of packaged foodFor maximum product quality, Dymond reliably detectsforeign objects, such as metal, glass, stone, boneand various plastics – regardless of their shape, sizeand position.The X-ray inspection system comprises fourconfigurable models for a range tailored to everyrequirement. Belt widths of up to 800 mm allowmulti‑lane applications with a maximum of eight lanes.Dymond guarantees safe inspection of food productsin cartons, boxes, sachets, bags, trays and evenmetallised single portion packs.The X-ray inspection system Dymond can be integratedinto any network via SPC@Enterprise, OPC-UA,ModBus and Ethernet.

Dymond – Inline inspection and integration into your networksAll of the Dymond series X-ray inspection devices guarantee reliable vertical inspection. Foreign objects made frommetal, glass, stone, bone and various plastics are detected inside food packaging and eliminated from the production line.A broad range of standard functions also ensure product integrity and quality, for example throughcompleteness checksproduct weighingdetermining weight of individual areasIntegrationEasy integration into your productionThe Dymond series systems can be quickly and easily integrated into your production forsystematic checking and analysis of machine and line performance. We offer interfaces toSPC@EnterpriseOPC-UAModbusEthernetSPC@Enterprise from Minebea Intec converts measured datainto useful information, which helps to ensure product quality, food safety and productivity.

The Dymond series sets a new standard in X-ray inspection for food with crystal-clear X-rayimages, a high degree of accuracy and low energy costs – all available in four different machine sizes.Simply choose the right solution for your products.Available withOPC-UA andconnection toSPC@EnterpriseDymond 40Front viewX-ray beam geometry800650Product height15015801490Product width90100120501490175Width of conveyor belt: 200 mmbis zu 200 mm784784184097014908006501840Rear view8006505071500200507bis zu 200 mm784149018402001500970bis zu 200 mmSide view15801580Dymond 40, 80, 120, 160 scale drawings1500200507

Dymond 80X-ray beam geometryProduct height1803250360Width of conveyor belt: 400 mm1430up to 200 mm784Rear view1500200148528940020050up to 200 mm143017701580784800 0400up to 200 mm1770 5004002001580up to 200 mm1770100Side viewProduct 580Front view

Dymond 120Front viewX-ray beam geometryProduct width323340Product 0524570Width of conveyor belt: 600 mm6000Rear view8002000650500700780up to 200 90Side view600700365780up to 200 mm1730199020001610780up to 200 mm173019901715

Dymond 160X-ray beam geometryProduct height800650Product 728.58759.611770819.2019608006501530Front viewbis zu 200 mmRear view1800180050090088019608801770780500780bis zu 200 mmSide view900780780Width of conveyor belt: 800 mm

Technical specificationsTechnical data – X-ray inspection system DymondDymond 40Dymond 80Dymond 120Dymond 160X-ray power70 kV, 1.2 mA70 kV-1.2 mA80 kV-2 mA80 kV, 2 mA90 kV, 3.5 mADetector resolution0.4 mm (standard)0.8 or 0.4 mm0.8 mm (standard)0.8 mm (standard)Belt speed range10 to 49 m/min(with standard drum motor)/up to 73 m/min10 to 49 m/min(with standard drum motor)/up to 73 m/min10 to 49 m/min(with standard drum motor)/up to 79 m/min10 to 49 m/min(with standard drum motor)/up to 79 m/minApprovalsCE, UL/ CSACE, UL/ CSACE, UL/ CSACE, UL/ CSASafety locksSIL 3 Category IV PL e,magneticSIL 3 Category IV PL e,magneticSIL 3 Category IV PL e,magneticSIL 3 Category IV PL e,magneticUser interface15-inch touchscreen15-inch touchscreen15-inch touchscreen15-inch touchscreenOperating temperature 5 C to 40 C withair cooling / 5 C to 30 Cwithout air cooling 5 C to 40 C 5 C to 40 C 5 C to 40 CMachine cooling500 W air cooling(optional with Nema4X / IP65)500 W air cooling(optional with Nema4X / IP65)500 W air cooling(optional with Nema4X / IP65)500 W air cooling(optional with Nema4X / IP65)Relative air humidity20% to 90%, no condensation20% to 90%, no condensation20% to 90%, no condensation20% to 90%, no condensationDigital outputs4 available4 available4 available4 availableDigital inputs7 available7 available7 available7 availableUSB portYesYesYesYesNetwork ed air5.5 to 6.9 bar5.5 to 6.9 bar5.5 to 6.9 bar5.5 to 6.9 barRadiation protectionFDA CFR 21 part 1020.40(additional regionalcertifications available fromthe manufacturing plant)FDA CFR 21 part 1020.40(additional regionalcertifications available fromthe manufacturing plant)FDA CFR 21 part 1020.40(additional regionalcertifications available fromthe manufacturing plant)FDA CFR 21 part 1020.40(additional regionalcertifications available fromthe manufacturing plant)International protection classIP 34 (standard) / IP 65 withNema4X air cooling / IP69Kon requestIP 34 (standard) / IP 65 withNema4X air cooling / IP69Kon requestIP 34 (standard) / IP 65 withNema4X air cooling / IP69Kon requestIP 34 (standard) / IP 65 withNema4X air cooling / IP69Kon requestElectrical supply230 V AC 10% (standard) /190 to 240 V AC 50/60 Hz230 V AC 10% (standard)230 V AC 10% (standard) /190 to 240 V AC 50/60 Hz230 V AC 10% (standard) /190 to 240 V AC 50/60 HzMax. product sizeSee X-ray beam geometry.Possibly lower throughprotective curtains.See X-ray beam geometry.Possibly lower throughprotective curtains.See X-ray beam geometry.Possibly lower throughprotective curtains.See X-ray beam geometry.Possibly lower throughprotective curtains.Max. throughput*, dependingon product length80 m/minute40 m/minute40 m/minuteMax. power consumption16 A16 A16 A16 AWeight(standard configuration)450 kg500 kg600 kg680 kgHeight800–999 mm800–999 mm800–999 mm800–999 mm40 m/minute or 80 m/minute*depending on riseRemote controlBarcode readerAcoustic signal emitterService contractsExtended warrantiesSeparation andfill level monitoringAir pressure monitoringLateral guidesOptionsVarious additional optionsSafety guards

Ejection systemsX-ray inspection system with pulse blow out ejectorX-ray inspection system with pusherStandard collection containerExample:Collection containerDymond 80Depending on model and product length, variouslockable collection containers are available.Digital lock also available.The technical data given serves as a product description only and should not be understoodas guaranteed properties in the legal sense.Specifications subject to change without notice.Last updated 03/2019Minebea Intec Aachen GmbH & Co. KGAm Gut Wolf 1152070 Aachen, GermanyPhone -intec.com

Front view X-ray beam geometry The Dymond series sets a new standard in X-ray inspection for food with crystal-clear X-ray images, a high degree of accuracy and low energy costs - all available in four different machine sizes. Simply choose the right solution for your products. Dymond 40, 80, 120, 160 scale drawings Side view Rear view .

![[AWS Black Belt Online Seminar] AWS X-Ray](/img/17/20200526-blackbelt-x-ray.jpg)