Transcription

Continuing Education Contact Hours Participants must complete the entire presentation/seminarto achieve successful completion and receive contact hourcredit. Partial credit will not be given. STERIS Corporation is an approved provider of continuingnursing education by the CBRN (provider # CEP 11681) for 1contact hour along with CBSPD and IAHCSMM.Wet Packs:How to Prevent Them All of the presenters are employees of STERIS Corporationand receive no direct compensation other than their normalsalaries for participation in this activity. STERIS Corporation is providing the speakers and contacthours for this activity. However, products referred to or seenduring this presentation do not constitute a commercialsupport by the speakers.Learning ObjectivesWhat Is A Wet Pack?Upon completion of this presentation, you will be able to:A wet pack is a, “Package or container with moistureafter the sterilization process is completed.” Recognize and identify potential causes of wet packsin steam sterilization Describe preventative measures in order to abate wetpacksIAHCSMM (2016)What does that really mean?A wet pack means: Compose and incorporate quality audittools/measures to negate wet packs Potential for microorganism penetration Unsterile pack Indication of changeSteam Sterilization:Key ComponentsSteam Sterilization: MechanicalMechanical: Steam delivery system Sterilizer performanceEnvironment: Room temperature and humidity Steam delivery system‒ Boiler/Generator Sterilizer performance (Autoclave)Human: Daily equipment inspection Preparation and packaging Load content and configuration1

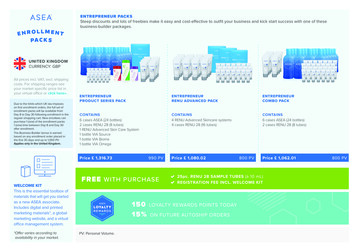

Boiler SchematicThe BOILERBoiler Components1.a1.b2.03.a3.bWater Level RodWater Level FloatSight GlassManual Blow Down ValveSkimmer ValveSteam Generator4.a4.b5.a5.b6.0Manual Chemical FeedAutomatic Chemical FeedBoiler Internal BaffleBoiler Take-OffPressure GaugeSterilizerVisual Inspection (Daily): Chamber Improperly Leveled The Steam Generator createsthe steam required for thesterilization process. An improperly functioningsteam generator can causewater to enter the chamber andmay contribute to wet packs. Steam traps and strainers non-operational Chamber steam baffle failure or removal Sterilizer door Loading car/cartBe aware of: Steam to Chamber valve leakage Chamber drain valve or check valve leakage Sterilizer improper calibration Steam generator operation & Steam pressure regulatorSteam Sterilization: EnvironmentSteam Sterilization: Human Heating, ventilation, and air condition (HVAC) Monitor HVAC performance parameters Daily equipment inspection Small variance vs. large variance Preparation and packaging Conduct a risk assessment when parametervariance occurs Load content and configuration2

Daily InspectionPreparation and Packaging:Complex ProcessPreparation: PackagingMaterial SelectionPackaging Material Allow air removal, steampenetration, and steam removal Provide a barrier againstmicroorganisms Be compatible with the intendedsterilization methodsPreparation: Basin Set Place all basins in the samedirection Nested utensils separated withnonlinting absorbent material Permit air removal, steampenetration and removal Sterilization Wraps– Woven– Non-woven Paper-Plastic Pouches Rigid ContainersInstrument Set Preparation Instruments should be:‒ Clean and dry‒ Inspected for cleanliness anddamage‒ Assembled; and packagedaccording to IFU3

Instrument Sets: Configuration Use compatiblecontainers/organizing accessories Position instruments to allow sterilantcontact with all surfaces Open lumened ports Unlatch ratcheted instruments Use tip-protectors Do not use rubber bands to secureinstrumentsInstrument Set: Configuration, continued Concave or flat surfaces should beplaced on edge Place heavy instruments so as not todamage delicate items Position lighter items to protect tips andprevent damage from changes inposition Sets should not weigh 25 lbs. Use approved organizing containers andaccessories Use appropriate sized instrument tray Ok to use approved matInstrument Set ContentsWoven Wraps Instruments must be dry Woven wrap density Open box locks (stringers) Consult newer textile manufacturers Even instrument distribution Disassemble instruments– Preparation instructions– Sterilization parameters Alternate heavy handle instruments Organizing accessories may used if: Designedand intended for sterilizationEvents During theSterilization ProcessHeat Transfer Heat Transfer Condensation Re-vaporization4

CondensationRevaporizationSterilization Process Steam contacts metal surface Heat energy absorbed by metal Steam becomes waterLoading the Sterilizer Acceptable absorbent shelf liners Consult manufacturer’s instructions for useSterilization Process Drying Water becomes steam Steam removed from chamberLoading the Sterilizer, continued Do not allow items to touchchamber walls User sterilizer cartswhenever possible Thoroughly cool items onsterilizer carts Avoid overloading Position correctlyLoading the Sterilizer, continued Separate loads if possible Mixing load contentsLoading the Sterilizer, continuedWhen mixing load contents: Textiles on top shelves on edge Wrapped hard goods below Containers below hard goods Instrument trays placed flat on shelves Basin sets tilted and on edge Use baskets to contain small items5

Basin Sets – On Edge TiltedTextile PacksLayers Perpendicular to ShelfNot correctPaper/Plastic Peel Poucheson EdgePlacement of Peel Pouches34 pouches6

Unload the Sterilizer: When? Leave in chamber or pull out Allow items to thoroughly cool on cart Prevent condensationUnload the Sterilizer: Where?Examining Individual PacksDo not place hot or warm items On cold surfaces In boxes / bins Stacked on top of each other Plastic dust covers External Internal7

What Should Be Done When aWet Pack is Discovered?Wet Pack LogStop: Stop the processing of any additional loads Begin investigation Document the occurrence Keep and maintain a wet pack log/recordInvestigate Operator Error Equipment MalfunctionTroubleshooting External MoistureTroubleshooting Internal MoistureLocalized moisture Poor steam quality Check valve failureDispersed moisture Metal Mass: Entrapment and locationof moisture Load configuration Sterilizer malfunction Absorbed moisture within a pack Poor technique Documentation Collaboration with OR Drying phaseExamining Individual Packs General Rule for examining warm fabrics: Do not check until thoroughly cool Ignoring the General Rule then:– Open the pack– Shake them (fabric) out– Feel for moistureWet Pack Prevention: Collaboration Identify contributors to the steam sterilizationprocess– Engineerso Facility, Maintenance, Plant, Clinical or Biomed Equipment manufacturer’s service technician orrepresentative SPD leadership, educator, and staff (operators) Infection Preventionist Quality Assurance personnel8

Wet Pack Prevention: Audits EquipmentAudit: EquipmentDepartment Checklist Steam delivery system Process Autoclave EnvironmentAudit: ProcessPersonnel Sterile Processing Supervisors Sterile Processing Personnel Steam supply competitionProcess Audit:Sterilizer Processing Personnel Supervisory StaffPreparation and Packaging Assembly Packaging Loading/unloadingPolicy and ProcedureProcess Audit:Preparation and PackagingProcess Audit:Preparation and Packaging, continuedReview Processes Assembly Wrapping Loading/Unloading9

Process Audit:Policy and ProcedureProcess Audit: EnvironmentPolicies and Procedures:– Clear Seasonal maintenance– Organized Construction– Easily followed Renovation projectsStates recall procedures Temperature and humidity– Staff education– Is in accordance with current recommended standardsand guidelinesAction ItemsPrevention is key: Appropriate training Correct Package Selection Collaboration with Facility’s engineers/service reps– Routine maintenance schedule Daily inspection Proper prep and pack Proper load configuration, unloading and storageWhen wet packs occur: Document and investigateReferences Schule, R.W., (2012). Your next steam sterilization moisture event.Healthcare Purchasing News, (para. 5). Retrieved df Science Learning Hub (n.d.). Heat energy. Retrieved nce-Ideas-andConcepts/Heat-energyReferences Association for the Advancement of Medical Instrumentation(2013). ANSI/AAMI ST77 containment devices for reusablemedical device sterilization. Arlington, VA: Author. Association for the Advancement of Medical Instrumentation(2017). ANSI/AAMI ST79 comprehensive guide to steamsterilization and sterility assurance in health care facilities.Arlington, VA: Author. International Association of Healthcare Central Service MaterielManagement (2016). Central Service Technical Manual (8th ed.).Chicago, IL: Author. Rutala, W. A., Weber, D. J., (2000). Choosing a sterilization wrapfor surgical packs. Infection Control Today. Retrieved packs.aspxEvaluation and Summary Thank you for attending this CE activity Please complete and submit the evaluation form STERIS Corporation (2003). Preparing instruments, utensils, andtextiles for sterilization and wet pack problem solving. Mentor, OH:Author STERIS University (2014). Wet Pack Trouble Shooting Workbook(p. 2). Mentor, OH: Author10

QuestionsHandoutsTo access the handouts for this presentation, visit:university.steris.com/wpGo omPlaying a part in your professional development todayTo help you achieve your career vision for tomorrow11

Compose and incorporate quality audit tools/measures to negate wet packs What Is A Wet Pack? A wet pack is a, "Package or container with moisture after the sterilization process is completed." IAHCSMM (2016) What does that really mean? A wet pack means: Potential for microorganism penetration Unsterile pack Indication of change