Transcription

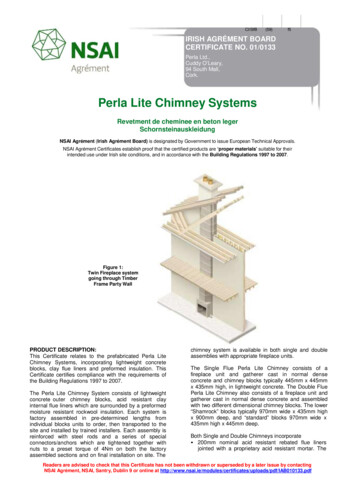

CI/SfB(59)f5IRISH AGRÉMENT BOARDCERTIFICATE NO. 01/0133Perla Ltd.,Cuddy O’Leary,94 South Mall,Cork.Perla Lite Chimney SystemsRevetment de cheminee en beton legerSchornsteinauskleidungNSAI Agrément (Irish Agrément Board) is designated by Government to issue European Technical Approvals.NSAI Agrément Certificates establish proof that the certified products are ‘proper materials’ suitable for theirintended use under Irish site conditions, and in accordance with the Building Regulations 1997 to 2007.Figure 1:Twin Fireplace systemgoing through TimberFrame Party WallPRODUCT DESCRIPTION:This Certificate relates to the prefabricated Perla LiteChimney Systems, incorporating lightweight concreteblocks, clay flue liners and preformed insulation. ThisCertificate certifies compliance with the requirements ofthe Building Regulations 1997 to 2007.The Perla Lite Chimney System consists of lightweightconcrete outer chimney blocks, acid resistant clayinternal flue liners which are surrounded by a preformedmoisture resistant rockwool insulation. Each system isfactory assembled in pre-determined lengths fromindividual blocks units to order, then transported to thesite and installed by trained installers. Each assembly isreinforced with steel rods and a series of specialconnectors/anchors which are tightened together withnuts to a preset torque of 4Nm on both the factoryassembled sections and on final installation on site. Thechimney system is available in both single and doubleassemblies with appropriate fireplace units.The Single Flue Perla Lite Chimney consists of afireplace unit and gatherer cast in normal denseconcrete and chimney blocks typically 445mm x 445mmx 435mm high, in lightweight concrete. The Double FluePerla Lite Chimney also consists of a fireplace unit andgatherer cast in normal dense concrete and assembledwith two different dimensional chimney blocks. The lower“Shamrock” blocks typically 970mm wide x 435mm highx 900mm deep, and “standard” blocks 970mm wide x435mm high x 445mm deep.Both Single and Double Chimneys incorporate 200mm nominal acid resistant rebated flue linersjointed with a proprietary acid resistant mortar. TheReaders are advised to check that this Certificate has not been withdrawn or superseded by a later issue by contactingNSAI Agrément, NSAI, Santry, Dublin 9 or online at f/IAB010133.pdf

flue liners are surrounded with a high temperaturemoisture resistant rockwool insulation. Glass Reinforced Concrete corbels, Glass ReinforcedPlastic covers and prefabricated dense concretecapping units.USE:The Perla Lite Chimney Systems are designed to offerfast and efficient erection on site and are suitable for alltypes of domestic heating appliances. The systems aredesigned for use with both open fire and closedappliances with an output of up to 45kW and fueled bygas, oil or solid fuel consisting of coal, manufacturedsolid fuel, wood or peat. The systems are suitable foruse in domestic prefabricated buildings such as Timberand Steel frame as well as traditional masonryconstruction.Only one fuel appliance should be connected to eachflue. Where the Double Perla chimney system is used inparty walls in prefabricated steel and timber frameconstruction, the party walls of the system must bedesigned to accommodate the Perla chimney system.It is essential that all Perla Lite Chimney Systems areassembled and installed in accordance with therequirements of this Certificate and the manufacturer’sinstructions.MANUFACTURE:The Perla Lite Chimney Systems a re manufactured,distributed and erected under licence by:Croom Concrete Ltd.,Off Church Road, Croom, Co. Limerick.Tel: 061 397479Fax: 061 397479Email: sales@croomconcrete.ieO’Rourke BrosQuarry Products Ltd., Poulregan,Castlebridge, Co. Wexford. Tel: 05359297Fax: 053 59300Email:P Plunkett Concrete Ltd.,Williamstown, Finea, Co. Westmeath.Tel: 043 81240Fax: 043 81380Part One / Certification11.1 ASSESSMENTIn the opinion of NSAI Agrément, the Perla Lite ChimneySystems if used in accordance with this Certificate canmeet the requirements of the Building Regulations 1997to 2007, as indicated in Section 1.2 of this Certificate.1.2 BUILDING REGULATIONS 1997 to 2007REQUIREMENT:Part D – Materials and WorkmanshipD3 – The materials used in the Perla Lite ChimneySystems, as certified in this Certificate, are comprised ofproper materials fit for their intended use (see Part 4 ofthis Certificate).D1 – The Perla Lite Chimney Systems when used inaccordance with this Certificate can satisfy therequirements for workmanship.Part A - StructureA1 – LoadingThe Perla Lite Chimney Systems, when installed inaccordance with this Certificate and the manufacturer’sinstructions, have adequate strength and stability andcan satisfy this Regulation provided that they arecorrectly installed and supported and the maximumheight restrictions are observed as referenced in thisCertificate (see Parts 2 and 3 of this Certificate).Part B – Fire SafetyB3 (1) – Internal Fire Spread (Structure)The Perla Lite Chimney System will retain its stability fora reasonable period in the event of a chimney fire.B3 (2, 3) – Internal Fire Spread (Structure)The Perla Lite Chimney Systems used in accordancewith this Certificate will inhibit the spread of fire andsmoke within the building.Part C – Site Preparation and Resistance to MoistureC4 – Resistance to Weather and Ground MoistureThe Perla Lite Chimney Systems are fabricated fromapproved building materials and when assembled inaccordance with this Certificate using traditional flashingand damp proofing materials can satisfy therequirements of this regulation. The fireplace units mustbe protected from contact with the ground by usingtraditionaldampproofingmaterials.Part E – SoundE1 – Airborne Sound (Walls)When installed in accordance with this Certificate, thePerla Lite Chimney System can meet or exceed therequirements for airborne sound for walls (see Part 4 ofthis Certificate).Part J – Heat Producing AppliancesJ1 – Air SupplyThe Perla Lite Chimney System meets this requirement,however attention is drawn to the need to locate airCertificate No. 01/0133 / Perla Lite Chimney Systems2

ducts to obviate draughts within the room where thechimney is located. The installation of the chimneysystem should comply with the conditions set out inSection 2.4 and Part 3 of this Certificate.J2 – Discharge of Products of CombustionThe Perla Lite Chimney System has adequate provisionfor the discharge of the products of combustion to theoutside air, as the flues, flue pipes and chimney of thechimney system have been assessed as being of: Sufficient size. Contain openings only necessary for inspection,cleaning and efficient working of the appliance.Part Two / Technical Are lined with suitable materials. Are constructed at roof level so as to discharge in asafe manner.Where chimney stacks are constructed at roof level soas to assist in the discharge of products of combustion,the heights of the chimney stack should be inaccordance with Section 4.4 of this Certificate.J3 – Protection of BuildingWhen used in accordance with Part 4 of this Certificate,the Perla Lite Chimney System can meet therequirements of this Regulation.Specification and Control Data2.1 PRODUCT DESCRIPTIONThe Perla Lite Chimney Systems are fabricated to orderin pre-determined assembled lengths incorporating therequisite fireplace unit in the first section. The secondsection consists of lightweight concrete blocks with clayrebated liners and preformed moisture resistantrockwool insulation. The third section is similar to thesecond but also may include the corbel and is topped offwith the capping. Each system is delivered to site andcontains all the materials necessary to construct achimney from the base to the chimney pot.The lightweight blocks/sections have holes cast in eachcorner which are used to locate the steel reinforcing rodsduring assembly. The 12mm diameter steel reinforcingrods which originate in the fireplace unit extend s are used to join the rods betweensections thus giving continuous reinforcing over the fulllength of the chimney system. When the system is fullyassembled on site a pre-determined torque of 4Nm isapplied to the reinforcing rods.Each chimney system is installed on site by trained andapproved contractors who operate under the guidance ofPerla Ltd.Externally exposed chimneys must be finished inbrickwork, rendered and/or have the special glassreinforced plastic (GRP) cover fitted above the roofline.Traditional roof flashing must be used with all finishes.2.1.1 Fireplace UnitsThe Perla Single and Double Fireplace Units aremanufactured from normal density concrete (see Table 1for dimensions and weights).2.1.2 Lightweight BlocksThe single lightweight block is used for the full lengthwith the single fireplace unit (Figure 2).For the double chimney two separate lightweight blocktypes are used in the lower assembly. These consist of a“Shamrock” block measuring 970mm x 435m x 900mm(ref. Figure 4) and the “standard” blocks measuring970mm x 435mm x 445mm (ref. Figure 3).22.1.3 Clay Flue LinersThe clay flue liners used in both single and doublechimneys are rebated, with a nominal internal diameterof 200mm and a nominal working length of 400mm meetthe requirements of IS EN 13502:2002 Chimneys –Requirements and test methods for clay/ceramic flueterminals and IS EN 1457:1999 Chimneys –Clay/ceramic flue liners – Requirements and testmethods.It should be noted that solid fuel burning open firesrequire a chimney with an internal diameter of not lessthan 200mm.Ancillary Items: Corbels and cappings Glass fibre reinforced plastic cover (for above roofline with specified) Reinforcing bars Connectors/anchors, nuts and washers Masonry stainless steel or galvanised steel ties Timber frame stainless steel ties (with provision forrestrained vertical movement).2.2 MANUFACTURE2.2.1 Fireplace UnitsThe fireplace units are cast in steel moulds and aremade from normal density concrete and are air cured.Threaded anchors are cast into the concrete to receivethe steel reinforcing rods.2.2.2 Perla Lite Flue BlocksThe flue blocks for both chimney types aremanufactured from lightweight concrete. Liapor, anexpanded clay aggregate and Ordinary Portland Cementare used in a lightweight concrete designed mix to give apre-determined strength and density. A Liapor concretemix is also used for infilling the voids around theinsulated flue liners in the Shamrock blocks which areused in the lower assembly of a double chimney system.Special accessory blocks incorporating soot doors andblocks to facilitate side entry stoves and boilers are alsomanufactured from lightweight concrete for bothchimneytypes.Certificate No. 01/0133 / Perla Lite Chimney Systems3

Table 1: Dimensions and Weights of elements of Perla Lite Chimney SystemsProductVolumeWeightDimensionsConcreteSingle Fireplace0.205 m3490 kg(W) 880 mm(H) 920 mm(D) 480 mmDense ConcreteTwin Fireplace0.443 m31065 kg(W) 970 mm(H) 920 mm(D) 960 mmDense ConcreteShamrock Block0.124 m3173 kg(W) 970 mm(H) 435 mm(D) 900 mmLightweight Aggregate OPCStandard Blocks*0.095 m3114 kg(W) 970 mm(H) 435 mm(D) 445 mmLightweight Aggregate OPCSingle Flue Block*0.045 m346 kg(W) 445 mm(H) 435 mm(D) 445 mmLightweight Aggregate OPCSingle Corbel0.0152 m324 kg(W) 725 mm(H) 75 mm(D) 725 mmGRCTwin Corbel0.0244 m346 kg(W) 1250 mm(H) 75 mm(D) 725 mmGRCSingle Capping0.0471 m353 kg(W) 890 mm(H) 55 mm(D) 890 mm(W) 630 mm(H) 90 mm(D) 630 mmDense ConcreteTwin Capping0.0645 m3110 kg(W) 1330 mm(H) 55 mm(D) 860 mm(W) 1145 mm(H) 90 mm(D) 600 mmDense Concrete* Special blocks with soot doors and blocks to facilitate side entry stoves and boilers are also available.Figure 2: SingleFlue BlockFigure 3: TwinFlue Block withedge recessFigure 4:Shamrock Flue BlockCertificate No. 01/0133 / Perla Lite Chimney Systems4

2.2.3 Flue LinersInner refractory clay flue liners are manufactured to ISEN 1457:1999.2.2.4 CorbelsThe precast corbels used in the Perla Lite ChimneySystems are manufactured from Glass ReinforcedConcrete (GRC).2.2.5 CappingsThe precast cappings used in the Perla Lite ChimneySystems are manufactured from normal dense concrete.2.2.6 CoversThe special covers used in the Perla Lite ChimneySystems are manufactured from Glass ReinforcedPlastic (GRP). When specified these are used above theroof line of the system as a replacement for brick facingor render.2.2.7 AccessoriesSpecial proprietary connectors/anchors, nuts andwashers are used with the 12mm steel rods in the PerlaLite Chimney Systems.2.3 QUALITY CONTROLQuality control procedures are operated to check thedensity, dimensions and crushing strengths of themanufactured Perla Lite Blocks, Corbels and Cappings.9.10.11.12.13.14.15.16.17.18.19.The quality of all imported materials is monitored on anongoing basis.2.4 DELIVERY, STORAGE AND MARKINGThe fabricated sections of the Perla Lite Chimney aredelivered to the site and each section has markingsindicating the NSAI Agrément logo and Certificatenumber. Instructions for storage on site, mechanicalhandling and the final assembly of the Perla LiteChimney systems are the responsibility of themanufacturer.2.5 INSTALLATION2.5.1 General1. Ensure adequate scaffolding, ladders and Health &Safety equipment before any work is commencedand advise the site supervisor of any problems.2. At all times hard hats, hi visibility vests andharnesses are to be used when working at height.3. Check Perla Chimney components on site beforeerection. Replace or repair any parts which havebeen damaged on site, and record the data.4. Mark out the exact location of the chimney, andagree location with site supervisor.5. Place DPC on the concrete slab and cover withlayer of mortar.6. Using a crane or other suitable lifting equipment, liftthe base section into place, level and plumb. Thisbase section is normally 3.14m high.7. The timber frame is then erected, including the rooftrusses, by the contractor or their agents.8. Remove the lifting plate by unscrewing the four topnuts. Retighten the nuts on the four threaded barsby using a 19mm socket and torque wrench,ensuring the threaded bars are centred in the metalcups. Cut the four protruding threaded bars down to10mm above the block, and file the top of the bars.20.21.22.23.24.25.26.27.28.29.30.31.Place fire cement around the top of the fluesensuring a continuous bead of fire cement aroundthe flue. Place a layer of mortar on top of the block,and place safety spacers 30mm deep on top of themortar.Carefully unscrew two of the threaded bars ofsection 2 diagonally.Lift section 2 of the Perla Chimney system with acrane or other suitable equipment into place – useof a safety rope attached to the chimney isrecommendedinwindyweather.Carefully connect the two loosened threaded bars ofsection 2 and connect them to base section barsusing connectors provided.Remove the safety straps from the flues.Lower the flues and ensure good bond betweenupper and lower flues.Remove 30mm safety blocks and lower section 2,connect remaining two bars.Lower section 2 and plumb chimney.Remove the lifting plate on section 2 by unscrewingthe four top nuts. Retighten the nuts on the fourthreaded bars by using a 19mm socket and torquewrench, ensuring the threaded bars are centred inthemetalcups.For section 3, repeat as per items 8 to 17, cut theprotruding bars flush with the top of the block afterthe nuts have been tightened using a torquewrench.The contractor or their agents finish the roof, i.e.leated, felted, the chimney flashed as per aconventional chimney and either tiled or slated.The installer places a roofing ladder on the roof.The GRP cover is then cut to the pitch of the roof.The GRP cover is lifted up on the scaffolding usinga teleporter or other suitable lifting equipment.The GRP cover is placed down over the chimneyand secured using a coarse thread screw with awhite plastic washer and cap.A bed of mortar is placed on top of the chimney.The chimney cap is then lifted up on the chimneyusing a teleporter or other suitable lifting equipmentandbeddedinplace.A flue liner is then inserted as a flue terminal andthe top of the chimney is haunched with mortar tothrow off rain water.Any mortar that has fallen down is cleaned up andthe roof ladder is removed.For the Single Chimney, two stainless steel orgalvanised steel U-shaped brackets are fixedaround the chimney, one at first floor and thesecond in the attic space. These brackets musthave provision for 20mm of vertical movement toallow for timber shrinkage.For the Double Chimney, two stainless steel orgalvanised steel angle brackets are fixed either sideof the chimney. These angles must be long enoughto span at least two roof joists – this is to allow foradequate fixing of the bracket.All tools are packed up.Before leaving the site, the installer must obtain asignature from the site supervisor.This is the general method of placing chimneys.Certificate No. 01/0133 / Perla Lite Chimney Systems5

The Perla Chimney System is factory assembled toorder. Where the Double Perla Chimney used in partywalls in prefabricated steel and timber frameconstruction the party walls of the system must bedesigned to accommodate the Perla Chimney System.Installation must be carried out in accordance with thisCertificate and the manufacturer’s instructions.Installation of the Perla Lite Chimney does not presentany undue difficulty when installed within traditional orsystem-built dwellings.Installation achieves an appreciable saving in sitetime over traditional block or brick masonrychimneys.Chimneys exposed externally must be either clad inbrickwork, rendered or fitted with the proprietary GRPcover and secured to the roof members using stainlesssteel straps. Where brick cladding is used above theroofline, it is supported on a corbel unit (see Figure 10).The opening in the roof must be suitably trimmed bytimber fixed to the roof members. The detailing wherethe chimney passes through the roof, the junctionbetween the chimney units, the sarking felt and flashingis similar to that for a traditional block/brick chimneyexcept that the sawing (or cutting) of grooves is notpermitted. Otherwise the flashing of the chimney at theroof level is the same as for a traditional masonrychimney construction. Prior to the application of theplaster or rendering coats, the flashing may be held inposition by bonding it to the chimney units usingproprietary adhesive.The chimney must be terminated so as to preventdischarge gases from entering the building in which it isinstalled, or any adjacent building.The height and location of the chimney above theroofline must be in accordance with the TechnicalGuidance Document to Part A of the BuildingRegulations 1997 to 2007.Only one appliance or open fire is to be used per flue.2.5.2 FoundationThe Perla Chimney Systems are constructed fromlightweight concrete blocks and lintels. As these blocksare lighter than normal density blockwork, aconventional concrete foundation is adequate.2.5.3 Constructional HearthsA constructional hearth must be provided to all PerlaChimney Systems. The constructional hearth should beconstructed in accordance with the TGD to Part J,Section 2.18 and 2.19 of the Building Regulations 1997to 2007. The installation of the constructional hearth isthe responsibility of the main contractor.2.5.4 Trimming at First Floor Level Floor joists running parallel or perpendicular to achimney stack must be trimmed around the stack. Where the chimney passes through the ceiling agap should be left, this gap should be 40mm forstructural timbers or 30mm for a concrete ceiling.The gap is then filled with a 100mm strip of rockwool or similar non-rigid, non-combustiblematerial.To comply with the Building Regulations 1997 to2007 the chimney must be constructed so that:(a) There is a minimum separation distance of200mm between the flue and combustiblematerial.(b) There is a minimum separation distance of40mm between the outer surface of thechimney and any combustible material.Floorboards, skirting, dado, picture rail,mantelshelf or architrave are excluded incondition (b).2.5.5 PartyWallsinSteel/TimberFrameConstructionDuring installation of the plasterboard slabbing, a 50mmwide dry wall adhesive or other proprietary intumescentmaterial is placed into the edge recess (see Figure 3) ofthe Perla Lite Double Chimney System. The plasterslabs are then fixed into the recess and fitted to the studpartitions in the traditional way (see Figures 7 and 8). Allgaps around the chimney must be packed with 100mmhigh density rockwool.Before any slabbing commences it is necessary to checkthat all firestopping has been installed and that no voidshave been left unfilled in party walls and all necessarystainless steel strapping has been correctly fixed inplace. In the case of timber frame construction, the strapmust have provision for 20mm of vertical movement toallow for timber shrinkage (in a two storey high dwelling).2.5.6 Rendering/Plastering of ChimneysChimneys exposed externally throughout their lengthmust be either clad in brickwork or rendered. Theinternally exposed faces of the Perla Lite ChimneyBlocks can be plastered on the exposed faces or boxedin with plasterboard and skim coated.The chimney breast to all chimney systems must be drylined or plastered on the three exposed faces. Theplasterboard sheets used in the dry lining are fixed to thechimney breast using dabs of drywall adhesive at notgreater than 600mm centres. A 50mm wide dry walladhesive ribbon must be applied along all edges of thedry lining, e.g. around openings. Fire stopping at thejunction of ceiling and chimney is achieved by using acontinuous fillet of dry wall adhesive. Where the chimneyfaces of a Perla Lite System are left exposed in anuninhabited attic, it is not necessary to render thesurfaces, however all exposed chimney blockwork mustbe rendered.2.5.7 Chimney Stack with Brick or Block CladdingFor chimneys that require a brick or block cladding acorbel and chimney tray are provided with the system.Weep holes are required in all brickwork. The GRC corbel is placed on the Perla Lite chimneyblock as shown in Figure 10. This gives the supportfor laying the required number of brick or blockworkcourses to reach chimney DPC tray level, generallytwo courses of brickwork is sufficient. Continue to build the chimney blocks on the corbel,inserting the DPC tray at the appropriate level.Certificate No. 01/0133 / Perla Lite Chimney Systems6

2.5.8 Inspection of Installed SystemOnce the Perla Lite Chimney System has been installedthe following should be inspected: All joints in blockwork have been checked. All fire stops and spacers are properly located andsecured in accordance with this Certificate and themanufacturer’s installation instructions. The fitting of terminal and roof flashing above thecorbel should be inspected before scaffolding isremoved.Figure 5:Single Perla system going throughfirst floor fixed to masonry wallPurpose made stainlesssteel strap positioned asspecified40mm gap to be filled with100mm strip of high densityRockwool fire stopTwo layers of continuous plasterboardfixed to stud partitionsPurpose made stainless steelstrap positioned as specifiedwith provision for 20mmvertical movement (in a twostorey high dwelling)Figure 6:Single Perla system going through firstfloor strapped to stud wall for support(Timber frame construction)Certificate No. 01/0133 / Perla Lite Chimney Systems7

Gap around chimney andbetween floor joists to bepacked with high densityRockwool fire stop40mm gap filledwith 100mm ofwire high densityRockwoolContinuousribbon ofplaster dab orother approvedintumescentmaterialContinuous twolayers ofplasterboard fixedto stud partitionsFigure 8:Fire stopping at party wall going through first floorFigure 7:Fixing detail of plasterboard to Perla Lite twinblockand timber frame party wallWeep holes must beprovided in brickworkFigure 9:Twinblock tied to masonry partywall with stainless steel right anglewall tiesFigure 10: Twinblock in amasonry party wall with brickchimneystack supported on acorbelCertificate No. 01/0133 / Perla Lite Chimney Systems8

Part Three / DesignData33.1 GENERALPerla Lite Chimney System, when installed inaccordance with this Certificate, will perform in a safeand satisfactory manner when used in domestic housingor commercial/industrial buildings with a heat output ofup to 45kW. The chimney systems can be used inconjunction with gas, oil or solid fuel burning appliancesas described in Section 4 of this Certificate. The term‘solid fuel’ relates to those fuels listed in Appendix A ofBA 1846-1:1994 Glossary of terms relating to solid fuelburning equipment – Domestic appliances.Each flue in a Perla Lite Chimney is for a singleappliance with an output not exceeding 45kW.3.2 DESIGN REQUIREMENTSThe Perla Lite Chimney System is designed to besuitable for open fire and closed heating appliances thatmight be installed during the lifetime of the dwelling. Thesize and formation of fire openings must be inaccordance with BS 1251:1987 Specification for openfireplace components and BS 8303-1:1994 Installation ofdomestic heating and cooking appliances burning solidmineral fuels – Specification for the design ofinstallations. Appliances must allow access to thechimney for cleaning.The design of the chimney must be in accordance withnormal good practice. For example, the chimney mustbe terminated so as to prevent discharge gases from reentering the building, or entering any other adjacentbuilding. The structure to which the chimney system isattached must be in accordance with the relevant Codesof Practice and Standards. Only one appliance or openfire per chimney must be used.The Perla Lite block units comply with the generalrecommendations for materials for flue block chimneyscontained in BS 6461-1:1984 Installation of chimneysand flues for domestic appliances burning solid fuel(including wood and peat) – Code of practice formasonry chimneys and flue pipes.Completed chimneys should be left to cure for 4 to 5days before the appliance is used. Normal good practicedictates that initial fires in completed chimney systemsshould be small and then gradually increased to fulloperating capacity.3.3 FOUNDATIONWhere a chimney is built up from foundation level, itmust be supported on a concrete foundation designed inaccordance with normal good practice. This foundationmust reach a frost-free depth i.e. approximately 1mbelow ground level if the chimney system is installedexternally or approximately 400mm below floor level ifthe chimney system is installed internally in the building.3.4 CONNECTION TO STRUCTUREThe chimney units should not be bonded into thebuilding structure, but external chimneys must be tied tothe structure at not more than three block unit intervalsand at the point of departure from the roofline, using thespecified stainless steel ties (see Figures 5 and 6).Consideration must be given to the effects on theadjacent structure of the loads imposed by the chimneyfixings. Internal chimneys must be tied to the structureusing the specified stainless steel wall ties at eight blockunit intervals; the necessary support must be providedduring and after construction by the intermediate floorsand by the timber trimming at roof level. For timberframe constructions the stainless steel wall ties must beprovided with vertical slots which will facilitate verticalmovement of approximately 20mm in a two storey highdwelling.3.5 FLOOR DETAILWhere the chimney system passes through concretefloors, a sliding joint must be made using mineral wool orsimilar non-combustible material. Bonding between thechimneys and the floor or structure must be avoided. Aminimum clearance of 40mm must be maintainedbetween the outer surface of the chimney block andtimber structural members such as joists and rafters.After the units have been positioned, the gap must befilled with mineral wool having a minimum density of 252– 30kg/m .3.6 CAVITY WALLSWhen an external chimney is erected the design andinstallation of the flue connection to the appliance mustbe in accordance with BS 6461-1:1984. Particular caremust be taken to comply with the weather details for theconnection flue where it passes through the cavity wall.3.7 AIR SUPPLYHeat producing appliances are required to be providedwith an adequate supply of air for combustion of fuel andfor efficient operation of the chimney or flue. For thisreason a Perla Lite Chimney System must be locatedwhere the chimney has adequate air supply (ventilation).The chimney system can be used with solid fuel, oil andgas burning appliances. The following are the id Fuel Burning Appliances with outputrating not more than 45kWThe ventilation requirements must comply with Table 1Section 2 of TGD to Part J of the Building Regulations1997 to 2007.(ii) Oil Burning Appliances with output rating up to45kWThe ventilation requirements should comply with cl. 4.1of TGD to Part J of the Building Regulations 1997 to2007.Certificate No. 01/0133 / Perla Lite Chimney Systems9

Part Four / TechnicalInvestigations4.1 DOMESTIC APPLIANCESThe Perla Lite Chimney Systems incorporating the200mm nominal diameter clay flue liners are suitable foruse with open fires and appliances fuelled with gas, oiland solid fuels. Appliances must be installed inaccordance with the manufacturer’s instructions.Reference should also be made to BS 1251:1987, BS6461-1:1984 and BS 8303-1:1994.4.2 COMMERCIAL AND INDUSTRIAL USE NOTEXCEEDING 45kW OUTPUTThe Perla Lite Chimney Systems are suitable for usewith gas, oil and solid fuel appliances. Installations inthis category shall be under the design and supervisionof a Chartered Heating Engineer.4The basic compressive strength for Perla Lite Chimneyblocks can be taken at a nominal value of 5Mpa2(5N/mm ) net cross sectional area.4.5 PROXIMITY OF COMBUS

The Perla Lite Chimney System has adequate provision for the discharge of the products of combustion to the outside air, as the flues, flue pipes and chimney of the Are lined with suitable materials. Are constructed at roof level so as to discharge in a safe manner. Where chimney stacks are constructed at roof level so