Transcription

Wheelchair Design in Developing Countries2007 Public Service Design SeminarAmos Winter, Graduate Student, Dept. of Mechanical EngineeringSupported by Amy Smith, Senior Lecturer in Mechanical EngineeringIntroductionJames is a teenager in Tanzania. As a young child, he was disabled by polio. His familycannot afford a wheelchair. James’s only means of transportation is crawling on theground. He wears sandals on his hands for protection. James rarely leaves the housebecause his family is ashamed of him. While intelligent, James does not go to schoolbecause he is physically incapable and his family forbids it. James will grow up with nomarketable skills and will most probably end up begging on the street.There are hundreds of children and youth like James who are either forced to stay in theirhome or crawl on the ground because appropriate and affordable wheelchair technology isnot accessible. Well-intentioned organizations from the United States and Europe donatewheelchairs, but they are not designed for the rough conditions in rural East Africa, andoften break down after just one or two months. Locally-made wheelchairs and othermobility aids provide a much more appropriate solution, but are relatively expensive andcannot compete with the donated chairs on price. Furthermore, many designimprovements can be implemented to make them stronger, lighter and moremaneuverable. A sound understanding of engineering concepts can be taught in theredesign of these chairs, benefiting the students doing the design work as well as thepotential builders and users of the chairs.This document is a proposal for funds to establish a Public Service Design Seminarentitled Wheelchair Design in Developing Countries (WDDC). The purpose of the class isto educate MIT students about engineering and cultures in the developing world throughthe innovation of appropriate wheelchair technology. I am proposing this class because Ibelieve that MIT is in the unique position to solve the problem of appropriate wheelchairtechnology. By combining the resources, brainpower, and credibility of MIT with the

experience of established community partners already making chairs in developingcountries, wheelchair technology can be advanced to fully suit user needs.WDDC will inspire students by providing a significant real-world engineering applicationand showing them the power they have to improve the lives of others. During the course,students will conceive appropriate wheelchair design solutions using sound engineeringpractices while learning about cultural, economic, and resource considerations in thedeveloping world. The technology produced in the class will have far-reaching effects.Through community partners Whirlwind Wheelchair International (WWI), an organizationwhich has designed developing world wheelchairs for over 30 years, and the TanzaniaTraining Center for Orthopedic Technologies (TATCOT), the leader in wheelchairmanufacturing education in Africa, technology developed in WDDC will be disseminatedand implemented in wheelchair workshops around the world.BackgroundMotivation to teach this class arises from my own experience with inadequate wheelchairtechnology in Tanzania. I spent the summer of 2006 conducting a study entitled“Assessment of Wheelchair Technology in Tanzania,”1 which was funded by a PublicService Center Fellowship and supervised by WWI and TATCOT. The project includedinterviewing a variety of stakeholders involved with Tanzanian wheelchairs, includingusers, manufacturers, and advocacy groups. Over the entire study, approximately 100interviews were conducted throughout Tanzania in both rural and urban locations.The results of my assessment showed that wheelchair technology in Tanzania isinsufficiently meeting the needs of users. Many chairs break down prematurely because ofimproper design, as shown by the example in Figure 1, where the frame has bent becausethe tubing was not strong enough to support the load. Further analysis showed that thefailure occurred where the bending moment was at its maximum. Other problems withcurrently produced chairs include underutilization of building materials, improper1“Assessment of wheelchair technology in Tanzania.” 2005. Amos Winter. 23 Mar. 2006 0TZ%20WC%20technology%20-%20final.pdf

mounting of bearings, inaccurately predicting stresses and failure points, using inefficientmanufacturing methods, and not taking advantage of locally available components.Center ofgravityFReactionFReactionPosition along chairFrame weaknessMomentMax MomentPosition along chairFigure 1 Example of a poorly designed frame buckling and corresponding bending momentAdditionally, many people rely on donated wheelchairs which may be inexpensive but arenot designed and built to suit the needs of users in developing countries. Some of theorganizations that distribute free chairs judge success by the number of chairs donated,rather than how many people obtain a sustainable mobility solution. Many of these chairsbreak down in the first year and cannot be repaired because replacement parts areunavailable. Even worse, many chairs are given away without proper fitting, which can beextremely dangerous for the user. Hard surfaces, like the plastic seat on the donatedwheelchair in Figure 2, or improper chair geometry, can cause pressure sores which canlead to infection and sometimes even result in death.

Figure 2 Foreign made, donated wheelchair with no custom fitting and dangerous plastic seatMIT students’ specialties are sound engineering and innovation, which are the ingredientsneeded to solve many of the technological problems identified in Tanzanian-made chairs.By improving in-country technology, locally made wheelchairs can be better built,correctly fitted to users, and affordably priced. This not only helps wheelchair users, butalso stimulates the local economy by increasing business for local manufacturers.Class descriptionWDDC will be a seminar in which engineering fundamentals are taught in the context ofwheelchair engineering. The lectures will introduce the cultural, economic, and resourceconsiderations in wheelchair design, and show how sound engineering can be used to formrobust, appropriate design solutions. The class will be divided into groups of 3 to 5students for term-long projects with a specific wheelchair technical problem to be solved.The students will learn engineering fundamentals to properly analyze their problem andappropriately design a solution. Several members of the MIT mechanical engineeringfaculty have already agreed to be guest speakers, as well as WWI founder Ralf Hotchkiss,and a wheelchair manufacturer in Tanzania.The intention of the class is to interest students in engineering through practicalapplication of theory, interaction with members of the faculty, and learning the broadercontext in which their knowledge and talents can be applied. The course material will bepresented from both the social and technical standpoint of wheelchair engineering. Socialconsiderations such as understanding cultural stigmas associated with the disabled and

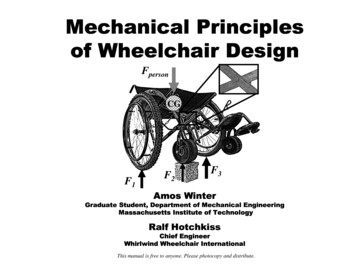

common causes of disability will be examined. The students will learn how to connectsocial constraints and requirements to technical design parameters, and then applyengineering knowledge to develop appropriate designs. Technical topics will span manyengineering disciplines including machine design, materials science, mechanics ofmaterials, biomedical engineering, and product/ergonomic design. The proposed syllabusis included in Appendix A.The text for WDDC will be a manual on engineering principles used in wheelchair designthat I will write during the summer of 2006. Ralf Hotchkiss, the founder of WWI, will bea co-author on this project. In addition to serving as the text for the class, this manual willalso provide African wheelchair manufacturers with the knowledge to improve and adapttheir products instead of relying solely on the designs of others. The manual will bepresented in the fall of 2006 at the African Wheelchair Congress to be held in Arusha,Tanzania. As the manual will provide simple, qualitative explanations geared towardspeople with little or no engineering training, more rigorous theory will be derived andpresented in WDDC classes.Proposed projectsThe following projects are based on the assessment of wheelchair technology in Tanzania.Each focuses on a specific technical problem that is of suitable scope, which a solutioncan be designed and prototyped in one semester. Some or all of these projects will bepursued in WDDC: Tanzanian hand-powered tricycle frame re-design: Current tricycle frames will beanalyzed and re-designed to increase strength and reduce weight through moreeffective use of moment of inertia and local materials. Optimization of hand-powered tricycle gear train: The gear ratios of currenttricycles vary significantly, as shown in Figure 3. Human hand power output willbe determined to predict the best hand crank position and gear ratio. Folding 3-wheeled frame: A frame will be designed to be kinematicallyconstrained to ground by 3 points, yet still foldable for transport in busses.

Rear axle/hub design using bicycle bearings: Different axle/hub/bearingconfigurations will be explored. Bicycle bearings are better suited to wheelchairloads, are cleanable, and are readily replaceable throughout Tanzania. A conceptfor a rear hub/axle design is shown in Figure 4. Creating testing metrics: Tests using local materials will be developed todetermine the safety of wheelchairs.FinFind1d1d2d2d3d4d3Foutd4FoutA) Tricycle made in CanadaB) DAGE Tricycle made in TanzaniaFigure 3 Gear ratios of two tricycles used in TanzaniaSingle parthub/axleLower cupassemblyThreaded axleFrameUpper cupassemblyFigure 4 Concept of single part hub/axle and bearing configuration, assembled and exploded view

This proposal includes the request for funds to allow three students to continue theirprojects during the summer of 2007. These students will travel to one or multiplecommunity partners producing wheelchairs and implement the technology developed inWDDC. Providing travel opportunities to the students enhances their educationalexperience while also greatly facilitating the dissemination of technology. WDDCstudents may be able to collaborate with MIT Public Service Fellows to establish jointprojects and maximize technology implementation.Guest lecturersGuest lecturers will be included in WDDC to 1) give students the chance to interact oneon-one with engineering faculty, 2) learn about each faculty member’s specialties in thecontext of wheelchair design, 3) see the perspective of engineers from the developedworld designing for the developing world, and 4) understand the challenges of being awheelchair manufacturer in the developing world. The following people have alreadyagreed to be guest lecturers in WDDC and present the described topics:Prof. Mary BoyceMIT Dept. Mechanical Engineering, Mechanics of Materials Performance of common steels Material weakening due to welding Stress concentrations Fracture toughnessRalf HotchkissFounder and Chief Engineer, Whirlwind Wheelchair International 30 years of WC design in developing countries Factors specific to developing world wheelchair designo Technical factors encounteredo Social factors encountered History of WWI designsAbdulah Munish

Wheelchair Technician, KCMC Wheelchair WorkshopInstructor, TATCOT Wheelchair Technologists Training Course Issues facing developing country wheelchair manufacturers Materials/parts available for wheelchair manufacturing in Tanzania Problems with designs of current wheelchairs Competition of poorly made, imported wheelchairs Intent/usage mismatch of Tanzanian-made chairsProf. Alexander SlocumMIT Dept. of Mechanical Engineering, Precision Machine Design Exact constraint design Structural loops/frame compliance Bearing choice Structures/trussesAmy SmithD-Lab Founder and Senior Instructor, MIT Dept. Of Mechanical Engineering Process of designing in a developing country Past successes and failures of D-Lab projects Contrasting design in the developed and developing worldProf. David WallaceMIT Dept. of Mechanical Engineering, Product Design Design for attractiveness with limited materials General product design methods Design considerations for the developing worldEducational significance and MIT impactWDDC will be a class aimed at freshmen but open to any student at MIT. It is meant tointroduce students to concepts from a variety of engineering fields including machinedesign, materials science, mechanics of materials, biomedical engineering, andproduct/ergonomic design. By combining many engineering fields and hopefully

attracting people from a variety of backgrounds, WDDC will foster interdisciplinaryrelationships between students and faculty.Service learning is a proven effective method of teaching engineering. Using wheelchairdesign as a project medium will engage students not only because it is a challengingtechnical issue, but also because it has a large human interest component. By conductinghands-on projects, the students will see the power of their engineering knowledge throughdirect application.Giving the students an opportunity to continue projects through the summer adds anotherdimension to the educational experience. The students will learn the challenges ofbringing an idea to final product and along the way gain the teaching experience oftransferring their technology to wheelchair manufacturers. Most importantly, the studentswill meet in-country wheelchair users. Fully understanding the struggles disabled peopleface in the developing world is a lesson that can never be fully conveyed in a classroom.The satisfaction of giving the freedom of mobility to another person will teach thestudents the power they have to improve the lives of others by using their technical skills.Impact beyond MITTechnology produced in WDDC will help one of the most disadvantaged populations inthe world: disabled people in the developing countries. Disability KaR2, which is helpingto oversee wheelchair projects in developing countries, reports that only 2% of people inAfrica who need a wheelchair actually have one. The Tanzania Association of theDisabled (CHAWATA) estimates there are 30,000 people who need wheelchairs inTanzania alone.3 WDDC will help in bringing appropriate, affordable wheelchairtechnology to thousands of disabled people. These are people who are frequently deniededucation, jobs, and dignity through no fault of their own. Giving mobility to a disabledperson sets them free; in developing countries this means freedom in the most basic andliteral sense. A wheelchair can allow a child to attend schools and participate with hispeers, or an adult to find a job and provide for his family.2Disability KaR. 10 June 2005 www.disabilitykar.net 3Conversations with CHAWATA (Tanzanian Association of the Disabled). 15 June 2005.

Locally-built wheelchairs have many benefits over imported chairs. Customers can be fitby trained technicians who know about pressure points that can cause open sores andinfections. By improving the product of workshops, locally made wheelchairs can becompetitive in price compared to chairs produced in other countries. This will givedonation groups more incentive to buy locally instead of importing low cost, poor qualityforeign chairs.EvaluationWe will formally survey all students and community partners at the end of the class. Thesurveys are based on models used for measuring service learning outcomes, and so areparticularly relevant for a project-based course with a social service theme. All surveys areapproved by the Research and Assessment Coordinator for the MIT Public Service Center,Sumi Gupta Ariely. The surveys include both open-ended qualitative questions and scoredquantitative questions relating to the class objectives, students attitudes, and the success ofthe team projects. The surveys will be independently evaluated by Public Service Centerstaff.At the end of the course, each project team will formally present their work to the rest ofthe class as well as demonstrate a prototype. The students will be required to write a finalreport in which they outline plans for implementing their technology in a wheelchairworkshop. These presentations highlight team productivity and outcomes, and will beevaluated with a standard scoring rubric.In subsequent years of WDDC, students and instructors will return to field sites usedduring previous summers. Consequently, future teams can evaluate the adoption anddissemination of WDDC projects into their target communities by observation, as well asinterviews and surveys. If field evaluation shows a WDDC project is not working ashoped, further work can be done by the original team as part of a continuing project or bya new WDDC team. In addition, our on-site community partners can provide on-goingfeedback and evaluation.

Long-term goalsWDDC is meant to be a seed project in a longer-term goal of establishing a center forwheelchair technology at MIT. This center will approach wheelchair technology indeveloping countries on a larger scale by 1) engineering complete wheelchair re-designs tofully satisfy user needs, 2) developing a full set of standards for in-country testing, 3)continuing classes on wheelchair technology, 4) facilitating projects for independentstudy, and 5) providing topics and supervision for senior theses.MIT is an ideal location for such a center, as it would serve as a hub for wheelchairinnovation. Through a combination of MIT’s resources, people, and reputation forexcellence with the practical knowledge of organizations like WWI and the in-countryexperience of community partners like TATCOT, each aspect of wheelchair design can beaddressed to produce an optimal product, appropriate for use in developing countries.ConclusionWDDC will enrich the learning experience of MIT students by combining engineeringwith service learning. This class has the potential for far-reaching positive effects: Thestudents will experience new cultures and learn sound engineering practices, while thepartnering organizations in developing countries will benefit from resources andtechnology that would otherwise not be available. The students will produce real,measurable results by developing technology that can be immediately implemented intowheelchair manufacturing in the developing world. WDDC students or other members ofthe MIT community can choose to continue a hands-on role in implementing thetechnology by traveling to community partners during IAP and summer fellowships.This class will engage students through the application of engineering skills to a real andvery important problem while helping out one of the most disadvantaged populations.Inviting guest lecturers with years of experience working with wheelchairs in developingcountries will show the students the boundless opportunities within engineering andbeyond. By including faculty as guest lecturers, students will have the chance to interact

with some of the most prominent engineering faculty and see how their research andtheoretical expertise can be used to address an interesting and real-life problem.

Budget and time-lineDevelopment and implementation of WDDC will be broken up into three phases. In thefirst phase during the summer of 2006, travel to Tanzania will be necessary to procurelocally made wheelchairs and tricycles, as well as raw materials and machine components,to be used for analysis in the class. The equipment will have to be shipped back to the US,as the tricycles have a large fixed frame that prohibits them from being carried onto aplane. Pictures, video, and statements from wheelchair manufacturers and users will alsobe gathered on this trip for use as class materials.The fall of 2006 will be used for curriculum development. Lectures will be designed andrelated reading materials will be assembled. The course website will be contracted andbuilt. Using the materials procured in Tanzania, and with the help of community partners,the course projects will be finalized.During the second phase when the class is in session, the funds required to fly AbdulahMunish and Ralf Hotchkiss to MIT justify the value these people will add to the class.Both will give a perspective on wheelchair design and manufacturing that could not beobtained from a faculty member. Prototyping materials are required for the class, as thestudents will build and test their design concepts.In the final phase students will travel to a community partner and implement their designsfrom WDDC. Allowing students to travel to the country for which they are developingtechnology will provide them with a valuable cultural experience while ensuring thetechnology is disseminated to wheelchair manufacturers. Additional prototyping materialswill be necessary during this time to allow the students to test their technology on multiplewheelchairs.

WDDC budgetCurriculum Development (Summer & Fall 2006)Personnelinstructorweb page designerassessment coordinator 15,000 500 1,000(covered by industry-sponsored RA)Travelairfare to Tanzaniaground transportationaccommodation 2,000 200 250digital camcorderdigital video tapeswheelchairsshippingprototyping materialsreference materialsposters & flyers 1,200 50 800 1,200 500 400 150 23,250 7,050(on loan from Edgerton Center) 10,000 250 1,000(covered by industry-sponsored RA)MaterialsTotalRequested from Alumni FundsCourse Implementation (Spring 2007)Personnelinstructorwebmasterassessment coordinatorTravelairfare from Tanzania (Abdulah Munish)airfare from San Francisco (RalfHotchkiss)ground transportationaccommodation in Boston 2,000 500 50 800Materialsprototyping materialsdemonstration materialscourse handoutsTotalRequested from Alumni Funds 2,000 1,000 250 17,850 7,850Project Implementation (Summer 2007)Travelairfare from Tanzania (3 students)ground transportationaccommodationtranslator 6,000 250 500 500prototyping materialsTotalRequested from Alumni Funds 1,000 8,250 8,250Total requested from Alumni Funds 23,150Materials

Appendix A: Class 6/2007Wheelchair TopicsEngineeringTopicsIntroduction towheelchairs inDeveloping CountryDeterministic designprocessStatistics on underservedpopulationsReview of common causesof disabilityPresentation of possibleprojectsWheelchair user habitsStrategy, Concepts,Modules, PartsReview of currently usedwheelchairswheelchairs currently beingbuilt in country (broughtback from Tanzania)Imported wheelchairs andUS wheelchairs (broughtback from Tanzania andborrowed from MITmedical)Review of means ofpurchasing/obtainingwheelchairs in developingcountriesStructuralcalculationsExamples of engineeringin the developing worldExamples of successfuland unsuccessfulengineering in thedeveloping worldFactors to consider whendesigning for developingcountriesConstraints/freedoms indesignidentification of designconstraints specific to thedeveloping worldIdentification of designopportunities and freedomsthat can be utilized in thedeveloping worldcommon operationenvironments encounteredin the developing hTATCOTDraw free-bodydiagrams for all late loads onmajor componentsIdea to productStakeholder analysisDetermination of userneedsAmy SmithMITForm projectteams, chooseprojectsImplementation in thefieldOutlining a s, freedomsIdentification ofdesignshortcomings incurrently builtwheelchairsOutlining offunctionalrequirementsMethods of propulsionBiomedicalengineering/Conservation lawsefficiency of wheelchair vs.tricycleBiomechanics ofhand-poweredpropulsionPresentation ofstrategiesBenefits and shortcomingsof 3 and 4 wheel chairsAnatomicalconsiderations,posture, body loadsJustification of beststrategyConservation laws:power, energy,efficiency

63/12/2007Operating a wheelchairin the developing worldReview of materialsavailable in the developingworld7891011123/19/20073/26/2007Material science/mechanics ofmaterialsProf. MaryBoyceMITStress/strain ofmaterials, materialbehavior,metal processing,fracture toughness,stress concentrations.Material choice fordesign. logies in thedeveloping worldManufacturingtechnologiesWhat is currently beingusedWhat is available andunderutilizedA focus on what isavailable in thedeveloping worldLean manufacturingtechniquesConcept sketchesof designparameters ofprojectsPresentation onchosen conceptSpring BreakProf. AlexSlocumMIT4/2/2007Review of locallyavailable componentsbearings, bushings,wheels, tires, tubes4/9/2007Inspection of materialsprocured in TanzaniaComparison of 3wheeled wheelchairs vs.4-wheeledPersonal identity andwheelchairsProduct design/Ergonomic designProf. DavidWallaceMITErgonomic ing a wheelchairAvoiding pressure soresand correctly matchingchair and user bodygeometryMachine elementsField Trip towheelchair usergroup meetingExact constraintdesignPresentation ofengineeringprototypesDesign review byRalf HotchkissMaking the chair stable134/30/2007Project workProject work145/7/2007Project workProject work155/14/2007Project workProject workFinal presentationof project with aworking prototype

WDDC will be a seminar in which engineering fundamentals are taught in the context of wheelchair engineering. The lectures will introduce the cultural, economic, and resource considerations in wheelchair design, and show how sound engineering can be used to form robust, appropriate design solutions. The class will be divided into groups of 3 to 5