Transcription

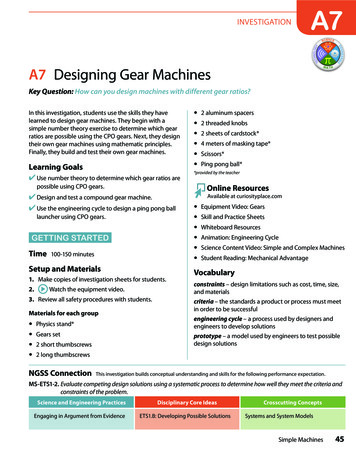

INVESTIGATIONA7GINEERINGENCHNOLOGYTESCIENCEM AT HA7 Designing Gear MachinesKey Question: How can you design machines with different gear ratios?In this investigation, students use the skills they havelearned to design gear machines. They begin with asimple number theory exercise to determine which gearratios are possible using the CPO gears. Next, they designtheir own gear machines using mathematic principles.Finally, they build and test their own gear machines.Learning Goals Use number theory to determine which gear ratios arepossible using CPO gears. Design and test a compound gear machine. Use the engineering cycle to design a ping pong balllauncher using CPO gears.yy 2 aluminum spacersyy 2 threaded knobsyy 2 sheets of cardstock*yy 4 meters of masking tape*yy Scissors*yy Ping pong ball**provided by the teacher Online ResourcesAvailable at curiosityplace.comyy Equipment Video: Gearsyy Skill and Practice Sheetsyy Whiteboard ResourcesGETTING STARTEDTimeyy Animation: Engineering Cycleyy Science Content Video: Simple and Complex Machines100-150 minutesyy Student Reading: Mechanical AdvantageSetup and Materials1. Make copies of investigation sheets for students.2. Watch the equipment video.3. Review all safety procedures with students.Materials for each groupyy Physics stand*yy Gears setVocabularyconstraints – design limitations such as cost, time, size,and materialscriteria – the standards a product or process must meetin order to be successfulengineering cycle – a process used by designers andengineers to develop solutionsprototype – a model used by engineers to test possibledesign solutionsyy 2 short thumbscrewsyy 2 long thumbscrewsNGSS ConnectionThis investigation builds conceptual understanding and skills for the following performance expectation.MS-ETS1-2. E valuate competing design solutions using a systematic process to determine how well they meet the criteria andconstraints of the problem.Science and Engineering PracticesEngaging in Argument from EvidenceDisciplinary Core IdeasETS1.B: Developing Possible SolutionsCrosscutting ConceptsSystems and System ModelsSimple Machines45

Designing Gear MachinesBACKGROUNDEngineers use science, math, and technology to solveproblems. Some solutions result in new products, suchas more fuel-efficient cars. Other solutions may beprocesses, such as recycling compost so that it can beused to make biomass fuels. In each case, engineersemploy a range of methods and practices to reachtheir solutions.The engineering cycle summarizes these practicesfor students by breaking the design process intosteps. The cycle helps students to identify and explaintheir background knowledge, to identify criteria andconstraints, to explore and plan for testing activities, andto plan communication of results.The Engineering CycleReqdanTe st f in eReao l in stout r mio n sateResearchfyeci entsSp uiremCommunicIDENTIFYA NEEDP ro to t y p e46Br SIdentify a Need is the triggering component of the cycle.This phase asks students to state the main problem thatneeds to be solved or process that needs to be improved.Research involves organizing background knowledgethat is useful in solving the problem. It can include theprocess of acquiring additional information through websearches, interviews with experts, etc.Criteria, constraints, and trade-offs are all part of SpecifyRequirements. Criteria are the standards a successfulproduct or process must meet. Student should beencouraged to break down the design goals intoobjectives that can be measured and achieved. Next,the student should list constraints to the design process.Constraints are limitations such as time, cost, availabilityof materials, and size of product. When considering limitson time and resources, students should identify strategictrade-offs.The remaining steps of the engineering cycle involvecreation, construction, and testing of the design. InBrainstorm Solutions, students think about designs andshare their ideas with their groups. Sometimes a groupmay describe several possible designs and select designfeatures to merge into a single prototype. In othercases, the group may choose the design they believe ismost likely to meet the criteria. Once a design is chosen,it is assembled in the Prototype phase and then testedin Test and Refine. Often students move back and forthbetween these phases of the engineering cycle as designfeatures are tested, evaluated, and improved. Finally,students share their ideas with an audience during theCommunicate phase.

A75E LESSON PLANEngageType “rotary egg beater” into an internet search engineor shopping site. You will find photos of a wide varietyof egg beaters, from inexpensive models with plasticgears to high-quality, ergonomically designed stainlesssteel models. Show photos of two different designs tothe class. Ask them to think about the process that wentinto designing each one. Which one is probably theleast expensive? Can students identify possible criteria/constraints that the designer of each tool may havebeen working with? For whom would each tool be thebest choice?This investigation will give students an opportunityto practice designing their own gear machines. Theywill figure out which gear ratios are possible within theconstraints of the available gear sizes, and then choose tobuild one of the possible designs.ExploreHave students complete Investigation A7, Designing GearMachines. In this investigation, students use the skills theyhave learned to design gear machines. They begin with asimple number theory exercise to determine which gearratios are possible using the CPO gears. Next, they designtheir own gear machines using mathematical principles.Finally, they build and test their own gear machine thatwill launch a ping pong ball.Science Content VideoSimple and ComplexMachinesAnimationEngineering CycleElaborateInvite several different types of engineers to speakto your classes in a round-table discussion format.Some interesting fields include electrical, mechanical,aerospace, civil, chemical, and biomedical engineering.Ask each to explain how they use the engineeringprocess in their work. What do they enjoy most abouttheir work? What are some of the challenging constraintsof their current project? Can they describe a significantdesign change they havemade to a project? How isteamwork important intheir field?ExplainRevisit the Key Question to give students an opportunityto reflect on their learning experience and verbalizeunderstandings about the science concepts explored inthe investigation. Curiosityplace.com resources, includingstudent readings, videos, animations, and whiteboardresources, as well as readings from your currentscience textbook, are other tools to facilitate studentcommunication about new ideas.Evaluateyy D uring the investigation, use the checkpointquestions as opportunities for ongoing assessment.yy A fter completing the investigation, have studentsanswer the assessment questions on the Evaluatestudent sheet to check understanding of theconcepts presented.Simple Machines47

Designing Gear MachinesExploreINVESTIGATIONA7Name DateA7 Designing Gear MachinesMaterials: Physics standHow can you design machines with different gear ratios? Gears setHow many different gear ratios can you make from gears with 36, 24, and 2 short thumbscrews12 teeth? In this investigation, you will determine the possible gear ratios 2 long thumbscrewsand then, using the engineering cycle, design and build a gear machine with 2 aluminum spacersa ratio of your choosing. You’ll use what you learned from this process todesign your own ping pong ball launcher. 2 threaded knobs 2 sheets of cardstockWhich gear ratios can you make? 4 meters of masking tapeThe three gears have numbers of teeth in the ratio of 36:24:12. Because all the Scissorsnumbers in the ratio are divisible by 12, this ratio can be reduced to 3:2:1. Ping pong ball This means that you can only build gear machines with ratios that aremultiples of the numbers 1, 2, and 3.a. How many numbers between 1 and 20 can you make by multiplying the numbers 1, 2, and 3 together?You can use the same number more than once. The group of numbers that make up your answer is anexample of a set. A set is a group of numbers that are all related. For example, the number 8 belongsto this set because 8 2 2 2. Find all of the numbers between 1 and 20 that are included in this setand write them below.The set of numbers that can be used to create ratios for CPO gears includes :12Copyright CPO ScienceCan be duplicated for classroom use34681 of 69121618A7 Designing Gear MachinesSimple MachinesGuiding the INVESTIGATION Which gear ratios can you make?Some groups may come to a point where they havefilled some, but not all, of the ten boxes for multiplesof 1, 2, and 3 and then say that they can’t think ofany others. At that point, encourage them to take asystematic approach: Consider each whole numberfrom 1-20 in order. Ask yourselves, “Can I multiplysome combination of 1, 2, and/or 3 to make thiswhole number?” If so, add it to your table. If not,move on to the next whole number.SCIENCE AND MATHPrime factorization In order to determine whichgear ratios are possible using a certain set of gears,students need to be able to determine the primefactorization of the number of teeth in each gear.Students may benefit from a quick review of primefactorization. Here is a simple review exercise:To find the prime factorization ofa number, try the “birthday cake”method.1. Write the starting number as thefirst layer of your cake:422. To the left of the first layer, write a prime42 evenly into the startingnumber that will divide7 4242number.427 4267 424242 as the second3. Divide and write your77answerlayer of the cake.642742426 67 7424237 642424. To the left of the second7 42layer, write a primenumber that will divide3 6 evenly into this number.4213 36 667 4272 264217 4272142261get factorizationPrime 3 25. Divide. Repeat until 2youthe number 1 at7the27422a “birthday2top. Think of the 1 as42candle”and366 The prime factorscelebrate that you’re3Primedone! 7 are3 26 factorization742the numbers listed totheleftofyourcake.Primefactorization 7 Prime factorization 7 3 3 2 27 421362122 23 6617 Prime42 factorization 7 3 22 2Prime factorization 7 3 212 2Prime factorization 7 3 236Prime factorization 7 3 24812 2

A7ExploreINVESTIGATIONA7Each of these numbers can be part of a gear ratio for a machine that you can build using the gears. Pick onenumber from the set for the numerator (top number) and another for the denominator (bottom number) of agear ratio. Express the gear ratio as a fraction and a number (divide the numerator by the denominator).ExploreSample data table: 3 Gear ratio 0.75 4 Table 1: Your gear machinenumberAxle Design and build your own gear machineInner positionOuter positionX or number of teethX or number of teethIn the last investigation, you learned to build a compound gear machine by stacking gears on top of each otherand using multiple axles. You also learned to calculate the gear ratio of the machine by multiplying the gearratios of the pairs of gears that mesh.136X21236Now, try designing and building your own gear machine with gear ratios that contain any combination of thenumbers from your set in Part 1. You may need to combine with other groups in the class to get enough gears tobuild the machines you design. If possible, each group in the class should choose a different gear ratio to build.32412412XUse the chart on the next page to create your design. Try using the fewest pairs of gears to get the final gear ratio.56a. Use the numbers from your set in Part 1 to choose a gear ratio that only your group will build.Note: In this sample setup, the 24-tooth gear at the third axle goes under Gear ratio fractionA7b. Use the table below to record your design. Each axle can have a gear in the inner position and/or the outerposition. Use the table to write down the number of teeth in the gear you have in each position. You canalso use the spacers in places where you do not wish to use gears. Put an X in the spaces where there areno gears. Circle the pairs of gears that mesh.Example :fractionINVESTIGATIONthe 36-tooth gear at the second axle. The 24-tooth gear does not meshwith the 12-tooth gear on the second axle in this arrangement.numberc. Each place where gears mesh defines a gear ratio. Use the space below to write down the gear ratios inyour machine as fractions. Multiply the ratios to calculate the total gear ratio. This number should beequal to the gear ratio in step a.Sample answer: Gear ratio 18/1 18313 2 18 1 1 1d. Build your machine and test it. Did the machine have the same gear ratio as the design?Yes, our machine had a gear ratio of 18:1, just like our design.Copyright CPO ScienceCan be duplicated for classroom use2 of 6A7 Designing Gear MachinesSimple MachinesCopyright CPO ScienceCan be duplicated for classroom use3 of 6A7 Designing Gear MachinesSimple MachinesSCIENCE AND TECHNOLOGYIn this investigation, students move from a scientificactivity (learning how gears work) to a technologyfocused activity (using gears to accomplish a task).This is a good time to discuss the differences betweenscience and technology.Science is the process of building knowledgeabout the physical world through observation andexperimentation. Technology is the application ofscience to solve problems or accomplish usefultasks. Technology includes all of the inventions andtechniques humans have developed over the years,such as cars, microwave ovens, and smartphones. Italso includes processes such as laparoscopic surgeryfor gall bladder removal, which uses a much smallerincision and has a faster recovery rate than traditionalopen surgery.To guide students in distinguishing between scienceand technology, read aloud each statement below.Have students tell whether

y Science Content Video: Simple and Complex Machines y Student Reading: Mechanical Advantage Vocabulary constraints – design limitations such as cost, time, size, and materials criteria – the standards a product or process must meet in order to be successful engineering cycle – a process used by designers and engineers to develop solutions prototype – a model used by engineers to test .