Transcription

Nalco AT ORP Sensor to Measure andControl Corrosion Stress and Corrosivity ofBoilers Feed water SystemsEssential Expertise for Water, Energy and Air SMPresented by: Philip DixonOctober 2011Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVERCONTROL OF CORROSION AND CORROSIONPRODUCT TRANSPORT IN BOILERS CONDENSATEAND FEED-WATER SYSTEMS IS CRITICAL TOMAINTAINING RELIABLE, EFFICIENT OPERATIONS.HIGH CORROSION RATES CAN LEAD TO A VARIETYOF SYSTEM PROBLEMS, WHICH INCLUDELOCALIZED CORROSION AND FAILURE OF FEEDWATER HEATER TUBES, BOILER TUBE CORROSIONAND FAILURES, BOILER DEPOSITS AND FREQUENTCLEANINGEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVER Control of the corrosive environment through the use ofpassivator is a widely accepted practice and a part of theEPRI recommendation is to utilize oxidation-reductionpotential (ORP) for passivator control in AVT-Rprograms. However, the use of low-temperature ORP formonitoring and control of redox stress in the feed-watersystem has been quite problematic for most users as thelow-temperature ORP systems cannot detect the truereduction/oxidation stress that is found under operatingtemperatures in feed-water systems.Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVER There have been new developments inautomation technology for boiler feed watertreatment monitoring and control to help meetthese challenges. This paper discusses Nalco’s best practice forboiler feed water treatment automationtechnology using AT ORP probe, with the3DTrasar boiler technology.Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVER Traditional FW REDOX stress managementphilosophy is to: Feed an oxygen scavenger/reductent at aconstant feed rate to the FW. Analyze FW or boiler for residual levels ofscavenger perhaps once per shift Scavenger feed rate is adjusted accordingly tomaintain a desired residual amount in thewater.Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVER The drawback to these REDOX stress managementcontrol scenarios is that they are incapable of truesystem REDOX stress control, because REDOX stress isnot being measured and systems themselves rarelyoperate at steady state. To address the need for improved monitoring andcontrol of boiler FW REDOX stress events, NalcoCompany in 2000 began a research effort to develop atechnology that could measure the actual FW REDOXstress at the temperatures and pressures of theoperating boiler systems.Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVER After 10 years extensive R&D effort we developed aninnovative @T ORP sensor technology that measures thenet oxidation-reduction potential (ORP) of the water atactual FW system temperatures and pressures The @T ORP provides a quantum improvement in FWREDOX stress management greatly improving preboilercorrosion control with continuous, real-time monitoringand diagnostics Measuring and reacting to the changing corrosivity of thesystem at actual operating conditions. The @T ORPtechnology automatically feeds chemicals on demandbased on true at-temperature and pressure REDOXchanges.Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVER Nalco @T ORP provides a quantum improvement (andparadigm shift) in FW REDOX stress management by: greatly improving preboiler corrosion control with continuous, real-time monitoring anddiagnostics by measuring and reacting to the changingcorrosivity of the system at actual operatingconditions. The @T ORP technology automatically feedschemicals on demand based on true at-temperatureand pressure REDOX changes.Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

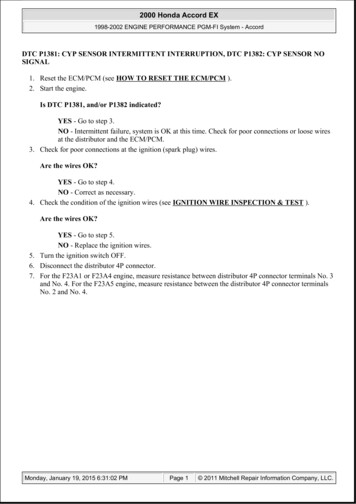

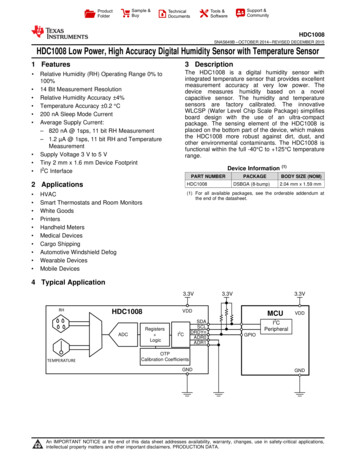

What is ORP?Oxidation Reduction Potential (REDOX)VoltageSolution[DO] ORP [Scavenger] ORP Noble MetalTypeTemp.Reference ElectrodeAg Cl- AgCl éEPBRE vs sat KClExternal Pressure Balanced Reference ElectrodeEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

WHAT DOES AT ORP DO?DETECT DETERMINE DELIVERNCSM with AT ORP technology: Providesa paradigm shift in corrosion stressmeasurement, understanding and controlORP Cell Internal ConfigurationORP Cell Internal ConfigurationWater OutActivePlatinumElectrodeWater InReferenceElectrodeCeramicJunction3/8” StainlessSteel ORP Cellwith 1/4”Reducers The AT ORP program feedsreductant to maintain thesystem in an AT ORP controlzone It responds to AT ORP stress,which correlates with systemcorrosion events The AT ORP probe respondsquickly and with the appropriatemagnitude / sensitivity to theactual redox stress event Action is taken immediately24/7 to resolve the issue withinthe MOC constraints of the plant Chemistry is fed on demandEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM10

DETECT DETERMINE DELIVERNCSM – A Custom-Built ORPAnalyzer ORP Oxidation Reduction Potential Considerations:– Corrosion is linked to REDOX potential– REDOX potential is indicated by ORP voltage (mV)– ORP voltage can be used to assess bulk FWcorrosivity FACT: Reducing conditions, as indicated by morenegative ORP values, tend to result inlower corrosion. Oxidizing conditions,similarly, tend to be more corrosive.11Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

NCSM: How does it work?DETECT DETERMINE DELIVERThe NCSM compares a reference electrode(EPBRE) to an inert, platinum electrode.The inert electrode does not participate in anycorrosion reactions , unlike a corrator probe.VoltageBulkWaterInert Metal (Pt)12External Pressure BalancedReference Electrode(EPBRE)Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVERORP indicates the potential forwater to corrodeCorrosion REDOX ReactionsREDOX Reactions Electron FlowElectron Flow ORP (mV) (OxidationReduction Potential)ORP bulk FW corrosivityEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVERReducing conditionsminimize corrosion(more negative ORP)ORP ( mV) 400F, 204CMore 100Dissolved Oxygen (ppb)Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM1000

DETECT DETERMINE DELIVERHow does NCSMcontrol corrosionstress? Detects REDOX stress in a boiler feed watersystem (ORP at operating T & P) Determines correct response to REDOX stress Delivers the correct amount of scavenger tominimize the corrosivity of boiler feed waterEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVEROxygen Corrosion Control Mechanical Deaeration primary means of O2 removal Chemical Oxygen Scavenging removal of trace amounts of O2 remainingafter deaeration Maintain Reduced Conditions minimize corrosivity promote passivationEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

MU water flow variations andtheir effect on REDOX stress200-300100-4000Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and 4008/23/20070SM17BFW MU to V-973 (klbs/hr)AT ORP vs EBPRE (mV)DETECT DETERMINE DELIVER

AT ORP on Scavenger addition(Deaerated DIW: DO 6 ppb)iAT ORP vs EPBRE (244F) - mV100Scavengers AT ORP performanceis a function of DO scavenging andspecific reductant type within allPBS 600700Oxygen Scavenging Equivalents Fed (ppb)Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and Air800Plot 2 AT ORP 1.qpcSM18

Example of NCSM operating ranges forsulfite & carbon steel system (400F)NCSM (mV) 300 Dissolved Oxygen (ppb DO) 100 20030-50Pitting Attack 10004-7-100Good0Confidence LineDeaerator -200Sulfite residual(ppb DO scavenging-300equivalents)0.8 mpy-400 300.5 mpy-500 600.2 mpy-6002500Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVERCurrent Oxygen CorrosionMonitoring Check mechanical deaeration Plume Dome & Storage Section Temperature Differential Monitor & Control product residual in BW Oxygen Testing Online DO Analyzer Chemets Total Fe & Fe 2 TestingEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVERCorrosion & @T ORPCorrelations Corrosion Higher, more positive @T ORP Soluble species such as Fe2O3 Lower Corrosion Lower @T ORP Soluble species such as Fe2O3 minimized Low oxygen, reduced state Lowest Corrosion - Passivation Lower @T ORP with higher pHSolid phases such as Fe3O4Solid, protective oxide film inhibits further metal dissolutionCorrosion will be minimizedEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

DETECT DETERMINE DELIVERExample: Engineering Alloys andCorrosion -300-200-100Carbon Steel vs EPBRE(T) - VDissolved Oxygen (ppb)140-700E-0.3160oHigh T ORP vs EPBRE(400 F) - mVIn this case notice how the corrosion potential of carbon steel declines as oxygen is removed from thesystem with the oxygen scavenger erythorbic acid. The data is plotted with the @T ORP data at 400F.Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

Case Study #1Gulf Coast Refinery Utilities Unit NaZ MU 600# BoilersEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

3D TRASAR Pre-Boiler Corrosion Controlwith the NCSM (AT ORPTM)Excursions still happenBegin Control ModeOptimized ControlEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

Dissolved OxygenBefore & After Automatic ControlExcursions still happenBegin Control ModeEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSMOptimized Control

Dissolved OxygenBefore & After Automatic ControlEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

Summary Poor operating Graver unit results in excessively high FW DO levelswhich cause severe corrosion stress conditions NCSM AT ORP detects & responds immediately to changes in BFWREDOX/corrosion stress conditions caused by poor operating DA Manual feed of scavenger provides poor BFW corrosion stress control The use of AT ORP to automatically control feed of EliminOxsignificantly reduces the DO & corrosion stresses Feeding EliminOx instead of sulfite reduces the overall solids loadingon the boiler Opex Reduction: chemical oxygen scavenger spend 75K Net Result – Improved Reliability Decreased potential for pitting corrosion Decreased potential for super heater tube foulingEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

Case Study #3West Coast Refinery #600 WHBs at Isomerization Unit RO & Condensate MUEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

System LayoutEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSM

ResultsAT ORP and DO for Monitoring and Control Tests10030MonitoringMonitoringModeControl Tests10, 12,Tests13 –ControlModeTuning PID02520-10015-20010-300LP BFW DO (ppb)AT ORP vs EPBRE (mV)ControlTestsControl3,4, 8Mode5-400070 DaysEssential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and AirSMUnit Series AT ORP and DO 1.q pc

0081/30/200812/30/200711/30/20070Essential Expertise for Water,Energy and AirSMEssential Expertise for Water, Energy and /30/2007Total IronFe (II) Low alyzed bisulfiteDiethylhydroxylamine and hydroquinoneCarbohydrazideCatalyzed bisulfiteCatalyzed bisulfite3/30/20087/30/20088/30/20070.15Scavenger 1720 0/20074/30/2008Iron - ppm (V-973)5/30/20080.250CarbohydrazideCatalyzed bisulfiteDiethylhydroxylamine and hydroquinoneCarbohydrazideCatalyzed bisulfiteCatalyzed bisulfite3/1/20080.3Scavenger 20Nalco ChemistryDate Range8/21/07 - 1/3/081/3/08 - 2/12/082/12/08 - 3/30/083/30/08 - 6/10/086/10/08 - 7/31/087/31/08 - presentNalco Chemistry407/30/200710123124Date Range8/21/07 - 1/3/081/3/08 - 2/12/082/12/08 - 3/30/083/30/08 - 6/10/086/10/08 - 7/31/087/31/08 - presentO2 Scavenger ger product used, GPD (V-973)Dissolved Oxygen7011/30/2007CarbohydrazideCatalyzed bisulfiteDiethylhydroxylamine and hydroquinoneCarbohydrazideCatalyzed bisulfiteCatalyzed bisulfite10/30/2007Scavenger 30/2007Nalco Chemistry8/30/2007Date Range8/21/07 - 1/3/081/3/08 - 2/12/082/12/08 - 3/30/083/30/08 - 6/10/086/10/08 - 7/31/087/31/08 - /30/2007Dissolved Oxygen - Chemets (ppb) (V-973)Results- Grab Samples

Results Best System Specific Scavenger found & utilized Det

Nalco AT ORP Sensor to Measure and Control Corrosion Stress and Corrosivity of Boilers Feed water Systems. Essential Expertise for Water, Energy and Air Essential Expertise for Water, Energy and Air SM SM DETECT DETERMINE DELIVER CONTROL OF CORROSION AND CORROSION PRODUCT TRANSPORT IN BOILERS CONDENSATE AND FEED-WATER SYSTEMS IS CRITICAL TO