Transcription

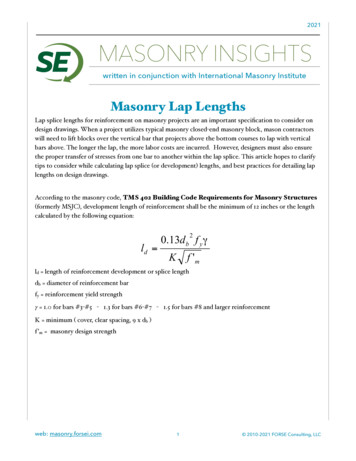

2021MASONRY INSIGHTSwritten in conjunction with International Masonry InstituteMasonry Lap LengthsLap splice lengths for reinforcement on masonry projects are an important specification to consider ondesign drawings. When a project utilizes typical masonry closed-end masonry block, mason contractorswill need to lift blocks over the vertical bar that projects above the bottom courses to lap with verticalbars above. The longer the lap, the more labor costs are incurred. However, designers must also ensurethe proper transfer of stresses from one bar to another within the lap splice. This article hopes to clarifytips to consider while calculating lap splice (or development) lengths, and best practices for detailing laplengths on design drawings.According to the masonry code, TMS 402 Building Code Requirements for Masonry Structures(formerly MSJC), development length of reinforcement shall be the minimum of 12 inches or the lengthcalculated by the following equation:2ld 0.13d b f yγK f 'mld length of reinforcement development or splice lengthdb diameter of reinforcement barfy reinforcement yield strength𝛾 1.0 for bars #3-#5 - 1.3 for bars #6-#7 - 1.5 for bars #8 and larger reinforcementK minimum ( cover, clear spacing, 9 x db )f ’m masonry design strengthweb: masonry.forsei.com1 2010-2021 FORSE Consulting, LLC

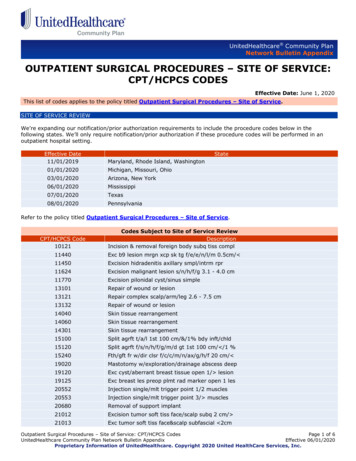

2021wall thickness, tw:8 inchesreinf. spacing:64 incheswall strength, f 'm:2500 psireinf.position:centeredreinf. Strength, fy:60000 psiBarBar diameter, dbγKdevelopmentlength, ld#30.37513.37512 inches#40.513.562512 inches#50.62513.517 inches#60.751.33.437533 inches#70.8751.33.37546 inches#811.53.312571 inches#91.1251.53.2591 inchesExample 1: DEVELOPMENT LENGTH TABLEBased on TMS 402 Equation 6-1Note that for epoxy-coated bars, TMS 402 requires that development length shall be increased by a factorof 1.5. The International Building Code, IBC references the TMS code, and also provides a maximumdevelopment length or lap length of 72 times bar diameter, db. This maximum length parameter generallyonly affects the development/lap lengths for larger bars or bars at each face. Refer to Example 2.thickness, tw:8 inchesreinf. spacing:48 inchesstrength, f 'm:2500 psireinf.position:centeredreinf., fy:60000 psiBardbγKdevelopmentlength, ldMaximum of 72 x db(from IBC)#30.37513.37512 inches27 inches#40.513.562512 inches36 inches#50.62513.517 inches45 inches#60.751.33.437533 inches54 inches#70.8751.33.37546 inches63 inches#811.53.312571 inches72 inches#91.1251.53.2581 inches81 inchesExample 2: DEVELOPMENT LENGTH TABLEBased on TMS 402 and IBCweb: masonry.forsei.com2 2010-2021 FORSE Consulting, LLC

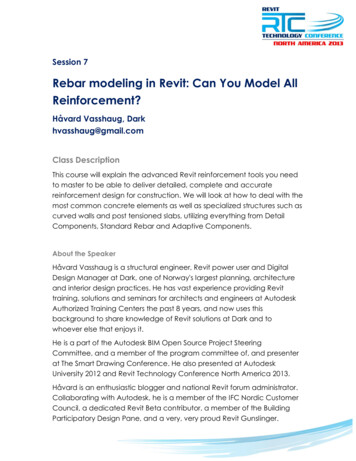

2021The old method of determining reinforcement laps were based on a simple formula of 48 times db.This old method is too simple. In most cases the development length/ splice length based on 48*db is toolong (overly conservative) for smaller bars - see Example 3 below.thickness, tw:8 inchesreinf. spacing:48 inchesstrength, f 'm:2500 psireinf.position:centeredreinf., fy:60000 psiBardbγKdevelopmentlength, ld48 * dbcomment#30.37513.37512 inches18 inchestoo long#40.513.562512 inches24 inchestoo long#50.62513.517 inches30 inchestoo long#60.751.33.437533 inches36 inchestoo long#70.8751.33.37546 inches42 inchestoo short#811.53.312571 inches48 inchestoo short#91.1251.53.2581 inches54 inchestoo shortExample 3: OLD METHOD COMPARISON FOR DEVELOPMENT LENGTHS, BARS CENTEREDThere are also times, especially with reinforcement at each face, when development length/ splice lengthbased on 48*db is too short (un-conservative) - see Example 4 below.thickness, tw:12 inchesreinf. spacing:48 inchesstrength, f 'm:2500 psireinf.position:each facereinf. cover:2.0 inchesreinf., fy:60000 psiBardbγKdevelopmentlength, ld48 * dbcomment#30.37512.0 inches12 inches18 inchestoo long#40.512.0 inches20 inches24 inchestoo long#50.62512.0 inches30 inches30 inchestoo short#60.751.32.0 inches54 inches36 inchestoo short#70.8751.32.0 inches63 inches42 inchestoo short#811.52.0 inches72 inches48 inchestoo short#91.1251.52.0 inches81 inches54 inchestoo shortExample 4: OLD METHOD COMPARISON FOR DEVELOPMENT LENGTHS, BARS EACH FACEweb: masonry.forsei.com3 2010-2021 FORSE Consulting, LLC

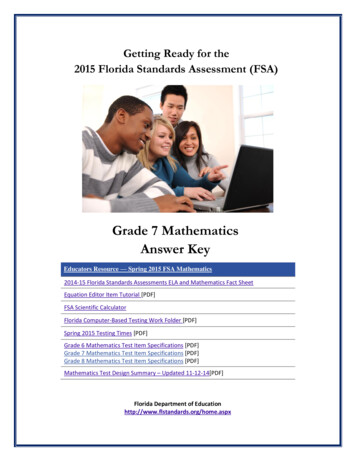

2021Finally, adding the lap splice length to the masonry wall schedule is a good way to communicate therequired lap lengths for reinforcement within masonry walls. A wall schedule is often referred to whilecontractors build the walls, and it is a simple, clear, and easy way to identify the required lap length.VERTICAL REINFORCEMENTWALL TYPETHICKNESSBAR(S) @SPACINGLAPDISTANCEW18”1-#4 @ 64” O.C.12 inchesW28”2-#4 @ 16” O.C.20 inchesW38”1-#6 @ 48” O.C.33 inchesW48”1-#7 @ 48” O.C.46 inchesCONSIDER REINFCOUPLERW512”2-#6 @ 16” O.C.54 inchesCONSIDER REINFCOUPLERNOTESf ’m 2500 PSIExample 5: MASONRY WALL SCHEDULE WITH LAP LENGTHSConfinement of ReinforcementLap splice lengths can be reduced if the lap splice is properly confinedby transverse reinforcement per TMS 402. Providing a #3 or largerbar transverse to the lapped bars and within 8” from each end of thelap splice allows the lap splice length to be reduced by theconfinement reinforcement factor per equation below. However, thelap splice length shall not be less than 36db. The clear space betweenthe transverse bars and lapped bars shall not exceed 1.5”, and thetransverse must fully develop beyond the intersection with lappedbars in grouted masonry.Asc area of the transverse bar, not greater than 0.35 in2db diameter of reinforcement barFigure 1 illustrates minimum requirements for confinementreinforcement per NCMA TEK 12-6a (2013).web: masonry.forsei.com4Figure 1: CONFINEMENTREINFORCEMENT AT LAPSPLICE PER NCMA TEK 12-6A 2010-2021 FORSE Consulting, LLC

2021Additional Tips for DesignersUsing a wall schedule is a good way to show that the same bar may have different lap lengths required indifferent situations, as is shown in WALL TYPE W1 and W2. Lap lengths do vary based on all thevariables shown in the equation on page 1.Lap lengths increase when:- Using lower f ’m- Increasing bar size, and/ or- Decreasing reinforcement cover or spacing distance between reinforcementWays to avoid long lap lengths are to use the maximum allowed f ’m , use smaller bar diameters whenpossible, try to avoid tight bar spacings, and try to avoid small reinforcement covers (double reinforcedwalls) when possible.When there is a situation where a larger lap distance is needed (larger bars are needed, small spacing, and/or double reinforced walls are needed) as shown in WALL TYPE W4 and W5, it may be advisable toconsider using a reinforcement coupler instead of lapping the reinforcement bars. Reinforcementcouplers can be a threaded splice coupler or a mechanical sleeve coupler. Couplers must be selectedcarefully as masonry cells are confined spaces and may not have sufficient space for all types ofcouplers.In conclusion, considering ways to reduce lap splice lengths (use of higher f ’m, centering bars within cellswhere possible, selecting smaller bar diameters, confinement of laps, etc) will help towardsconstructability and labor costs, possibly offsetting any additional material costs. Implementing wall,lintel, or pier schedules specifying lap splice lengths specific to reinforcement conditions in lieu of moregeneral statements in General Notes will also lead to more efficient masonry detailing.web: masonry.forsei.com5 2010-2021 FORSE Consulting, LLC

Masonry Lap Lengths Lap splice lengths for reinforcement on masonry projects are an important specification to consider on design drawings. When a project utilizes typical masonry closed-end masonry block, mason contractors will need to lift blocks over the vertical bar that projects above the bottom courses to lap with vertical bars above.