Transcription

T&B Conduit FittingsTable of ContentsGeneral InformationRigid and IntermediateMetal Conduit FittingsSpecifications for Rigid Metal Conduit45-535-10Locknuts, Sealing Fittings,Bonding and Grounding Wedges11,12Bushings13-20Knockout Plugs21,22 Chase Nipple23Threaded Bullet Hubs24-27T&B Hub28-31Threadless Fittings/Couplings32-34Set Screw Fittings/Couplings35, 36Short Elbows37Erickson Threaded Couplings38-40Conduit Straps and Spacers41-44Combination Couplings,Beam Clamps, Conduit SupportsMethods of Bonding and GroundingElectrical Metal Tubing(EMT) Fittings4546-5354-59Specifications for EMT54-56EMT Fittings57-59Flexible Cord and Cable Fittings60-80Specifications for FlexibleCord and Cable60-62Selection Guide63, 64Specifications for LiquidtightFlexible Cord and Cable FittingsStrain Relief FittingsRanger Series LiquidtightStrain Relief FittingsAluminum Liquidtight StrainRelief FittingsSilver Grip — TCF SeriesTray-Cord FittingTray-Star FittingsBlack Beauty SeriesLiquidtight Fittings6566-6970, 71, 737274, 757576, 77Wiremesh Grips78Nonmetallic Cable Glands79Metric Adapters, Fittings and Plug80

2

T&B Conduit FittingsTable of ContentsService Entrance Cable Fittings81-85Specifications81-83Service Entrance Cable Fittings84, 85Liquidtight Flexible Conduit FittingsSpecifications for LiquidtightFlexible Metal Conduit86-10886-88High Temperature FlexibleMetal Liquidtight Fittings89Liquidtight Flexible MetalConduit Fittings90-98, 101-104Specifications — Type A NonmetallicConduit FittingsLiquidtight Flexible NonmetallicConduit FittingsISO Metric BulletTM Liquidtight FittingsArmoured Cable and FlexibleMetal Conduit Fittings99100, 105108109-117Specifications for ArmouredCable and Flexible Metal Conduit109-112Fittings for Armoured Cableand Flexible Metal Conduit113-117Nonmetallic SheathedCable Fittings118-124Specifications for NonmetallicSheathed Cable Fittings118, 119Fittings for Nonmetallic SheathedCable Fittings120-124Liquatite Flexible ConduitApplication Guide125,126Steel127-133, 135, 137140, 142, 143Aluminum134, 136, 141Shielding138, 139Nonmetallic144, 145 Corrlok System146-150Engineering Information151, 152Packaging153Conduit Dimensional Data154, 155Conduit Chemical Resistance Guide156-159Alphanumeric Index160-176

T&B Conduit FittingsGeneral InformationThomas & Betts The Complete Product LineSince the turn of the century, Thomas & Bettshas been a recognized leader in electricalfittings. Industry standards such as Chase Nipples and Erickson Couplings wereintroduced by Thomas & Betts and arestill registered trademarks. This leadershipcontinues. Here’s why.Innovative DesignsThe real test of product design ofelectrical fittings lies in two areas: jobsuited installation and life-of-the-jobreliability. Thomas & Betts Fittingsprovide both because we listen. We listento problems and suggestions from thefield. Most of the products in this sectionresult from the good suggestions ofknowledgeable electrical people. Manywere customer specials to solveparticular installation and performanceproblems. You can benefit from theirexperience.Approvals and CertificationsElectrical raceways require accessoryfittings that provide the mechanicalstrength, ground continuity, andenvironmental integrity of the system.As new raceways have beenintroduced, Thomas & Betts engineershave designed fittings which meet therequirements of the Canadian electricalcode, as well as the CanadianStandards Association. You can useThomas & Betts Fittings with confidence.Note: All dimensions in this catalogue areapproximate.4High Performance ProductsQuality and performance resultwhen engineering design skills arecombined with the manufacturingtechnologies required to produce them.The Thomas & Betts Fittings in thissection are produced from manymaterials and by many manufacturingmethods, each carefully selected for itsend use suitability. This combinationgives you the reliable performance youexpect from Thomas & BettsRaceway Fittings.Lower Installed CostIt is a function of purchase cost,availability, installation advantage, andperformance. Lower installed cost comesin every carton of Thomas & BettsRaceway Fittings.

T&B Conduit FittingsRigid Metal Conduit FittingsSpecifications — Rigid Metal Conduit/PVC Coated Rigid Metal ConduitRef. CEC Rule 12-1000Rigid Metal Conduit affords maximummechanical protection to conductorswithin the raceway. Rigid metal conduitcan be installed indoors and outdoors, indry locations or wet locations, exposed orconcealed, in all atmospheric conditionsand in hazardous locations.Galvanized rigid steel conduitinstalled in concrete does not requiresupplementary corrosion protection.Galvanized rigid steel conduit, installed incontact with soil, does not generallyrequiresupplementarycorrosionprotection. However, when buried incorrosive soil (corrosive soil ischaracterized by low resistivity of lessthan 2,000 ohm-centimeter) or cinders, aprotective coating of bitumastic, asphaltbased paint or a PVC coating is appliedto the conduit. CEC Rule 12-934requires that rigid steel conduit installed inor under permanently moist cinder fill beencased in at least two inches ofcinder-free concrete unless the conduit isat least 18 inches below the fill. Steelconduit protected from corrosion solely byenamel can only be used indoors and inoccupancies not subjected to severecorrosive influences.Rigid nonferrous metal conduit(aluminum)cannotbedirectlyembedded in concrete containingsoluble chlorides such as calciumchloride; unwashed beach sand,seawater, or coral bearing aggregates.However, if adequately treated by aprotective coating of bitumastic orasphalt-based paint or PVC coating, theconduit can be installed in concretecontaining chlorides.Supplementary nonmetallic coatingspresently used on ferrous rigid metal ornonferrous metal have not beeninvestigated for resistance to corrosion.CEC Rule 12-920 requires that whenconduit enters a box or fitting, a bushingmust be provided to protect wires fromabrasion unless the design of the box orfitting provides equivalent protection.According to CEC Rule 12-906where No. 4 or larger ungroundedconductors enter or leave a conduit, aninsulating bushing with a smooth wellrounded insulating surface must beprovided to protect conductors unlessthe terminating fitting is equipped with aninsulated throat, firmly secured in placeproviding equivalent protection. Theinsulating bushing or insulating materialmust have a temperature rating of not lessthan the insulation temperature rating ofinstalled conductors. When conduitbushings are constructed wholly ofinsulating material, a locknut must beinstalled both inside and outside of theenclosure to which the conduit isattached.Fittings and couplings are requiredto be of concrete-tight type whenembedded in masonry or concrete or indry locations and of the raintight typewhen installed in wet locations.In wet locations or locationswhere walls are frequently washed orwhere there are surfaces of absorbentmaterials, the entire wiring systemincluding boxes, fittings, conduit andcables must be supported suchthat there is at least 1/4 inch air spacebetween it and the supporting surface(CEC Rule 2-122).CEC Rule 12-3024 requires that theraceways be metallically joined togetherinto a continuous electric conductorand must be mechanically connected toall boxes, fittings and cabinets as toprovide effective electrical continuity.Conduit is required to be supportedadequately and conduit bends inone run are restricted to the equivalentof four quarter i.e. 360 degrees total.5Listed below are some of theadvantages of rigid aluminum conduitover rigid steel conduit.1. Non-sparking—eliminates hazard inexplosive atmospheres2. Non-magnetic—reduces power lossdue to voltage drop3. Resists most corrosive atmospheresand industrial environments4. Lightweight—reduces costof handling and installation5. Attractive appearance

T&B Conduit FittingsRigid Metal Conduit FittingsSpecifications—Rigid Metal Conduit/PVC Coated Rigid Metal Conduit (continued)For further details and completeinformation please refer to the following:1. ANSI C80.1 Rigid Steel ConduitZinc Coated, Specifications for2. ANSI C80.2 Rigid Steel Conduit,Enameled, Specifications for3. ANSI C80.5 Rigid AluminumConduit. Specifications for4. ANSI C80.4 Fittings for Rigid MetalConduit and Electrical MetallicTubing, Specifications for5. WW-C-581 Federal Specification,Conduit, Metal, Rigid & Coupling,Elbow, and Nipple, ElectricalConduit, Zinc Coated6. WW-C-540 Federal Specification,Conduit, Metal, Rigid (Electrical,Aluminum)7. WW-C-571 Federal Specification,Conduit, Metal, Rigid, and Coupling,Elbow, and Nipple, ElectricalConduit Enameled8. U.L. 6 Standards for Safety. RigidMetal Conduit9. U.L. 2142 Standards for Safety.Intermediate Metal Conduit10. ANSI C33.84 Standards forSafety, Outlet Boxes and Fittings11. CEC Section 12-1100 Rigid andFlexible Conduit12. CSA C22.2 No. 45 SafetyStandards for Rigid Metal Conduit13. CSA C22.2 No. 18 SafetyStandards for Outlet Boxes,Conduit Boxes and Fittings14. NEMA FB-1 StandardsPublication. Fittings and Supportsfor Conduit and Cable Assemblies15. A-A-50553 Federal Specification.Fittings for Conduit Metal Rigid(Thickwall & Thinwall [EMT] Type)Please NoteThe excerpts and other material herein, whether relating to theCanadian Standards Association, the Underwriters Laboratories, Inc.listing, to industry practice or otherwise, is not intended toprovide all relevant information required for use and installation.Reference to original or primary source material and data ismandatory before any application or use is made of the product.6

T&B Conduit FittingsRigid Metal Conduit FittingsSuggested Specifications for Rigid Metal Conduit/PVC Coated Rigid Metal Conduitand Fittings meets 2002 CEC Rule 2-112Cat. #CP8KOPR-SHIELD** TM of Jet-Lube, Inc.Cat. #AP8ALUMA-SHIELD Rigid ferrous metal conduit or PVCcoated rigid conduit prior to coatingshall be of the hot dipped galvanizedtype adequately protected againstcorrosion inside and outside includingthreads, and conforming to thefollowing applicable specifications:-Rigid Ferrous Metal Conduit FederalSpecification WW-C-581/ANSIC80.1/U.L. 6/CSA C22.2 No. 45-PVC Coated Ferrous Metal ConduitApplicable listed under (i) and inaddition conforming to NEMAPublication No. RNI-1974 (Type A)PVC coating on conduit and associated fittings shall have no sags,blisters, lumps or other surfacedefects and shall be free of holes. Rigid nonferrous metal conduit shallconform to Federal SpecificationWW-C-540/ANSI C80.5/U.L. 6/CSAC22.2 No. 45.Series 1451Knockout PlugSeries 1470Plug, Conduit/Fitting All field cuts shall be square, reamedand deburred. Conduit threads shallbe tapered for entire length with 3¼4”taper per ft. Conduit threads prior toassembly shall be clean and coatedwith grease metallic type conductivecompounds such as series CP8KOPR-SHIELD for ferrous conduit orseries AP8 ALUMA-SHIELD fornonferrous(aluminum) conduit as manufacturedby Thomas & Betts. To prevent ingress of plaster, dirt,trash or moisture in raceways, boxes,fittings and equipment during courseof construction, all open ends shallbe closed with rugged thermoplasticplugs as manufactured by Thomas &Betts, series 1470 and 1451. Plugsshall be firmly secured in place toprovide adequate seal and shall befunctionally unaffected by moisture.Thermoplastic plugs shall be rated at105 C/221 F and have a U.L.flammability rating of 94V-1.7

T&B Conduit FittingsRigid Metal Conduit FittingsSuggested Specifications for Rigid Metal Conduit/PVC Coated Rigid Metal Conduitand Fittings (continued)Series 1276Conduit StrapSeries 690Conduit SupportsSeries 700Adjustable BeamClampSeries 1350Conduit SpacerSeries 140LocknutSeries 106Bonding LocknutSeries 5302Sealing GasketSeries 370Threaded Hub(Raintight)Series 485 PVCCoated ThreadedHubs (Raintight)Series 8123Threadless Fitting(Concretetight)Series 8120Threadless Coupling(Concretetight)Series 8125Set Screw Fitting(Concretetight) Conduit shall be securely fastened inplace, at intervals as specified by thecode, using suitable straps, hangersand other supporting assemblies asindicated on plans and asmanufactured by Thomas & Betts,series 1276, 690 and 700. All straphangers and supporting assembliesshall be of rugged constructioncapable of supporting weight with areasonable factor of safety and shallbe adequately protected againstcorrosion. Where applicable shallconform to Canadian StandardsAssociation Standard C22.2 No. 18. In wet locations or in locations wherecorrosive conditions are present,vertical and horizontal runs of conduitshall be firmly supported so thatthere is at least 1¼4” air spacebetween the conduit and the wallor supporting surface. Spacers andsupporting straps shall be ofmalleable iron construction, hotdipped galvanized conforming toCanadian Standards AssociationStandard C22.2 No. 18 such asThomas & Betts series 1276 straps andseries 1350 spacers.Nonferrous metal straps and spacersmay be substituted as required. Where threaded conduit terminatesinto a threadless opening, a locknutshall be provided both inside andoutside the box or enclosure andthe conduit end shall be fitted withan insulating bushing. In wetlocations, a suitable gasket shallbe provided between the outsidelocknut and the opening.Locknuts shall be rugged, ofhardened steel or malleable ironconstruction, electro-zinc platedand capable of cutting throughprotective coating on box orSeries 8124Set Screw Fitting(Concretetight)8enclosure to insure positive bondsuch as Thomas & Betts series 140. Where raceway and associatedfittings are used as part of anequipment grounding system,terminating fittings shall be equippedwith bonding typelocknuts such as Thomas & Bettsseries 106 bonding locknuts.Sealing gaskets shall beconstructed of oil resistant/moistureresistant rubber and shall be suitablyprotected by and permanentlybonded to a stainless steel retainersuch as Thomas & Betts series 5302. Where threaded rigid metal conduit isinstalle

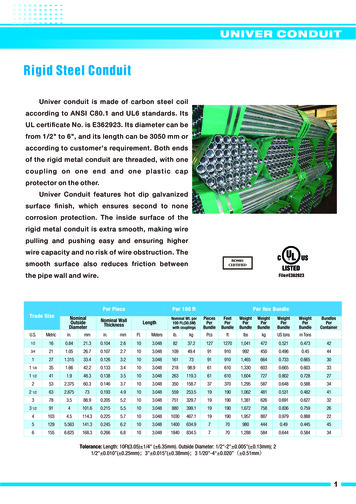

1. ANSI C80.1 Rigid Steel Conduit Zinc Coated, Specifications for 2. ANSI C80.2 Rigid Steel Conduit, Enameled, Specifications for 3. ANSI C80.5 Rigid Aluminum Conduit. Specifications for 4. ANSI C80.4 Fittings for Rigid Metal Conduit and Electrical Metallic Tubing, Specifications for 5. WW-C-581 Federal Specification, Conduit, Metal, Rigid & Coupling, Elbow, and Nipple, Electrical .