Transcription

GUIDE TO INDUSTRIAL PAINTING03STORAGE OF FLAMMABLE PRODUCTSR.D. 379/2001Regulations regarding the storage of chemical products and theadditional technical instructionsfor specific products and theircategories. This section looks at themain characteristics regarding storage,ie: tanks, drums, portable containers,bottles, etc. It also considers the loca-tion of the storage, ie: above ground,below ground, inside, cupboards, etc.and the protective measures againstthe risks that are present in thesestorage areas.additional technical inSTRUCTIONS FOR FLAMMABLE LIQUIDS “APQ-001”Product classification:They are classified as A, A1, A2, B,B1, B2, C and D, depending on theirflammability and the conditions ofstorage.Combustion temperature orFlashpoint. This is the minimumtemperature at which a flammableliquid gives off enough vapour tocreate a flammable mixture with theair surrounding the surface of theliquid or inside a container. In thetest to determine the flashpoint, aflame is used as a source of ignition.The liquid is heated slowly from atheoretical lower temperature and asthe temperature increases, a flame isapplied to the vapour chamber. Thepoint of ignition is the temperature atwhich a spark is observed when theflame or source of ignition is applied.Spontaneous ignition can sometimesbe called the temperature/point ofauto-ignition and could also appearas ignition point. It is important toensure that there is no confusion withthe temperature of ignition or flashpoint, especially if data from tests ortables is not available. In cases wherethese values are not available, it mustbe assumed that the auto-ignitiontemperature is much higher than theflashpoint. In the majority of casesthis is between 200 and 700 ºC. Thisparameter should be used as a reference for operations with a significantrise in temperature but without an ignition source such as heat treatment,heat exchangers with insulating oils,covered electric motors, etc.Temperature of spontaneousignition. This is the minimumtemperature at which a substancein contact with air ignites spontaneously without any source ofignition. At this temperature there isenough energy to start combustion.BERNARDO ECENARRO, S.A. Ugarte Industrialdea, 147 - 20720 Azkoitia. (Gipuzkoa) - Spain - Tel. 34 943 74 28 00www.besa.es

INDUSTRIALLABORSAFETY GUIDE TO INDUSTRIAL PAINTING03PREVENTIONAND TREATMENTSTORAGE OF FLAMMABLE PRODUCTSThe ignition temperature of hydrocarbons in the air decreases as the molecularmass increases. For example:Methane . 537 ºCn-butane . 405 ºCn-decane . 208 ºCThe ignition tempetature of hydrocarbons in the air, eg: paint thinners, decreasesas the container s size increases.The ignition temperature of toluene is 580 ºC in a container of 0,05 l.The ignition temperature of toluene is 480 ºC in a container of 15 l.The ignition temperature of methanol is 475 ºC in a container of 0,05 l.The ignition temperature of methanol is 375 ºC in a container of 15 l.The temperature of autoignition can decrease significantly due to a catalyst,such as particles of iron oxide dust, atmospheres rich in oxygen and under highpressures.Class ALiquefied products, whose absolute vapour pressure at 15 C is greater than 1 bar. Depending on the temperature at which they are stored,, they can be considered as the following:a. Subclass A1. Products of class A that are storedliquefied at a temperature below 0 C.Class B*b. Subclass A2. Products of class A that are storedliquefied in other conditions.Products of which the ignition point is below 55 C and are not included in class A. Depending on theirignition point, can be considered as the following:a. Subclass B1. Products of class B of which ignitionpoint is below 38 C.b. Subclass B2. Products of class B in which theignition point is equal or greater than 38 C andbelow 55 C.Class CProducts which have an ignition point in the range of 55 C and 100 C.Class DProducts which have an ignition point greater than 100 C.* The majority of products sold by Bernardo Ecenarro S.A. are categorised as Class B. The physical chemical properties of all the products sold are listed in section number 9 of the corresponding safety data sheet.BERNARDO ECENARRO, S.A. Ugarte Industrialdea, 147 - 20720 Azkoitia. (Gipuzkoa) - Spain - Tel. 34 943 74 28 00www.besa.es

GUIDE TO INDUSTRIAL PAINTING03STORAGE OF FLAMMABLE PRODUCTSadditional guidance for storing flammable liquids“APQ-001” (CONT.)These technical intructions applyto the storage, loading, unloadingand the decanting of flammableliquids, such as paints and thinners,with the following exceptions:1. Storage with a capacity below 50 l.of class B products, 250 l. of class Cor 1,000 l. of class D.3. Storage of products where theflamepoint is higher than 150 C.2. Storage within a process area where the capacity is limited to what isnecessary for the continuity of theprocess.4. Storage of products where specificindustrial safety regulations exist.Exclusions that apply to the additional guidance for storing flammable liquids:1. Internal use in process installations2. The storage of paint, clearcoat orsimilar mixtures where they aregoing to be used within a 30 dayperiod and only once.3. The temporary storage of productswaiting to be redistributed andwhere the expected storage willnot exceed 72 hours continuously.In all cases, if the products are tobe stored for more than 8 daysper month or 36 days per year, thestorage cannot be considered temporary and the long term storageguidelines should be followed.BERNARDO ECENARRO, S.A. Ugarte Industrialdea, 147 - 20720 Azkoitia. (Gipuzkoa) - Spain - Tel. 34 943 74 28 00www.besa.es

INDUSTRIALLABORSAFETY GUIDE TO INDUSTRIAL PAINTING03PREVENTIONAND TREATMENTSTORAGE OF FLAMMABLE PRODUCTSregistration with the department of industryNew projects for storing flammableliquids in buildings or non industrialestablishments can be part of a largerproject or a project on their own. Where a storage facility is being designedon its own, the plans will be drawn upand signed by a competent designengineer. Where the design engineeris not the general project designer,they must work alongside the generalarchitect and comply with the basicaspects of the installation as statedin the general design project of thebuilding.A project which refers to the storage regulations of chemical productsshould be composed of the followingdocuments:technical appendixThis should list, as a minimum, thefollowing sections:Warehousing and containers types, adescription of capacities, dimensionsand other characteristics. It should listthe products to be stored with theirsafety data sheets and make reference to the regulations regarding newsubstances and their classification. Itshould also contain details of the packaging and labelling of harmful substances and the maximum pressuresand temperatures expected. It shouldalso demonstrate compliance with thedesign regulations.Systems, equipment and methods ofprotection against fire, defining theregulations, the measures that will beused and carrying out the calculationsrequired.BERNARDO ECENARRO, S.A. Ugarte Industrialdea, 147 - 20720 Azkoitia. (Gipuzkoa) - Spain - Tel. 34 943 74 28 00Other considerations of safety and adescription of their characteristics.The methods used to protect materialsagainst corrosion and/or other dangerous effects.Information about the transfer ofchemicals, their characteristics andquantities.Study of the classified zones.Geographical and topological aspectsof the surrounding area,consideringnatural disasters that may happen,such as, landslides, flooding, etc. and adescription of the protective measuresrequired in each case.Certification of the compliance withthese complementary technical instructions or other measures employed.www.besa.es

GUIDE TO INDUSTRIAL PAINTING03STORAGE OF FLAMMABLE PRODUCTSregistration with the deparment of industry (CONt.)PlansThese should include the following asa minimum:Geographical maps preferably usingscales 1:25,000 or 1:50,000. Each mapshould show the storage and accessroutes, urban concentrations andrelevant topographical risks within a10km radius centered on the warehouse.Separate plans of the installationshould be provided which should showthe position of all fixed fire fightingequipment. A detailed plan of the firealarm system should be provided aswell as the drainage, antipollution systems and all other safety equipment.A general map of the area showingthe safe distances according to theregulations.Detailed plans for each type of container and their safety systems should beprovided.proposalInstructions for the use, maintenance and the safety of the installation,regarding personnel, goods and the environment.for warehouses with a capacity less than the following:Product classLiters insideLiters outsideB300500C3,0005,000D10,00015,000The project should be submitted witha written document signed by theowner of the warehouse or it s legalrepresentative. This document shoulddescribe the products that are goingBERNARDO ECENARRO, S.A. Ugarte Industrialdea, 147 - 20720 Azkoitia. (Gipuzkoa) - Spain - Tel. 34 943 74 28 00to be stored along with their characteristics. It should also describe thewarehouse and all the safety measuresthat are going to be used.www.besa.es

INDUSTRIALLABORSAFETY GUIDE TO INDUSTRIAL PAINTING03PREVENTIONAND TREATMENTSTORAGE OF FLAMMABLE PRODUCTSregistration with the deparment of industry (CONt.)COMMERCIAL PREMISES OPEN TO THE PUBLICThe quantity of stored liquid must notexceed 0,8 m3 (800 liters) per squaremeter of floor area, without exceedingthe following total quantities of:0,2 m3 (200 liters) of class A product;0,25 m3 (250 liters) of product subclassB1 with boiling point below 38 ºC;0,5 m3 (500 liters) of product subclassB1 with boiling point of 38 ºC or higher,1,0 m3 (1,000 liters) of product subclassB2; 2,5 m3 (2,500 liters) of product classC; 10 m3 (10,000 liters) of productclass D.The floor area of the warehouse maybe calculated by adding the maximumcapacity likely to be reached to thesame floor area for adjacent aisles.For liquids soluble in water withinclasses B, C and D the above quantities may be doubled. The sameapplies when the area of storage hasan automatic fire extinguising systeminstalled.BERNARDO ECENARRO, S.A. Ugarte Industrialdea, 147 - 20720 Azkoitia. (Gipuzkoa) - Spain - Tel. 34 943 74 28 00Containers shall never exceed onemeter in height or be piled one on topof another (whatever is the greater),unless adequate shelves or supportsare available. Filling, transferring orhandling of liquids in classes A andB1 is not allowed below ground level.Where these operations are carriedout above ground level, a maximum of0,04 m3 (40 liters) per square meter offloor area must be followed and a lowvoltage electrical installation must bein operation. This must be installed inaccordance with the current regulations for electrical installations in areaswith a risk of explosion or fire (EX).In these buildings, people other thanemployees from the warehouse areexpected to have access.For example, customers who purchaselarge quantities of paints and solventsfor retail sale, may collect their ownstock. A safe and organised warehouseis essential.www.besa.es

GUIDE TO INDUSTRIAL PAINTING03STORAGE OF FLAMMABLE PRODUCTSsummary of requirements for compliance to APQ-001LOCATION OF THE WAREHOUSEIn general, for all warehouseswith portable containershaving an individual capacityof less than 3,000 liters, theunstable liquids of classes B, C andD should be treated as if they were aproduct of subclass B1. Flammableaerosols should be treated as if theywere of subclass B2.Storage of product classes A and B1are not allowed underground.PROTECTION AGAINST RISKSA. Transport: Portable containersmust comply with the dangerous goods blity road regulations (ADR).B. Pressure relief valves: Containers which have a capacity greaterthan 250l. should have an emergency venting valve. The capacity ofthis valve must not be less than thecapacity on a fixed container. Thermalrelief devices, such as fusible plugs,should be used when the product mayblock other methods of venting. Theoperating temperature of these devicesmust not be greater than 150 ºC.C. Volumes and quantities: Whenliquids of mixed classes are to be stored in the same stack or shelf, the whole group of liquids should be treated asbeing in the most restrictive class. Ifthe warehouse is organised in stacksor separate shelves, the total quantitiesstored must not exceed the quantitiespermitted for each class.D. Evacuation: Warehouses withinbuildings must have at least twoindependent escape routes, whichare clearly signed. The length of theemergency exit corridor must not begreater than 25 m. Access to otherareas should have 60 min. automaticfire doors. The corridor should be aminimum of 1 m. wide, except wherespecific warehouses demand a greaterwidth.BERNARDO ECENARRO, S.A. Ugarte Industrialdea, 147 - 20720 Azkoitia. (Gipuzkoa) - Spain - Tel. 34 943 74 28 00E. Electrical installation: It shouldcomply with the current regulationsfor areas with a risk of explosion (EX).It should also comply with regulationMI-BT-026.F. Location: Where shelving is usedwith wooden shelves or platforms, theymust be strong and have a minimumthickness of 25 mm. The containersshould be packed, palletised and stacked ensuring stability and followingthe maximum stacking height. Thisis to prevent excessive weight in thelower pallets. The highest point ofthe stored products must be at least1 meter below any beam, buildingstructure, sprinkler head or othervertical obstruction. This height mustnot exceed the values given in tables IIand III of section three of the ITC.G. Ventilation: The warehouse musthave natural or forced ventilation.This must comply with regulation 3 ofsection three of the ITC.H. Spillages: The floor and thefirst 100 mm of the walls around thewarehouse area should be resistant toliquids including doors and openings.Alternatively, the floor may drain to asafe place.I. Protection against fire: Sectionthree of the ITC lists the necessaryfire protection measures for mobilecontainers and are shown in section 5,of table 5.www.besa.es

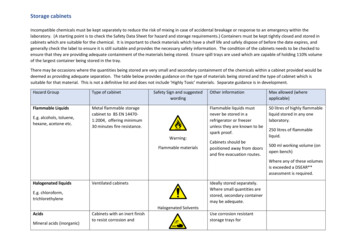

INDUSTRIALLABORSAFETY GUIDE TO INDUSTRIAL PAINTING03PREVENTIONAND TREATMENTSTORAGE OF FLAMMABLE PRODUCTSsummary of requirements for compliance to APQ-001 (CONT.)LOCATION OF THE STORAGEPROTECTION AGAINST RISKSSafety cabinets: No more than threecabinets should be installed in thesame area, unless each group of threeis separated by a minimum of 30 m.They must have a minimum firerating factor of RF-15. They must havevisible labelling stating “flammable”.Where class A products are being stored, it is obligatory to have ventilationto outside. The maximum permittedquantities inside a cupboard are 100l.of class A, 250l. of class B, 500l. of classC or the total quantity of class A, B andC must not exceed the quantities of Aand B.Internal storage rooms: They aretotally enclosed inside the building anddo not have outside walls.They should be fire resistant and haveboth a maximum occupation densityand a maximum permitted volumefollowing Table one in section threeof the ITC. No container should be situated more than 6 m. from a corridor.The maximum stacking height canbe found in Table two of section threeof the ITC, with the exception of classB1 products in containers greater than100l. These should not be stacked.Separate storage rooms: Inside abuilding, but with one or more outsidewalls.Easy access must be provided forfire fighting through windows,openings or fireproof walls.Annexed storage rooms: Whereonly one common wall exists with abuilding used for other purposes.The maximum room height, themaximum stacking height and themaximum total storage can be foundin the ITC, section 3, Table two. Thestructure, ceiling and walls which joinwith other areas or buildings must befire resistant to RF-120 and the doorsto RF-60.BERNARDO ECENARRO, S.A. Ugarte Industrialdea, 147 - 20720 Azkoitia. (Gipuzkoa) - Spain - Tel. 34 943 74 28 00www.besa.es

GUIDE TO INDUSTRIAL PAINTING03STORAGE OF FLAMMABLE PRODUCTSsummary of requirements for compliance to APQ-001 (CONT.)LOCATION OF THE WAREHOUSEPROTECTION AGAINST RISKSInternal industrial storage: Parts ofbuildings that are designed specificallyfor storage.Buildings should have a limited capacity and should be at least 15m. fromother buildings or have a fire resistantwall to RF-120 and automatic doorsto RF-60. There shouldn t be any containers more than 6m. from a corridor.Follow the maximum stacking height,which can be found in Table 3 of section 3 in the ITC. The minimum widthof main corridors should be 2,5 m.,lateral corridors should be 1,2 m wideand access doors, windows and otherExternal industrial storage: Wherethe ratio between open space andvolume is greater than 1/15 m2/m3.The capacity can be found using article 4.3.2 of section three in the ITC. Itshould also be in accordance with Table four of section three in the ITC. Thestorage area should have a enoughconnections should be 1m.The stacks should be separated bycorridors or non flammable materialshaving a minimum width of 1,2 m.in both cases. If the storage area isgreater than 2,500 m2 this area shouldbe separated into sections using firecurtains to RF-120. Where the storagearea is 2,500 m2 or less, water curtainscan be used to divide the sections.slope to avoid any leaks towards thebuildings or should be bunded. Thisbund should be 150 mm. minimum talland drain to a safe place.VERY IMPORTANT:Always store the containers in a well ventilatedplace, which is not exposeddirectly to sunlight or neara source of heat. The optimum temperature shouldbe between 5 and 30 ºC.BERNARDO ECENARRO, S.A. Ugarte Industrialdea, 147 - 20720 Azkoitia. (Gipuzkoa) - Spain - Tel. 34 943 74 28 00www.besa.es

ADDITIONAL GUIDANCE FOR STORING FLAMMABLE LIQUIDS "APQ-001" (CONT.) These technical intructions apply to the storage, loading, unloading and the decanting of flammable liquids, such as paints and thinners, with the following exceptions: 1. Storage with a capacity below 50 l. of class B products, 250 l. of class C or 1,000 l. of class D. 2.