Transcription

REVIEWDeveloping a quality control program fordigital mammography: achievements sofar and challenges to comeDetection of breast cancers with mammography is a challenging task. Images must be of high quality ifcancers are to be found at the earliest possible time. This motivates the need for a quality assurance program.It has long been recognized that the performance of a complex imaging system such as mammography candrift over time and, therefore, quality control procedures must be in place to ensure that all componentsof the imaging chain are operating properly. While digital mammography overcomes many of the technicallimitations of screen-film mammography, its performance can easily be diminished if it is carried out in asuboptimal manner. Routine quality control is equally important for digital mammography as it was forscreen-film imaging. While the need to monitor film processing generally disappears when digital imagingis employed, there are new requirements for quality control related to the display workstation and imagingsoftware. Furthermore, to aid in controlling radiation dose to the breast, it is important to establish alinkage between digital signal value and dose and to monitor signal levels over time. The availability ofimages in a digital format offers an opportunity to improve efficiency in that it permits automated testingto be performed.KEYWORDS: digital mammography n quality controlMammography has been demonstrated to beinvaluable in the detection of breast cancersbefore they cause symptoms or can be foundby physical examination. Employed in routinescreening programs of women over 40 years ofage, mammography has been demonstrated tocontribute to a reduction in mortality due tobreast cancer of 25% or more [1–4] .The radiologic signs of breast cancer includemass lesions, microcalcifications, asymmetriesbetween images of the two breasts, and architec tural distortion. In order for breast cancer to bedetected accurately at the earliest possible oppor tunity, all factors influencing the acquisition,display and interpretation of the mammogrammust be optimized and those optimum condi tions must be maintained over time. This process,referred to as quality assurance, requires the coop erative efforts of several individuals: the technolo gist (radiographer), the radiologist, the equipmentmanufacturer and the medical physicist.Detection of breast cancer requires that thebreast be properly positioned in the mammo graphy system and appropriately compressed bythe technologist (radiographer). The exposurefactors must be properly selected. Furthermore,the equipment used to acquire and display theimage must be properly designed to facilitateincluding as much breast tissue as possible in theimage and producing an image with excellentcontrast and spatial resolution, with minimumdistortion or artifact. This should be accom plished at the lowest radiation dose to the breast,compatible with these aspects of image quality.Quality assurance embraces a wide range ofactivities, including the training, evaluation andcontinuing education of radiologic technologistsand radiologists, the selection of equipment,reporting, dissemination of results and mainte nance of records. The article focuses on qualitycontrol (QC), a term used to describe the programof testing the technology used in mammographyto ensure that it is operating within an acceptablerange of its optimum performance. I will con sider the changes in the QC program that shouldoccur as digital mammography replaces screenfilm technology, concentrating on the philosophyand principles of testing and on what needs to betested. Detailed procedures for carrying out thetests have been described elsewhere [5–9] . Wherepossible, I have based the commentary in thisarticle on material in the scientific literature andreferences are given where available. However, Ihave also included my observations that derivefrom working in the laboratory with digital mam mography systems for over 15 years leading a largeteam of medical physicists who since 1990 havedeveloped QC procedures and used them for test ing film and digital (since 2005) equipment inThe Ontario Breast Screening Program.10.2217/IIM.10.63 2011 Future Medicine LtdImaging Med. (2011) 3(1), 123–133Martin J YaffeSunnybrook Health Sciences Centre,2075 Bayview Avenue, Toronto, ON,M4N 3M5, CanadaTel.: 1 416 480 5715Fax: 1 416 480 5714martin.yaffe@sunnybrook.caISSN 1755-5191123

REVIEWYaffeThe principles of modern QC came fromearlier work in general radiology and mam mography [10–16,101] . Both in Europe and NorthAmerica there was considerable effort in estab lishing recommendations for organized QCprograms for mammography [17,102] . In NorthAmerica, much of the momentum towardimplementing routine QC in mammographycame from the American College of Radiology(ACR) who began developing QC recommen dations for mammography in 1987 and pub lished comprehensive QC manuals in 1992,1994 and 1999 [18] .A QC program will ensure that the tools usedfor mammography are operating properly. It isessential, however, to keep in mind that theskills and knowledge of the people who use thesetools, the technologists who acquire the mam mograms and the radiologists who interpretthem, are absolutely critical in establishing highquality in detection and radiological diagnosisof breast cancer. The 1999 Quality ControlManual published by the ACR [18] , which hassections for the radiologist and radiologic tech nologist, continues to be an excellent referencefor this purpose, although hands-on continuingeducation courses provided by experts are prob ably the best resource for maintaining skills atthe state-of-the art.Digital mammographyDigital mammography was introduced in 2000and has been shown in several studies to pro vide superior performance in screening [19–23]for breast cancer, particularly in women withdense breasts and those who are under 50 yearsof age or are pre- or peri-menopausal [19] .Overviews of these and other studies evaluat ing the performance of digital mammographyare given in [24,25] . Digital mammography alsohas potential for increased efficiency in imagearchiving and retrieval, the possibility of avoid ing the costs, complexity and waste disposalproblems associated with chemical processingof film. In addition there is enhanced ability toperform quantitative imaging (e.g., computeraided diagnosis), contrast subtraction stud ies and 3D mammography (tomosynthesis).These factors have driven a steady replacementof film mammography by digital systems. Thispresents both opportunities and challenges tothose involved in delivering mammographyservices. One of the important challenges is tohave in place, in a timely fashion, an appropri ate framework of quality assurance for digitalmammography systems.124Imaging Med. (2011) 3(1)Approach to QCA QC program for digital mammographyshould monitor all aspects of the image acqui sition, archiving and display operations thataffect clinical image quality or radiation dose.Clinical image quality refers to those factors thatcan affect the ability to make an accurate radio logical diagnosis. Radiation dose is of concernbecause x-rays have carcinogenic potential. Theguiding principle of radiological protection isthat doses should be as low as reasonably achiev able. Clinical image quality is, to some extent,related to radiation dose, and therefore, theword ‘reasonably’ implies that the dose shouldbe high enough to provide the necessary clinicalimage quality.The approach to QC is to establish appropri ate baseline or reference values for the factorsrelated to image quality and for the dose and tomonitor on a routine basis that those factors andthe dose remain within an acceptable range ofthe reference level. Technical QC is carried outprimarily by two individuals, a QC radiologi cal technologist and a medical physicist. Testsare assigned to each of these according to theirbackground experience and their proximity tothe facility; the radiological technologist workingwithin the facility on a day-to-day basis carriesout tests that must be performed daily, while thephysicist, who may be available less frequently,performs those tests that require more expen sive specialized equipment or a sophisticatedu nderstanding of physics and mathematics.What requires monitoring?Quality control programs were initially devel oped for screen-film mammography and the testswere based around those factors of image acquisi tion, archiving and display that had an importantinfluence on image quality and that were likelyto drift from their optimum setting or condi tion. The tests specified in the ACR programfor screen-film mammography are listed in Box 1.In the ACR program, the first five tests andtest 11 are performed by the technologist whiletests 6 –13 and modified versions of tests 3 and4 are performed by the medical physicist. Inaddition, the physicist provides oversight of thetechnologist’s testing program as well as advice inproblem solving.Special considerations fordigital mammographyDigital mammography differs from screen-filmimaging in that the x-ray detector has a lin ear (or in some cases logarithmic) response tofuture science group

Developing a quality control program for digital mammographyx-rays over a very wide range of exposure levels.Furthermore, because the detector signal is digi tized and stored in computer memory, the imagecan be displayed and manipulated independentof the acquisition process. Unlike the case infilm mammography, the brightness and contrastof digital images can be adjusted independentof x-ray exposure while they are being viewedon a high-resolution monitor. Image processingcan be used to increase sharpness and alter thedisplay characteristics of the image, for exampleto magnify (zoom) the images, or to compen sate for changes in thickness of the breast atthe periphery.There is more variability in the technologyused for digital mammography in that there areseveral different types of detectors. While mostsystems acquire ‘snapshot’ radiographs, somesystems acquire the image by scanning a slotshaped beam of x-rays across the breast whilerecording the transmitted x-ray pattern with acorresponding slot-shape detector. In some sys tems the x-ray detector is a fixed integral partof the system, while in so-called ‘CR’ systems,the detectors are thin plates of a photostimulablephosphor that reside in lightproof cassettes dur ing image acquisition, and a cassette is trans ferred after each x-ray exposure to a separatereading device.Despite the improvements that have occurredwith the introduction of digital mammo graphy,routine QC testing is still necessary, but thetesting requirements are somewhat differ ent. Several jurisdictions have been active indeveloping QC programs tailored to the needsof digital mammography. These include TheEuropean Community [5] , The National HealthServices in the UK [6] , Norway [7] , Belgium,The International Atomic Energy Agency [8]and The American College of Radiology. Thisis not only due to the differences associated withdigital imaging, but also due to the maturing ofx-ray generation and control technology that hasoccurred over the past 25–30 years. Many of thetests remain the same, but some of the tests thatwere necessary for film mammography can nowbe eliminated and some new ones are requiredfor digital mammography [9] .The purpose of QC testing is to be able topredict departures in the performance of com ponents of the imaging system that could lead todegradation in clinical imaging performance andto correct them before such degradation occurs.The availability of images in digital form pro vides an enormous advantage in that it facilitatesthe introduction of tests that provide objectivefuture science groupREVIEWBox 1. Elements of the American College of Radiology qualitycontrol program for mammography. 1. The overall cleanliness and preparedness of the equipment and imagingenvironment 2. Film processing 3. Viewing conditions 4. Phantom imaging as an overall test of image quality 5. Repeat ana lysis 6. Safety of mechanical components 7. Proper collimation of the x-ray beam 8. Spatial resolution 9. Operation of the automatic exposure control system 10. Condition and performance of the image receptor 11. Artifacts 12. Tests of x-ray beam quality (kV and HVL) and quantity (output) 13. Estimate of mean dose to an ‘average’ breastAdapted from the 1999 Quality Control Manual published by the American College of Radiology.and quantitative measures of imaging perfor mance to replace those that required subjectiveevaluation used in QC for screen-film mammog raphy. These tests should provide more reliableresults, free from observer variability, allow sim plification of the testing procedure in some cases,as well as automatic logging of test results. It willbe necessary, however, on the basis of experience,to validate these tests in terms of their sensitivityand relevance in predicting failures.In addition to the purpose of QC, testingof equipment is carried out when the imagingequipment is installed or commissioned. In thiscase, a more comprehensive set of performancetests is usually conducted. Some of these tests areintended to ensure that the equipment complieswith applicable regulatory requirements or meetsthe specifications guaranteed by the manufac turer in the purchase agreement, but the teststhat form the routine QC program should alsobe performed. In many cases the results of thesetests comprise the baseline or reference valuesabout which the tolerances for the ongoing QCtests are set.Aside from the physical factors underlyingimage quality in mammography there are alsopractical considerations related to the consis tency of formatting and scaling of image dataand the manner in which they are presented atthe display workstation. The formatting of digi tal mammograms is prescribed by the DigitalImaging and Communications in Medicine(DICOM) standard [103] . There are two basicversions of digital mammograms, referred toas DICOM ‘for processing’ and DICOM ‘forpresentation’. The former consists of an imagewhose pixels are nominally linearly (or in thecase of CR images, logarithmically) related tothe number or intensity of x-rays transmittedwww.futuremedicine.com125

REVIEWYaffeby the breast. As such, these images are usefulfor quantitative evaluation of the image and par ticularly the performance of the x-ray detector.Certain operations may have been performedon the original detector signal in producingthis image. These include flat-field correctionand possibly a sharpening function to restorespatial resolution. The ‘for presentation’ ver sion of the image has been further processed toenhance contrast, adapt the dynamic range ofthe image to the display device and compensatefor large changes in attenuation by the breast atits periphery. In most cases, tests of the imagedisplay system should be performed using the‘for presentation’ image.The DICOM standard was developed to facil itate image communication between differentdevices and image storage systems. Additionalefforts have been made to strengthen the com patibility between image acquisition systems anddisplay workstations among a multiplicity ofvendors (e.g., multiple acquisition systems whoseimages are sent to one display workstation orshipment of images to a facility that uses anothervendor’s display system). Notwithstanding theseattempts, inconsistencies remain among systems,meaning that it is important to test the inter compatibility of components when they are putin place.In addition, an image formatted by a vendor’ssoftware for display on that vendor’s work stationmay display on another vendor’s workstation,but the contrast characteristics or even thearrangement in which individual images in anexamination are ‘hung’ may be other than whatis expected. Needless to say, this is very frustrat ing for clinical users, contributing to inefficiencyand possibly errors. To address issues of thistype, the Integrating the Healthcare Enterprise(IHE) Committee has worked to develop ‘pro files’ for ensuring greater compatibility [104] .It would be of value to require in a purchasespecification document that the componentsof a digital mammography system be compli ant with the most recent IHE profile for digitalmammography.It is recognized that the capacity for testingand the ability to maintain a specified level ofimaging performance will vary with economicconditions and availability of trained personnel.Therefore, the tests have been classified into twotypes – essential and desirable, with respect totheir importance in influencing image qualityand dose. The performance of the first categoryof tests is considered indispensable; however,it is recommended that the tests in the second126Imaging Med. (2011) 3(1)category be carried out if adequate humanresources and equipment can be made available.In a similar manner, the frequency at which test ing is performed can be classified in terms of anessential minimum level and a desirable morefrequent level.Following the practice in the QC programdeveloped by the European Community [5] testspecifications can also be defined at two lev els, a minimum acceptable level below whichimaging should not be performed and a higher,achievable (referred to in the European programas ‘desirable’) level, which is considered as thegoal for excellence. A facility should strive toensure that equipment operates at the achievablelevel of performance, as this will produce thehighest image quality and the most appropri ate dose performance. It is recognized, however,that limited resources, uncorrectable environ mental factors and other factors may prevent theachievable levels from being obtained. In no caseshould the facility continue to perform mam mography if the equipment does not meet theacceptable standard of operation because, belowthis level, the value of the procedure and/or itssafety is considered unacceptable.Many of the tests for digital mammographysystems employ algorithms that evaluate char acteristics of the digital data. If the ana lysisof images is carried out with the intention ofevaluating the characteristics of the acquiredimage (i.e., factors related to the x-ray beamand detector), it is desirable that test images bein ‘for processing’ DICOM format as this mostdirectly reflects those characteristics. Similarly. ifthe ana lysis of the acquired image is to be carriedout on a separate computer the image should beexported in ‘for processing’ DICOM format. Auser-friendly interface for exporting images is ahighly desirable feature.The International Atomic Energy Agencyhas developed a Harmonized Quality ControlProgram for Digital Mammography. The ele ments of this program have been based on thepractical experience in QC of imaging physicistsand clinical professionals from several countries.They have brought that experience and, in somecases, have borrowed from the strengths andattempted to avoid the perceived weaknessesof existing QC programs to develop what ishoped to be a practical set of tests. The testsrequired to be performed by technologists aregiven in Table 1, while those normally performedby a medical physicist are listed in Table 2 . Theexplanation of the rationale for each test anddetails for carrying it out are given in [8] .future science group

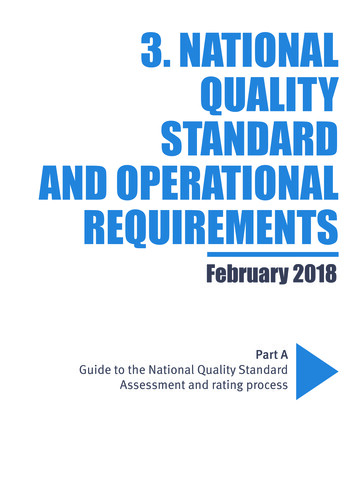

Developing a quality control program for digital mammographyDifferences between tests for digitaland screen-film mammographyThe principles that govern image quality indigital and screen-film mammography remainessentially the same. Nevertheless, the designand operation of digital mammography differsfrom those of screen-film mammography in sev eral important ways. These motivate differencesin the needs for QC testing and the manner inwhich the tests are conducted. Some of theseare discussed here with reference to the differentcomponents of the imaging process.X-ray generationAs in screen-film mammography, it is impor tant that the quantity and quality of x-raysproduced in each exposure is predictableand accurate. This is one of the areas wherechanges from historical QC programs arejustified. While, at one time, intensive test ing of all aspects of generator performancewas necessary, x-ray generators have becomemuch more sophisticated and reliable over thepast 25 years. Modern generators are based ona high-frequency design providing automaticcompensation for line voltage variations andinternal feedback systems to maintain accu rate kilovoltage and tube current. Digital expo sure timers are extremely precise and reliable.Typically, when a generator fails, it ceases tooperate rather than drifting away from propercalibration. Therefore, it is my opinion thatroutine monitoring of kilovoltage calibration isno longer necessary. Instead, a simplified QCprocedure is recommended where the quantityof x-rays emitted (x-ray output) is monitoredand the quality of the x-ray beam is measuredin terms of the half-value layer. Only if thehalf-value layer and/or output depart fromtheir normal values is it necessary to performmore detailed tests such as measurement ofk i lovoltage to diagnose a potential problem.Automatic exposure controlVirtually all digital mammography is performedusing automatic exposure control, in which theexposure time is determined by monitoring asignal related to transmission of x-rays by thebreast. In addition, the choice of x-ray targetmaterial and kilovoltage are also performedautomatically. As in film imaging these systemscan go out of proper operation and, therefore,as in screen-film imaging they should be moni tored as part of QC testing. This is accomplishedby imaging slabs of uniform x-ray attenuatingmaterial and monitoring the ability of the systemfuture science groupREVIEWTable 1. Quality control tests for digital mammography:radiological technologist.FrequencyTestPriorityDailyMonitor inspection, cleaning andviewing conditionsDigital mammography equipmentdaily checklistDaily flat-field phantom imageVisual inspection for artifactsLaser printer sensitometryImage plate erasure (CR systems only)Monitor QCView-box cleanlinessWeekly QC test object and fullfield artifactsImage quality with breast phantomSafety and function checks ofexamination room and equipmentFull field artifactsLaser printer artifactsPrinted image quality #Repeat image analysisSpatial resolution test (CR andmechanical scanning systems only)CR plate sensitivity matchingCR plate ��E§EEEDEEE¶EEEEEIt is desirable that this be performed on a daily basis and essential that it be performed weekly.On wet processors it is desirable that this be performed on a daily basis and essential that it beperformed on those days on which images will be printed for diagnostic purposes. For dryprocessors, only required monthly.§Perform secondary erasure daily and primary erasure weekly or as per manufacturer’s instructions.¶It is desirable that checks for laser printer artifacts are performed weekly and essential that they beperformed at least quarterly.#If laser film with wet processing is used for hard copy printing, please see relevant section in IAEAQuality Assurance Program for Screen-Film Mammography – IAEA Human Health Series #2 forguidance on storage, processing and darkroom issues.D: Desirable; E: Essential, basic requirement; QC: Quality control.Reproduced courtesy of International Atomic Energy Agency from [8].†‡to maintain a particular image parameter, typi cally signal level or signal-to-noise ratio (SNR),within a specified range of acceptability.Flat field (gain & offset) correctionDigital mammography systems, with the excep tion of those employing photostimulable phos phors in cassettes, have the advantage that spa tial variations in sensitivity of the detector can beeasily corrected. This is carried out by exposingthe digital x-ray detector to x-rays transmittedthrough a slab of uniform thickness, and record ing the resultant image. A second, ‘dark’, image isacquired without x-rays. The data from these twoimages can be used to produce a pixel-by-pixelcorrection for variations in detector sensitivity,offset (signal produced in the absence of radia tion), as well as spatial variation in the x-ray beamitself due to such phenomena as the heel effect orspatial v ariation in attenuation of beam filters.www.futuremedicine.com127

REVIEWYaffeTable 2. Quality control tests for digital mammography:medical physicist.FrequencyTestPriorityAnnually (E)Semiannually (D)Annually (E)Semiannually (D)Annually or after changes toAEC softwareCommissioning and after changesto AEC softwareCommissioning and afterdetector changeAnnually and after detector serviceAnnually and after detector changeUnit assembly evaluationECompression force andthickness accuracyTechnique chart andAEC evaluationSite baseline settings forradiographer SDNR testBaseline detector performanceEDetector response and noiseSpatial linearity and geometricdistortion of detectorAnnually and after detector change Detector ghostingAnnually and after detectorDetector uniformity andchange, etc.artifact evaluationAnnually and after detectorModulation transfer functionchange, etc.orlimiting spatial resolutionAnnually and after x-rayHalf value layertube changeAnnually and after x-rayIncident air kerma at entrancetube changesurface of poly(methylmethacrylate) slabsAnnuallyMean glandular dose (DG)EEAnnually and following x-ray tubeservice/replacementAnnually and following x-ray tubeservice/replacementAnnually and following x-ray y and after monitor yEEEEEEEEERadiation field/imagereceptor coincidenceCompression paddle/breastsupport alignmentMissing tissue at chest wallEArtifacts and uniformity (softcopy)EDEMonitor luminance response andviewing conditionsView-box luminance andviewing conditionsArtifacts and uniformityFilm densitiesPhantom image qualityEEEEDEEE: Essential, basic requirement; D: Desirable; SDNR: Signal difference to noise ratio.Reproduced courtesy of International Atomic Energy Agency from [8].While flat field correction is a powerful toolthat improves image quality by reducing whatis referred to as ‘fixed pattern noise’, drifts indetector sensitivity or temporal changes in thex-ray field can cause the correction to becomeless effective. Therefore, as part of the QC pro gram for digital mammography, a test of theflat-field correction is required. While full flatfield correction is not typically performed for thedetector plates of CR systems (because each ofseveral detector plates would have to be corrected128Imaging Med. (2011) 3(1)individually, possibly for each of the multiplex-ray systems), the spatial uniformity of theplate reader can vary over time and this shouldbe tested routinely so that it can be c orrectedif necessary.Overall image qualityHistorically, overall image quality in mam mography has been evaluated by radiograph ing phantoms, containing objects that mimicstructures of interest in the breast. Evaluation ofsuch images is subject to both intra- and interobserver variability. An objective test that wasintroduced for digital mammography as a pos sible replacement is the measurement of signaldifference to noise ratio (SDNR) as illustratedin Figure 1. The phantom is simply a slab of x-rayattenuating material with a small ( 1 cm2) cir cular or square area that represents a slightlydifferent attenuation. In the digital image, tworegions of interest (ROIs) are selected, one cor responding to the square or disc and the other ofsimilar area immediately adjacent to it. The dif ference between the mean signal levels measuredin the ROIs (the signal difference) is divided bythe standard deviation in the background ROI(the noise) to obtain the SDNR. This test incor porates a measure of image contrast, but alsoincludes the undesirable influence of randomfluctuation or noise in the image signal. Contrastalone is not a very useful measure of quality indigital imaging in that it can easily be ampli fied to any desired level at the display system.However, when such amplification is performed,the apparent image noise also increases, so thatwhen the signal difference (related to contrast)is compared with the noise the measure shouldbe more relevant.Spatial resolutionWith digital mammography, it is possible, usinga simple test object and a software algorithm, tomake a quantitative measurement of the spatialresolution characteristics of the imaging sys tem in terms of the modulation transfer func tion, something that is very difficult to do withfilm imaging, particularly as a field test. Thisgreatly facilitates tracking any changes in spatialr esolution that may occur over time.DoseFor QC in screen-film mammography, measure ments of x-ray output are made routinely andthey allow estimation of the ‘mean glandulardose’ that would be received by a breast of ‘aver age thickness and composition’ on the system.future science group

Developing a quality control program for digital mammographyKnowledge of the doses that are being deliveredis one of the factors that helps those providingmammography to determine that the equipmentis being operated appropriately.For screen-film mammography there is somedegree of safeguard that doses are within anacceptable range because a shift to higher orlower dose is likely to cause the optical densityto increase or decrease. These darker or lighterfilms will quickly be noticed and the unaccept able optical density and loss of proper contrastwill trigger complaints and remedial action.With digital mammography the image bright ness and contrast are controlled at the displayworkstation and, therefore, are largely indepen dent of x-ray exposure. As such, changes in radia tion exposure are much less likely to be noticed.For this reason, measurement of dose and pro vision of information to the technologists thatallows them to infer

Digital mammography Digital mammography was introduced in 2000 and has been shown in several studies to pro vide superior performance in screening [19-23] for breast cancer, particularly in women with dense breasts and those who are under 50 years of age or are pre or peri menopausal [19]. Overviews of these and other studies evaluat