Transcription

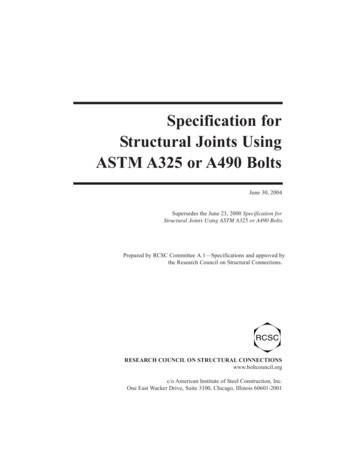

Specification forStructural Joints UsingASTM A325 or A490 BoltsJune 30, 2004Supersedes the June 23, 2000 Specification forStructural Joints Using ASTM A325 or A490 Bolts.Prepared by RCSC Committee A.1—Specifications and approved bythe Research Council on Structural Connections.RESEARCH COUNCIL ON STRUCTURAL CONNECTIONSwww.boltcouncil.orgc/o American Institute of Steel Construction, Inc.One East Wacker Drive, Suite 3100, Chicago, Illinois 60601-2001

iiCopyright 2004byResearch Council on Structural ConnectionsAll rights reserved. This book or any part thereofmust not be reproduced in any form withoutthe written permission of the publisher.The information presented in this publication has been prepared in accordance withrecognized engineering principles and is for general information only. While it isbelieved to be accurate, this information should not be used or relied upon for anyspecific application without competent professional examination and verification ofits accuracy, suitability, and applicability by a licensed engineer, architect or otherdesign professional. The publication of the material contained herein is not intended as a representation or warranty on the part of the Research Council on StructuralConnections or of any other person named herein, that this information is suitablefor any general or particular use or of freedom from infringement of any patent orpatents. Anyone making use of this information assumes all liability arising fromsuch use.Caution must be exercised when relying upon other specifications and codesdeveloped by other bodies and incorporated by reference herein since such materialmay be modified or amended from time to time subsequent to the printing of thisedition. The Research Council on Structural Connections bears no responsibility forsuch material other than to refer to it and incorporate it by reference at the time ofthe initial publication of this edition.Printed in the United States of AmericaSpecification for Structural Joints Using ASTM A325 or A490 Bolts, June 30, 2004RESEARCH COUNCIL ON STRUCTURAL CONNECTIONS

iiiPREFACEThe purpose of the Research Council on Structural Connections (RCSC) is:(1) To stimulate and support such investigation as may be deemed necessary andvaluable to determine the suitability, strength and behavior of various types ofstructural connections;(2) To promote the knowledge of economical and efficient practices relating to suchstructural connections; and,(3) To prepare and publish related standards and such other documents as necessaryto achieving its purpose.The Council membership consists of qualified structural engineers from academic andresearch institutions, practicing design engineers, suppliers and manufacturers of fastenercomponents, fabricators, erectors and code-writing authorities.The first Specification approved by the Council, called the Specification forAssembly of Structural Joints Using High Tensile Steel Bolts, was published in January1951. Since that time the Council has published fifteen successive editions. Each wasdeveloped through the deliberations and approval of the full Council membership andbased upon past successful usage, advances in the state of knowledge and changes inengineering design practice. This edition of the Council’s Specification for StructuralJoints Using ASTM A325 or A490 Bolts continues the tradition of earlier editions. Themajor changes are: Sections 5.1, 5.2, and 5.3 were editorially revised to clarify strengthrequirements of slip critical connections.Section 6.2.1 was modified to permit the use of A490 type bolts, with roundheads equal or larger in diameter than ASTM F1852 heads, without F436hardened washers.Table 6.1, footnote d, was added to clarify use of non-hardened plate washer tobe used in conjunction with an ASTM F436 hardened washer.Commentary Table C-2.1 bolt head and nut dimension locations F and W asshown in the artwork Figure C-2.2 was corrected.In addition, typographical changes have been made throughout this Specification.By the Research Council on Structural Connections,Raymond H. R. TideChairmanGeoffrey L. KulakVice ChairmanEmile W. J. TroupSecretary/TreasurerAbolhassan Astaneh-AslJoseph G. BahadrianPeter C. BirkemoeDavid W. BogatyCharles J. CarterHelen ChenRobert J. ConnorNick E. DealRobert J. DexterContinued on page iv.Specification for Structural Joints Using ASTM A325 or A490 Bolts, June 30, 2004RESEARCH COUNCIL ON STRUCTURAL CONNECTIONS

ivRobert O. DisqueJames M. DoyleG. Dean DroddyEdward R. Estes, Jr.John W. FisherKarl H. FrankMichael C. FrielRodney D. GibbleMichael I. GilmorGilbert Y. GrondinRoger D. HamiltonAllen J. HarroldIan C. HodgsonMark V. HollandDonald L. JohnsonCharles E. HundleyKaushik A. IyerPeter F. KasperLawrence A. KloiberPeter KneenRichard F. KnoblockChad M. LarsonDaeyong LeeJean-Claude LegaultKenneth B. LohrRichard W. MarshallJonathan C. McGormleyDavid L. McKenzieGreg MiazgaWilliam A. Milek, Jr.Eugene R. MitchellHeath E. MitchellWilliam H. MunseThomas M. MurrayRex V. OwenFrederick J. PalmerAndrew E. PfeiferThomas J. SchlaflyGerald E. SchroederDavid F. SharpRobert E. Shaw, Jr.W. Lee ShoemakerJames A. SwansonArun A. SyamThomas S. Tarpy, Jr.William A. ThorntonFloyd J. VissatI. Wayne WallaceCharles J. WilsonTed W. WinnebergerJoseph A. YuraSpecification for Structural Joints Using ASTM A325 or A490 Bolts, June 30, 2004RESEARCH COUNCIL ON STRUCTURAL CONNECTIONS

vTABLE OF CONTENTSSYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viiGLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ixSECTION 1. GENERAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11.1. Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11.2. Loads, Load Factors and Load Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . .11.3. Referenced Standards and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21.4. Drawing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3SECTION 2. FASTENER COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52.1. Manufacturer Certification of Fastener Components . . . . . . . . . . . . . . . . . . . . . .52.2. Storage of Fastener Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52.3. Heavy-Hex Structural Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62.4. Heavy-Hex Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122.5. Washers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132.6. Washer-Type Indicating Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132.7. Twist-Off-Type Tension-Control Bolt Assemblies . . . . . . . . . . . . . . . . . . . . . . .142.8. Alternative-Design Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14SECTION 3. BOLTED PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163.1. Connected Plies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163.2. Faying Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163.3. Bolt Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203.4. Burrs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22SECTION 4. JOINT TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234.1. Snug-Tightened Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254.2. Pretensioned Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254.3. Slip-Critical Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26SECTION 5. LIMIT STATES IN BOLTED JOINTS . . . . . . . . . . . . . . . . . . . . . .285.1. Design Shear and Tensile Strengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .295.2. Combined Shear and Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .325.3. Design Bearing Strength at Bolt Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .325.4. Design Slip Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .345.5. Tensile Fatigue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38Specification for Structural Joints Using ASTM A325 or A490 Bolts, June 30, 2004RESEARCH COUNCIL ON STRUCTURAL CONNECTIONS

viSECTION 6. USE OF WASHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .406.1. Snug-Tightened Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .406.2. Pretensioned Joints and Slip-Critical Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . .40SECTION 7. PRE-INSTALLATION VERIFICATION . . . . . . . . . . . . . . . . . . . .437.1. Tension Calibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .437.2. Required Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43SECTION 8. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .468.1. Snug-Tightened Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .468.2. Pretensioned Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46SECTION 9. INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .539.1. Snug-Tightened Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .539.2. Pretensioned Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .539.3. Slip-Critical Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56SECTION 10. ARBITRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57APPENDIX A. TESTING METHOD TO DETERMINE THE SLIPCOEFFICIENT FOR COATINGS USED IN BOLTED JOINTS . . . . . . . . . . . .59APPENDIX B. ALLOWABLE STRESS DESIGN (ASD) ALTERNATIVE . . . .70REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77Specification for Structural Joints Using ASTM A325 or A490 Bolts, June 30, 2004RESEARCH COUNCIL ON STRUCTURAL CONNECTIONS

viiSYMBOLSThe following symbols are used in this Specification.Ab Cross-sectional area based upon the nominal diameter of bolt, in.2DSlip probability factor as described in Section 5.4.2Du Multiplier that reflects the ratio of the mean installed bolt pretension to the specifiedminimum bolt pretension Tm as described in Section 5.4.1Fn Nominal strength (per unit area), ksiFu Specified minimum tensile strength (per unit area), ksiIMoment of inertia of the built-up member about the axis of buckling (see theCommentary to Section 5.4), in.4LTotal length of the built-up member (see the Commentary to Section 5.4), in.Lc Clear distance, in the direction of load, between the edge of the hole and the edge ofthe adjacent hole or the edge of the material, in.Nb Number of bolts in the jointPu Required strength in compression, kips; Axial compressive force in the built-upmember (see the Commentary to Section 5.4), kipsQFirst moment of area of one component about the axis of buckling of the built-upmember (see the Commentary to Section 5.4), in.3Rn Nominal strength, kipsRs Service-load slip resistance, kipsTApplied service load in tension, kipsTm Specified minimum bolt pretension (for pretensioned joints as specified in Table 8.1),kipsTu Required strength in tension (factored tensile load), kipsVu Required strength in shear (factored shear load), kipsdb Nominal diameter of bolt, in.tThickness of the connected material, in.Specification for Structural Joints Using ASTM A325 or A490 Bolts, June 30, 2004RESEARCH COUNCIL ON STRUCTURAL CONNECTIONS

viiit Total thickness of fillers or shims (see Section 5.1), in.ksSlip coefficient for an individual specimen determined in accordance withAppendix AφResistance factorφRn Design strength, kipsµMean slip coefficientSpecification for Structural Joints Using ASTM A325 or A490 Bolts, June 30, 2004RESEARCH COUNCIL ON STRUCTURAL CONNECTIONS

ixGLOSSARYThe following terms are used in this Specification. Where used, they are italicized to alertthe user that the term is defined in this Glossary.Coated Faying Surface. A faying surface that has been primed, primed and painted orprotected against corrosion, except by hot-dip galvanizing.Connection. An assembly of one or more joints that is used to transmit forces between twoor more members.Contractor. The party or parties responsible to provide, prepare and assemble thefastener components and connected parts described in this Specification.Design Strength. φRn, the resistance provided by an element or connection; the product ofthe nominal strength Rn and the resistance factor φ.Engineer of Record. The party responsible for the design of the structure and for theapprovals that are required in this Specification (see Section 1.4 and the correspondingCommentary).Fastener Assembly. An assembly of fastener components that is supplied, tested andinstalled as a unit.

High-Strength Bolt. An ASTM A325 or A490 bolt, an ASTM F1852 twist-off-type tension-control bolt or an alternative-design fastener that meets the requirements in Section 2.8. Inspector. The party responsible to ensure that the contractor has satisfied the provisions of this Specification in the work. Joint. A bolted assembly with or without collateral materials that is used to join twoFile Size: 830KBPage Count: 94