Transcription

Design .and operationof irrigation systemsfor smallholder agric ltu-re,in South Asia .·.''.,

FAO LIBRARY AN: 268069 vol 2sign and operationof irrigation systemsfor smallholder agriculturein South AsiaINVESTMENTbyD.E. CampbellFOODANDAGRICULTUREORGANliATIONOF THEUNITED NATIONSRome, 1986

The designations employed and the presentationof material in this publication do not imply theexpression of any opinion whatsoever on thepart of the Food and Agriculture Organizationof the United Nations concerning the legalstatus of any country, territory, city or area orof its authorities, or concerning the delimitationof its frontiers or boundaries.M-56ISBN 92-5-102481-2All rights reserved. No part of this publication may be reproduced,stored in a retrieval system, or transmitted in any form or by any means,electronic, mechanical, photocopying or otherwise, without the priorpermission of the copyright owner. Applications for such permission,with a statement of the purpose and extent of the reproduction, shouldbe addressed to the Director, Publications Division, Food and AgricultureOrganization of the United Nations, Via delle Terme di Caracalla, 00100Rome, Italy. FAO 1986

- i -FOREWORDThe FAQ Investment Centre's principal function is to assist membercountries in the preparation of agricultural and rural development projectsfor international, and sometimes local, financing. The Investment Centre isalso acknowledged as a source of assistance in the development of nationalcapacities for project preparation and execution.Over the last 15 years, irrigation has occupied a very importantposition in international lending for development andhasmadeaconsiderable contribution to increased agricultural production. There are,nevertheless, a number of problems in smallholder irri(ation which continueto limit the rate of effective implementation of such projects and occupymuch of the attention of development agencies in this field. Some of theproblems are technical, but more often they relate to the small cultivatorand his role in the operation of the project and the development of theirrigated area.This FAO Investment Centre Technical Paper comprises 5 papersselected from more than 30 prepared between 1974 and 1985 for the assistanceof Irrigation Department staff, mainly engineers, preparing and executingprojects in India assisted by the World Bank. Although these papers werewritten for projects in India, the principles involved apply in neighbouringcountries and further afield. However, when transposing costs to anotherregion,accountshould be taken of the comparatively low cost ofconstruction in India.Since I believe that the papers could be of considerable use topeople outside the Investment Centre who share our interest in thedevelopment of irrigation projects, I have decided to give them widercirculation by publishing them as part of our series of Technical Papers.The opinions expressed, however, remain those of the author and are notnecessarily endorsed by the Organization or the Bank.Any comments on the material or suggestions which could contributeto the greater usefulness of the paper would be most welcome and should beaddressed to the Investment Centre.Cedric FernandoDirectorFAO Investment Centre

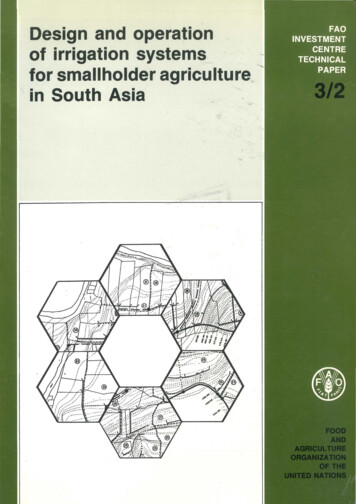

- ii i -DESIGN ANO OPERATION OF IRRIGATION SYSTEMS FOR SMALLHOLDER AGRICULTUREIN SOUTH ASIATABLE OF CONTENTSVOLUME IA.B.C.ISSUES AND OPTIONS IN DESIGN OF RESERVOIR AND CANALSYSTEMS1 -30WATER DISTRIBUTION FROM MINOR CANAL TO THE FIELD,AND LAND SHAPING IN IRRIGATION OF SMALLHOLDINGS31 -71IRRIGATION FROM SMALL TANKS73 - 120PLATES1 to 9121 - 137VOLUME IID.IRRIGATION FROM SUPPLY CANALS VIA BURIED PIPE DISTRIBUTIONSYSTEMSPLATES 01 to 08E.1 - 10537 -51TUBEWELL ANO RIVER-LIFT IRRIGATION107 - 131PLATES133 - 143El to E6

-V -D. IRRIGATION FROM SUPPLY CANALS VIA BURIED PIPE DISTRIBUTION SYSTEMSTABLE OF CONTENTSD.10.2THE APPLICATION OF BURIED PIPE TO GRAVITY SUPPLY SYSTEM BACKGROUNDIntroductionThe Problems of Distribution by Open ChannelWhere Holdings are SmallTypes of Pipe Distribution SystemDelivery at Individual Outlets Within a Distribution SystemCases to Be Considered3445THE KALLADA PROJECT PIPE SYSTEM DESIGN CONCEPTS AND OPTIONS6The Project AreaThe Special Requirements of Farm Water Distributionin the Upstream Portion of the Kallada AreaChoice Between Open Channel and Pipe Distributionfor KalladaRegulation of Flow at Delivery ValvesSelection of Pipe SystemOperation of the Kallada System The Role of the Cultivator0.33KALLADA PROJECT - GUIDELINES FOR LAYOUT AND DESIGNUPSTREAM (VALLEY-SLOPE) PORTION OF SERVICE AREAIntroductionRate of Supply per Hectare of Service Area(Irrigation Duty) at the Outlet from the CanalSize and Location of Service Areas (Outlet Commands)and Location of OutletsRequired Capacity of Pipe System, Upper Portionof the Kallada CommandDesign of Outlet Structure from Distributariesand Main CanalLocation of Delivery Points (Hydrants) and Line LayoutDetermination of Pipe Size - Hydraulics of SystemControl of Water-Hammer - Location of Surge Risers Rate of Valve ClosureOperation of System36678101213131314151618222326

- Vi -0.4KALLADA PROJECT - DOWNSTREAM (NEAR-FLAT) PORTIONOF SERVICE AREAIntroductionIrrigation Requirements - Separation of Supplyto Garden Lands and to Paddy AreasRate of Delivery to the Field and Size of Outlet CommandAlternative Distribution Systems - Open Channeland Buried PipePipe MaterialsPipe System LayoutPoints of Delivery from Pipe System Location and Area ServedRegulation of Flow to Pipe SystemStructures - Canal Outlet and Delivery PointsHydraulic DesignPreliminary Cost EstimatesComparison of Buried Pipe and Lined Open ChannelSystems for Lower KalladaConclusionsPLATES 01 to 08262627282929303031323233343537 - 51ANNEXESKallada Project - Soils, Cropping Patterns, andWater Requirements5302Kallada Project - Supply of Water to Valley BottomLands in Upper Portion of Command Area6103Kallada Project - Head Losses in Pipe DistributionSystems65Kallada Project - Water-Hammer in Buried Pipe730104

- Vii -E. TUBEWELL AND RIVER-LIFT IRRIGATIONTABLE OF CONTENTSE.1BACKGROUND AND SCOPE109E.2THE RANGE OF WELL CAPACITY AND TECHNOLOGY AVAILABLEIN GROUNDWATER DEVELOPMENT109Open WellsHand-Operated TubewellsSmall Tubewells with Mechanically-Driven Pump at Well-HeadSmall Tubewells and Submerged PumpsDeep Tubewells109110110111111E.3RELATIVE COSTS OF TUBEWELL SYSTEMS112E.4TECHNICAL AND SOCIAL FACTORS IN PLANNING OFGROUNDWATER DEVELOPMENT112Utilization of Aquifer PotentialPhysical Characteristics of the AquiferGroundwater Development in an Area of Canal IrrigationPower Supply for TubewellsSize of HoldingEquity in Distribution of GroundwaterExisting Wells and Possible Conflict in FurtherDevelopment of an Aquifer112113114115116E.5PRIVATE VERSUS PUBLIC DEVELOPMENT, A SUMMARY117E.6ECONOMIC AND FINANCIAL FACTORS118E.7DESIGN OF TUBEWELL DISTRIBUTION SYSTEMS120IntroductionDesirable Size of Delivery Stream (to the IndividualCultivator)Choice of Construction Material for Distribution SystemSize of Service Area of TubewellArea Supplied by an Individual OutletDivision of Tubewell Supply between OutletsLayout of Pipe SystemRegulation of Tubewell Output120121121122123123124124OPERATION OF THE TUBEWELL SYSTEM AND THE ROLE OFCULTIV6TOR GROUPS125AGR'.CULTUR L SUPPORTING SERVICES IN TUBE ELL RE S126E.8E.9116117

- viii -E.10RIVER-LIFT SYSTEMS127Design and OperationPrivate versus Public Development of River-Lift System127128TABLE ElPLATES131El to E6133 - 143

PAPER 0IRRIGATION FROM SUPPLY CANALS VIA BURIED PIPE DISTRIBUTION SYSTEMS

-3 -D. IRRIGATION FROM SUPPLY CANALS VIA BURIED PIPE DISTRIBUTION SYSTEMSD.l THE APPLICATION OF BURIED PIPE TO GRAVITY SUPPLY SYSTEM - BACKGROUNDIntroductionD.1.1Distribution of water from the supply canal to the individual farmremains the most troublesome feature of irrigation development in the Asianarea of smallholder cultivation. This is particularly the case where cropsother than paddy are being grown in at least one season of the year, whenthe simple field-to-field approach which is appropriate only to wet-landpaddy is not applicable. The latter is the situation considered in thefollowing notes.The use of buried pipes as a means of overcoming much of theD.1.2difficulty was introduced in Asia for distribution from tubewells and riverlift installations. Among the advantages of pipes compared with openchannels is freedom from right-of-way problems, particularly in areas ofsmallholdings, and the assurance of delivery at the design rate of flow tothe farthest cultivator in the service area, undiminished by losses orunauthorized diversions en route.0.1.3With a pumped source of water the use of pipe is facilitated, asthe pump can be designed to provide the additional head necessary toaccommodate the hydraulic friction in the pipe system. In the case of supplyfrom canals, however, pumped head is not available and a pipe system must bedesigned to operate within the limits of the gravitational head availablebetween the water surface in the supply canal and the elevation of the pointof delivery. The advantages of pipe distribution are nevertheless as realfor canal supplied systems as for pumped systems, and there are manysituations in which there is more than adequate gravity head to make the useof pipe possible.0.1.4An obvious example is a supply canal running along the side of avalley and serving an irrigation area on the slopes below it. In otherspecial circumstances, although the topography may be near-flat, theadvantages of buried-pipe distribution may be sufficiently compelling towarrant special measures to permit it, such as keeping the level in thesupply canal higher than usual above ground level (up to 1 m) and designingthe pipe system to operate on that very low head.The Problems of Distribution by Open Channel Where Holdings are Small0.1.5The advantages of pipe distribution over open channels have beenreferred to briefly above. Some are especially relevant to a typical Asiansituation in which there are smallholdings, often in several small parcels.Property boundaries follow no regular geometric pattern, and consolidationof holdings which would facilitate rational layout of surface channels isresisted by cultivators. Cultivators are also unwilling to give up land forchannel construction and land values may be high (Rs200,000/ha is notuncommon reaching as high as Rs500,000/ha in coastal Kerala). Furthermore,poor maintenance aggravated by intentional breaching of channels by upstreamcultivators makes delivery to downstream cultivators precarious. To thislist of conventional problems with open channel distribution can be addedspecial situations including distribution in semi-urban areaswherP

- 4 -interference to property access is a major disincentive to open channels,and the similar situation in the Kallada project to be described later wherethe presence of mature orchard trees is a further complication.Types of Pipe Distribution SystemD.1.6For the purpose of these notes, consideration is confined torelatively smallpipe systems of capacity not more than 2 cfs(56 litres/sec), generally less. These are basically distribution systems,with the associated main canal network providing conveyance down to thepoint where distribution to farms begins. Pipe, in considerably larger size,may also be used for conveyance in some situations in place of an open canalnetwork, but such systems involve substantially different technology and arenot considered herein.D.1.7The simplest form of pipe distribution system is sometimesdescribed as an "underground canal", and it functions in much the · samemanner as a canal. Runs of pipe connect a series of open delivery boxesspaced along the length of the line, from which water flows through gatedturnouts to farm channels, usually from one box at a time. The deliveryboxes function as drop structures when the line runs significantly downslope, and the pipe between successive boxes is under virtually no pressure.As with the corresponding open channel system, consisting of runs of openchannel between turnouts (and drops if required), this is an "upstreamcontrol" system. If all turnouts are closed, the outlet gate to the linefrom the supply canal must also be closed or water will spill at one of thedelivery boxes. This operational feature is inherent in all open-channeldistribution systems except the most sophisticated (level-top channels withlevel-control} and is not a major disability in most situations. It is notinherent in all pipe distribution systems, where there is also the option of11downstream control 11 , i.e. design such that when water ceases to be drawnoff at downstream points, it simply backs up in the line and stops supplyfrom the canal (as in a domestic supply system). Such downstream controlsystems either require the pipe to withstand pressure at the lower end, orinvolve the use of level-control or pressure-control valves at stations downthe length of the line. These options will be discussed further inChapter 0.3.Delivery at Individual Outlets Within a Distribution SystemD.1.8A central feature in the design of open-channel distributionsystems is the means adopted to ensure an appropriate rate of flow at eachturnout for efficient water management on the field. In most circumstances(Kallada is an exception), this implies a flow of from 15 to 30 litres/secat the farm boundary, or higher in some circumstances. This is referred toas the farm stream or delivery stream. The quantity of water supplied duringa particular irrigation is controlled by the duration of the period ofirrigation, not by varying the rate of delivery. l/ To achieve this, thepractice in India is increasingly to design the distribution channel(a watercourse or field channel) with capacity equal to the desired farmstream and to deliver the whole of it to each turnout in rotation, eachreceiving the water for a period determined by the size of the area which itserves, or other factors. This avoids the problem of regulating the flow atl/This subject is discussed in more detail in Volume I, Paper B.

- 5 -each turnout, which would be encountered if more than one turnout at a timewere to take water from the watercourse. Regulation is done at one pointonly, i.e. at the outlet from the canal. Within the area served by thatoutlet (the "outlet command", commonly 15 to 40 ha) the only controlrequired is organization of rotational supply to outlets.0.1.9With pipe distribution systems the same question arises, i.e. howto ensure an appropriate rate of delivery at each of the turnouts (or valvedoutlets). One means of doing so, the simplest, is in the same manner as foran open-channel watercourse, i.e. the distribution pipeline is designed toconvey the desired farm stream only, and the whole of the flow is taken ateach turnout or valved outlet in turn. Where a pipe system is simply analternative to a conventional open-channel watercourse served by an outletfrom a canal, this would normally be the type of design selected. However,where the capacity of the pipe delivery system needs to be greater than thesingle farm stream, this solution is not available. Examples from tubewelland river-lift projects are rates of delivery (determined by economics oftubewell capacity and other factors) of 40 litres/sec (UP tubewells),60 litres/sec (West Bengal tubewells) and 110 litres/sec (West Bengal riverlift). Equipment manufacturers have not yet developed a low-cost low-headflow controller with capacity in the range of 15 to 30 litres/sec, suitablefor installation at each valved outlet on a pipeline system. Consequently,the expedient adopted in the first two cases quoted is to subdivide the flowat the tubewell between sub-systems, two of 20 litres/sec in UP and three of20 litres/sec in West Bengal, each delivering the desired stream-flow at onedelivery valve at a time on the sub-system. The sub-division of flow at thetubewell is accomplished by a ·weir arrangement in an elevated opendistribution chamber (see Volume II, Paper E). In the case of West Bengalriver-lift where a 110 litres/sec installation is divided between six subsystems, the approach is similar, but primary and secondary distributionchambers are used. An adaptation of the same arrangement could be employedfor supply from a canal in certain circumstances. For pipe system of greatercapacity, a different approach would be used, outside the scope of thispaper.In the majority of cases of pipe distribution from open supply0.1.10canals, the simple arrangement of making pipe system capacity equal to farmstream is likely to be favoured. The special circumstances which make partof the Kallada project an exception are discussed below.Cases to Be ConsideredIn the current issue of these notes, the Kallada project is0.1.11considered in detail, as the project is under construction and the notes arerequired for operational purposes. The cases considered for Kallada are:- Distribution in steeply sloping garden lands, with associated nearflat valley-bottom lands.Distribution to near-flat garden lands in an area of very high landvalues.

- 6 -0.2 THE KALLADA PROJECT P.IPE SYSTEM - DESIGN CONCEPTS AND OPTIONSThe Project Area0.2.1In the Kallada area, in southern Kerala, the upstream half of thecommand area consists of steeply-graded va 11 ey s 1opes 1arge ly under 11 garden 11crops, with intervening valley-bottom lands mainly under paddy.Rainfall,averaging 2,500 mm per year, occurs principally in the monsoon season fromlate May to mid-November, the remaining six months of the year being mainlydry. Irrigation is required for crop production throughout the dry season,and also to bridge gaps in the monsoon, notably for paddy.0.2.2The garden crops include coconuts (which are particularlyresponsive to dry-season irrigation), arecanut, pepper, plantains, somecoffee and cocoa, and inter-crops of vegetables and cassava. Ory-seasonirrigation of rubber is also proposed on a limited scale. The valley slopesare generally in sandy loams of lateritic origin.·D.2.3In the valley-bottom areas, paddy has been the traditional wetseason crop, often followed immediately by a second crop early in the dryseason. However, these areas are increasingly being converted to non-paddycrops (coconuts, plantains), particularly around their margins. Vegetablesare also important. The valley-bottom soils are relatively free-drainingloams or sandy loams originating from erosion of the valley slopes.The grade is typically about 1% down the length of the valley, which ensuresgood surface drainage.The Special Requirements of Farm Water Distribution in the Upstream Portionof the Kallada AreaD.2.4The garden lands have been under rainfed crops, principallycoconuts, for many years prior to the advent of the project. The palms, nowmature, were generally planted in separate small bunded basins, each withoutparticular regard to the elevation of the neighbouring basins, in a more orless random fashion. Short of re-shaping and re-planting the whole areathere is no possibility of introducing a conventional arrangement of contourchannels serving rows of palms, and in much of the area irrigation has to beconveyed to each individual palm, or to its small bunded basin, separately.There are some larger basins, for instance, 15 to 20 min length and 5 minwidth with plantains planted on ridges, in which conventional furrow-in-abasin could be practised, but these are the excepti n.D.2.5Technically, one solution could have been a sprinkler system, andthere is sufficient gravity head for such operation in parts of the area,but not in most of it. Elsewhere sprinklers would require pumping, which isundesirable at this stage of development of the area. In the upstream halfof the command where slopes are commonly in the range of 3% to 5% and thetopography is highly irregular, there is no alternative to delivery of waterto each individual palm and this implies the use of flexible hose in oneform or another. It is essentially a horticultural operation.D.2.6A key question is the desirable rate of delivery in thesecircumstances. Farm streams in the range of 15 to 30 litres/sec werereferred to earlier for efficient farm water management of field crops.However, a stream of that amount delivered from a hose could cause excessiveerosion around the base of a palm. Furthermore, a water-filled hose of thatsize would be difficult to drag from one palm to another and would damageinter-crops en route. On the basis of tria1s in the area, a delivery stream

-7 -of nominally 2.5 litres/sec has been adopted. However. each delivery pointon the line has two outlets of that capacity, in effect making available toany cultivator on the valley slopes a combined rate of delivery (two hoses)of 5 litres/sec. This is sufficient to supply the water requirements of atypical 0.5 ha holding in garden lands in about 12 hours of irrigation onceper week.D.2.7Irrigation on the valley-bottom lands is of a very differentnature. Requirements of paddy and also of perennials and vegetables must bemet. Where possible. direct supply from the canal outlet down to the valleybottom, by open channel or pipe, is provided in order to permit short-termsupply at a relatively high rate (about 30 litres/sec). Where this is notpossible for topographic reasons, and the valley-bottom area has to besupplied from points on the pipeline extending along the valley slope,outlets of 10 litres/sec are generally provided (in very small areas down to5 litres/sec) for this purpose. The particular problems and provisions forsupply to the bottom lands are discussed in more detail in Annex 02.D.2.8The above discussion refers mainly to the upstream portion of theproject area. Downstream, towards the coast, the topography becomesprogressively flatter. It is still divided between wet-land areas devotedmainly to paddy and extensive near-level areas largely under coconuts.In this area, the problem of differences in elevation between adjacentbasins serving individual palms is much reduced and supply by farm channelsis possible. There is insufficient head for application by hose. However,land values have become extremely high, largely influenced by potential forresidential use. In such circumstances, open-channel distribution from canaloutlet to the individual holding would have to face the problems of highcost of right-of-way and cultivator resistance to the loss of access andconsequent reduction in property values which could result from constructionof open channels in this area. Buried-pipe distribution is likely to be thepreferred arrangement, but in view of the small amount of head available aspecial design approach is necessary (see Chapter 0.4).D.2.9To summarize, irrigation of the mature garden lands on the valleyslopes in the upstream portion of the project is necessarily horticultural,rather than conventional. Re-shaping of the area to simplify waterdistribution is not practical at this stage of development of the area.The unit of delivery, the 11 farm-stream 11 adopted, is 2.5 litres/sec(approximately 0.10 cfs), which will in most cases be applied by 50 mmflexible hose from valved outlets. These are in pairs, two per hydrant,giving a nominal rate of delivery of 5.0 litres/sec at the hydrant.Choice Between Open Channel and Pipe Distribution for Kallada0.2.10This question has largely been answered, at least for the upstreamportion of the project, in the above description of the area.Cost comparison of a unit length of buried pipe and a unit length of openchannel (which would have to be lined, and with drop structures) would inany case favour the pipe on these slopes. However, the choice of pipe wasnot on economic grounds. It was imposed by two factors:- Layout of open watercourses in much of that area would beimpractical due to the presence of existing palms, dwellings,irregular stone-walled terracing, and highly irregular topography.- A proportion of the palms on the valley slopes cannot be served byconventional open channel at ground level. The possibility of using

- 8 -elevated open flume was considered, but obstruction to right-of-wayin this semi built-up area would rule out such a solution.0.2.11Buried pipe distributionproportion of the Kallada command.is clearly indicated in this upstreamRegulation of Flow at Delivery ValvesWith a "farm-stream" as small as 2.5 litres/sec or evenD.2.12considering the combined capacity of the two delivery valves(5.0 litres/sec) at a hydrant as the farm stream, it would be impractical todesign the pipe distribution system for a capacity equal to a single farmstream, with rotational delivery at one point at a time only, as discussedin para 0.1.9. With the design duty of the Kallada canal system of1.0 litres/sec/ha (see Annex 01), the areas which could be served by 2.5 or5.0 litres/sec would be simply 2.5 and 5 ha respectively. Such small "outletcommands" would require an extensive system of sub-minor canals and anundesirable number of canal outlets.0.2.13The nominal area of outlet command which has been adopted for theproject, with the above factors in view, is 10 ha. For topographic reasonsthe area varies, from 5 to 20 ha, and in some cases larger. Referring to a10 ha system, of capacity nominally 10 litres/sec, 1/ four 2.5 litres/sec·delivery valves will normally be in operation at one time. This necessarydeparture from the simplicity of one supply point being in service at a time(para 0.1.9) raises the key question of how to regulate the flow from fourseparate valves at possibly four points on the pipe system (at least two)with some approximation to equality, bearing in mind that points may be atdifferent elevations and under different hydraulic pressures. This questionis discussed further hereunder. The other central questions are the distancebetween delivery points (hydrants), the means of conveyance from a deliveryvalve to the individual palm or plot, and the layout and cost of theassociated buried pipe system.0.2.14Regulation of flow between a number of delivery valves operatingsimultaneously is a trade-off between simplicity of design and accuracy ofthe result aimed at. The simplest solution, conceptually, would be a flowcontrol device at each of the delivery valves, limiting the discharge to2.5 litres/sec regardless of line pressures (above a certain minimum).This may well be the eventual solution for Kallada or other similarprojects. It is technically feasible and could very simply be added, but atpresent the industry does not have available a valve suitable to Kalladaflows and pressure.D.2.15Alternatives, within current technology, include the following:a) Installation of in-line pressure regulators atlocations on the buried distribution line.appropriateb) Provision of float-controlled pressure-regulating pipes at eachhydrant. These could be added at any time. The same installationcould also be arranged to function as a flow controller.l/For discussion of design duty of individual systems, as a functionof percentage of paddy, see also Annex 01.

- 9 -c) Provision of the same type of float-controlled pressure-regulatingstand-pipes at intervals on the main line itself.d) For approximate regulation, the use of orifice-plates with variousappropriate sizes of orifice, installed immediately upstream of thedelivery valves, or varying sizes of valve.D.2.16As background to evaluation of these alternatives,factors are noted:thefollowing- The maximum rate of diversion to a Kallada pipe system is regulatedat the design value by the setting of the gate or valve opening ateach outlet from the supply canal. It is not influenced by factorswithin the pipe system itself such as location or number of valvesin operation at any particular time. The latter factors may controlthe actual rate of diversion at any time, but not the maximum(refer to discussion of design of outlet structure, paras 0.3.160.3.25).- The quantity of water delivered at a particular valve perirrigation depends not only upon the rate of delivery at thatvalve, but also upon the time for which the valve is open.The latter is a question of cultivator cooperation in sharing ofsupply (rotational operation) rather than of technology.- The variation in line pressure between the valves open at any onetime, typically four, and the consequent variation in theirdischarge unless flow regulators are used, can be minimized byappropriate selection or grouping of valves to be opened together.This again is an organizational rather than a technical matter.- Service areas which are elongated laterally can present a problemin providing sufficient head to reach the high points on theservice area farthest from the canal outlet. Supply at rather lessthan the design rate may be necessary in such circumstances,regardless of any provision for flow regulation, with correspondingadjustment of the duration of supply at that point to compensatefor the reduced rate of delivery.- Apart from automatic methods of flow regulation, manual regulationof delivery by adjustment of valve opening by the cultivatorsthemselves can be assumed in circumstances in which it is in theinterest of the individuals to do so. For instance, at a point oflow elevation on a distribution line the locally high hydraulichead could cause a fully-open valve to deliver substantially morethan 2.5 litres/sec, in the absence of a flow regulator. However,such flow, unless throttled down by partial valve closure, would belikely to blow the hose off the valve outlet, or in any case wouldresultin too high a velocity of flow from the hose forsatisfactory application to crops. It can reasonably be assumedthat the cultivator would reduce the flow by partial valve closurein such circumstances.- The individual Kallada pipe systems, due to their number, willnecessarily have to function with a minimum of departmentalattention. A canal supervisor with responsibility for 500 ha willhave at least 50 pipe systems in his charge and will be principallyoccupied w

a. issues and options in design of reservoir and canal systems b. water distribution from minor canal to the field, and land shaping in irrigation of smallholdings c. irrigation from small tanks plates 1 . to . 9 volume ii d. irrigation from supply canals via buried pipe distribution . 1 - 30 . 31 - 71 . 73 - 120