Transcription

Part 623 IrrigationNational Engineering HandbookChapter 4Surface Irrigation(623–VI–NEH, September 2012)

Chapter 4Surface IrrigationPart 623National Engineering HandbookIssued September 2012The U.S. Department of Agriculture (USDA) prohibits discriminationagainst its customers. If you believe you experienced discrimination whenobtaining services from USDA, participating in a USDA program, or participating in a program that receives financial assistance from USDA, you mayfile a complaint with USDA. Information about how to file a discriminationcomplaint is available from the Office of the Assistant Secretary for CivilRights. USDA prohibits discrimination in all its programs and activities onthe basis of race, color, national origin, age, disability, and where applicable, sex (including gender identity and expression), marital status, familialstatus, parental status, religion, sexual orientation, political beliefs, geneticinformation, reprisal, or because all or part of an individual’s income isderived from any public assistance program. (Not all prohibited bases applyto all programs.)To file a complaint of discrimination, complete, sign, and mail a programdiscrimination complaint form, available at any USDA office location oronline at www.ascr.usda.gov, or write to:USDAOffice of the Assistant Secretary for Civil Rights1400 Independence Avenue, SW.Washington, DC 20250-9410Or call toll free at (866) 632-9992 (voice) to obtain additional information,the appropriate office or to request documents. Individuals who are deaf,hard of hearing, or have speech disabilities may contact USDA throughthe Federal Relay service at (800) 877-8339 or (800) 845-6136 (in Spanish).USDA is an equal opportunity provider, employer, and lender.Persons with disabilities who require alternative means for communicationof program information (e.g., Braille, large print, audiotape, etc.) shouldcontact USDA’s TARGET Center at (202) 720-2600 (voice and TDD).2(210–VI–NEH, September 2012)

AcknowledgmentsChapter 4 and 5 was originally prepared and printed in 1974 and 1983 respectively, under the direction of Conservation Engineering Division (CED),Washington, DC, Soil Conservation Service (SCS), now Natural ResourcesConservation Service (NRCS).In 2003, under the direction of Ron Marlow, (retired), director, Conservation Engineering Division (CED), Washington, DC, Dr. Wynn R. Walker,irrigation engineer, and Professor at Utah State University, Logan, Utahsubstantial reviewed, rewrote and combined the two chapters to the newchapter 4. Revisions and editing to the combined chapters were providedby Clarence Prestwich, irrigation engineer, West National TechnologyCenter (WNTSC), NRCS, Portland, Oregon; John Busch, (retired), stateirrigation engineer, NRCS, Baker Oregon; John Hester, state irrigationengineer, NRCS, Dexter, Missouri; Bruce Sandoval, state irrigation engineer, NRCS, Twin Falls, Idaho; Leigh Nelson, state irrigation engineer,NRCS, Ephrata, Washington; Chris Stoner, state irrigation engineer, NRCS,Stillwater, Oklahoma; and Mark Tweffort, assistant state engineer, NRCS ,Reno, Nevada. It was finalized under the guidance of Doug Toews, nationalwater management engineer, CED, NRCS, Washington, DC. The editing,illustrations, and formatting were provided by Lynn Owens, editor; WendyPierce, illustrator; and Suzi Self, editorial assistant, National GeospatialManagement Center (NGMC), NRCS, Fort Worth, Texas.(623–VI–NEH, September 2012)4–i

Chapter 44–iiSurface Irrigation(210–VI–NEH, September 2012)Part 623National Engineering Handbook

Chapter 4ContentsSurface Irrigation623.0400The practice of surface irrigation4–1(a) Introduction. 4–1(b) Surface irrigation configurations. 4–3(c) Water management in surface irrigation systems. 4–11623.0401Surface irrigation principles4–20(a) Introduction. 4–20(b) Important surface irrigation concepts. 4–20(c) Field evaluations. 4–34623.0402Design processes4–40(a) The objective and scope of surface irrigation design. 4–40(b) Basic design process. 4–41(c) Basic design computations. 4–42(d) Distribution system. 4–52(e) Headland facilities. 4–53(f) Drainage facilities. 4–62(623–VI–NEH, September 2012)4–iii

Chapter 4Surface IrrigationTablesTable 4–1General comparison of surface irrigation surfacemethods4–10Table 4–2Average rooting depths selected crops in deep,well-drained soils4–22Table 4–3Average 6-hour intake rates for the furrow-basedreference intake families4–26Table 4–4Continuous flow furrow intake families—initialirrigations4–27Table 4–5Continuous flow furrow intake families—laterirrigations4–27Table 4–6Surge flow furrow intake families—initial irrigations4–28Table 4–7Surge flow furrow intake families—later irrigations4–28Table 4–8Continuous flow border/basin intake families—initial irrigations4–29Table 4–9Continuous flow border/basin intake families—later irrigations4–29Table 4–10Surge flow border/basin intake families—initialirrigations4–30Table 4–11Surge flow border/basin intake families—laterirrigations4–30Table 4–12Typical values of maximum velocity4–45Table 4–13Recommended siphon and spile sizes for surfaceirrigation systems4–56Table 4–14Recommended ditch gate sizes for surface irrigationsystems4–57Table 4–15Recommended check outlet and large ditch gate sizesfor surface irrigation systems4–57Table 4–16Recommended gated pipe diameters for various frictiongradients4–60Table 4A–1Layered SCS ring infiltrometer data4A–1Table 4A–2Comparison of original and revised furrow intakefamily value4A–44–iv(210–VI–NEH, September 2012)Part 623National Engineering Handbook

Chapter 4Surface IrrigationFiguresFigure 4–1Layout and function of irrigation system components4–2Figure 4–2Basic phases of a surface irrigation event4–3Figure 4–3Typical basin irrigation system in the Western UnitedStates4–3Figure 4–4Furrow irrigation using siphon tubes from a field bay4–5Figure 4–5Contour furrow irrigation4–6Figure 4–6Border irrigation in progress4–8Figure 4–7Illustration of contour border irrigation4–8Figure 4–8Tailwater outlet for a blocked-end border system4–9Figure 4–9Field smoothing can be done by a land plane4–12Figure 4–10Typical tailwater recovery and reuse system4–13Figure 4–11Typical border and basin field outlets4–14Figure 4–12A wheel lift slide gate before and after automation4–15Figure 4–13Two methods of supplying water to furrows4–15Figure 4–14Gated pipe options for furrow irrigation4–16Figure 4–15Schematic cablegation system4–17Figure 4–16Advance and recession trajectories for a surge flowsystem4–18Figure 4–17Early surge flow system with individual gate control4–19Figure 4–18Automated butterfly surge flow valve4–19Figure 4–19Close up of surge valve and gate pipe setup4–19Figure 4–20Automated butterfly surge flow valve watering one side4–19Figure 4–21Components of the soil-water matrix4–20Figure 4–22Components of soil water4–21Figure 4–23Variation of available soil moisture with soil type4–22Figure 4–24Average 6-hour intake rate for the revised NRCSfurrow intake families4–25(210–VI–NEH, September 2012)Part 623National Engineering Handbook4–v

Chapter 44–viSurface IrrigationPart 623National Engineering HandbookFigure 4–25Reference furrow wetted perimeters for the revisedNRCS intake families4–31Figure 4–26Relationship of reference flow to intake family4–31Figure 4–27Distribution of applied water in surface irrigation4–31Figure 4–28Cross-sectional shapes for furrow and border/basinirrigation4–35Figure 4–29Field measurement points for advance and recessionevaluations in the field4–36Figure 4–30Flowing furrow infiltrometer4–37Figure 4–31Field surface slope4–44Figure 4–32Stages of a blocked-end irrigation4–47Figure 4–33Schematic tailwater reuse system4–50Figure 4–34Typical surface irrigation head ditch configurations4–55Figure 4–35Typical head-discharge curve for gated pipe outlets4–56Figure 4–36Example of gated pipe layout with head control box4–59Figure 4–37Layout of free draining furrow gated pipe system4–62Figure 4A–1Comparison between the average 6-hour intake rate4A–3and the basic intake rate of the original SCS intake familiesFigure 4B–1Main Surface screen4B–2Figure 4B–2Surface command bar4B–2Figure 4B–3Surface input tabbed notebook4B–3Figure 4B–4Surface tabular output screen4B–4Figure 4B–5Field characteristics panel of the input tabbed notebook 4B–5Figure 4B–6Illustration of multipled slope surface irrigated field4B–6Figure 4B–7Border, basins, furrow flow cross section4B–7Figure 4B–8Infiltration characteristics panel of the input tabbednotebook4B–8Figure 4B–9NRCS reference intake family for initial continuous flow 4B–9furrow irrigations(210–VI–NEH, September 2012)

Chapter 4Surface IrrigationPart 623National Engineering HandbookFigure 4B–10 Inflow controls panel of the input tabbed notebook4B–11Figure 4B–11 Hydrograph input panel of the input tabbed notebook4B–13Figure 4B–12 Main simulation screen4B–14Figure 4B–13 Typical advance/recession plot from the Surfacegraphics output4B–16Figure 4B–14 Typical runoff hydrograph from the Surface graphicsoutput4B–16Figure 4B–15 Typical plot of intake distribution for the Surfacegraphics output4B–17Figure 4B–16 Surface design panel4B–17Figure 4B–17 ProjectDataForm for design printout4B–20Figure 4B–18 Cross-sectional shapes for furrow and border/basinirrigation4B–22Figure 4B–19 Cross section evaluation using the Surface software4B–23Figure 4B–20 Field measurement points for advance and recessionevaluations in the field4B–24Figure 4B–21 Advance/recession curve for the exampleFreeDrainingFurrow 2.cfg data4B–25Figure 4B–22 Final simulated tailwater hydrograph forFreeDrainingFurrow 2.cfg data4B–25Figure 4B–23 Corrected advance/recession curve forFree-DrainingFurrow 2.cfg data4B–26Figure 4B–24 FreeDrainingFurrow 1 advance/recession trajectory4B–26Figure 4B–25 FreeDrainingFurrow 1 tailwater hydrograph4B–26Figure 4B–26 Soil moisture distribution from FreeDrainingFurrow 1 4B–28dataFigure 4B–27 Surface Design Panel for initial FreeDrainingFurrow 1 4B–28conditionFigure 4B–28 Improved design for initial irrigations4B–29Figure 4B–29 Selecting the later irrigation conditions4B–30Figure 4B–30 FreeDrainingBorder 4 advance and recession plotsfor initial irrigations4B–31(210–VI–NEH, September 2012)4–vii

Chapter 44–viiiSurface IrrigationPart 623National Engineering HandbookFigure 4B–31 Tailwater hydrograph for FreeDrainingBorder 4 data4B–31Figure 4B–32 Design panel for the final design of theFreeDrainingBorder 4 initial irrigation example4B–32Figure 4B–33 Stages of a blocked-end irrigation4B–33Figure 4B–34 Simulation of the BlockedEndBorder.cfg data4B–35Figure 4B–35 Simulated tailwater hydrograph using theCutbackDesign.cfg data file4B–36Figure 4B–36 Schematic tailwater reuse system4B–36Figure 4B–37 FreeDrainingFurrow 2.cfg design of the field usingthe main water supply4B–38Figure 4B–38 Surge flow advance and recession plot forFreeDrainingFurrow 1Surge example4B–40Figure 4B–39 Design Panel for the FreeDrainingFurrow 1Surge.cfgexample4B–41(210–VI–NEH, September 2012)

Chapter 4Surface Irrigationheart of the irrigation system. While it is necessary tolimit the scope of this chapter to a guide for the evaluation and design of the surface irrigation system itself,it should be appreciated that the surface irrigationsystem is entirely dependent on the other componentsfor its performance.623.0400 The practice ofsurface irrigation(a) IntroductionSurface irrigation is the oldest and most commonmethod of applying water to croplands. Also referredto as flood irrigation, the essential feature of this irrigation system is that water is applied at a specific location and allowed to flow freely over the field surface,and thereby apply and distribute the necessary waterto refill the crop root zone. This can be contrasted tosprinkle or drip irrigation where water is distributedover the field in pressurized pipes and then appliedthrough sprinklers or drippers to the surface.Surface irrigation has evolved into an extensive arrayof configurations that can broadly be classified as: basin irrigation border irrigation furrow irrigation wild floodingThe distinction between the various classificationsis often subjective. For example, a basin or bordersystem may be furrowed. Wild flooding is a catchall category for the situations where water is simplyallowed to flow onto an area without any attempt toregulate the application or its uniformity. Since no effort is made to regulate the application or uniformity,this type of surface irrigation does not need attentionin this handbook. If control of the wild flooding eventis introduced, it then evolves into a border, basin, orfurrow system.(1) Surface irrigation processesThere are three general phases in a surface irrigationevent (fig. 4–2): advance wetting or ponding recessionThe advance phase occurs between when water is firstintroduced to the field and when it has advanced to theend. Between the time of advance completion, or simply advance time and the time when water is shutoff orcutoff, is the period designated as the wetting or ponding phase. The wetting or ponding phase will not bepresent if the inflow is terminated before the advancephase is completed, a typical situation in borders andbasins, but a rarity in furrows.The wetting phase is accompanied by tailwater runofffrom free-draining systems or by ponding on blockedend systems. After the inflow is terminated, waterrecedes from the field by draining from the field and/or into the field via infiltration. This is the recessionphase. All numerical models of surface irrigation attempt to simulate these processes.An irrigated field is only one component of an irrigation system (fig. 4–1). Water must be diverted froma stream, captured and released from a reservoir, orpumped from the ground water, and then conveyedto the field. Excess water needs to be drained fromthe field. Each of these components requires design,operation, and maintenance of regulating and controlstructures. For the system to be efficient and effective,the flow not only must be regulated and managed, butmost importantly, it must also be measured. Thus, theon-field component (surface, sprinkle, or drip), is the(623–VI–NEH, September 2012)4–1

Chapter 4Surface IrrigationFigure 4–1Part 623National Engineering HandbookLayout and function of irrigation system componentsBroad crested flumeWater supplyCheckWaterdeliverysystemGated pipeDropHead ditchDivision boxWater usesystemTail water ditchWater removal systemOutlet structure4–2(210–VI–NEH, September 2012)

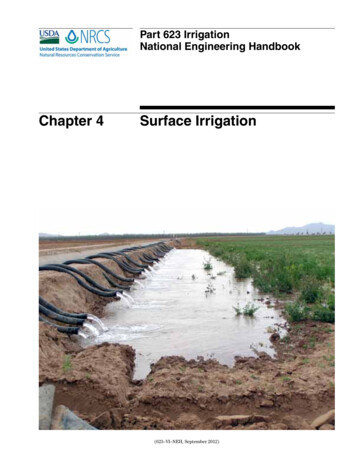

Chapter 4Figure 4–2Surface IrrigationBasic phases of a surface irrigation eventWetting RecessiontimetimeTime of cutoffTime of advanceAdvancetimeTime since irrigation startedTime of recessionL/2Distance from field inletL(b) Surface irrigation configurationsChoosing a particular surface irrigation system for thespecific needs of the individual irrigator depends onthe proper evaluation and consideration of the following factors: costs of the system and its appurtenances field sizes and shapes field slope and slope variability soil intake and water holding characteristics the quality and availability (timing of deliveries,amount, and duration of delivery) of the watersupply climatePart 623National Engineering Handbookoperate and manage. Land leveling is the most costlydevelopment and maintenance requirement, althoughthe perimeter diking can also be expensive to form andmaintain. In areas where turnouts from the deliverysystem have relatively small discharges, developmentcosts may also be increased by necessary changes inthe irrigation system upstream of the basin.Since basins are typically designed to pond the wateron their surfaces and prevent tailwater, they are usually the most efficient surface irrigation configurations.In addition, management is almost always simpler.Field geometry—In the absence of field slope to aidthe movement of water on the field surface, the runlength, or distance the water has to advance overthe field, tends to be minimized. Many basins takeon a square rather than a rectangular shape, but thisdepends entirely on the availability of sufficient flowrates and the intake characteristics of the soil. One ofthe major advantages of basins is their utility in irrigating fields with irregular shapes and small fields.Soil characteristics—Basin irrigation systems usually operate at less frequent intervals than furrows orborders by applying a larger depth during irrigation.Consequently, medium- to fine-textured soils with theirhigh moisture holding capacity are better suited tobasins than coarse-textured soils. The efficiency anduniformity of basin irrigation depend on the relativeFigure 4–3Typical basin irrigation system in the WesternUnited States cropping patterns historical practices and preferences accessibility to precision land leveling services(1) Basin irrigationBasin irrigation is distinguished by a completely levelfield with perimeter dikes to control and/or preventrunoff. Figure 4–3 illustrates the most common basinirrigation concept.Development costs—Basin irrigation is generally themost expensive surface irrigation configuration todevelop and maintain, but often the least expensive to(210–VI–NEH, September 2012)4–3

Chapter 4Surface Irrigationmagnitude of the field inflow and the soil intake. A soilwith a relatively high intake characteristic will requirea substantially higher flow rate to achieve the sameuniformity and efficiency as for a heavier soil.Since the water may cover the entire basin surface, asoil that forms dense crusts upon drying may have detrimental impacts on seed germination and emergence.It is common practice to furrow soils of this nature toreduce crusting problems. On the other hand, basin irrigation is an effective means for reclamation and saltleaching.Many of the heavier soils will form cracks betweenirrigations which may be responsible for much of thewater that infiltrates during irrigation. These soils arealso susceptible to forming compacted layers (hardpans or plow pans) at the cultivation depth. The impact of cracking in basin irrigation is an increased applied depth. The impact of a plow pan is to restrict it.Water supply—The water supply to a basin irrigatedfield has four important characteristics:The duration of irrigation is dependent on the depthto be applied, the flow rate onto the field, and theefficiency of the irrigation. Basin irrigation’s typicallyhigh discharges and high efficiencies mean that basinirrigations may require less total time than borders andfurrows. This, coupled with the fact that basins usuallyirrigate heavier soils and apply larger depths, meansthat the irrigation of basins are typically less frequentthan borders or furrows. The duration and frequencyof basin irrigation can impose different requirementson the water supply system compared to systems operated to service border and furrow systems.Climate—Whenever water ponds on a croppedsurface for an extended period of time, the oxygencarbon dioxide exchange between the atmosphere andthe roots is disrupted. If the disruption is long enough,the crops will die. This process is sometimes calledscalding. Scalding is perceived as a serious risk inbasin irrigation by irrigators in hot dry climates. Ricefarming, however, depends on this process for weedcontrol.Another climate-related impact of basin irrigation isthe effect of water temperature on the crop at different stages of growth. Irrigation with cold water earlyin the spring can delay growth, whereas in the hotperiods of the summer, it can cool the environment—both of which can be beneficial or detrimental in somecases. quality flow rate duration frequency of deliveryThe quality of the water added to the field will be reflected in the quality of the water throughout the rootzone. Salinity is usually the most important quality parameter in surface irrigation, and the higher the salinity in the irrigation water, the higher the concentrationof salts in the lower regions of the root zone. However,since basins do not apply water to the crop canopy asdoes sprinkle irrigation, water supplies with relativelyhigh salinities can be used. Some water supplies alsohave poor quality due to toxic elements like boron.The most important factor in achieving high basinirrigation uniformity and efficiency while minimizingoperational costs is the discharge applied to the field.In basin irrigation, the higher the available dischargethe better, constrained only by having such a highflow that erosion occurs near the inlet. The waterdelivered to a basin is usually done with jack gates orother methods that can apply large amounts of waterquickly.4–4Part 623National Engineering HandbookOne important advantage of basins in many areas ofhigh rainfall is that they can more effectively captureit than can borders or furrows. Thus, basins enjoy thebenefits of higher levels of effective precipitation andmay actually require less irrigation delivery duringrainy periods as long as the crops are not damaged bysubsequent scalding or flooding.Cropping patterns—With its full wetting and largeapplied depths, basin irrigation is most conducive tothe irrigation of full-stand crops like alfalfa, grains,grass, and rice. Row crops can be and often are grownin basins, as well. Widely spaced crops like fruit treesdo not require as much of the total field soil volume tobe wetted and thus, basin irrigation in these instancesis less useful. Although, it should be noted that minibasins formed around each tree and then irrigated inpass-through or cascade fashion are found in manyorchard systems. Cascading systems are usually less(210–VI–NEH, September 2012)

Chapter 4Surface Irrigationefficient and have low uniformity due to poor watercontrol.Basin irrigation is also more effective with deep-rooted crops like alfalfa than with shallow-rooted cropslike vegetables. Crops that react adversely to crownwetting do not favor basins.Cultural factors—Because surface irrigation dependson the movement of water over the field surfacewhose properties change from year to year and cropto crop, as well as from irrigation to irrigation, surfaceirrigation management is a difficult task to do well andconsistently. Basin irrigation reduces this burden byeliminating tailwater from the management process.However, where basin irrigation has not been practiced previously, the added costs and the uncertaintyassociated with a lack of experience are often substantial barriers to its adoption.Basin irrigation is less common in the United Statesthan either border or furrow systems but has beenshown to have significant advantages. Nevertheless,most irrigators will stay with practices that have beenused previously in their area rather than take therisk associated with a new technology. Consequently,demonstrations are often necessary to introduce basinirrigation.One of the major criticisms of basin irrigation is theequipment turning time. Because basins lengths aregenerally shorter, they require more preparation timein turning equipment during cultivating, planting, andharvesting operations.Part 623National Engineering Handbookpractice is laser-guided leveling. Precision land leveling is an absolute prerequisite to high-performancesurface irrigation systems, including basins. Thisincludes regular precision maintenance during fieldpreparations (land smoothing).(2) Furrow irrigationFurrow irrigation is at the opposite extreme of thearray of surface irrigation configurations from basins.Rather than flooding the entire field, small channelscalled furrows, and sometimes creases, rills, or corrugations, are formed and irrigated (fig. 4–4). Theamount of water per unit width on a furrow-irrigatedfield may only be 20 percent of the water flowing overa similar width in a basin. Infiltration is two-dimensional through the wetted perimeter rather than a vertical one-dimensional intake. Furrows can be blockedat the end to prevent runoff, but this is not a commonpractice unless they are used in basins or borders tocompensate for topographical variation or provide araised seed bed to minimize crusting problems. Thedistinction between a furrowed basin or a furrowedborder and furrow irrigation lies in the semanticpreference of the user. For purposes of evaluation anddesign, both of these situations would fall under theterm furrow irrigation.Development costs—Furrow irrigation systems are theleast expensive surface irrigation systems to developand maintain primarily because minimal land level-Figure 4–4Furrow irrigation using siphon tubes from afield bayLand leveling—Before the advent of the laser-guidedland grading equipment, it was common to find surface elevations as much as one or two inches loweror higher than the design elevations of the field. Landleveling operators varied in skill and experience. Theprecision of laser-guided land grading equipment ismuch greater and does not depend nearly as much onoperator skill and experience.Since the field surface must convey and distributewater, any undulations will impact the flow and, therefore, the efficiency and uniformity. Basin irrigation issomewhat more dependent on precision field topography than either furrow or border systems because ofhigh flows or the ponding. Many users of basin irrigation insist that the most important water management(210–VI–NEH, September 2012)4–5

Chapter 4Surface Irrigationing is required to implement a furrow system and lessprecise land smoothing is necessary for maintenance.The furrows themselves can be formed with cultivation equipment at the time of planting.While less expensive to implement, furrow systems aresubstantially more labor intensive than basins. Variations in individual flows, slopes, roughness, and intakealter the advance rate of each furrow, and there areoften substantial differences in how long it takes thewater to reach the end of the furrow. In addition, somefurrows are compacted by the wheel traffic of plantingand cultivation equipment and have substantially different characteristics than nontraffic furrows. Irrigators compensate for the difference in advance rate byadjusting the furrow flows. This requires the operatorto remain longer at the field to observe advance patterns of the water. Further, they also have to assesshow long to allow the water to run off the field beforeshutting it off, as opposed to shutting the flow off in abasin when the correct total volume has been added tothe field.Because most furrow systems allow field tailwater,they are seldom as efficient as basin systems and,thereby, require more water per unit area. Measuressuch as the capture and reuse of tailwater can beemployed to increase efficiency. Another alternativeis a concept called cutback that involves reducingthe furrow inflow after the flow has reached the endof the furrow. Surge flow and cablegation systems areexamples of automated cutback systems.Figure 4–54–6Part 623National Engineering HandbookField geometry—Furrow irrigated fields generallyhave slopes in both the direction of the flow and thelateral direction. These slopes can vary within a field;although, the slope in the direction of flow should notvary significantly unless it is flattened at the end of thefield to improve uniformity. Figure 4–5 illustrates theuse of contour furrows to irrigate irregularly slopedfields. One of the major advantages of furrow irrigation is that undulations in topography have less impacton efficiency and uniformity than they do in eitherbasin or border irrigation.Soil characteristics—Furrow irrigation can be practiced on nearly all soils, but there are two importantlimitations. First, the risk of erosion is higher in furrow irrigation than in either basin or border irrigationbecause the flow is channeled and the flow velocitiesare greater. Secondly, since the furrow actually wetsas little as 20 percent of the field surface (dependingon furrow spacing), applying relatively large depths ofirrigation water in the fine-textured soils can requireextended periods of time and will result in low efficiencies. A 4- or 6-inch irrigation application is common in basin and border irrigation but would not befeasible with a furrow system on a particularly finetextured soil.Furrow irrigation is more impacted by soil cracks thanborders and basins since the cracks often convey flowacross furrows. Furrows are probably less impactedby restrictive layers due to their inherent two-dimensional wetting patterns.Contour furrow irrigation(210–VI–NEH, September 2012)

Chapter 4Surface IrrigationWater supply—Since the flow on the field is substantially less than in a basin or border system, a majoradvantage of furrow irrigation is that it can accommodate relatively small delivery discharges per unitarea. As furrows typically apply smaller depths perirrigation, the availability of the delivery must be morefrequent and for longer durations. More water on a volumetric basis is required for furrow irrigation becauseof its lower application efficiency in most cases. Watercan be delivered to the furrow through a variety ofways (e

(210-VI-NEH, September 2012) 4-v Part 623 National Engineering Handbook Chapter 4 Surface Irrigation Figure 4-1 Layout and function of irrigation system components 4-2 Figure 4-2 Basic phases of a surface irrigation event 4-3 Figure 4-3 Typical basin irrigation system in the Western United 4-3 States