Transcription

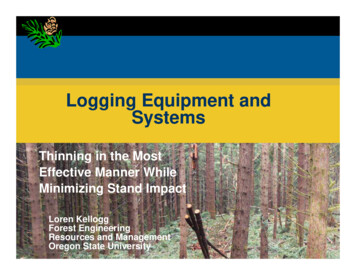

Logging Equipment andSystemsThinning in the MostEffective Manner WhileMinimizing Stand ImpactLoren KelloggForest EngineeringResources and ManagementOregon State University

Logging Equipment and SystemsPresentation Outline Overview of equipment and systemsfor thinning Costs of thinning systems Matching technologies to timberconditions Minimizing stand damage and soilcompaction

Skyline ThinningEquipment and Systems

Equipment & Carriage OptionsStanding Skyline &Slackpulling Carriage Uphill yarding preferred 1000 – 1500 ft. yardingdistance 2,000 – 5,000 poundpayload capacity 50,000 - 450,000equipment cost Yarding crew size from2 – 6 people

Purpose-Built Small WoodYardersExamplesKoller 501SkyleadChristyTMY 40

Versatile Mobile YardersDiamond 210 Swing YarderMadill 071

Non-Guyline YardersYoaderTong-ThrowerPhoto Credit: Pete Bailey, Skyline ThinningCompany

Koller MultiMatick Yarder/ProcessorPhoto Credit: Koller and Lee Miller,Miller Timber Services14

AutomaticOperatingCycleStart of theautomatic outhaulby key press andthe control ispassed onArrival at the startingpoint and loweringthe load onto thelandingAutomatic inhaulstarts and the controlis transferred againBreak out bythe operator(ChokerSetter)Photo Credit: Koller and Miller Timber Services

Equipment & Carriage OptionsMechanical SlackpullingManual Slackpulling

Multispan Skyline Carriages

OtherThinning Harvesting SystemsCut-To-LengthSystemForwarderSingle-Grip Harvester

OtherThinning Harvesting Systems

OtherThinning Harvesting Systems

Costs ofThinning Systems

Harvesting Cost ComponentsFelling, Yarding, Loading Fixed costs Variable costs including labor Move-in costs (seasonal restrictions) Supervision, administration Equipment utilization (SMH vs PMH)Road Construction and MaintenanceTransportation

Variables that Affect Harvesting CostSome Examples Yarding, skidding or forwarding distance Tree size Volume removal or residual basal area Terrain conditions (topography) Landing size and layout Road conditions Guyline anchor availability

Typical Productivity and Costs Low to High Thinning CostsHorseChainsaw felling and skiddingCut-to-LengthCableHelicopter Daily Range of Productivity1 – 10 truck loads (3 - 5 loads common)4 – 40 MBF per day - stump to truck Daily Costs 1,000 - 25,000 ( 2,500 - 4,500 common) Cost per MBF (felling, yarding loading) 100 to 500 ( 200 - 250 common)

Some ExamplesVariables that Affect Thinning Costs Equipment Versatility and UtilizationRick McKay Logging

Thinning Intensity AffectsHarvesting Costs8071.9269.337064.9757.4760Cost in /Net Cunit50.1553.1850Move In/OutYarding40Felling302010030 TPA60 TPAYachats100 TPA30 TPA60 TPAHebo100 TPA

Thinning Cost ComparisonMid-size yarder8 person crewSmall yarder5 person crew12% lower yarding cost

Prebunching Logs for SkylineThinning Operations

Prebunching Equipment Alternatives

Early CommercialThinning Systems

Native Forest ReGrowthEucalyptus ThinningAustraliaSystem 2 Questions: What are theproductivity and costimpacts –small treesand thinning? Where/how canproductivity beincreased? How do alternativeharvesting systemscompare? What are the nicheareas for differentharvest systems?System 1

Research ResultsHow do small trees affect thinning costs?70.060.0Unit cost ( 3335373941DBH (cm)HarvesterFeller/processors (15 -20 )Feller/processors (10 -15 )Feller/processors ( 10 )

Early Commercial Thinning“Best” Harvesting Options: Cut-to-length system Small skyline yarder Whole tree yarding Prebunching for biggerequipment & systems

Matching HarvestingTechnologies to TimberConditions

Small Commercial Thinning Timber 100 bf/tree;10-14 in DBH;30-40 yrs D. FirHarvesting System Alternatives Cut-to-length Small skyline yarder ( 35% slopes) Horse Crawler Tractor

Medium Commercial Thinning Timber 100-150 bf/tree; 12-16 in DBH; 35 - 50 yrs D. FirHarvesting System Alternatives Cut-to-length Medium skyline yarder ( 35% slopes) Crawler Tractor Small or Medium Size Helicopter

Large Commercial Thinning Timber 150 bf/tree; 16-24 in DBH;40 - 70 yrs D. FirHarvesting System Alternatives Chainsaw Felling or Feller Buncherand Crawler Tractor Medium Skyline Yarder ( 35% slopes) Medium-Size Helicopter ( 35% slopes)

Minimizing Stand Damageand Soil CompactionPLANNING – PLANNING - PLANNING

Different Equipment, Expertise andHarvest PlanningClearcutting vs. Thinning

T15S, R7W8109T15S, R6W1211Gunsight789Ben LaneAlseaNutmegWhitebark17Jason ThinTower CanyonBilly Tower151614BlacktopPrairie RoadSale NameVolume2005 Blacktop76352005 Total763520 Ben Lane21 50602006Chinkapin2793Jason Thin52302006 Total130832007 Billy Tower5700Poolside9400Whitebark47002007 Total1980029 Mark Time28 89392008Nutmeg2800Bottomline20002008 Total117392009 East Chinkapin1622Prairie Road2165Tower Canyon4116West 18th50012009 Total129042010 Alsea3063Gunsight2624Leibo Canyon441South Fork771Trip West60682010 Total12967131817Trip West16West 18thFYSouth Fork22Poolside23241920212928East ChinkapinChinkapinLeibo CanyonMark Time27262530Strategic and Tactical HarvestPlanning for Different SystemsPhoto Credit: Cheryl Bright, BLM

Operational Planning(Unit, Sale, Project)

Skyline Yarding Roads and Landings

Skyline Deflection

Skyline Corridor Field LayoutPhoto Credit: Pete Bailey,Skyline Thinning Company

Skyline Corridor Layout

Skidding and ForwarderTrail PlanningForwarding PatternSkidding Pattern

Minimizing Residual Stand DamageDuring Logging Operations Skyline corridor layout Felling pattern Crew experience & techniques Slackpulling carriage control Skyline corridor spacing (100 – 150 ft) Use of intermediate supports &tailtrees where needed Rub trees along the corridors Tree pads when needed Extra care during sap flow

Thank you

Equipment & Carriage Options Standing Skyline & Slackpulling Carriage Uphill yarding preferred 1000 - 1500 ft. yarding distance 2,000 - 5,000 pound payload capacity 50,000 - 450,000 equipment cost Yarding crew size from 2 - 6 people