Transcription

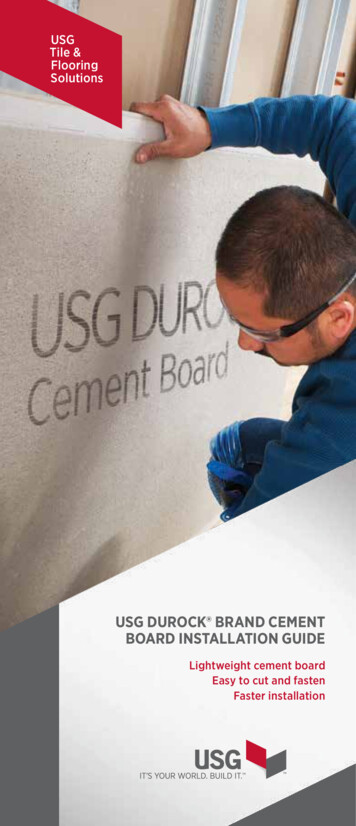

USGTile &FlooringSolutionsUSG DUROCK BRAND CEMENTBOARD INSTALLATION GUIDELightweight cement boardEasy to cut and fastenFaster installation

USG DUROCK BRANDCEMENT BOARDFor more than 30 years, USG Durock Brand CementBoard has set the standard for proven performancein the backerboard category. USG Durock cementboard installs quickly and easily, while maintainingthe brand’s tradition of quality and reliability.Other benefits include: Lightweight cement board for easier handling Easy to cut and fasten 30-year limited warrantyWater durable and mold resistant, with better tilebond than fiber-cement boards or bare plywood,USG Durock cement board is an outstandingbackerboard for a wide variety of reasons. Choosethis high-performance alternative to fiber-cementboards or bare plywood surfaces for:Superior Tile BondPrevents tile pops and grout cracks, up to40% greater tile bond than fiber-cement board.The Strength of Portland CementWill not swell, soften, rot, warp, delaminate ordisintegrate if exposed to water. Noncombustible.Backed by a 30-year limited warranty.Superior Mold ResistanceReceives rating of “0” for no mold growth as testedper ASTM G21. Scores a 10 out of 10 on ASTM D3273.

WHAT YOU’LL NEEDFloors 1/4", 1/2", 5/8"thicknessSubfloor should be minimum5/8" APA span-rated plywoodor OSB with an Exposure 1classification or better.Countertops 1/4", 1/2", 5/8"thicknessMinimum 3/4" APA spanrated plywood or OSB withan Exposure 1 classificationor better.Cover base with USG Durock Brand Tile Membrane, 15 lb.felt or 4-mil polyethylene andattach with 1/4" galvanizedstaples.CuttingUSG Durock Brand CementBoard panels should becut to size with a knife andstraightedge. A power sawshould be used only if itis equipped with a dustcollection device. Alwayswear a NIOSH/MSHAapproved mask and eyeprotection when cuttingUSG Durock panels. Utility knife: Using astraightedge, score panelface with utility knife andcut through glass-fiberreinforcing mesh, then snapand cut backside mesh tobreak cleanly. Use a rasp tosmooth any rough edges.Walls and Ceilings 1/2" and5/8" thickness onlyMaximum stud spacing: 16"o.c. Maximum allowabledeflection, based on studproperties only, L/360.Maximum fastener spacing:8" o.c. for wood and steelframing; 6" o.c. for ceilingapplications.WaterproofingIf waterproofing is desired,use USG Durock TileMembrane or USG Durock Brand WaterproofingMembrane. See USGliterature piece CB492 forUSG Durock Tile Membraneproduct information. See USGliterature piece CB595 forUSG Durock WaterproofingMembrane productinformation. P ower saw: Use a low-RPMportable saw with 3-1/2"carbide-tipped blade. Tomake cutouts for pipes andfixtures, use utility knife to cutthrough mesh on both sidesof panel and punch out witha hammer from back side.Or, use an electric drill witha hole-saw bit.WARNING: Dust can contain silica.Prolonged breathing can causelung damage and cancer. See SDSfor more information.3

Floor Installation1/4", 1/2", 5/8"POSITIONINGFit ends and edges ofpanels closely but not forcedtogether, maintaining 1/4"space between panels andperimeter walls. Staggerjoints a minimum 16" so fourcorners never meet. Offsetpanel joints a minimum 8"from subfloor joints.1/4" gapfactory edgescutedge16"underlayment16"subfloorLEVELING BEDApply Type 1 organicadhesive with 5/32"v-notched trowel, latexfortified mortar with 1/4"square-notched trowel.Comb out adhesive ormortar in straight, parallelrows (as shown below) andimmediately cover withpanel. Adhere panels tosubfloor, one panel at a time.FASTENINGSecure panels while adhesiveis still wet. Space fasteners8" o.c. around the perimeterand in the field of the board.Wood framing andcountertops: fasten with1-1/2" 11-gauge hot-dippedgalvanized roofing nails,or USG Durock BrandTile Backer Screws forwood framing or 1-1/4"USG Durock Tile BackerScrews for wood framing orequivalent.JOININGFill joints with latex-fortifiedmortar or Type 1 organicadhesive and immediatelyembed alkali-resistant,fiberglass mesh joint tape.FINISHINGTile or almost any flooringmaterial.**Not for use with vinyl flooring.4

CountertopInstallationWall & CeilingInstallationCover plywood base with USGDurock tile membrane, 15 lb.felt or 4-mil polyethylene andattach with 1/4" galvanizedstaple.FASTENINGFasten to studs spaced 16"o.c. Space fasteners 8" o.c.for walls, 6" o.c. for ceilings.Fit ends and edges of panelsclosely but not forcedtogether.1/4", 1/2", 5/8"1/2" & 5/8" only W ood framing: 1-1/2" hotdipped galvanized roofingnails or 1-1/4" USG Durock tile backer screws for woodframing or equivalent.POSITIONFit ends and edges of panelsclosely but not forcedtogether. Stagger panel jointsfrom plywood base joints. S teel framing: 1-1/4"USG Durock tile backerscrews for steel framing orequivalent.FASTENSpace fasteners 8" o.c.around the perimeter and inthe field of the board.JOININGFill joints with latex-fortifiedmortar or Type 1 organicadhesive and immediatelyembed alkali-resistant,fiberglass mesh joint tape.JOININGFill joints with latex-fortifiedmortar or Type 1 organicadhesive and immediatelyembed alkali-resistant,fiberglass mesh joint tape.SHIMPlace a 1/4" spacer strip orshim around lip of bathtub orshower pan to hold bottomedge of panel off the fixture.FINISHInstall tile.FINISHInstall tile.Note: Because cement boardfasteners may protrude throughthe plywood base when 1/4"cement board is used, 1/2" or 5/8"cement board is preferred in thisapplication.See SA932 for finishingrecommendations to nontiledcement board.5

1/4", 1/2", 5/8"POSITIONINGWhere tile will not coverentire wall surface, suchas above tub and showersurrounds, determine whereyou want the tile to endand draw a level line at thisheight. Be sure to allowfor height of tile cap, ifapplicable.capheight of tileUse this first row as a guideto keep tiles and grout lineslevel and ensure alignmentwith tiles of adjacent tubor shower surround. If newflooring will be installed,leave a sufficient gapbetween lowest tile andsubfloor.level linevertical starting linePlanning Your TileInstallationlevelhorizontal startinglinefloor tilecutcutcutfloor levelOn walls where tile will reachthe floor, determine whetherfloor is level by measuringdistance to desired tile heighton both sides of area to betiled. If there is a difference(e.g., the floor is lower on oneside), lay one vertical row oftile from highest point downto floor. Affix tiles with dabsof mastic.6On bathroom floors, start byplacing full tiles in front ofbathtub or shower and alongthe adjoining wall to avoidcut tiles in this highly visiblearea.

InstallingCeramic TileApply latex-fortified mortar orType 1 organic adhesive with anotched trowel. Hold trowel atan angle to maintain uniformthickness. Refer to settingmaterial manufacturer forspecific information related totrowel type and size.Working a small area at atime, press tile into placewith a slight twisting motionto seat properly. Preventadhesive buildup on tile edgeand in grout space. If adhesivesqueezes from under tile,remove excess before it dries.Keep tiles and joints straightand uniform. Use tile spacersif desired.7

PRODUCT INFORMATIONSee usg.com for the most up-to-date product information.CUSTOMER SERVICE800 621-9523TECHNICAL SERVICE800 USG.4YOU (874-4968)WEBSITEusg.comNOTICEWe shall not be liable for incidental and consequential damages,directly or indirectly sustained, nor for any loss caused by applicationof these goods not in accordance with current printed instructionsor for other than the intended use. Our liability is expressly limited toreplacement of defective goods. Any claim shall be deemed waivedunless made in writing to us within thirty (30) days from date itwas or reasonably should have been discovered.NOTEProducts described here may not be available in all geographicmarkets. Consult your USG Company sales office or representativefor information.DANGER!May cause cancer or damage lungs by prolonged or repeatedexposure to respirable crystalline silica. Do not handle until all safetyprecautions have been read and understood. Do not breathe dust.Use only in a well-ventilated area, wear a NIOSH/MSHA-approvedrespirator. Wear protective gloves/protective clothing/eye protection.If swallowed, inhaled or skin irritation occurs, immediately getmedical attention. Dispose of in accordance with local, state andfederal regulations.For more information call Product Safety: 800 507-8899 orsee the SDS at usg.com.KEEP OUT OF REACH OF CHILDREN.CB237/rev. 12-15 2015 USG Corporation and/or its affiliates. All rights reserved. Printed in U.S.A.The trademarks USG, DUROCK, IT’S YOUR WORLD. BUILD IT., the USG logo, the design elements andcolors, and related marks are trademarks of USG Corporation or its affiliates.

embed alkali-resistant, fiberglass mesh joint tape. FINISH Install tile. Note: Because cement board fasteners may protrude through the plywood base when 1/4" cement board is used, 1/2" or 5/8" cement board is preferred in this application. Wall & Ceiling Installation 1/2" & 5/8" only FASTENING Fasten to studs spaced 16" o.c. Space fasteners 8" o.c.