Transcription

Southern California EdisonSF6 Gas Management ProgramUpdateByMarc FloresAlex SalinasSouthern California Edison

Overview Goals and objectives of“Gas ManagementProgram” Gas Management process Program Implementation Program results Program Challenges Future Goals and Objectives

Goals and ObjectivesGas Management Program Conform with EPA/MOU Reduce overall emissions Reduce O & M costs Improve productivity Increase data collection accuracy Enhance asset management decisions

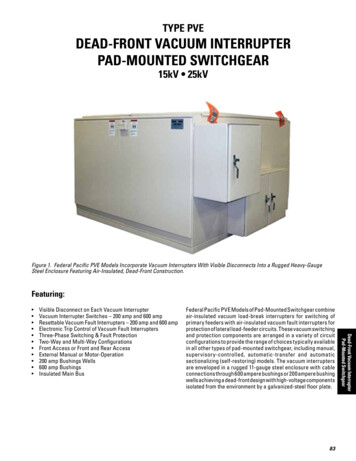

Gas Management Process Total Gas in Equipment– 2361 Gas Circuit Breakers– Four GIS Facilities– 540,000 lbs. SF6 Total– Net increase of 40,000 lbs since 2000 Inventory Cylinders 34,000 lbs. annuallyGas Distribution in Equipment67%12%2%3%16%66 kV115 kV220 kV500 kVGIS

Gas Management Process (cont) Tracking Method– Weigh cylinders before returning to supplier– Log and report quarterly– Cylinders returned to supplier– Residual– Gas purchasesAnnually reporting – “Mass Balance Approach”––––Total residualUsed gas removed from retired equipmentRecycledNew equipment

Program Implementation Identify leaks using asset management tools Work management system– Frequency of gas added– Type of equipmentEquipment history– Dual pressure systems et al Leak detection methods C02 laser leak detection technologyConventional (soap bubbles, halogen)

Program Implementation (cont.)ÂDevelop priority list leak detection ÂWorst leaks “low hanging fruit”Station with most leaking equipmentScheduled internal inspectionsIncorporate priority list in PMA process Specialist surveys equipment using laser leak detectionequipmentProcess initiates reportEnables better asset management decisions– Repair vs replace

Leak Detection Results217320Number of leaks identified bylocation on equipmentGas MechanismsTanksBushings

Program ChallengesÂTension between priorities ÂData Gathering ÂRequired scheduled maintenance vs. repairing leakingequipmentResource constraintsAccuracy in documentationConsistency in following the established processYear End Data Analysis Cumbersome and time consuming

Program Challenges (cont.) Buy in to program Culture change with supervisors and maintenancepersonnelCompleting repairsCylinder consolidationEmptying cylinders Large Projects Outage constraintsHandling large quantities

Program Challenges (cont.) Equipment Repairs BushingsLeak sealingParts issues, tubing, manifolds etc. Facility Service Agreements Third party equipment ownershipLimited authorization to make repairsCase justification for equipment replacement

Program ResultsSF6 Emission Rate – Comparison of SCE andPartners of the SF6 Emission Reduction Partnership

Lessons Learned“Mass Balance Approach” can be effective whenguidelines are followed ÂÂChecks and balances– Control in data reportingEffective allocation of resourcesCloser oversight would be resource depleting Weighing cylindersCentralizationReducing emissions on older equipment is not as easyas it appears

Future Goals and Objectives Develop equipment criteria rating Cost benefit analysis for repairsEstablish equipment criticality to the “grid”Technical benefits for replacement Realize program benefits Quantifying financial resultsEmission reduction goals

Future Goals and Objectives (cont.)Â Develop automated data collection process Data collection would migrate into dedicateddatabaseDatabase can generate emission reportsPopulate annual reporting formProcess would improve data accuracy

CONCLUSIONMaking progress for emission reduction goals despitesetbacks Laser leak detection equipment demonstrates benefitsand strong potential Closed loop and automated process is essential movingforward Programs must allow for process improvementÂSouthern California Edison

Southern California Edison SF6 Gas Management Program Update Author: Marc Flores Alex Salinas Subject: Southern California Edison SF6 Gas Management Program Update Keywords: Southern California Edison SF6 Gas Management Program Update By Marc Flores Alex Salinas Southern California Edison Created Date: 12/17/2004 10:28:06 PM