Transcription

Tier I Spill Prevention, Control, & Countermeasure(SPCC) PlanGuidance and Template for Dairy ProducersPrepared byThe Dragun Corporation30445 Northwestern HighwaySuite 260Farmington Hills, MichiganOn behalf ofUnited States Department of AgricultureNatural Resources Conservation Service(USDA-NRCS)National Milk Producers FederationThis material was made possible, in part, by a Contribution Agreementfrom the United States Department of Agriculture’s Natural ResourceConservation Service (NRCS). It may not necessarily express NRCS’ views.Important Instructions – Please Read Before Proceeding:1.In this document, general instructions are highlighted in green boxes. Detailed instructions for completing the Tier I SPCCPlan Template for Dairy Producers are provided in Appendix A.2.Definitions are provided for bold, blue italicized words in Appendix B of the Tier I SPCC Plan Template for DairyProducers.3.Page iii of this document outlines the purpose of this document, introduces the SPCC regulations, and presents importantdefinitions. Please read this information.4.Use the flowchart on page iv and the Oil Storage Capacity Calculation Form on page v (if necessary) to determine if yourfarm is subject to the SPCC regulation.5.If your farm is subject to the SPCC requirements, answer the questions on page vi to determine if you are eligible to selfcertify your SPCC plan and use the template included herein.1

Table of ContentsPurpose . iiiDisclaimer. iiiWhat is SPCC? . iiiWhat is oil?. iiiWhat facilities are covered under the SPCC program?. iiiWhat is the definition of a farm under the SPCC program? . iiiDo the SPCC regulations apply to your farm? . 4Oil Storage Capacity Calculation Form . 5Do I qualify to self-certify my SPCC Plan? . 6SPCC Plan Compliance Deadlines . 1Instructions to Complete the Template . 2Tier I Qualified Facility SPCC Plan for Dairy Producers .5Facility Description . 5I. Self-Certification Statement (§112.6(a)(1)) . 5II. Record of Plan Review and Amendments . 6III. Plan Requirements . 81. Oil Storage Containers and Capacities (§112.7(a)(3)(i)): . 82. Facility Layout and Oil Storage Locations (§112.7(a)(3)) . 93. Secondary Containment and Oil Spill Control (§§112.6(a)(3)(i) and (ii); 112.7(b), (c), (d), (h), (i) and (k); 112.9(c)(2)and (d)(3); and 40 CFR 109): . 104. Inspections, Testing, Recordkeeping and Personnel Training (§§112.7(e) and (f), 112.8(c)(6) and (d)(4),112.9(c)(3), 112.12(c)(6) and (d)(4)): . 135. Security (§112.7(g)) (excluding oil production facilities): . 176. Emergency Procedures and Notifications (§§112.7(a)(3)(iv), (v) and §112.7(a)(5)):. 177. NRC Notification Procedure (§112.7(a)(4) and (a)(5)): . 208. SPCC Spill Reporting Requirements (Report within 60 days) (§112.4): . 21IV. Additional Requirements . 22A. Onshore Facilities (excluding production) (§§112.8(b) through (d), 112.12(b) through (d)): . 23B. Onshore Oil Production Facilities (excluding drilling and workover facilities) (§112.9(b), (c), and (d)): . 26C. Onshore Oil Drilling and Workover Facilities (§112.10(b), (c) and (d)):. 28APPENDIX A: TEMPLATE INSTRUCTIONS. A-1TEMPLATE INSTRUCTIONS . A-2APPENDIX B: DEFINITIONS . B-1DEFINITIONS . B-2APPENDIX C: OIL SPILL CONTINGENCY PLAN AND WRITTEN COMMITMENT OF RESOURCES . B-1OIL SPILL CONTINGENCY PLAN . B-2ii

PurposeThis document is designed to help you(1) Determine if your farm needs a Spill Prevention, Control, and Countermeasure (SPCC) Plan.(2) Determine whether your farm is eligible for you to self certify your SPCC Plan.(3) Complete an SPCC Plan if you are eligible for self certification.DisclaimerThis document is not intended to be a comprehensive review of the SPCC Requirements. This guidance and Templatewas prepared based on the SPCC Rule revisions dated November 13, 2009, and the Tier I Qualified Facility SPCC PlanTemplate (Ver.1-E-doc-3-18-10) published by the Environmental Protection Agency (EPA). Completion of this Templatedoes not guarantee compliance. Each owner/operator is responsible for ensuring that his or her facility meets therequirements of 40 CFR 112 (74 FR 58811) and its proposed revisions. After an acceptable SPCC Plan is generated foryour facility, the Plan must be implemented to meet the rule requirements.What is SPCC?The Spill Prevention, Control, and Countermeasure (SPCC) regulation is 40 CFR 112 (Code of Federal Regulations, Title40: Protection of Environment, Part 112: Oil Pollution Prevention). According to the EPA, “the goal of the SPCC programis to prevent oil spills into waters of the United States and adjoining shorelines.” An important part of this programrequires farmers and owners/operators to have an oil spill prevention plan, called an SPCC Plan. Each farm that qualifiesunder the rule must have and implement an SPCC Plan by the following dates:A farm starting operation Must.On or before August 16, 2002* Continue to maintain its existing SPCC Plan in accordance with the SPCC rule.Amend and implement that Plan no later than November 10, 2010**.After August 16, 2002, throughNovember 10, 2010** Prepare and implement an SPCC Plan no later than November 10, 2010**.After November 10, 2010** Prepare and implement an SPCC Plan before beginning operations.* August 16, 2002 is the date that the amended SPCC rule became effective.** On July 28, 2010, EPA proposed to extend the compliance date up to an additional one-year for facilities with milk containers, associated pipingand appurtenances that are constructed according to the current applicable 3-A Sanitary Standards, and subject to the current applicable Grade"A" Pasteurized Milk Ordinance (PMO) or a state dairy regulatory requirement equivalent to the current applicable PMO. Dairy producers are stillrequired to comply with SPCC regulations for all other oil storage as listed above.What is oil?Under the SPCC program oil is defined as “oil of any kind or in any form, including, but not limited to: fats, oils, orgreases of animal, fish, or marine mammal origin; vegetable oils, including oils from seeds, nuts, fruits, or kernels; and,other oils and greases, including petroleum, fuel oil, sludge, synthetic oils, mineral oils, oil refuse, or oil mixed withwastes other than dredged spoil” [§112.2]. This definition includes milk.What facilities are covered under the SPCC program?According to the SPCC rule, the SPCC program “applies to any owner or operator of a non-transportation-relatedonshore or offshore facility engaged in drilling, producing, gathering, storing, processing, refining, transferring,distributing, using, or consuming oil and oil products, which due to its location, could reasonably be expected todischarge oil in quantities that may be harmful” into waters of the U.S. or adjoining shorelines, such as interstate waters,intrastate lakes, rivers, and streams [§112.1(b)]. Therefore, the owner/operator of a farm (onshore facility) that storesand/or uses oil (in specific quantities) that could be released into the waters of the U.S. is subject to the SPCC regulation.What is the definition of a farm under the SPCC program?Under the SPCC program a farm is defined as “a facility on a tract of land devoted to the production of crops or raising ofanimals, including fish, which produced and sold, or normally would have produced and sold, 1,000 or more ofagricultural products during a year” [§112.2].iiiNEXT

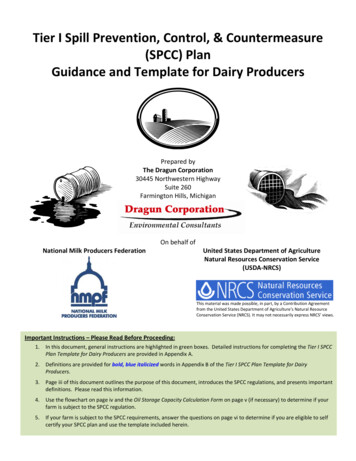

Do the SPCC regulations apply to your farm?Do you store, transfer, use,consume, drill, produce,process, refine, or distributeoil or oil products on yourfarm?NoYou need an SPCC Plan andmust prepare andimplement it by November10, 2010.YesDo you store a total ofmore than 1,320 USgallons of oil or oilproducts in abovegroundcontainers -or- more than42,000 US gallons of oil oroil products in buriedcontainers? Go to the OilStorage CapacityCalculation Form onpage v for assistance.You do not need an SPCC Planunder the current USEPARegulations. (1)YesYesAre these materials storedon the same farm (facility)and on the same parcel ofland?NoNoA site-specific evaluationby an environmentalprofessional may benecessary.Individual States may requiresimilar Spill Plans for oil andother chemicals stored in bulk.View EPA SPCC Information for Farmers1However, it is recommend that you complete page v of this document and keep a record of it on your farm.ivNEXT

Oil Storage Capacity Calculation FormType ofContainer –Aboveground2 (A)or Buried3 (B)ContainerContents(Type of oilstored)Container Shell Capacity(US gallons)Instructions:1. If you store oil or oil products onyour farm, complete the table todetermine if your farm is regulatedunder the SPCC rule.----2.Only include containers with astorage capacity of 55 US gallons orgreater. List the entire volume (shellcapacity) of the container, not thevolume of oil in the container.3.Include every container that is usedto store oil or oil products as definedunder §112.2 (see note 1 below fora list of exclusions).4.Include containers even if they areonly used to store oil or oil productsperiodically.5.Adjacent or non-adjacent parcels,either leased or owned, may beconsidered separate facilities forSPCC purposes. Containers onseparate parcels (that you identify asseparate facilities based on howthey are operated) do not need tobe added together in determiningwhether the 1,320-gallonaboveground or 42,000-gallonburied applicability threshold is met.Use copies of this form for eachseparate facility to determine whichrequire an SPCC plan. A site specificevaluation by an environmentalprofessional may be necessary.6.Use additional pages as necessary.7.Add the aboveground storage tankcapacities together, add the buriedstorage tank capacities together,record the respective values below,and follow the instructions at thebottom of the page.---------------Notes:1Containers excluded from SPCC rule: Fuel oil containers used solely for a single-family residence, Containers that are “permanently closed” (contents removed, piping disconnectedand plugged, valves closed, and signs posted indicating closure), “Motive power” containers (e.g. automotive or truck fuel tanks), Hot-mix asphalt or Hot-mix asphalt containers, Containers used only for wastewater treatment, and Pesticide application equipment and related mix containers (e.g. ground boomapplicators, airblast sprayers, and specialty aircraft). [§112.1(d)(2)]2Aboveground Containers – oil storage containers that are not completely buried and includecontainers in vaults, partially buried tanks, or bunkered tanks (containers “constructed orplaced in the ground by cutting the earth and re-covering the container in a manner thatbreaks the surrounding natural grade, or that lies above grade, and is covered with earth, sand,gravel, asphalt, or other material“ §112.2)3Buried Containers – oil storage tanks that are completely buried (“any container completelybelow grade and covered with earth, sand, gravel, asphalt, or other material” §112.2)1. TOTAL ABOVEGROUND STORAGE CAPACITYIs this 1,320 US gallons?YesNo2. TOTAL COMPLETELY BURIED STORAGE CAPACITYIs this 42,000 US gallons?YesNoIf you answered YES to one or both questions above, you must prepare and implement an SPCC plan for your farm. Sign and datethis form below, and return to the flowchart on the previous page and complete the questions.If you answered NO to both questions above, please sign and date this form below. Keep a copy of this completed form for yourrecords.Date Completed:BACKSignature:v

Do I qualify to self-certify my SPCC Plan?Instructions:1. If you already have an SPCC Plan, update it. If you do not have an SPCC Plan, you should prepare and implement one.2.Under the SPCC regulation, Tier I qualified facility owners/operators are eligible to implement and self-certify their newor amended SPCC Plans and use the template included herein.Answer the questions below to determine if your farm is a Tier I qualified facility and if you are eligible to self-certifyyour plan and use the included SPCC Plan template.1. In the past three years have you had a single discharge of oil (including milk) to navigable waters oradjoining shorelines that was greater than 1,000 U.S. gallons?*YesNo2. Have you had two discharges of oil (including milk) to navigable waters or adjoining shorelines which wereeach greater than 42 U.S. gallons within any 12-month period?*YesNo3. Do you have a total aboveground oil storage capacity of more than 10,000 U.S. gallons?YesNo4. Does your farm have one or more individual aboveground oil storage containers with a capacity greaterNothan 5,000 U.S. gallons?YesIf you answered NO to all four questions, your farm qualifies as a Tier I qualified facility and you (owner/operator)are eligible to self-certify your SPCC Plan. Continue to the next page to access and use the SPCC Plan templateincluded. If your facility was in operation before August 16, 2002, and you do not already have a Plan, thenimplement this template immediately.If you answered YES to any of the four questions, your farm does NOT qualify as a Tier I facility. Review the SPCCregulation or contact a Professional Engineer to assist you in completing an SPCC Plan for each of your farm facilities.See the next page of this document for SPCC Plan deadlines.*Please note: Discharges do not include discharges that are the result of natural disasters, acts of war, or terrorism. When determining theapplicability of this SPCC reporting requirement, the gallon amount(s) specified (either 1,000 or 42) refers to the amount of oil that actually reachesnavigable waters or adjoining shorelines not the total amount of oil spilled. EPA considers the entire volume of the discharge to be oil for thepurposes of these reporting requirements.viNEXT

Tier I Spill Prevention, Control, & Countermeasure(SPCC) PlanTemplate for Dairy ProducersPrepared byThe Dragun Corporation30445 Northwestern HighwaySuite 260Farmington Hills, MichiganOn behalf ofNational Milk Producers FederationUnited States Department of AgricultureNatural Resources Conservation Service(USDA-NRCS)This material was made possible, in part, by a Contribution Agreementfrom the United States Department of Agriculture’s Natural ResourceConservation Service (NRCS). It may not necessarily express NRCS’ views.SPCC Plan Compliance DeadlinesA farm starting operation Must.On or before August 16, 2002* Continue to maintain its existing SPCC Plan in accordance with the SPCC rule.Amend and implement that Plan no later than November 10, 2010**.After August 16, 2002, throughNovember 10, 2010** Prepare and implement an SPCC Plan no later than November 10, 2010**.After November 10, 2010** Prepare and implement an SPCC Plan before beginning operations.* August 16, 2002 is the date that the amended SPCC rule became effective.** On July 28, 2010, EPA proposed to extend the compliance date up to an additional one-year for facilities with milk containers, associated pipingand appurtenances that are constructed according to the current applicable 3-A Sanitary Standards, and subject to the current applicable Grade"A" Pasteurized Milk Ordinance (PMO) or a state dairy regulatory requirement equivalent to the current applicable PMO. Dairy producers are stillrequired to comply with SPCC regulations for all other oil storage as listed above.1

Instructions to Complete the TemplateThis template is intended to help the owner or operator of a Tier I qualified facility develop a self-certified Spill Prevention,Control, and Countermeasure (SPCC) Plan. To use this template, your facility must meet all of the applicability criteria of a Tier Iqualified facility listed under §112.3(g)(1) of the SPCC rule. This template provides the SPCC rule requirements necessary for aTier I qualified facility, which you must address and implement. You may complete this template either electronically or by hand(1)on a printed copy.Template Structure:Section I. Self-Certification Statement (§112.6(a)(1))Section II. Record of Plan Review and AmendmentsSection III. Plan Requirements (sub-sections 1 through 7)Section IV. Additional Requirements (sub-sections A, B, and C)All Tier I qualified facility self-certifiers must complete Sections I, II, and III of the plan template. Additionally, the owner oroperator of an Onshore facility (excluding production) must complete Section IV (A),Onshore oil production facility (excluding drilling and workover facilities) must complete Section IV (B),Onshore oil drilling and workover facility must complete Section IV I.Included in the Template are three Appendices which are referenced in the Template text. Step-by-step Instructions forcompleting each section of the template are provided in Appendix A, and definitions of terms used in the Template are providedin Appendix B. It is recommended that you print and use the Template Instructions and Definitions as you complete the Tier ISPCC Plan Template for Dairy Producers. If you complete the form electronically, select the “Go to Instructions” button to theright each section title to reference the instructions in Appendix A, and click on the bold, blue italicized words in the text toaccess the definitions in Appendix B.Complete the Template by filling in the appropriate information in the spaces provided. Where check boxes are provided, readthe corresponding text and check the box next to the requirement to indicate that it has been adequately addressed for yourfarm. Where a section requires a description or listing, write in the spaces provided (or attach additional descriptions if morespace is needed). Write “N/A” (Not Applicable) in the space or next to the box to indicate those requirements that are notapplicable to the farm.Important Instructions:After you have completed all appropriate sections, certify and date your Plan, and then implement it by thecompliance date. If your facility was in operation before August 16, 2002, and you do not already have a Plan,implement this template immediately. Conduct inspections and tests in accordance with the written proceduresthat you have developed for your facility.If your farm is normally attended at least four hours per day, keep a complete copy of the SPCC Plan at your farm,or for a farm attended fewer than four hours per day, keep the Plan at the nearest field office. Keep a record ofinspections and tests with the SPCC Plan for a period of three years. The records should be signed by theappropriate supervisor or inspector.Review your Plan at least once every five years and update it when you make changes to your farm. You mustprepare amendments within six months of each change, and implement the amendments as soon as possible, butnot more than six months after an amendment is prepared.In the event that your facility releases oil to navigable waters or adjoining shorelines, immediately call theNational Response Center (NRC) at 1-800-424-8802. The NRC is the federal government's centralized reportingcenter, which is staffed 24 hours per day by U.S. Coast Guard personnel.1Please note that the use of this template is not mandatory for a Tier I qualified facility. You may also meet the SPCC Plan requirement bypreparing a satisfactory Tier II qualified facility Plan, preparing a satisfactory Plan that is certified by a Professional Engineer, or by developingan equivalent Plan for a Tier I qualified facility. Further information on the requirements of these methods can be found in 40 CFR part112.6(a)(1). If you use any of these alternative methods you must include a cross reference in your Plan that shows how the equivalent Planmeets all applicable 40 CFR part 112 requirements.2

Regulatory Reference Table of Contents40 CFR 112.6(a)(3)RequirementRegulatory Reference*(40 CFR 112.3(d) and112.6(a)(1))(40 CFR 112.4(a-f) and112.5(a-c))(40 CFR 112.5(b))(40 CFR 112.5(b))(40 CFR 112.7)(40 CFR 112.7(a)(1))(40 CFR 112.7(a)(2))(40 CFR 112.7(a)(3))(40 CFR 112.7(a)(3))(40 CFR 112.7(a)(3)(i))(40 CFR 112.7(a)(3)(ii))(40 CFR 112.7(a)(3)(iii))(40 CFR 112.7(a)(3)(iv))(40 CFR 112.7(a)(3)(v))(40 CFR 112.7(a)(3)(vi))(40 CFR 112.7(a)(4))(40 CFR 112.7(a)(5))(40 CFR 112.7(b))(40 CFR 112.7(c)(1)(i-vi))(40 CFR 112.7(c)(1)(vii))(40 CFR 112.7(c)(1)(i))(40 CFR 112.7(d))(40 CFR 112.7(e))(40 CFR 112.7(f)(1-3))(40 CFR 112.7(f)(1))(40 CFR 112.7(f)(2))(40 CFR 112.7(f)(3))(40 CFR 112.7(g)(1-5))(40 CFR 112.7(g)(1))(40 CFR 112.7(g)(2))(40 CFR 112.7(g)(3))(40 CFR 112.7(g)(4))(40 CFR 112.7(g)(5))(40 CFR 112.7(h)(1-3))(40 CFR 112.7(h)(1))(40 CFR 112.7(h)(2))(40 CFR 112.7(h)(3))(40 CFR 112.7(j))CertificationSPCC plan amendmentSPCC plan reviewSPCC evaluation logManagement approvalConformance with 40 CFR 112.7Deviation from applicable requirements of 40 CFR 112.7Facility informationFacility descriptionBulk storage tanksDischarge prevention measuresDischarge controlsCountermeasureMethods of disposalContact listDischarge reporting proceduresReadily usable emergency response proceduresPotential spill predictions, volumes, rates, and controlsContainment and diversionary structuresLocation of spill response equipmentSecondary containment systemsDemonstration of practicabilityInspections and recordsTrainingPersonnel instructionsDesignated person accountable for spill preventionSpill prevention briefingsSecurityFencingFlow valves lockedStarter controls lockedPipeline loading/unloading connections securely cappedLightingFacility tank car and truck loading/unloading operationsSecondary containment in tank truck unloading areasWarning system for tank truck unloadingExamination of tank trucks following unloadingCompliance with applicable state requirements3Template SectionPageI5III.8 and IIIIIIIIIIII.2Before Section IIII.1III.3III.3III.6III.6III.6III.7III.6 and 7III.3 (Table .5III.5III.5III.5III.5III.5III.3III.3 (Table 4)III.3III.3III.321, 66755595810-1110-11171718-192017, 201110-11910-1110-1113-1614, 1614, 161414, 161717171717171010-11101010

RequirementRegulatory Reference*Template SectionPageOil-filled operational equipment requirementsConformance with general requirementsFacility drainageDrainage from diked storage areasValves used on diked storage areasPlant drainage systems from undiked areasFinal discharge of drainageFacility drainage systems and equipmentBulk storage containersTank compatibility with contentsAboveground storage tanksPrecipitation drainageUnderground storage tanksPartially buried storage tanksAboveground storage tank periodic integrity testingControl of leakage through defective heating coilsTank installation fail safe engineeringInspection of effluent treatment facilitiesVisible dischargesAppropriate position of mobile or portable oil storage tanksFacility transfer operationsBuried piping installation, protection, and examinationNot in service and standby service terminal connectionsPipe support designAboveground valve and pipeline examination(40 CFR 112.7(k))(40 CFR 112.8(a))(40 CFR 112.8(b)(1-5))(40 CFR 112.8(b)(1))(40 CFR 112.8(b)(2))(40 CFR 112.8(b)(3))(40 CFR 112.8(b)(4))(40 CFR 112.8(b)(5))(40 CFR 112.8(c)(1-11))(40 CFR 112.8(c)(1))(40 CFR 112.8(c)(2))(40 CFR 112.8(c)(3)(i-iv))(40 CFR 112.8(c)(4))(40 CFR 112.8(c)(5))(40 CFR 112.8(c)(6))(40 CFR 112.8(c)(7))(40 CFR 112.8(c)(8))(40 CFR 112.8(c)(9))(40 CFR 112.8(c)(10))(40 CFR 112.8(c)(11))(40 CFR 112.8(d)(1-5))(40 CFR 112.8(d)(1))(40 CFR 112.8(d)(2))(40 CFR 112.8(d)(3))(40 CFR V.AIV.AIV.AIV.AIV.AIV.AIV.AIV.AIV.AIV.AIV.A and 323232323232525252523, 923-2525252525Aboveground piping protection from vehicular traffic(40 CFR 112.8(d)(5))IV.A25Oil production facility drainage(40 CFR 112.9(b))IV. B26-27Oil production facility bulk storage containers(40 CFR 112.9(c))III.3, IV. B11, 23-27Facility transfer operations, oil production facility(40 CFR 112.9(d))III.3, IV. B12, 25-27Onshore oil drilling/workover facility general requirements(40 CFR 112.10(b))IV.C28Onshore oil drilling/workover facility equipment locationsOnshore oil drilling/workover facility dischargecontainment(40 CFR 112.10(c))IV.C28(40 CFR 112.10(d))IV.C28Onshore facility drainage(40 CFR 112.12(b))IV.A23Onshore facility bulk storage containersOnshore facility transfer operations, pumping, and facilityprocess(40 CFR 112.12(c))IV.A23-25(40 CFR 112.12(d))25Oil Spill Contingency Plan(40 CFR 109)IV.AIII.3 andAppendix C12, C-1*Review the regulatory requirements to determine applicability. Click on the following link and scroll to the appropriate section ofthe regulation. 40 CFR part 1124

Tier I Qualified Facility SPCC Plan for Dairy ProducersThis template constitutes the SPCC Plan for the facility, when completed and signed by the owner or operator of a facility thatmeets the applicability criteria in §112.3(g)(1). This template addresses the requirements of 40 CFR Part 112. Maintain a completecopy of the Plan at the facility if the facility is normally attended at least four hours per day, or for a facility attended fewer thanfour hours per day, at the nearest field office. When making operational changes at a facility that are necessary to comply with therule requirements, the owner/operator should follow state and local requirements (such as for permitting, design andconstruction) and obtain professional assistance, as appropriate.Facility DescriptionGo to InstructionsFacility NameFacility AddressCityStateCountyTel. Number (ZIP)-Owner or Operator NameOwner or Operator AddressCityStateCountyTel. Number (I. Self-Certification Statement (§112.6(a)(1))ZIP)-Go to InstructionsThe owner or operator of a facility certifies that each of the following is true in order to utilize this template tocomply with the SPCC requirements:I1.2.3.4.5.6.7.8.certify that the following is accurate:I am familiar with the applicable requirements of 40 CFR part 112;I have visited and examined the facility;This Plan was prepared in accordance with accepted and sound industry practices and standards;Procedures for required inspections and testing have been established in accordance with industry inspectionand testing standards or recommended practices;I will fully i

(3) Complete an SPCC Plan if you are eligible for self certification. Disclaimer This document is not intended to be a comprehensive review of the SPCC Requirements. This guidance and Template was prepared based on the SPCC Rule revisions dated November 13, 2009 , and the . Tier I Qualified Facility SPCC Plan