Transcription

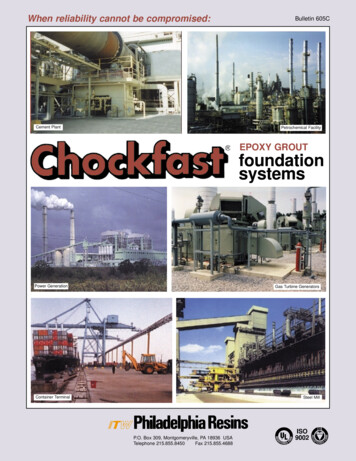

When reliability cannot be compromised:Cement PlantBulletin 605CPetrochemical FacilityEPOXY GROUTfoundationsystemsPower GenerationGas Turbine GeneratorsContainer TerminalSteel MillP.O. Box 309, Montgomeryville, PA 18936 USATelephone 215.855.8450Fax 215.855.4688

From monolithic vibration damping ofpump foundations to large reciprocatingcompressors, CHOCKFAST maintains precise, permanent machinery alignment.CHOCKFAST RED general-purpose, high strength deep-pour grout for new installations; quickturnaround retrofits; and fast, convenient quick-cure foundation reconstructionCHOCKFAST GRAY thin-pour groutCHOCKFAST BLUE oil-resistant foundation cap/grout for new installations; also strengthensand seals old foundations, while restoring original heightsCHOCKFAST ORANGE chocks for hot-running machinery; also used to assemble bearings; tomaintain alignment of rails; and as a high-strength groutCHOCKFAST BLACK deep-pour chocks allow a free flow of air under hot-running machinerywhile maintaining permanent frame alignment. Virtually 100% effective bearing areapermanent alignment . chemical resistant . vibration damping . worldwide service

Foundation Systems With Built-in ReliabilityAdvantages of CHOCKFAST RedCHOCKFAST RED is a user-friendly,chemically resistant, low dusting epoxygrout with high compressive, tensileand shear strengths. Excellent compatibility withconcrete and steel minimizes or eliminates horizontal bond-line cracks, common to traditional epoxygrouts.A gentle exothermic reaction during cure reducescast-in stresses and allows single pours up to 48”.(For single pours deeper then 18”, contact aCHOCKFAST Representative.) Deep pours expediteinstallation of new equipment. They also reducecostly downtime for foundation repairs.Low dusting formulation simplifies installationand cleanup procedures.Tools and mortar mixers can be cleaned with water.Low Curing Temperature Prevents ProblemsOf Cast-In Stresses With Chockfast Red200180Temperature, FThis 24-hr cure structural epoxy is formulatedto provide excellent vibration damping for staticand dynamic loads plus permanent monolithicsupport with intimate contact between equipmentbedplates and underlying concrete foundations.Turbogenerator: Installed on thick-pour ChockfastRed and oil-resistant Chockfast Blue160140120100800123456 7Cure Time, Hours89CHOCKFAST BLUE Foundation CapThis multi-purpose grout was developed for use under hot-running machinery. It provides a strong cap and excellent “oil-seal”for new foundations; strengthens and seals old foundations, while restoring their original height; andserves as a substitute for steel soleplates or rails.A gentle exothermic reaction during cure eliminatesexcessive cast-in stresses to reduce or eliminate cracking, common to high exotherm grouts. Lifts of 48” ormore can be poured, allowing savings of 20 days ormore compared to traditional concrete reconstruction.What is a CHOCKFAST Chock?It’s a conveniently pourable structuralepoxy that replaces tediously fittedsteel shims (steel chocks); andassures intimate contact withmachined or unmachined equipmentbedplates.Like steel chocks, these structural epoxies allow afree flow of air under hot-running machinery toreduce “thermal humping” which can cause misalignment when equipment is mounted on full-bedgrouts.With low thermal conductivity, Chockfast chocksreduce heat build-up on foundations. They alsoprovide a high coefficient of friction betweenequipment bedplates and foundations to maintainunsurpassed security of alignment, thus protectingcostly equipment from damage and downtime.Hot-Running Compressor:Installed on Chockfast Black Chocks,supported on Chockfast Blue and Red grouts3

foundationsystemsGas turbine generator foundation on deep-pour CHOCKFASTRED, ready for CHOCKFAST BLUE foundation sealTurbine generator for cogen facility was installed onCHOCKFAST RED and BLUESkid-mounted compressor package, precisely aligned,prior to pouring CHOCKFAST REDLow dusting aggregate with CHOCKFAST REDsimplifies installation and cleanup proceduresPipe supports for natural gas transmissionpipeline, aligned on CHOCKFAST REDCrane rail installation with CHOCKFAST RED (or ORANGE)eliminates expensive, corrosion-prone leveling platespermanent alignment . chemical resistant . vibration damping . worldwide service4

foundationsystemsBaseplates for a pair of horizontal pumps, ready for groutingand vibration damping with CHOCKFAST REDVertical pump, mounted on CHOCKFAST REDTemporary shelter for cold-weather grouting;and “conditioning” of all CHOCKFAST RED SG(with cold-weather additive) componentsSingle deep-pour minimizes downtime, whileCHOCKFAST RED effectively damps vibrationsTurbocharger foundation, CHOCKFAST RED ispoured over underlying concrete (center) .CHOCKFAST BLUE provides impervious “oil seal”permanent alignment . chemical resistant . vibration damping . worldwide service5

foundationsystemsPower-plant equipment is precisely and permanentlyaligned on CHOCKFAST RED, BLUE and ORANGE1400 tons of CHOCKFAST maintain precise alignmentof rising sector gates in River Thames flood barrierTwo new process vessels, ready for installationin refinery on CHOCKFAST ORANGE6Cogen engine is positioned on foundation,then chocked with CHOCKFAST ORANGEPower plant turbine, supported ondeep-pour CHOCKFAST REDTurbine balancing machine, aligned onCHOCKFAST RED and BLUEpermanent alignment . chemical resistant . vibration damping . worldwide service

foundationsystemsCHOCKFAST supports wind-powerturbines, onshore and offshoreSkid-mounted reciprocating compressors are supportedon deep-pour CHOCKFAST BLACK chocks❷CHOCKFAST BLACKCHOCKFAST RED❷CHOCKFAST systems are widely used on offshore platformsHot-running gas pipeline compressor is permanently aligned onCHOCKFAST RED, BLUE and BLACKEngine-room fire did not affect integrity ofCHOCKFAST RED or BLACKTurbine cogeneration installations onCHOCKFAST BLUEpermanent alignment . chemical resistant . vibration damping . worldwide service7

Factory-trained and certified CHOCKFAST REPRESENTATIVESare available for onsite technical support worldwidePetrochemical plant/ChockfastBlack, Orange, Blue and RedGas turbine generators, skid-mounted onChockfast RedPower plant generators onChockfast Orange, Blue, RedSewage system engines on ChockfastOrange, Blue and RedCement kiln support rollerson deep-pour Chockfast RedVertical pump/Chockfast Blue;horizontal pump/Chockfast RedRe-grout of poorly alignedpump, now on Chockfast RedReciprocating compressor onChockfast Black, Blue, RedSand/gravel plant: ChockfastGray, Red, Blue and OrangeChockfast Orange provides accuratelycast races for large diameter bearingsJack-up platform on offshore rig,bearing plate on Chockfast OrangeRailcar loading in petrochemicalplant/Chockfast RedCrane rails in container terminalon Chockfast RedOre conveyor piers supportedon Chockfast GraySluice gate guides/Chockfast GrayPipe supports on Chockfast RedCoke ovens in steel planton Chockfast Red and BlueTurbine balancing machine, aligned onChockfast Blue and RedSkid-mounted compressor package onChockfast Blue and RedEmergency Power, EPCOT Center,DisneyWorld/Chockfast Blue 1996, ITW Philadelphia ResinsPrinted in USA, 0996/15MAn Illinois Tool Works CompanyP.O. Box 309130 Commerce DriveMontgomeryville, PA 18936Telephone 215.855.8450FAX 215.855.4688

Printing this ManualIf you would like to print a copy of this Technical Manual, pleasereview the following instructions:This manual is already formatted for printing on the front and backsides of each page.Color PrinterWhen printing from a color printer, enter the properties dialog boxfor your printer and select the appropriate settings for two-sidedprinting and follow be sure to follow your printer’s instructions fortwo-sided printing.Professional Print ShopsYou may also take this pdf file on CD or flash drive to a print shopto make copies. Be sure to instruct the attendant to provide thefollowing: Designate the number of manual sets desired.Print color copiesTwo-sided printingIf you plan to use your own three-ring binder, request the document be three-hole punched onlyIf you would like the print shop to bind the document with a frontand back cover, request clear plastic covers front and back andcoil bound.130 Commerce DriveMontgomeryville, PA 18936P: 215.855.8450F: 215.855.4688

This Page Left Intentionally Blank

Index & Quick Reference

This Page Left Intentionally Blank

This Specification Manual is furnished byChockfast Engineered Grouting SystemsITW Philadelphia ResinsAnd Your Local Chockfast DistributorFor the name of your local stocking distributorplease call Chockfast Grouting Systems Customer Service at215-855-8450 or fax your inquiry to 215-855-4688 1991, ITW Philadelphia Resins

This Page Left Intentionally Blank

INDEXQUICK REFERENCESECTION 1.SPECIFICATIONS FOR GROUTINGA.PUMP BASEPLATES, RAILS, OR SOLEPLATESB.RECIPROCATING EQUIPMENT USING RAILS, SOLEPLATES, ORFULLBED GROUTINGC.EPOXY GROUTING FOR SKID MOUNTED EQUIPMENTSECTION 2.GROUTING PREPARATIONSECTION 3.EXPANSION JOINTSSECTION 4.INSTALLATION PROCEDURESA.B.C.D.E.SECTION 5.PUMP GROUTINGA.B.C.SECTION 6.FLOW VS. CLEARANCEGROUTING IN HOT WEATHERGROUTING IN COLD WEATHERREBUILDING FOUNDATIONS WITH EPOXY GROUTREBAR AND EPOXY GROUTSRESIN INJECTION (TECH. BULLETIN 661)PRE-GROUTING OF API PUMP BASEPLATESPRESSURE GROUTING MACHINERY BASE PLATES TO ELIMINATE VOIDS ANDIMPROVE ALIGNMENTSKID CHOCKINGA.B.CHOCK DESIGN WORKSHEETCHOCK DIMENSION SHEETMAINTAINING PRIME MOVER ALIGNMENT WITH EPOXY CHOCKSSECTION 7.EDGE LIFTINGSECTION 8.ANCHOR BOLTSA.SECTION 9.PROPER ANCHOR BOLT TENSIONING AND ITS RELATIONSHIP TO CHOCK LIFECHECKLIST - MATERIAL AND EQUIPMENTA.B.PROJECT DATATECH. SERVICE

This Page Left Intentionally Blank

The following is a quick reference to determine the product required for general application.USEPRODUCTEquipment GroutingEnginesCompressorsSkid mounted unitsPumpsSole PlatesRailsChockfast RedChockfast Red S.G.Chockfast BlueAcid Resistant Grout and/orHigh temperature applicationsChockfast BlueEpoxy Chockssometimes referredto as pourable shimsChockfast BlackChockfast Orange Anchor bolt or Rebar installationVertical (pourable)Horizontal (putty)Anchorfast Phillybond Blue 6AHigh flow grout 1/4"-1-1/4" depthChockfast GrayDiscuss application withITW Philadelphia Resins todetermine expansion joint locations.Concrete ReconstructionSize and Depth of PourChockfast Red7'x7'x18" (& Deeper)

Concrete Repair CompoundFor repairing spalled concretesmoothing and fairingAny application 1/2" or greaterfor vertical or overheadapplicationPhillybond Blue 6A or(Phillyclad 5020 for floors)Concrete Bonding AgentFor bonding new concreteto old concretePreferred1775/620TS(Chockfast Redresin & hardenerwill work equallywell but will curemore slowly)Pressure injection groutFor repairing cracks inexisting concrete structuresor for pressure injectingloose pump bases or rails.Preferred1775/620TS(Chockfast Redresin & hardenerwill work equallywell but will curemore slowly)Crane Rail GroutingChockfast GrayChockfast RedChockfast BlueProduct choicedepends on designand depth of pour.The above are suggested applications. Ambient temperature and other conditions could be a factor, so itis a good practice to discuss your particular application with your local ITW Philadelphia Resinsdistributor or representative.

Section 1

This Page Left Intentionally Blank

MATERIAL SPECIFICATIONS AND PROCEDURESFOR EPOXY GROUTING OF PUMP BASEPLATES, RAILS, OR SOLEPLATES8/1/91

This Page Left Intentionally Blank

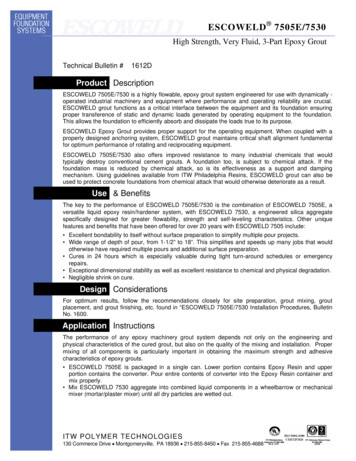

21.0GENERAL GUIDELINES (CHOCKFAST GROUTING SYSTEMS)1.1THIS SPECIFICATION COVERS EPOXY GROUTING OF MECHANICAL EQUIPMENTON CONCRETE FOUNDATIONS USING BASEPLATES, RAILS OR SOLEPLATES.1.1.1PRIOR TO ANY WORK BEING PERFORMED, THE GROUT MANUFACTURER OR HISREPRESENTATIVE SHALL BE CONTACTED AND A PRE-JOB MEETING ARRANGEDTO DISCUSS ALL ASPECTS OF EQUIPMENT GROUTING. AT THIS MEETING THECONTRACTOR SHALL BE PRESENT. IF NO OUTSIDE CONTRACTOR IS BEINGUSED, THEN THE PLANT MAINTENANCE FOREMAN AND/OR CREWSUPERVISOR SHALL BE IN ATTENDANCE.1.1.2THE MACHINERY ENGINEER SHALL DEFINE THE RESPONSIBILITIES OF THEGROUT MANUFACTURER OR HIS REPRESENTATIVE, AND WILL DIRECT TOWHOM THE GROUT MANUFACTURER OR HIS REPRESENTATIVE WILL REPORTDURING THE COURSE OF THE PROJECT OR JOB.1.1.3A WRITTEN SUMMARY OF THIS MEETING WILL BE DISTRIBUTED TO ALL PARTIESCONCERNED PRIOR TO THE JOB START UP.2.0MATERIALS2.1EPOXY GROUT SHALL MEET THE FOLLOWING MINIMUM REQUIREMENTS:2.1.1FIRE RESISTANT AS PER ASTM D-635.2.1.2MINIMUM COMPRESSIVE STRENGTH - 12,000 PSI (ASTM C-579)2.1.3POT LIFE 2-3 HOURS @ 72 F2.1.4CLEAN UP SOLVENT - WATER2.1.5GROUT MUST HAVE LOW ENOUGH EXOTHERM TO PROVIDE DEEP POURCAPABILITY UP TO 18" DEEP X 7' X 7' OR GREATER.2.1.6EVEN AGGREGATE DISTRIBUTION THROUGHOUT THE CURED GROUT WITH NORESIN RICH SURFACE.2.1.7MAXIMUM COEFFICIENT OF THERMAL EXPANSION 11.2 X 10-6 per F , ASTM D-6962.1.8AGGREGATE MUST BE LOW DUST TYPEChockfastSpec. Doc.Sect. 1ARev. 1/8/92

33.0MATERIAL STORAGE3.1ALL GROUT MATERIALS SHALL BE STORED IN A DRY AREA IN ORIGINALUNOPENED CONTAINERS.3.2ALL EPOXY GROUT COMPONENTS SHALL BE PRECONDITIONED TO A MINIMUMOF 65 F AND A MAXIMUM OF 80 F FOR AT LEAST 48 HOURS PRIOR TO MIXINGAND PLACEMENT.4.0PREPARATION OF FOUNDATION:4.1NEW CONCRETE4.1.1PERFORM SHRINKAGE TEST AS PER ASTM C 157-80 ON NEW CONCRETE TODETERMINE WHEN SHRINKAGE IS COMPLETE.4.1.2IF NO SHRINKAGE TEST IS PERFORMED, CURE TIME WILL BE APPROXIMATED ASFOLLOWS:STANDARD CEMENT 21-28 DAYS MINIMUMHI-EARLY CEMENT (6-7 BAG MIX) 7 DAYS MINIMUM4.1.3CONCRETE COMPRESSIVE STRENGTH SHALL BE A MINIMUM OF 3500 PSI.4.1.4CONCRETE TENSILE STRENGTH SHALL BE A MINIMUM OF 350 PSI AS PER ASTM C496-90.4.2CONCRETE SURFACE PREPARATION: OLD OR NEW CONCRETENOTE: HAND CHIPPING GUNS ONLY WILL BE USED. NO JACKHAMMERS WILLBE PERMITTED.4.2.1THE CONCRETE FOUNDATION SHALL BE DRY AND FREE OF OIL.4.2.2THE CONCRETE SHAL

chemically resistant, low dusting epoxy grout with high compressive, tensile and shear strengths. Excellent compatibility with concrete and steel minimizes or eliminates horizon-tal bond-line cracks, common to traditional epoxy grouts. This 24-hr cure structural epoxy is formulated to provide excellent vibration damping for static