Transcription

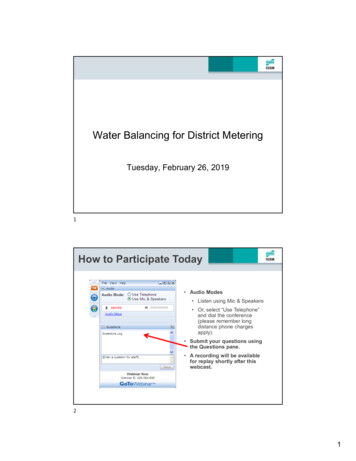

Water Balancing for District MeteringTuesday, February 26, 20191How to Participate Today Audio Modes Listen using Mic & Speakers Or, select “Use Telephone”and dial the conference(please remember longdistance phone chargesapply). Submit your questions usingthe Questions pane. A recording will be availablefor replay shortly after thiswebcast.21

Today’s PresenterJohn Van NostrandSoutheast Regional andMunicipal Manager3Technology is changing water management442

Purpose Inform water users of Metering concerns for waterconservation plans. Expect to solve metering problems and improve waterbalance, collections and treatment.55Learning Objectives Attendees will learn about Global water concerns How the AWWA Lead and Copper Rule can affect flowmeasurement Developments in Ultrasonic Technology How Turn down affects accuracy Overcome metering concerns Reduce Costs and Improve Revenue663

Global Concerns Changing ClimateMore people More Money More demandGround water is being depleted.Water Infrastructure is in poor conditionNatural Infrastructure is being ignoredToo much water is wastedThe pricing is wrong7Water Resource InstituteWater Risk Atlas of the Aqueduct84

Water Resource educt-atlas9Reducing Water LossGrowing political pressure to reduce water loss Local Political pressure Competition amongstmunicipalities for low waterloss rates and increaserevenue Municipalities with highloss rates are regarded asbadly managed, Regulation pressure onmunicipalities to reduce waterloss by pushing them to feel therevenue loss. Utilities must monitor theirnetworks more preciselyWarmer105

Think in terms of Dollars Stop thinking in terms of Percent of water loss! Every drop of water that is pumped out of the ground comes ata cost and is a potential for revenue. Regulators want us to think of water as a commodity– To effectively manage water loss, a utility should be able to answerseveral questions: Where did we lose the water? How much water was lost, expressed as a volume? How much did the loss cost the utility? Why did we lose the water? Some have already implemented water loss regulations basedon the need and the future legislation from the EPA– Texas, Georgia, Washington, California, Delaware River users includingNJ, NY, PA, & DE, and Tennessee1111AWWA is there to helpThis is the Manual forwater resourcemanagement.One of the key activities ismetering the water.It helps to change themind set of waterabundance to water as arevenue stream.12126

Lead and CopperThe Lead and Copper Rule LCR, was originally established in 1991,encouraged putting anti‐corrosion additives into drinking water to coat theinsides of the pipes to prevent metals from leeching into the drinking water.The Action Level (AL) for lead in drinking water is fifteen partsper billion (15 PPB).Lead is particularly dangerous to childrentheir growing bodies absorb more lead than adultstheir brains and nervous systems are more sensitive to the damagingeffects of lead.The LCR is evolving to include enforcement of Lead andCopper reduction.Corrosion Control Treatment (CCT). Those that serve fewer are notrequired unless they exceed the Lead and Copper Action Level of 15PPB13Why has my Magmeter become useless?Injecting chemicals have unintended consequences on magneticflowmeters.The coating fouls the electrodes and renders the Magmeter useless.147

How do you know if you have aninflow and infiltration issue? Your lift station pumps run for a long timeafter a rain event, or there are more pumpstarts and stops after it rains. Identify the leaks with FlowMonitoring. Pipes back-up. Residential or businessbasements flood during a rain event.SSO’s occur. Manhole inspections You see significant spikes in flow at yourwastewater treatment plant correspondingto precipitation events or high groundwaterconditions. Dye testing Smoke testing TV Inspections.15Flow Measurement in Water andwastewater applicationsThe Water and Wastewater industry requirescontinuous process measurement systems.FLEXIM offers the mostreliable measurementsystem for water production,distribution, collections,treatment and reuse168

Technology is changing in water andwastewater1717Improved Monitoring of District Metered Areas (DMAs)Extreme low flow measurements with ultrasound Measuring low flows withultrasound technology has alwaysbeen a strength of FLEXIM Even the slowest flow velocityof the media measured leadsto transit time differences of theultrasound signals FLEXIM has now developed aflow meter with even greateraccuracy in the measurement ofextremely low flowsValue proposition189

Improved Monitoring of District Metered Areas (DMAs)FLUXUS XLF: Detection of weep leaks The FLEXIM ultrasonicflowmeter can measure flowvelocities of 0.03 ft/sec withXLF to o.oo3 ft/secFLUXUS XLF with M sensor on a DN200 pipe Leaks below 2 gpm areclassified as very small“weep leaks”* Using the unique XLF ultrasoundsound technology water supplierscan detect even very small leaks* Hamilton and Charalambous (2013): “Leak Detection – Technology and Implementation”Our solution19Improved Monitoring of District Metered Areas (DMAs)FLUXUS XLF: Technical advantages Ambient temperature variationscan have a strong influence onultrasound measurements ifthey are not compensated FLEXIM is the onlymanufacturer of clamp-onultrasonic flow meters thatinstalls temperature probes inevery sensor By continuously monitoring the sensortemperature and compensatingtemperature variations themeasurements of FLEXIM have anunrivaled repeatabilityValue proposition2010

Improved Monitoring of District Metered Areas (DMAs)FLUXUS XLF: Technical advantagesCompetitors usingcoupling gel: Maintenance-freedue to permanentcoupling pads No connectionson the sensorheads forprotection againstwater ingression Robust designand highquality material(SS 316)Competitorproduct videoCompetitorproduct videoValue proposition21Improved Monitoring of District Metered Areas (DMAs)FLUXUS XLF: Technical advantages Extremely robust andfully closed mountingsystem Sensors cannot be seenand installation thereforedoes not attractattention Mounting system can only be opened witha tool, to reduce the danger of tamperingValue proposition2211

FLEXIM2323Improved Monitoring of District Metered Areas (DMAs)Low flows are Normal flows Most municipal water systemsare designed for futuregrowth. Working with ourcustomers has helped usrealize that flow velocities indrinking water pipes 6” – 12”seldom exceed 3 ft/sec A further realization is that inthese pipes the minimumnightly flow velocity isusually below 0.26 ft/s In a considerable amount ofcases it was also discovered, tothe great surprise of theoperator, that during the times ofminimum consumption the flowdirection changed Flow velocities into DMAs are much lower than assumedReframe2412

Improved Monitoring of District Metered Areas (DMAs)Who cares about 0.6 – 3 ft/s? Most flow meters used includingmagmeters, ensure relatively stableaccuracies for flow velocities of 0.6– 3 ft/sArea of certainty These flow velocities are totallyirrelevant for DMA monitoring as theyare never reachedArea of certaintyArea of certaintyRational drowning25Improved Monitoring of District Metered Areas (DMAs)What accuracies for flow velocities 1 m/s? The inaccuracy ofmagmeter flowmeasurementincreasesdramatically for flowvelocities below 3ft/sec But flow velocitiesbelow 3 ft/sec areprevalent whenmonitoring DMAsRational drowning2613

How do you measure?2727The use of Primary elementsFigure 1Figure 2282814

Square root lawCalibration curve of a typical dp transmitter2929Improved Monitoring of District Metered Areas (DMAs)Why such high inaccuracies below 3 ft/sec? Magmeters measure inducedvoltage If flow velocitiesbecome too low,then the inducedvoltage is nolonger measurableRational drowning3015

Improved Monitoring of District Metered Areas (DMAs)Does increasing flow velocity improve accuracy? Yes, increasing flow velocitywould improve the accuracyof the magmetermeasurement One way of increasing theflow velocity for DMAmonitoring is by usingmagmeters with reduced bore But reducing the bore is oftennot acceptable as it will resultin a pressure drop in the DMAthat is monitoredRational drowning31Improved Monitoring of District Metered Areas (DMAs)FLUXUS XLF: Technical advantages Installed without cutting ordamaging the pipe Simple and fast installationprocess No pipe flushing required, as nocontact to the water is made No water supply interruption No field zero calibrationneeded Large overall time and costsavingsValue proposition3216

Square root lawCalibration curve of a typical dp transmitter3333Magmeters343417

FLEXIM3535Improved Monitoring of District Metered Areas (DMAs)An increase in the establishment of DMAs In order to do this drinkingwater suppliers are furtherdividing their networks intoDMAs that are separatelymonitored for flowDMA boundaryDistribution line This enables them tocalculate water balances anddetermine the consumption ineach individual DMAMain distribution lineUltrasonic flow meter Precise flow monitoring also helps toidentify DMAs with high leakage ratesand detect new leaks at an early stageWarmer3618

Ultrasonic Flowmeter - UFMMeasurement Principle: Transit Time(or time-of-flight principle)Theory:Signal in the direction of flow travels faster comparedto signal against the flow directionThe difference in transit time is a measure for the flowvelocityA swimmer swims faster with the flow ascompared to against the flowThe sonic signal does the same external measurement of internal flow37Piezoelectric Crystal3819

Flexim AdvantagesFlexim utilizes smart digital processing where the signal is digitized manytimes over the entire sinusoidal wave, leaving no margin for error.1/16/2012 1:49:05 PM A: .0 528.0 529.0 530.0 531.0 532.0 533.0 534.0 535.0 536.0 537.0 538.0 539.0 540.0 541.0 542.0 543.0 544.0time [µs]Flexim utilizes a fully digitizedsignal of 50 to 200 pointsdepending on transducer frequencyrange, ensuring a high qualitysignal.FleximOthersOther manufacturers use a single digitalmark in the average of the signal. Thedigital mark movers based on changingtemperature and process conditions,creating meter drift and often fallingoutside of the meters detection limits,which leads to loss of signal.39Signal Waveforms4020

Better Signal Processing Up to 1000 signals persecond Fast signal processingusinga digital signal processor(DSP) High noise suppression- For high accuracy- For short inlet and outletstraight lengths- For high moisture or solidcontents- For small diameters ( DN25) Stabile zeroflow(no zeroingnecessary) No drift No offset41Competitors Signal Processing Only 1 single point on thesignal is processed Manual adjustment ofcrossover point4221

Cross Check Signal ProcessingCross Correlation Up to 1000 signals per secondare generated Fast signal evaluation withDSP (digital signal processor) Time difference calculated bycross correlation excellent noisesuppression whole signal is employed Resolution and Zero Stability: 1/4000 of a Signal period 0.75mm/s for a 16“ /DN400 Natural Gas Line43Transducer Technologies FLEXIM offers two differentcomplementary transducer technologies Maximum flexibility depending onapplication specification. Shear wave transducer: All pipe wall materials All pipe wall thicknesses Lamb wave transducers: Multi Product Pipelines Changing Liquids (e.g.concentration) Viscous liquids4422

pgDistrict Metered Areas(DMAs) Extreme low flowmeasurements withultrasound Measuring low flows withultrasound technologyhas always been astrength of FLEXIM Even the slowest flowvelocity of the mediameasured leads totransit time differences ofthe ultrasound signals FLEXIM has now45 developed a flow meterwith even greaterValue proposition45Doppler in Flow MeasurementDoppler meters use sound pulse reflection principle tomeasure liquid flow rate, solids or bubbles insuspension in the liquid reflect the sound back to thereceiving transducer. Assumption - Reflected particle external measurement of internal flowrepresentative of average flow4623

Dual Mode“Transit Time – Doppler”The Flexim meter can be set up to automaticallyswitch from Transit Time to Doppler (Noisetrek)Both measurements made from the sametransducer external measurement of internal flow47Transit Time - Clamp onEmbedded RTD - temp compensation as per ASME MFC 5Mw Meter formulac vl k c di t2 t FFluidAcoustic calibration factork c Q A kRe vlc sin Snells Law:front panelAmultiplexerDpulseformingDSPdata processing,squence controlinterfacesccc sin sin sin Fluid mechanicalcalibration factorQ A kRe vl4824

Temperature CompensationFlexim is the only Ultrasonic Flowmeter on themarket that meets ASME requirements fortemperature compensation.ASME MFC- 5M: Measurement of Liquid Flow inClosed Conduits Using Transit-Time UltrasonicFlowmetersFlexim has NO Temperature drift!RTD in transducer tocompensate for temperaturechanges.No other manufacturer doesthis!49Zero Stability real zero stability due to matching of transducers inproduction and temperature compensation long-term drift free measurement meets ANSI/ASME MFC-5M-1985standard12" Pipe Flexim Versus Competitor Zero Test10Flexim66.45Other 7133 199 265 331 397 463 529 595 661 727 793 859 925 991 1057 1123 1189 1255 1321 1387 14535025

Temperature Stability testFlexim – Siemens – GE51Clamp-on meteringDrift testTemperature change is 70oF to 115oFFlexim Clamp-on MeterNo zero drift5226

Clamp-on meteringBrand X Clamp-on Meter Drift of 2cm/sec .07 ft/sec 6 GPM on a 6” pipe 6GPM represents 6,000 CHW season53Clamp-on meteringBrand Y Clamp-on Meter Drift of 3cm/sec .1 ft/sec 9 GPM on a 6” pipe 9 GPM represents 9000 CHW season5427

Calibration Facility – Flexim NY55TypicalCalibrationCertificate5628

pgDistrict Metered Areas(DMAs)FLUXUS XLF: Detection ofweep leaks The FLUXUS XLF canmeasure flow velocitiesof about 0.03 ft/sec Leaks below 2 gpm areclassified as very small“weep leaks”* Using the unique XLFultrasound soundtechnology watersuppliers can monitorDMAs and detect even57 very small leaksFLUXUS XLF with M sensor on a DN200 pipe* Hamilton and Charalambous (2013): “Leak Detection – Technology and Implementation”Our solution57pgDistrict Metered Areas(DMAs)FLUXUS XLF: Technicaladvantages Ambient temperaturevariations can have a stronginfluence on ultrasoundmeasurements if they are notcompensated FLEXIM is the onlymanufacturer of clamp-onultrasonic flow meters thatinstalls temperature probes inevery sensor By continuously monitoring58 the sensor temperature andcompensating temperatureValue proposition5829

pgDistrict Metered Areas(DMAs)FLUXUS XLF: Technicaladvantages Maintenance-free due topermanent coupling pads No connections on thesensor heads for protectionagainst water ingression Robust design and highquality material (SS 316)59Value proposition59pgDistrict Metered Areas(DMAs)FLUXUS XLF: Technicaladvantages Extremely robust andfully closed mountingsystem Sensors cannot be seenand installation thereforedoes not attract attention Mounting system canonly be opened with atool, to reduce thedanger of tampering60Value proposition6030

pgDistrict Metered Areas(DMAs)FLUXUS XLF: Technicaladvantages Installed without cutting ordamaging the pipe Simple and fast installationprocess No pipe flushing required, asno contact to the water ismade No water supply interruption No field zero calibrationneeded 61 Large overall time and costsavingsValue proposition61Solution626231

FLEXIM6363May 21, 2012John Van NostrandCase Study: The 5th largest utility in the nation has issues withmeters coating with magnatite.6432

Customer and Case The City of Jacksonville Florida has extremetly hard water and magnatite coatsthe inside of magnetic flow meters causiong a short and meter reads low andlower over time. JEA is the 5th largest utility in the Nation.65Application - CustomerMotivation Potable water wells are monitored for depth, conductivity for salt waterintrusion and flow. A World Class Magnetic flow meter company thought they had a solution withtheir electrode cleaning circuit. The magnetic flow meters came calibrated from the factory and workedperfectly measuring water production wells for the first six months. The flow meters began to drift downward after six months until they read 50%of the actual flow after a period of one year. When the 12 inch meters were removed from service, and the electrodescleaned with Vinegar, the meters once again read accurately. JEA has hundreds of meters and can not remove them and clean them every sixmonths.6633

Application - MeasurementPoint A meter test was performed between all ultrasonic meters agains their metertest standard. A newly calibrated electromagnetic flowmeter A newly calibrated turbine flowmeter A graduated tank over time. The utility tested the meter over various flow rates The accuracy of the Flexim meter was 0.9%67Application - TechnicalDetails Potable water Re-Use water Raw Sewage 8” – 36” Ductile Iron pipe with cement liner 60 to 80 F operating temperature. 26 to 100 F ambient temperature. 5 to 70 PSIG pressure.6834

Solution - Installation Flexim single channel 5107 and 7404 meters M transducers strapped directly to the ductile iron pipe. Permalok is used to protect the transducers from the elements 4-20mA output for volumetric flow69Solution - Results Based on previous testing, customer recently placed order for (36) completededicated meters, and 2 portable meters.7035

Customer Benefits Improved system reliability. Installation is easy. The utility no longer has to remove the magnetic flowmeters and clean them. The utility managers can trust the readings. Calibration of the meters satisfies the governing authority. The cost does not increase with the size of the meter. No special equipment and no down time.71Applications in the water and wastewater industry1603 mm – 45 years old: Reflex mode on a very corroded pipeFLEXIM Water and Wastewater, February 20177236

Applications in the water and wastewater industryAsbestos cement pipe: IP68 sensors suitable for buried installationsFLEXIM Water and Wastewater, February 201773Applications in the water and wastewater industryVersatile installation options: High placement tolerance of sensorsFLEXIM Water and Wastewater, February 20177437

Applications in the water and wastewater industrySensors for mobile and fixed transmittersFLEXIM Water and Wastewater, February 201775Applications in the water and wastewater industryPrestressed Concrete Cylinder Pipes (PCCP)- Very large wall thickness- Several layers of different material- High amount of interfering signals (reflections)FLEXIM Water and Wastewater, February 20177638

Applications in the water and wastewater industryFLEXIM’s key to success on PCCP- Very powerful low-frequency sensors- Advanced signal evaluation and noise suppression software- Extensive installation experienceFLEXIM Water and Wastewater, February 201777Applications in the water and wastewater industryA competitor was failing on this 2880 mm pipe, so the customer called FLEXIMto tryFLEXIM Water and Wastewater, February 20177839

Applications in the water and wastewater industryOur ultra low-frequency G sensors made it easy FLEXIM Water and Wastewater, February 201779Applications in the water and wastewater industry although the pipe material looked like thisFLEXIM Water and Wastewater, February 20178040

Applications in the water and wastewater industryPenstock monitoring with FLEXIM flow metersFLEXIM Water and Wastewater, February 201781Applications in the water and wastewater industryÉlectricité de France (EDF): 2880 mm pipe with lamb wave transducers for high flowvelocities.Application: Maximum flow velocity control for penstock safety.FLEXIM Water and Wastewater, February 20178241

Applications in the water and wastewater industryENEA Poland: 4800 mm steel pipe with flow volume of up to 60 m³/s.Application: Monitoring turbine efficiencyFLEXIM Water and Wastewater, February 201783Applications in the water and wastewater industryMighty River Power, New Zealand: 5500 mm pipe.Application: Monitoring turbine efficiency and run-off amounts for environmentalreasons.FLEXIM Water and Wastewater, February 20178442

Applications in the water and wastewater industryMunicipality of Munich (Leitzach), Germany: 4045 mm carbon steel with cementlining of a pumped-storage hydro power plant. Application: Leakage detectionFLEXIM Water and Wastewater, February 201785Applications in the water and wastewater industryMunicipality of Munich (Leitzach), Germany: 4045 mm carbon steel with cementlining of a pumped-storage hydro power plant. Application: Leakage detectionFLEXIM Water and Wastewater, February 20178643

Installation in Japan87Hydroelectric powergeneration water lineF704 G transducer(2 path)Condition: Over 30 years (Old pipe)Pipe material:Carbon SteelPipe size:1.8mPipe thickness:11 Water(15 ,1467m/s)8844

Competitors trial testGE sensingConfiguration: 1 Pass, 1 ChannelResult: Failure due to poor field service engineer experienceInstallation: it took 1 day by 2 persons.Tokyo Keiki( Ex-Tokimec)Configuration: 1 Pass, 2 ChannelResult: Measurement, but, many times re-installationInstallation: it took 1 day by 3 persons.FLEXIMConfiguration: 2 pass, 1 Channel, magnet type mounting fixture for testResult: Good stable measurementInstallation: it took 30 minutes by 1 person89Installation 29045

DiscussionIs there something specific you would like toknow about?9191FLEXIMThank you for participating.929246

ReferencesBest Brands Interbrand - -brands/2018/ranking/cocacola/Investing Our Way Out Of the Global Water Crisis. 23 Aug, 2016. Admin retrieved from: -water-crisis/Lancaster Water System To Start Installing Remote Meter Reading TechnologyHow To Identify and Reduce Inflow and Infiltration (i&i) in a Collection SystemMarissa McManus - -inflow-and-infiltration-collection-systemOil: Change It Often. You Are Not Pouring Money Down the -drain/TIM Writer - ngtechnology/article 4ce6a916-555a-11e8-a58c-9b41338e565c.htmlScada For Water and Wastewater astewater-management/Shiao, T. A Closer Look at Aqueduct's New Global Water Stress Maps. (Oct. 3, 2011). Retrieved from cts-new-global-water-stress-mapsWater Resource Institute - AQUEDUCT Water Risk Atlas Retrieved from: as939347

5 6 4 Global Concerns Changing Climate More people More Money More demand Ground water is being depleted. Water Infrastructure is in poor condition Natural Infrastructure is being ignored Too much water is wasted The pricing is wrong Water Resource Institute Water Risk Atlas of the Aqueduct 7 8 5 Water Resource Institute