![20160924 修正版 System Keisoku ENG.ppt [互換モード]](/img/4/companyprofileinenglish.jpg)

Transcription

1

Company ProfileBusiness Content Loading test (impact, rapid, static) Plate loading test, boring surveys Ground anchoring test Pile development consulting Pile reuse planning and surveys Seismic diagnosis Pile soundness testing (IT test), borehole sonar Measurement works for earth retaining condition Cast-in-place concrete bell pile construction methodsQualified PersonnelEstablished March 19891-26-4 Kamezawa, Sumida-ku, Tokyo 130-0014Tel: 03-5611-2500, Fax: 03-3625-2100E-mail: /Registration of Office of 1st Class Qualified ArchitectsTokyo Metropolitan Registration NoNo. 30394Construction Business PermitTokyo Metropolitan Permit No. 91270(Civil engineering, Building construction, Scaffolding construction,Steel structure construction, Drilling)Construction consultancy registrationMinistry of LandLand, Infrastructure and Transport (Ken 16)registration No. 6701Geological surveyor registrationMinistry of Land, Infrastructure and Transport (Shitsu 17)registration No. 1872Capital: 10,000,000Ph.D in engineering1Professional engineers (Construction Division)4Structural design 1st class architects31st class architects5P fProfessionalil engineersiffor groundd qualitylit evaluationl ti31st class civil engineering works execution managing engineers72nd class civil engineering works execution managing engineers21st class building operation and management engineers2Environmental surveyors (noise and vibration)1Foundation construction engineers162

Provision of Testing Grounds for Construction Method Development (Approximately 50 iron and steel,prefabricated pile and construction method manufacturers)SystemMeasurementMaterials &M hiMachineryCCentertT ti groundTestingd(Test Center No.1)Miyauchi Testing GroundNo.16 System Measurement Materials & Machinery Center4-4 6 Aza Miyauchi, Oaza Wago, Sakaimachi, Sashimagun, Ibaraki (3,300 )TEL&FAX:0280-87-5796 Inao Testing Ground No.3Sakaimachi, Sashimagun, Ibaraki (2,640 ) Kuriyama Testing Ground No.5486-1,4, Aza Oyama, Oaza Kuriyama, Sakaimachi, Sashimagun, Ibaraki(5 280 )(5,280 Chikusei Testing Ground No.62158-1 Ebigashima, Chikusei-shi, Ibaraki (13,200 ) Bando Testing Ground No.91186 1 4 Aza Tatemichi1186-1,4Tatemichi, MatateMatate, BandoBando-shi,shi Ibaraki (4(4,620620 ) Kawashima Testing Ground No.11919 Kamiyatsubayashi, Kawajimamachi, Hikigun, Saitama (1,980 ) Iwaki Testing Ground No.122-44244 Aza Kameishicho, Takijiri, Izumimachi, Iwaki-shi,Iwaki shi, Fukushima (1,320 ) Bando Sakasai Testing Ground No.13Aza Uchino, Sakasai, Bando-shi, Ibaraki (3,300 ) Nishihara Testing Ground No.141785-3 Aza Nishihara, Oaza Wago, Sakaimachi, Sashimagun, Ibaraki (6,600 ) Takagakke Testing Ground No.15436-1 Aza Takatanido Minami, Oaza Wago, Sakaimachi, Sashimagun,Ibaraki (6,600 ) MiyauchiMihi TTestingti GGrounddNNo.1616On the grounds of the Equipment Center (3,960 )3

Static Loading TestNo. of reactionpiles N 24Total load-bearinggggirder weightgW 400 tonsPile Push-in Test(System Measure Co.,Ltd. Testing Ground No.3)Pile Pull-out Test(Tokyo Skytree)Pile-toe loading test(static load)4

Ph tPhotograph-1:h 1 PilPile ddriverittypeGuide pipePhotograph 2: Unic typePhotograph-2:PC300kg plumb bobCushioning (Tires)Pile headcap56t plumb bob, maximumdrop height: 3 mAD converterAmpIndicatorLoad acceleration meter5PileLoad acceleration meterRapid loading test device incorporated into the pile driver

{ Earth Retaining Wall MeasurementHazardous changes such as earth retaining wall collapse, obstruction to the surrounding grounds, heaving andboiling are checked in advance and measured in order to quickly cope with such phenomena.InclinometerSurface straingaugeKM-100BEarth Retaining wallmeasurement siteSwitchboxMeasurements beingtaken in the site officeJack pressuregaugeCenter hole typeload meterManual inclinationmeasurementThermometerInstallation of a multi-layerClinometerSurface strain gaugeKM-100BEarth pressure gaugeStrain gaugeStress transducer6

Displacement Measurement byTotal StationDeformation Measurement of RailwayBridge Using a CommunicatingCommunicating-tubetubeDisplacement Transducer and ClinometerWire(Each bridge pier M10secured)Communicating tubeMeasurement cable100V cableTotal stationSurvey referencepoint al stationClinometerSettlementSttltgaugeSurvey referencepoint device7

NEW-EAGLE Pile Construction Method(1)NEW EAGLE Pile Construction Method (Bell piles)NEW-EAGLEBCJ( The building Center of Japan) appraisals - FD0307–02, December 2012xxxxPull outPull-outforceNEW-EAGLEEarthquake-resistantPile ConstructionMethodEnlarged pile base construction diameter Dw 900 - 5,500mmHorizontalAngle of inclination θ 21.1 forceEnlarged pile base ratio 1.1 - 7.3Concrete strength Fc 18 - 60 N/mm2NEW-EAGLE Earthquake-resistant Pile Construction Method(Steel pipe-wrapped pile head)(2)BCJ appraisals - FD0444–01, February 2014GBRC( General Building Research Corporation of Japan) performance evaluation No.10-25, Revised, December 2011Push-inforceFlat steel ppipep typeypFlat steel ppipep Welded reinforcingg barsSimple superposed strength Universal superposed strength EPull-out PileConstruction MethodPull-outresistance forceλ μS RCRCSMMS RCRCSNtN0NtNAngle of inclinationθ 21.1 Fc 18 - 60 N/mm2N0NNEW-EAGLE Pull-out Pile Construction Method(3)(Equation for the allowable bearing capacity in the pile pull-out direction)Evaluation CBL( Center for Better Living) FP016 – No.14 , June 2015Enlarged pile base pull-out resistance (θ 33 - 2121 ))λ (Sand ground) 4.0 - 14.5 μ (Clay ground) 0.4 - 0.8Enlargedg ppile base ratio1.1 - 7.3NEW-EAGLEPile ConstructionMethodEnlarged pile base construction diameterDw 900 - 5,500mm8

Effects of Inclination Angle during Construction((Mechanical Method))Wing inclination of EAGLE bell pile machine 21.1 Compact earthdrillKE1500Diameter ofenlarged pilebase: 2800 mmEnlarged pilebase ratio: 7.29Angle ofinclination: 21.1 Front height 6.5 m21.1 Front heeight 4.2 mLow height compared to 12 bell pile machineConventional general-purposelargeg earth drillConstruction machine usedwith a bell pile bucket with 4100mm diameter of enlarged baseand 1212 angle of inclinationLarge earth drillED6200HDiameter ofenlarged pilebase: 5500 mmEnlarged pilebase ratio: 6.61Angle ofi li tiinclination:18.3 18 3 9

Development of the multi-belled pileMulti-belled pile excavation procedure1.3.Pile shaft.Pile shaft 2.Pile middle-part re-excavationdia. enlargingexcavationexcavationConstruction test4. Pile Enlargedbase excavationThe shape of excavation has been retained with no pit hole collapse.Pile Middle-part dia. enlarging bucket (AB-30 )Enlargementdiameter2800mmGravel groundExcavation by 30AB Middle-part dia. enlargingbucket (Φ1000Φ2800mm)10

EAGLE KZ Construction Method NETIS Registration (KT-120104-A) Registered on February 8, 2013zExcavation using an engaging joint jigzThe engaging joint jig mechanically joins to the casing tubezExcavation is performed by the EAGLE drilling bucket by rotating the casing.zN hzNohydraulicd li mechanismsh iare used.dzThe all-around rotation excavator torque is transmitted directly to the bucket to improveconstruction performance.Enlarged base ratio: n X7.3 (Shaft Diameter: 1.0m, Enlarged baseconstruction diameter: 2.8m)Enlargedbase ratioConventionalconstructionmethodCrane hookCrane hookEAGLE pileilconstructionmethodCasingAll-aroundrotation excavatorDedicated casingNEW-EAGLE pileconstructiont timethodEngaging joint jigTransition of Bell Piles SpecificationEagle baseenlarging bucketShaft part excavationConstruction Results mainly in the metropolitan Tokyo areaTotal: Approximately2600 projectsEnlarged-base excavationEngaging joint jig65 Member Companies of the EAGLE PilePromotion AssociationEarth TechnoCorporationEarthtecAITOP Co., Ltd.Aoyama Kiko Co., Ltd.Ajisawa KikoKiko. CoCo., LtdLtd.Ambic Co., Ltd.Ishikawa Kogyo, Inc.Inoue Kiko Co., Ltd.Iyo BulldozerConstruction Co., Ltd.Eiko Inc.OkadagumiKakuto CorporationKyobashi BussanKinjyo JyukiKeiai System Co., Ltd.Koki Co., Ltd.Kouki. Co.Goyo bussanSakamoto ShokaiSan-eiSanei CoCo., LtdLtd.Sanyo Koji Co., Ltd.Geotech Co., Ltd.Shinji Co., Ltd.Shinmei Gikou Co., Ltd.Shinwa Kiko Co., Ltd.Sugisaki Kiso Co., Ltd.Seiwa Kiko Co., Ltd.Seiwa Technos Co.,Ltd.Senki Industries Co., Ltd.Sougou Chishitsu Co.,Ltd.Daiyo Kiko Industry Co.,Ltd.Taiyo Foundation CoCo.,Ltd. (Tokyo)Taiyo Seramu Co., Ltd.Takaki CorporationTakayama Kiso KogyoCo., Ltd.Tanabe Kogyo Co. Ltd.Delight Co., Ltd.Tohken Engineering Co.,Ltd.Tosei Sangyo Co., Ltd.Toyoken Co., Ltd.Trust Co., Ltd.Nagae Kenzai KogyoCo., Ltd.Nichiei Kiko Co., Ltd.Nissin Koei CorporationNozaki KenkoHayabusa Co., Ltd.Hanshin Kensetsu Co.,LtdLtd.Fuji IndustryFutabashizai Co., Ltd.Blast Co., Ltd.Hokuei Sangyo Inc.Horie Industries Co.,Ltd.Maruko Shoji Co., Ltd.Marugo FoundationCorp.Marumon ConstructionCo., Ltd.Mitani engineering Co.,Ltd.MIK CorporationMunehiro Kiso KogyoCo., Ltd.Yuken Co., Ltd.Yushin Co., Ltd.Yoki CoCo., LtdLtd.Yoshida ConstructWakasa Co., Ltd.Washin Kogyo Co., Ltd.Watanabe-toshi KogyoCo., Ltd.Number of pprojectsDrillingb projectsprojectsj tprojectsDesignEnlarged baseSteel pipesTotal11Transition of the EAGLE Construction Method Sales Record

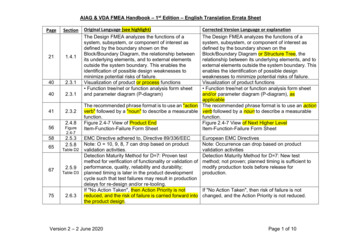

Cushioning (Tires) AD converter 5 Rapid loading test device incorporated into the pile driver Indicator Load acceleration meter 56t plumb bob, maximum drop height: 3 m Load acceleration meter Pile Amp Pile head cap {Earth Retaining Wall Measurement Hazardous changes such as earth retaining wall collapse, obstruction to the surrounding grounds, heaving andHazardous changes such as earth .