Transcription

Smarter Steelsfor Peopleand PlanetNorth American Automotive1

Smar ter Stee ls forPeople and PlanetAbout UsArcelorMittal boasts some of the most technologically advancedautomotive operations in the world, incorporating a range of modernsteelmaking technologies.About ArcelorMittalWith approximately 168,000 global employees across 17 countries, ArcelorMittal ismore than just a company. We are a community. We are driven by an entrepreneurialspirit and a passion for excellence. As a leading steel manufacturer in North America,South America and Europe, we never accept that the limits of our material havebeen reached. We continue to push the boundaries of steel, whether developingtechnologies to reduce the carbon footprint of steel, transforming the built environmentwith new construction solutions, 3D printing automotive parts using steel powdersor adopting artificial intelligence and advanced automation across our operations.ArcelorMittal North America by the NumbersNearly 12,000 hardworking employees inNorth AmericaMore than 3B investmentin decarbonizationannounced21 Facilities serving theautomotive marketNet-zero carbonemissions by 20502 Global R&D CentersMore than 12 million tonsof Hot Roll capacity tosupport the NorthAmerican market2In Canada, the United States and Mexico, ArcelorMittal operates 21facilities that serve the automotive market. Two state-of-the-art R&Dsites, located in East Chicago, Indiana and Hamilton, Ontario, areprimarily devoted to research on flat products, including those forautomotive, with global responsibility for process and productdevelopment. In addition, our Automotive Product Applications R&Dteam in Southfield, MI, dedicated to steel solutions and new productimplementation, is an industry leader in customer technology engagementand is at the leading edge of ArcelorMittal’s global R&D excellence.Guided by our values of safety, sustainability, quality and leadership, wefoster a culture of innovation. We put R&D at the heart of our operationsto make a positive difference through smarter steels for people and planet.ArcelorMittal’s commercially available advanced and ultra high-strengthsteels, coupled with emerging and longer-term breakthrough steels, areat the forefront of the automotive industry. Our automotive steel solutionscover most metallurgical ‘families’ of steels – distinguished by theirdifferent properties and compositions.With a multi-disciplined, focused and flexible automotive team, weproactively respond to our customers’ needs by offering a wide range ofproducts, an extensive supply chain and logistics network and an industryleading research and development, engineering, and sales support system.This customer support spans the life cycle of each product. It begins atthe collaborative development of new automotive steel solutions andcontinues through vehicle design and on to mass production.As the world’s leading steelmaker for the automotive sector, it’s also ourresponsibility to lead the charge in sustainable automotive steels. We workto meet society’s need for steel with an ever-decreasing carbon footprint.Our XCarb umbrella brand combines all of ArcelorMittal’s current andfuture reduced, low and carbon neutral steel making and supports ourintention to become carbon neutral by 2050. As one of the only completelyreusable and recyclable materials, steel will play a critical role in buildinga circular economy and the sustainable automotive industry of the future.3

SustainabilitySmar ter, Decarbonized Steelsfor a Sustainable WorldLike all parts of ArcelorMittal’s business, our automotive and mobility solutions focus on creatingsustainable products and solutions which are safe and use resources responsibly. We understandthat while a developing world needs steel, a sustainable world needs better steel – steel that’smade smarter and with less carbon.ArcelorMittal is driving change on this front with a commitment tobe carbon neutral by 2050. Current projects underway put us wellon our way to reaching this target. Through our XCarb initiative,we are developing steels using innovative processes which use lessenergy, emit significantly less carbon and reduce costs – steelsthat are cleaner, stronger and recyclable.Ensuring steel continues to be the world’s most used and versatile material is what drives us everyday. For that to remain the case, steel must decarbonize. We are embracing this with energy anddetermination, excited to make a significant contribution to reducing global emissions. Harnessingour technical capabilities with an innovative mindset and a passion to make a positive differencefor people and planet, we intend to lead the decarbonization of our industry.Through innovative concepts like S-in motion , a set of steel solutions developed by ArcelorMittal forcarmakers who wish to create lighter, safer and more environmentally friendly vehicles, we offer a rangeof steel solutions that can be implemented today for lighter vehicles at the most affordable cost.With steel at our core, our inventive people and an entrepreneurial culture at heart, we will help toshape a more sustainable world - this is what we believe it takes to be the steel company of the future.North American Decarbonization ProjectsIn North America, we have more than 2.2 billion in combined investments planned before 2030. By2028, all slabs for flat steel that are produced by ArcelorMittal North America will be produced on anElectric Arc Furnace (EAF). Not to increase capacity, but purely to decarbonize the steelmaking process.ArcelorMittal and Nippon Steel Calvert ExpansionA new 1.5MT per year Electric Arc Furnace (EAF), contributing to the reductionof global annual CO2 emissions will be in production by the first half of2023, supporting all automotive grades including PHS and Gen 3 steelsproduction capability.ArcelorMittal Dofasco Hamilton InvestmentA new 2.5MT per year Direct Reduced Iron (DRI) plant and 2.4MT per yearEAF will reduce annual CO2 emissions at ArcelorMittal’s Hamilton, Ontario,Canada facility by approximately 60% by 2028.For more information on our XCarb initiative and decarbonization efforts,visit 5

Technology / Innovation / R&DInnovative Steels forthe Future of Mobilit yArcelorMittal has been identified byLexisNexis as one of the Top 100 Innovatorswith exceptionally high performing andwell-maintained patent portfolios.The report, “Innovation Momentum 2022: The Global Top 100,”recognizes the top 100 technology owners with outstandinginnovation momentum and exceptional relevance for futuretechnologies and market developments.Today, mobility is evolving at a greater pace than ever before. New powertrains are challengingthe dominance of the internal combustion engine (ICE) and creating almost unlimited opportunitiesto transform vehicle design. It’s an exciting time to be part of the industry, and steel is continuingto adapt and evolve to support it.We have more than 500 researchers dedicated to automotive innovation globally. This ambidextrousorganization serves our business today while building the foundation for our business tomorrow. Broaddiversity of experience, a can-do mindset and global reach are the key strengths of our organization.In North America, ArcelorMittal operates R&D centers in East Chicago, Indiana, U.S.A. and Hamilton,Ontario, Canada employing approximately 230 professionals devoted to research on flat and longproducts, primarily for automotive applications. East Chicago played a major role in the developmentand promotion of 3rd generation advanced high-strength steels, now a worldwide focus forlightweighting and safety enhancement in the auto industry.As the world’s leading steelmaker for the automotive sector, ArcelorMittal is continuously innovatingour automotive portfolio. We work with carmakers to help them meet current and future challenges,from lightweighting and battery protection to ensuring the safety of passengers today and in anautonomous future. Our R&D engineers work with automakers throughout the life cycle of theirproducts to develop automotive steels that are enable lighter vehicles. In addition to flat steelproducts, through ArcelorMittal’s Tailored Blanks and Tubular Products divisions, we design andmanufacture leading-edge value added products like laser welded blanks and tubular steels thataddress key needs of the industry. Our technical co-engineering services include: Assisting carmakers to develop new vehicles up to six years before they come to market Assisting with parts industrialization through early vendor involvement Ensuring quality management and cost reduction by proactively responding to customerrequests to optimize products and/or processes for current production vehiclesIn this quickly evolving mobility sector, carmakers will strive to have the most efficient body-in-whitearchitecture in terms of weight savings, crash and life cycle analysis performance at the most affordablecost. And that pushes us in a direction where the development of steel solutions will accelerate.67

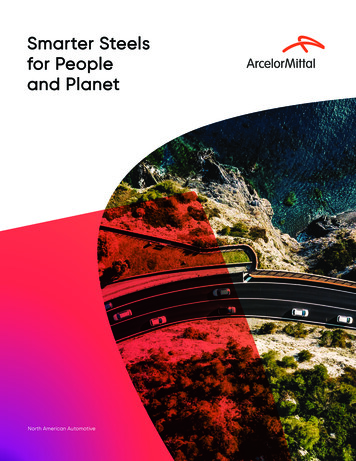

Grade DesignationArcelorMittal R&DExpanding the Limits inFormability and Strength of SteelDual PhaseSteelsThis chart demonstrates the traditional trade-off between formability and strength, and howArcelorMittal has developed and commercialized advanced high-strength steels and ultra highstrength steels to expand these limits in order to provide our customers with grades of steel thatsupport the design of lighter, safer, more energy-efficient vehicles.GenericNorth HYT590/Y450DP780T780/Y420,T780/Y440DP780 LCET780/Y420,T780/Y440DP980T980/Y600DP980 engthSteels(270-500MPa)70%Advanced High Strength Steels( 500 MPa)FerriteBainite/Stretch60%IFElongation (%)50%Complex/MultiphaseBHCMnHSHFDuctibor 20%HFHSLA1180HF1180HFFortiform 11801470HSHFFortiform 1470540SF590SF780SF600Usibor 900980T/Y700YMP980T800Y-CP980T/Y800 CPMP1500CP and SF300980T700Y MPMP1300DP10%0Fortiform 980980 MP-HHEIF-HS30%0Hot DipGalvanize (GI)980 MPMild40%Uncoated980HF980HFLow StrengthSteels( 270 MPa)Cold Rolled (CR)Hot Rolled(HR)1,2001,50022MnB51,800Tensile Strength (MPa)2,100PressHardenedSteelsUSIBOR 1500USIBOR 2000Ductibor 500Ductibor 1000Extragal Ultragal MILDHighStrength LowAlloy (HSLA)CarbonManganese(CMn)8Steels forHotstampingDualPhasesHot RollFerriteBainite SteelsFortiform CommercialIn Development9Galvanneal(GA)Aluminized(AlSi)

ArcelorMittal R&DCommercialSteel(CS)Typically produced using low carbon content, CS is used in applications with morelimited forming requirements.Drawing Steel(DS)DS is a readily available specification which offers good formability. DS is aluminumkilled and typically has lower carbon or controlled processing resulting in improvedformability.Deep DrawingSteel(DDS)A specification of steel with excellent formability characteristics which isrecommended for difficult forming applications. DDS is also available in standardand extra low carbon forms. It is sometimes produced using ultralow carbon (ULC)or interstitial free (IF) steels.Extra DeepDrawing Steel(EDDS)A highly formable specification of steel ideal for the most difficult formingapplications where other steels lack sufficient ductility. This product is producedusing IF steel, requiring the use of a degasser in steelmaking as well as close controlof alloy additions.Dual Phase(DP)DP steels offer an outstanding combination of strength and initial drawability asa result of their microstructure, in which a hard martensitic or bainitic phase isdispersed in a soft ferritic phase. These steels have high strain hardening capacity.As a result, finished part mechanical properties, especially yield strength, aresuperior to those of the initial blank. These steels have excellent fatigue strengthand good energy absorption capacity making them suitable for use in structuralparts and reinforcements.High Formability(HF)HF or GEN 3 grades exhibit the high formability of lower strength dual-phase steelgrades at higher strength levels and have excellent ductility. These steels allowthe realization of lightweight structural elements by cold forming methods suchas stamping and roll forming. These third-generation steels are used to provideadditional weight reduction thanks to their higher strength levels while maintainingthe same level of formability or by increasing their formability at same strengthlevels as the second-generation advanced high-strength steels grades. Thanks totheir combination of excellent mechanical properties and formability, these gradesare particularly suitable for automotive safety parts with requirements for energyabsorption at higher strength. Typical applications include front and rear rails,shotguns, sled runners and various cross-members.MILDBake Hardenable(BH) High-strength Low Alloy(HSLA)Carbon Manganese(CMn)Complex/MultiphaseThese specifications are unique in that they are designed to increase yield strengthafter the paint curing process, providing the benefit of both superior formabilityover traditional high-strength steels and higher part strength than previouslydescribed specifications. They acquire their added strength via the amount of straingenerated in the part during stamping, and through the time and temperatureinherent in the paint curing process.HSLA specifications offer higher strengths for applications where formingrequirements are not as severe as previously described specifications. The productis sold to guaranteed mechanical properties of yield strength, tensile strength andelongation. The strength is obtained not only through carbon and manganesebut also through the addition of one or more microalloys (Cb, Ti, V) coupled withcontrolled processing.Carbon steels containing more than 1.2 percent up to approximately 1.8 percentmanganese are referred to as Carbon Manganese steels. The manganese contentin carbon steels is increased for the purpose of increasing depth of hardening andimproving strength and toughness.Complex and Multiphase steels are multi-constituent phase grades that achievethe high tensile strengths of other Advanced and Ultra High-Strength Grades withhigher Yield Strengths and Lower Total Elongations than many Dual Phase steels.In exchange, they have improved local formabilty as measured by Hole Expansion,Bendability, etc. These grades are traditionally at the 780, 980 and 1180 MPa tensilelevels, however recent work done by ArcelorMIttal has pushed these grades tohigher tensile strengths.10Ferrite-Bainite/Stretch Flangeable(SF)SF grades extend the HSLA range of micro-alloyed steels to include productscombining high tensile strength (UTS) with excellent formability and hole expansion(stretch flangeability) based on their ferrite-bainite microstructure. As a result of theirhigh tensile strength and microstructure, these grades exhibit good fatigue strength.Applications are cold stamped automotive parts with applications including controlarms, cross members and wheels.Press Hardened Steels(PHS)PHS are designed to be heat treated and then quenched during the hot stampingprocess. The mechanical properties of the final part make significant weight savingspossible. The very high yield strength of these steels after heat treatment and hotstamping make them suitable for anti-intrusion components such as fender beams,door reinforcements and B-pillars.Usibor Ductibor Usibor has an aluminum-silicon pre-coating and was developed to protect themetal from oxidation (scale) and decarburization during the hot stamping process.The coating offers excellent resistance to oxidation resulting from the hot stampingheat treatment process. Final parts using this forming technology have improvedcorrosion resistance after painting.When Ductibor Al-Si coated products, e.g., Ductibor 500 and 1000, arecombined in a laser welded blank application, i.e., mated to Usibor 1500, “softerzones” in the finished/hot-stamped finished part are obtained without having toalter the hot-stamping parameters. These “soft zones” are areas where increasedcrash ductility is either a desirable or required characteristic.11

ArcelorMittal North America833 W. Lincoln Hwy Suite 200E, Schererville, Indiana 43675T 1 800 422 9422 ttal.com northamerica.arcelormittal.com dofasco.arcelormittal.com@ArcelorMittal @ArcelorMittal DMay 2022arcelormittalgroup12

Press Hardened Steels 22MnB5 USIBOR 1500 USIBOR 2000 Ductibor 500 Ductibor 1000 70% 60% 50% 40% 30% 20% 10% 0 Elongation (%) 0 300 600 900 1,200 1,500 1,800 2,100 Tensile Strength (MPa) Advanced High Strength Steels ( 500 MPa) High Strength Steels (270-500 MPa) IF Mild IF-HS BH CMn HSLA Ductibor DP HF HSHF Usibor Low Strength Steels .