Transcription

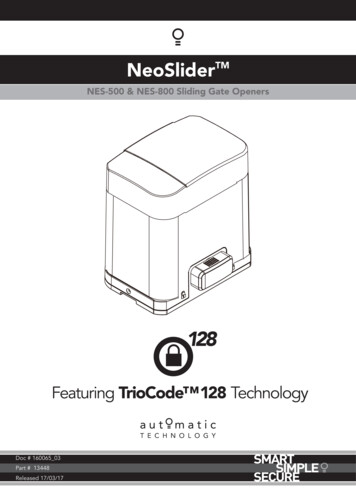

NeoSliderTMNES-500 & NES-800 Sliding Gate OpenersNe Slider Doc # 160065 03Part # 13448Released 17/03/17

NeoSliderTMSliding Gate Opener NES-500 / NES-800Contents1. Important Safety Instructions 32. Control Board Layout 43. Set Up Requirements 53.1 Kit Contents 53.2 Choosing your Set up 53.3 Initial Checking 54. Drive Unit Installation 64.1 Mounting the Drive Unit 64.2 Installing antenna 65. Rack & Limit Actuator Installation 75.1 Mounting rack to gate 75.2 Fixing limit actuator to rack 7TM6. Programming The NeoSlider 86.1 Common Programs 8TM6.2 Powering up the NeoSlider 87. Safety Beams 87.1 Installation of Safety Beams to the NeoSliderTM 87.2 Safety Beam Failure Emergency Close (SBFEC) 88. Setting Limits 98.1 Setting Travel Limits 98.2 Setting the left/right installation side settings 98.3 Setting close travel limit 98.4 Setting open travel limit 98.5 Automatic limit adjustment and load profile 98.6 Pedestrian access position 98.7 Errors during setting of travel limit 98.8 Recalculate Force Margins 99. Safety Obstruction Force Test 109.1 Testing Close Cycle 109.2 Testing Open Cycle 109.3 Force Pressure For Close and Open Cycle. 109.4 Reprofiling Travel 1010. Coding Transmitter 10.1 Coding Transmitter Button 10.2 Selecting Function Of The Button 10.3 Returning To Main Screen 10.4 Selecting The Function To Be Coded 11. Emergency Release 11.1 Your gate CAN NOT be used by the opener when: 11.2 Your gate CAN be used when: 11.3 To Disengage the Opener: 11.4 To Re-Engage the Opener: 12. Setting Pedestrian Position 12.1 Setting pedestrian position 12.2 Pedestrian Position Set 12.3 Error Displays 13. Auto-Close Mode 13.1 Setting Up Standard Auto-Close 13.2 Safety Beam Triggered Auto Close 13.3 Pedestrian Auto-Close 13.4 Auto-Close After Obstruction 14. Accessories Installation 14.1 Fitting Solenoid Or Magnetic Locks 14.2 Fitting Courtesy Lights 15. Battery Replacement 16. Battery Disposal 17. Specifications 18. Troubleshooting 19. Appendix A - Console Menu Structure B - Viewing & Editing Parameters C - Control Board Adjustments D- Diagnostic Tools E - Memory Tools F- Transmitter Editing G- Transmitter Managment 20. Warranty and Exclusion of Liability 17181821222324252627Automatic Technology Australia Pty Ltd to the extent that such may be lawfully excluded hereby expressly disclaims all conditions or warranties, statutoryor otherwise which may be implied by laws as conditions or warranties of purchase of an Automatic Technology Australia Pty Ltd Garage Door Opener.Automatic Technology Australia Pty Ltd hereby further expressly excludes all or any liability for any injury, damage, cost, expense or claim whatsoeversuffered by any person as a result whether directly or indirectly from failure to install the Automatic Technology Australia Pty Ltd Garage Door Opener inaccordance with these installation instructions.2Owner Installation Instructions NeoSlider - Sliding Gate Opener NES-500 / NES-800TM

1. Important Safety InstructionsThe safety alert symbols below indicate a personal safety or propertydamage instruction exists. READ THESE INSTRUCTIONS CAREFULLY.TMThis NeoSlider Sliding Gate Opener is designed and tested to offer safe serviceprovided it is installed and operated in strict accordance with the following safety rules.Failure to comply with the following instructions may result in death, serious personalinjury or property damage.WARNING! ELECTROCUTION! CAUTION:Entrapment fromoperating gate Installation SecurityEntanglement inor laceration frommoving gate The gate may operate unexpectedly, therefore do not allow anything to stay in thepath of the gate.Do not disengage the gate opener to manual operation with children/persons or anyobjects including motor vehicles within the gateway.Remove or disengage all gate locks and mechanisms prior to installation of theopener.Make sure the gate is fully open before driving into or out of the driveway.When using auto close mode, a Photo Electric beam must be fitted correctly andtested for operation at regular intervals. Extreme caution is recommended whenusing auto close mode. All safety rules must be followed.Do not immerse in or spray the NeoSlider with water .Disconnect the power cord from mains power before making any repairs orremoving covers. Only experienced service personnel should remove covers fromthe gate opener.If the power supply cord is damaged, it must be replaced by an Automatic Technologyservice agent or suitably qualified person.Connect the gate opener to a properly earthed general purpose 240V mains poweroutlet installed by a qualified electrical contractor.DO NOT operate the gate opener unless the gate is in full view and free from objectssuch as cars and children/people. Make sure that the gate has finished moving beforeentering or leaving the driveway.Do not allow children to play with gate controls or transmitters.In order for the NeoSliderTM to sense an object obstructing the gateway, some forcemust be exerted on the object. As a result the object, gate and/or person may sufferdamage or injury.Regularly check to make sure that the Safety Obstruction Force is working correctly,and is tested and set as per Section 12 of this manual. Failure to follow theseinstructions could result in serious personal injury and/or property damage. Thistest must be repeated at regular intervals and the necessary adjustments made asrequired.If using a key switch, keypad or any device that can operate the gate opener, make sureit is in a location where the gateway is visible, but out of the reach of children at aheight of at least 1.5m.For ADDITIONAL SAFETY protection we STRONGLY recommend the fitting of aPhoto Electric (Safety) Beam. In most countries Safety Beams are mandatory on allgates fitted with automatic openers.Ensure the gate(s) is in good working order . Faulty gates must be repaired by a qualifiedtechnician prior to NeoSliderTM installation.Make sure that the gate is fully closed before leaving the driveway.Keep hands and loose clothing clear of gate at all timesKeep clear of gate during operation as severe lacerations can occur on sharp edges ofgate.Owner Installation Instructions NeoSlider - Sliding Gate Opener NES-500 / NES-800TM3

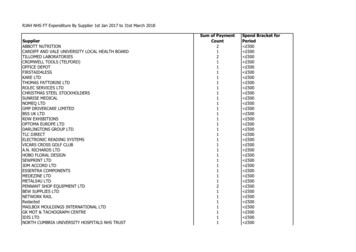

2. Control Board 2223131415162417Fig 2.101V 11PED N/O input terminal21Console Exit button020V120V22Console Down/Close button03SB2 (Safety Beam (2), two, threewire or wireless)SB1 (Safety Beam(1), two, threewire or wireless)0V13V 23Console SET button1424Antenna connector15OUT 2 (optional relaymodule coil drive)V 25Console display16OUT 1 N/C relay contact26PG3 programmer / network connector17Engageinput27Motor connector08OPN Programmable N/O orN/C input terminalSTP Programmable N/O orN/C input terminalCLS N/O input terminal2824VAC input connector09OSC N/O input terminal2910 AMP slow blow fuse10SWP N/O input terminal30Standby battery Console Previous button19Console Up/Open button20Console Next buttonOwner Installation Instructions NeoSlider - Sliding Gate Opener NES-500 / NES-800TM

or3. Set Up Requirements3.1 Kit ContentsITEMDESCRIPTIONQTY1DRIVE UNIT NES-500 / NES-80012TRIO-CODE 4B PTX-5V2 TRANSMITTER23METAL BASE PLATE14NUTS, BOLTS AND WASHERS45METAL FEET W/ DYNABOLTS (4)26ACTUATOR W/ 2 SCREWS27ANTENNA1617IMPORTANT WARNING!A qualified electrician must perform the installationwhere 240V AC power is used.CAUTION: Cables which have a green/yellowcoloured insulation are for earthing purposesonly.Never use these cables for any other purpose.43253.2 Choosing your Set upThe NeoSlider can be set up in various ways and thereforemay require additional items. Common Set ups are asfollows;Fig 3.1Set UpItems RequiredAutomated Set UpDrive Unit and transmitterAutomated Set Up Drive Unit, transmitterwith Safety Beamssafety beams (optional)and3.3 Initial CheckingBefore commencing installation of the NeoSlider , checkthe following:a. The gate moves freely and easily by hand for the fullopening and closing travel.b. The mounting point must be solidy constructed,e.g concrete, brick or steel, and must be capable ofwithstanding the full force applied to the gate.c. Select a suitable location for mounting the drive unit.This position is usually established by fully openingthe gate and mounting the drive unit within a suitabledistance of the gate edge.d. A weather-proof 240v 10 amp power outlet mustbe located within one (1) metre of the NeoSlider mounting point.e. If Safety Beams are to be installed, provision forunderground cabling should be made from one side ofthe gateway to the other.Fig 3.2Owner Installation Instructions NeoSlider - Sliding Gate Opener NES-500 / NES-800TM5

4. Drive Unit InstallationThe Automatic Technology NeoSlider sliding gate opener is designed to operate most residential sliding gates. Thegates must be in good working condition and should operate freely by hand. (Refer to 3.1 Initial Checking)4.1 Mounting the Drive Unit2mmFig 4.14.2 Installing antennaMount the antenna 7 at or above the height of thegate or fence (whichever is higher) for optimalreception.Do not cut the coaxial cable.6Owner Installation Instructions NeoSlider - Sliding Gate Opener NES-500 / NES-800TM50 25a. Prior to mounting the NeoSlider , determinethe distance from the gate to the outer edge ofthe rack (i.e. the rack width) and to the datum line(see Fig. 4.1 and Fig. 5.1). If using an AutomaticTechnology plastic rack, the width is 40mm. Ifusing a different brand of rack, please ensure it isModule 4 and then confirm the width, as this willvary.b. Mark a line parallel to the face of the gate for themounting holes. The distance from the gate isdetermined by the formula (38mm Rack Width).Therefore, if using an Automatic Technologyrack, the distance is 78mm. Otherwise, if usinga non-Automatic Technology rack, add your rackwidth (and spacers if required) to the 38mm(see Fig. 4.1).c. Place the metal feet 5 , metal base plate 3and Drive unit 1 in position. If satisfied with theposition, remove the Drive Unit and metal base plate(Fig. 4.2).d. Mark the position of the four holes in the metalfeet 5 . Drill the four holes.e. Hammer the dynabolts 4 into position, placemetal feet 5 and fix with the four washers, springwashers and nuts 4 .f. Place the metal base plate 3 onto of metal feetand align holes with metal feet.g. Put Drive unit 1 onto metal base plate and affixwith bolts and washers provided. Rememberwhen tightening the bolts to allow fine adjustmentof the NeoSlider later on.1 100The NeoSlider mounting holes are slotted forfine adjustment of pinion gear and gate rackalignment. Follow the procedure below to ensurefinal adjustments can be made later.25Fig 4.2

5. Rack & Limit Actuator Installation5.1 Mounting rack to gateGateRackwidthTo bottom ofrack toothRackTo top ofpinionMaximum height of rackA strong base on the gate is required formounting the rack.a. Manually open the gate and place a racksection to mesh with the pinion gear on theDrive Unit. Mark the top of the rack. Movethe gate and mark the rack for the entirelength of the gate (Fig. 5.1).b. Position the top edge of the rack on this lineand mark the centres of the rack’s mountingslots. The first section of rack should start20mm from the edge of the gate.c. Drill and tap for 6mm (¼”) screws.d. Once the first section of the rack is mounted,check that it meshes with the NeoSlider pinion gear.e. When joining subsequent sections of rack,check the mesh by placing a spare sectionupside down (teeth facing upwards) andputting it into mesh with the racks beingjoined (Fig. 5.2).f. Tighten the racks. This will ensure that theNeoSlider pinion can run along the rackswithout obstruction.Datum lineFig 5.1Drivegear5.2 Fixing limit actuator to racka. Manually open the gate to the openposition and mark this on the gate rackunder the actuating arm.b. Manually open the gate to the openposition and mark this on the gate rackunder the actuating arm.c. Place the start of the limit actuator 6 atmarked position and move it 5 to 10mmtowards the centre of the gate. Screw thelimit actuator to the rack (Fig. 5.3). Repeatfor the close position.d. Re-check limit positions by manuallyopening and closing the gate, checking tosee that the limit is activated at the desiredopen and close position. If neccessary,make adjustments by sliding the actuatorin the required direction.Fig 5.2Screws andwashersActuatorStartOwner Installation Instructions NeoSlider - Sliding Gate Opener NES-500 / NES-800TMFig 5.37

6. Programming The NeoSliderTM6.1 Common ProgramsThe two most common programs are;ProgramMenu’s requiredFunctionSectionAutomated Set UpMenu 10.1Setting the Limits8.1Safety Obstruction Force9.1 and 9.2Coding the Transmitter10.1Setting the Limits8.1Menu 1Automated Set Up with Menu 10.1Safety BeamsSafety Obstruction Force9.1 and 9.2Menu 1Coding the Transmitter10.1Menu 3Auto Close Times13.2, 13.3 and 13.4Fig 6.1NOTE: Fitting Safety Beams enables the Auto-Close feature to become active.CAUTION: Before plugging the gate control system in, check thepower cord for damage and ensure it cannot become entangled inany moving partsStart up screenA.T.A NES-500Firmware #.##6.2 Powering up the NeoSliderTMa. After checking the initial wiring, apply power to the NeoSlider . Thecontroller will go through a startup sequence displaying the STARTUPSCREEN which indicates the controller type and firmware version(Fig. 6.2). After a short delay the MAIN SCREEN will be displayed.b. If this is the first time the NeoSlider has been used, the MAIN SCREENshould indicate that the limits are not set. If the display shows that someinput is active then rectify the situation before proceeding. If a defaultsetting is to be changed it should be done now before setting the travellimits.Fig 6.27. Safety Beams7.1 Installation of Safety Beams to the NeoSliderTMa. Follow the Installation Manual provided with the SafetyBeam to correctly install the Safety Beam.b. By default the NeoSlider will take two wire safety beams.c. Ensure you program the NeoSlider to idenitfy what typeof Safety Beam or combination of Safety Beams you haveinstalled.i. Press NEXT to Navigate to Menu 7ii. Press SET to display Menu 7.1 (for SB1).iii. Ensure the Safety Beam type is set to two wires.iv. Press SET to accept the selection.v. Repeat the same process for Menu 7.2 (SB2) if installed.NOTE: Wireless Safety Beam functionality is equivalent to 2WIRE Safety Beamsvi. NOTE: The Power control for one or both three wirebeams is controlled via OUT 1 or OUT 2. To use theOUT 1, connect black wire from SB to OUT 1. To enablepower control from OUT 1, go to Menu 7.13 and changeOUT1 mode to 3 wire SB 0V.WARNING: When using Safety Beams, thegateway must be clear of all obstructions andpersons at all times. The location of the beamsand manner in which it is installed might notgive safety protection at all times. Check tomake sure that the height of the beam andtype used give maximum protection possibleWARNING: Tampering with Safety Beamscould result in serious personal injury and/orproperty damage and will void the warranty.7.2 Safety Beam Failure Emergency Close(SBFEC)When the user finds that they are unable to movethe gate and suspect that it is due to a faultySAFETY BEAM they can attempt to enter SafetyBeam Failure Emergency Close mode by pressingand holding a pre-coded button on the remotecontrol or OPEN/CLOSE button on the console formore than five seconds. the gate will start closing.See Appendix C Menu 7.16.NOTE: In the case that OUT 1 is used for some other function,OUT 2 can be used to control 3 wire beams power. Connectthe black wire from SB to OUT 2, then change the OUT 2 modeOwner Installation Instructions NeoSlider - Sliding Gate Opener NES-500 / NES-8008in Menu 7.14 to 3 wire SB 0V.TM

8. Setting LimitsThe NeoSliderTM has the alternate ability to set travel limits using a TrioCodeTM128 transmitter, allowing free movementaround the gate to better assess the desired limit positions. In order to use a transmitter, it must first have at least one ofits buttons coded to the gate controller. The function assigned to the transmitter’s buttons is of no concern here as thebuttons are temporally assigned to OPEN, CLOSE and SET (Fig. 8.1).NOTE: Gate should be moved manually to fully open position. Whenre-engaging opener, nudge gate until click is heard to confirm piniongear has engaged fully.8.1 Setting Travel LimitsNavigating to “code transmitter” menuButton 1(InchOpen)Button 2(Set)a. Press NEXT to navigate to Menu 1.b. Press SET to enter the code set procedure.Storing Transmitter Codec. Controller will prompt to press one of the transmitter’s Button.d. Press the transmitter button you wish to use to operate the gateopener (e.g. button 1) .e. Press the same transmitter button again as prompted by display.f. Press the SET button to store the transmitter.Button 4Fig 8.1(InchClose)Navigating To “Set Gate Travel Menu”a. Press PREV to navigate to Menu 10.b. Press SET to display MENU 10.1.c. Press SET two times to enter the limit setting procedure.Follow LCD prompts.IMPORTANT NOTE:Only TrioCodeTM128 Technology Transmittersare compatible with this product.8.2 Setting the left/right installation side settingsa. Select left or right installation side by pressing open buttonfor the correct side (Fig. 8.2).b. Press SET to confirm.8.3 Setting close travel limit8.6 Pedestrian access positiona. Press and hold Button 4 on the transmitter to close the gatei. If the gate is closed too far, press Button 1 to “inch” thegate towards open.ii. When happy with the close limit position, press Button 2to store this in the memory.After completing the above procedure, the Pedestrianaccess position is automatically set to a position whichis five (5) seconds from the fully closed position of thegate. The position can be manually set by followingthe SETTING PEDESTRIAN POSITION procedure (SeeSection 12).NOTE: Limit will not be accepted unless the gate is driven inthe close direction.8.4 Setting open travel limita. Press Button 1 to open the gate.b. If the gate is opened too far, press Button 4 to “inch” thegate towards closec. When happy with the open limit position, press Button 2 onthe transmitter to store into memory.NOTE: Limit will not be accepted unless the gate is driven inthe open direction.WARNING: The gate will automatically close andopen once next step is performed. Ensure that nopersons or objects are in the gates path8.7 Errors during setting of travel limitDuring the above procedure, many error checks arepreformed. If an error is detected, a message will bedisplayed indicating the error.8.8 Recalculate Force Marginsa. Reprofiling is a simplified way of re-learning the travelcharacteristic of a previously setup Limit Switch travelinstallation. Re-profiling can be used when the travelcharacteristics of the gate change due to mechanicaladjustments etc.b. To initiate a re-profile simply locate “MENU 10.2Reprofile Travel”WARNING: The gate(s) will automaticallyclose and open. Ensure that no persons orobjects are in the gates path.d. The gate will now automatically close and open to calculate thesafety obstruction settings.8.5 Automatic limit adjustment and load profilec. Press SET then follow the prompts. The gate will startAfter a brief pause, the controller will automatically close andto move and re-calculate force margins. The gate canopen the gate several times. This adjusts the speed at whichmove between the open and close limit positions upthe limits are approached and helps to learn the normal loadto two (2) times (depending on the position of the gateprofile of the gate. When the setup is complete, the MAINand the power up condition).SCREEN will be displayed with the gate shown to be OPEN.d. A single beep will be heard once the process isThe Gate can now be used.complete and setup complete message will beNOTE: Do not press transmitter duringadjustmentOwnerlimitInstallationInstructions NeoSliderdisplayed- Sliding Gate Opener NES-500 / NES-8009process.TM

9. Safety Obstruction Force TestWARNING! Take care when testing or adjusting theSafety Obstruction Force. Excessive force may causeSERIOUS PERSONAL INJURY and/or PROPERTYDAMAGE.9.1 Testing Close Cyclea. Press the OPEN button to open the gate.b. Place a piece of timber approximately 40mm wide on theground directly next to the closing pilon / fence (Fig. 9.1).c. Press the CLOSE button to close the gate. The gate shouldstrike the object and start to re-open.Fig 9.19.2 Testing Open Cyclea. Press the CLOSE button to close the gate.b. Press the OPEN button to open the gate. When the gatereaches the half open point, grab the side rail of the gatefirmly and the gate should stop.c. If the gate does not reverse readily when closing, or stop whenopening, the force may be excessive and need adjusting.40mm Block ofwoodWARNING! If the gate fails these tests, put theopener into manual mode, only operate the gate byhand and call for service.Safety Obstruction ForceThe Safety Obstruction Force is calculated automatically during setup.Adjusting this is normally only necessitated by environmental conditionssuch as windy or dusty areas, and areas with extreme temperature changes.Menu 2Current Trips9.3 Force Pressure For Close and Open Cycle.Navigating To “Current Trips”Fig 9.2a. Press NEXT or PREV to navigate to Menu 2 Current Trips.b. Press SET (Fig.9.2)c. MENU 2.1: CLOSE Margin is displayed (Fig. 9.3).d. Press UP arrow to increase or DOWN arrow to decrease the value.e. Press SET to save the new value.f. Test the force again as per “Safety Obstruction Force Test” in Section9.1.PRESS9.4 Reprofiling Travela. Reprofiling is a simplified way of re-learning the travel characteristicof a previously setup Limit Switch travel installation. Re-profiling canbe used when the travel characteristics of the gate changes due tomechanical adjustments etc. To initiate a re-profile, simply locate“MENU 10.2 Reprofile Travel”, press SET and follow the prompts. Thegate will start to move and re-calculate force margins. The gate canmove between the open and close limit positions up to two (2) times(depending on the position of the gate and the power up condition).b. A single beep will be heard once the process is complete.c. Test the force again as per “Safety Obstruction Force Test” (Section 9.1and 9.2).10Close Margin(Amps) 0.7Owner Installation Instructions NeoSlider - Sliding Gate Opener NES-500 / NES-800TMFig 9.3PRESS

10. Coding TransmitterThe NeoSliderTM can store up to thirty (30) transmitters in itsmemory. Each transmitter can be allocated an alpha-numeric IDlabel up to eleven (11) characters in length and each button canbe assigned to one of several control functions. The settings for atransmitter are represented in Fig. 10.1. It shows the transmitter’sstore number, ID label or serial number and the functionsassigned to each of the four buttons. To toggle between ID/SNdisplay, press UP/DOWN with the cursor on the ID/SN indicator.The procedures below code, delete, replace, edit and copytransmitter records.10.1 Coding Transmitter ButtonNavigating To Menu 1 “Code Transmitter”a. Press NEXT to navigate to Menu 1).b. Press SET to enter the code set procedure.IMPORTANT NOTE:Only TrioCodeTM128 Technology Transmittersare compatible with this product.ID/SN displayindicatorStorenumberButton 1function123IDI.D label/SerialnumberName/SNFig 10.1OSC PED LGT VACButton 2 Button 3function functionButton 4functionStoring Transmitter Codea. The controller will prompt to press one of the transmitter’sbuttons.b. Press the transmitter button you wish to use to operate theopener (e.g. button 1) (Fig. 10.2) .c. Press the same transmitter button again as prompted by thedisplay.Press Tx’erButtonLIST PRESSFig 10.210.2 Selecting Function Of The ButtonThe controller will now show the transmitter’s record, with a cursoron the field for the button being coded (Fig. 10.3). Use OPEN/CLOSE to select the function for the button.Available functions:VAC (Vacation Mode)LGT (Courtesy Light)STP (Stop)OPN (Open)CLS (Close)SWP (Swipe)PED (Pedestrian access) OSC (Open/Stop/Close)OFF (No action)# 1 [ No Name ]OSC OFF OFF OFFFig 10.3PRESSPress SET to save the settings or STOP to abort without saving.10.3 Returning To Main ScreenPRESSPress EXIT to return to the MAIN SCREEN and test the transmitter.NOTE: To edit the other settings, refer to transmitter editprocedure in Appendix F.If a transmitter is already coded into the opener, additionaltransmitters can be coded without being in direct contact withthe opener’s wall console unit.Existingtransmitter10.4 Selecting The Function To Be Codeda. Using the existing transmitter, operate the gate with thetransmitter button which has the function to be coded (e.g.Button 1 has been coded with the OSC function assigned).b. Use a small pin / pen to press and hold through the Coding Holeof the existing transmitter for 2 seconds (Fig. 10.4).c. Within 10 seconds, press the button on the new transmitteryou wish to code for 2 seconds and release (Fig. 10.5).d. Press the same button again for 2 seconds and release.e. Test Operation. The new transmitter button should nowfunction as the existing transmitter.Fig 10.4PRESSNewtransmitterNOTE: To Manage your Transmitters, refer to TransmitterOwner Installation Instructions NeoSliderManagement in Appendix G.TM- Sliding Gate Opener NES-500 / NES-800Fig 10.511

11. Emergency Release11.1 Your gate CAN NOT be used by the opener when:a. There is a power failure.11.2 Your gate CAN be used when:a. There is an emergency, by disengaging the opener.b. There is a power failure, by disengaging the opener.Step 1Step 2Step 3Fig 11.111.3 To Disengage the Opener:a. Push the lid of release chamber and move to the right.b. Insert the key and turn counterclockwise to unlock the device.c. Turn the lever counter-clockwise to release the motor.11.4 To Re-Engage the Opener:a. Turn the lever clockwise to engage the motor.b. Turn the key clockwise to lock the device.c. Move the release chamber to the left to close.12. Setting Pedestrian PositionNeoSliderTM can be instructed, via its pedestrian control feature, topartly open and provide pedestrian access but prevent vehicle access.NOTE: Before setting the pedestrian access position the gate must bein the fully closed position. As with the Setting Travel Limit procedure,a transmitter can be used to complete the pedestrian position settingprocedure.Ped’n OpeningTime5PRESSNOTE: The pedestrian default position is set at five (5) seconds from fullyclosed position and can be changed as follows:.Fig 12.1PRESS12.1 Setting pedestrian positionNavigating to “Menu 10.3 Set Pedestrian”a. Press PREV to navigate to Menu 10.b. Press SET - MENU 10.1 is displayed.c. Press NEXT to go to MENU 10.3.d. Press SET to enter Set Pedestrian procedure.Ped’n AccessPress to Access MENUTo Set pedestrian positiona. Press OPEN to change the pedestrian access position time (Fig. 14.1).b. Press SET to record new time.c. Press transmitter coded for pedestrian function to test.12.2 Pedestrian Position SetThe controller will return to the MAIN SCREEN with the gate statusshown as being in pedestrian access mode (Fig. 14.2).12.3 Error DisplaysDuringthe above proceduremany error checks are performed. If an errorOwner Installation Instructions NeoSlider - Sliding Gate Opener NES-500 / NES-80012is detected, a message will be displayed indicating the error.TMFig 12.2

13. Auto-Close ModeWARNING! The Auto-Close function is notavailable unless Safety Beam is installed.13.1 Setting Up Standard Auto-CloseMenu 3. Auto-Close TimesAuto-Close mode is a function that automatically closesthe gate a preset time after the Safety Beam recognise thata vehicle has left the gateway. The Auto-Close timer onlystarts after the Safety Beam path is broken and the AutoClose timer has been set. If the Safety Beam path is notbroken, the gate will remain open until the path is broken.If the opener incurs a physical obstruction (i.e. not from theSafety Beam) while closing, the gate will re-open and notAuto-Close until the Safety Beam path is broken again.Menu 3.1 Auto-CloseThis mode is selected by entering a non-zero time for theSTD Auto-Close parameter. When selected, the gate willAuto-Close after being fully opened (except when the gatehas reversed to the open position after a motor obstructionor overload unless A/C after open and/or close Obstructionare selected). Countdown is suspended by: S.B., OPN orSWP input being active. The countdown is aborted if theSTP input is activated. If the gate is already open and theOPN or the SWP input is activated, then the countdownwill start.13.2 Safety Beam Triggered Auto CloseMenu 3.2 (SB AC Trig)This mode is selected by entering a non-zero time for the“Safety Beam Auto-Close” parameter. This mode is usedto Auto-Close the gate but only after an object has passedthrough the gateway and has triggered the Safety Beaminput. Any Safety Beam or combination of Safety Beamscan be configured to activate Safety Beam Auto-Closemode and combinations are:One Beam onlyi. Safety Beam 1ii. Safety Beam 2Either Beami. Safety Beam 1 or Safety Beam 2Combinationii. Safety Beam 1 and Safety Beam 2iii. Safety Beam 2 then Safety Beam 1NOTE: The swipe input can be used to clear the SafetyBeam triggered status so that the Safety Beam input mustbe activated again before the countdown will start. As withthe other Safety Beam modes, the STP input will abortcountdown and the OPN and SWP inputs will restart thecountdown if the gate is OPEN.13.3 Pedestrian Auto-CloseMenu 3.3 Safety Beam Auto-CloseThis mode is selected by entering a non-zero time for the“Safety Beam Auto-Close” parameter. This mode is usedto Auto-Close the gate but only after an object has passedthrough the gateway and has triggered the Safety BeaminputMenu 3.4 Pedestrian Auto-CloseThis mode is selected by entering a non-zero tim

Owner Installation Instructions NeoSliderTM - Sliding Gate Opener NES-500 / NES-800 3 WARNING! The gate may operate unexpectedly, therefore do not allow anything to stay in the path of the gate. Do not disengage the gate opener to manual operation with children/persons or any objects including motor vehicles within the gateway.