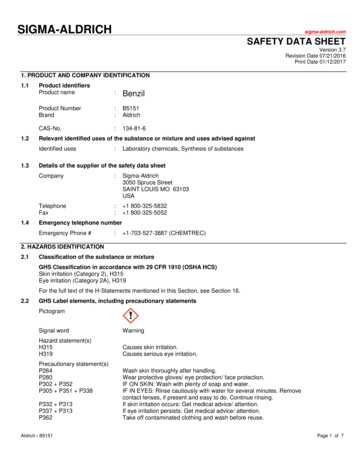

Transcription

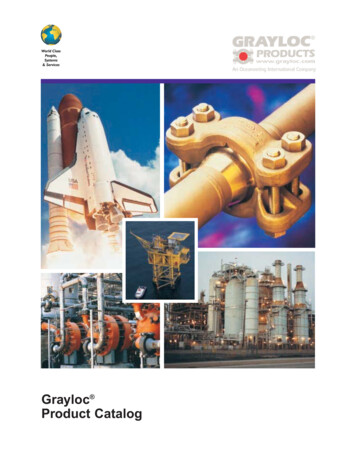

Grayloc Product Catalog

Grayloc ProductsEngineering Services Custom designFinite element analysisRetrofit designsTesting program developmentProject technical supportState of the art metal-to-metal seal designsQuality Programs ASME Section VIII, Division 1 & 2MIL-I-45208A inspection system requirementsISO 9001Total product materials traceabilityComplete calibration program, with certifications, traceable to the National CalibrationBureau of Standards and TechnologyCustomer Order Processing Highly trained personnelState of the art machine toolsLarge raw material inventoryLarge service oriented finished goods inventoryAction team for critical ordersFactory trained field service techniciansavailable 24 hours a day, 7 days a week Packaging and shipment preparation thatexceeds industry standards Project managementGrayloc Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3The Grayloc Metal-to-Metal Seal . . . . . . . . . . . . . . . .4Grayloc Connector Applications . . . . . . . . . . . . . . . . .5Tension, Compression, Bending . . . . . . . . . . . . . . . . .6Conserves Space and Weight . . . . . . . . . . . . . . . . . .7Saves Time and Money . . . . . . . . . . . . . . . . . . . . . . .8How to Select Grayloc Connectors . . . . . . . . . . . . . . . . .9Part Numbers/ Dimensions . . . . . . . . . . . . . . . . . . . . . .10Butt Weld Hubs . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Blind Hubs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13Clamp Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . .16Seal Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17Other Products and Piping Accessories . . . . . . . . . . .18Seal Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18Heavy-Duty Connectors . . . . . . . . . . . . . . . . . . . . . .19Hubs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21Special Connectors . . . . . . . . . . . . . . . . . . . . . . . . .22Jacketed Connectors . . . . . . . . . . . . . . . . . . . . . . . .23Remotely Operated Connectors . . . . . . . . . . . . . . . .24Grayloc Compact Flanges . . . . . . . . . . . . . . . . . . . .25Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26Thermowells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27Hinged Vessel Closures . . . . . . . . . . . . . . . . . . . . . .27Studded Vessel Closures . . . . . . . . . . . . . . . . . . . . .28Conversion and Torque Requirements . . . . . . . . . . . . .29API Flange to Grayloc Connector Conversion . . . . . .29Bolting Torque Required for Grayloc Clamps . . . . . . .29Installation and Maintenance Instructions . . . . . . . . . .30Standard Terms and Conditions . . . . . . . . . . . . . . . . . .31Engineering, Manufacturing andSales Locations . . . . . . . . . . . . . . . . . . .Back CoverGrayloc Products is pleased to offer its products with the products/services guarantee as set forth in the terms and conditions printed on page 31of this catalog. These terms and conditions apply to written or oral orders.The Grayloc product guarantee is only valid when the installation and maintenance instructions on page 30 are followed. For any questions about GraylocProducts or their selection, installation, use, or service, please contact thenearest office listed on the back cover for professional assistance and service.3

The Grayloc Metal-to-Metal SealA Grayloc connector has threecomponents: Metal Seal Ring — The sealring resembles a “T” crosssection. The leg of the “T”forms a rib that is held by thehub faces as the connectionis madeup. The two armsform lip seals that create anarea of sealing surface withthe inner surface of the hub.Internal pressure works toreinforce this seal. Two Hubs — The clamp fitsover the two hubs and forcesthem against the seal ringrib. As the hubs are drawntogether by the clampassembly, the seal ring lipsdeflect against the innersealing surfaces of the hubs.This deflection elasticallyloads the lips of the seal ringagainst the inner sealingsurface of the hub, forminga self-energized seal. Clamp Assembly —Designed to provide nearly360 clamping contact withthe hubs. A relief notch inthe center of the clampsegments allow even distribution of makeup forces.No specific orientation isrequired when installed.How the Grayloc Connector SealsClampingSurfaceClampHubSeal RingSeal RingLipRib of the seal ring is clamped between hub faces. Lips ofthe seal ring engage inner hub surface in an interference fitwhich deflects the lips to achieve a seal.Under Pressure:Grayloc Connector vs. FlangeInternal pressure energizes theGrayloc seal lips, reinforcing the seal.4Pressure acts directly on the flange facesreducing seal integrity.Rib

Grayloc Connector ApplicationsThe simplicity, sealing efficiency,and economy of the Grayloc connector benefits a widerange of industries in variousapplications: Power Industry —General piping / valve ends,steam lines, pump inlet /outlet lines, and chemicalclean out closures. Petrochemical Industry —Reactor vessel nozzles,vessel closures, generalpiping / valve ends in petroleum refining and chemicalprocessing plants. Oil and Gas Production —Onshore and offshore wellheads, tees and ells, manifolds, chokes, valve ends,compressors, general piping,loading risers and pipelines.Synthetic Fuels, CoalGasification, and CoalLiquefaction —General piping, vesselclosures, reactor vessels,and valve ends. Marine — Subsea pipingand riser systems, floatingproduction, storage, offloading (FPSO) vessels, andtanker loading and unloadingfacilities. Aerospace —Rocket test stands, fuel lines,hydraulic and pneumaticpiping systems. Food Processing—Sanitary/general pipingconnectors, vessel closuresand valve ends. Environmental —Hazard waste disposaland fugitive emissionscontainment.The Office of Coal Research, U.S. Department of the Interior, and theAmerican Gas Association jointly sponsored a program to develop coalgasification technology. On this pre-quench tower for raw gas purification,two Grayloc vessel closures and several smaller Grayloc connectors wereused for pressures of 1,650 psi and temperatures to 650 F.Photograph courtesy of the Institute of Gas Technology.The use of Grayloc connectors, on a Centex Oil and Gas, Inc. platformin the Gulf of Mexico, saved 15" of horizontal space on the separatormanifolding of this skid-mounted production unit, and reduced the totaltopside platform weight by more than 11 tons.5

Tension, Compression, BendingAnything the pipe can take, so can the Grayloc ConnectorWhen manufactured from the same material as the pipe, the Grayloc connector surpasses thestrength of the pipe and that of most other components that may be connected.The rib of the seal ring prevents the seal lip from being crushed by over-tightening. While it acts asa positive stop during makeup, the rib also transfers compressive and bending loads from one hubelement to another. The rib bearing area is ample to carry the most severe loading that a pipingsystem can withstand.TensionBendingCompression Withstands greater tensionloads than conventionalANSI flanges In most cases, withstandsmore tension loading thanthe pipe itselfNumerous independent testshave shown that Grayloc connectors withstand severebending loads without leakingor looseningIn normal piping applications,it is not possible to overloadthe Grayloc connector or sealring in compression In one test, 2 " GR 20Grayloc connector waswelded to 21 2" Sch. XXpipe and subjected to a 2"cold bend, 36" on center —connector did not leak andclamp bolting remained tightWhen very high compressiveloads occur, the maximumload on the connector isdetermined by the limit ofthe pipe In most cases, the areaof the seal ring rib is equalto or larger than that ofthe cross section ofadjoining pipe In destructive tests, pipe canbe loaded in tension to failurewithout causing the Graylocconnector to leak12Examples of Grayloc connector applications inextreme service conditionsVibration:High Temperature:Service experience to 1700 F.Low Temperature:Routine liquefied gas service including liquidhydrogen and nitrogen to -425 F.Thermal Shock:Corrosion:Zero Leak Rate:680 to 200 cycles per second under 6,600 psiRoutine service with temperature changes up to300 F. per hour.Liquid sodium service at 1200 F.10-6 atm cc/s HeliumService ExtremesVibration, heat, cold and thermalshock often accompany servicein which Grayloc connectorsare heavily loaded. Graylocconnectors consistently withstand severe situations withoutroutine maintenance. Specialdesigns permit maintenancefree service even under theextreme conditions shownin the table.

Conserves Space and WeightThe Grayloc connector issignificantly lighter and smallerthan a comparably rated ANSIor API ring joint flange connection, providing an opportunityto design lightweight, compactsystems. Close piping andhookup arrangements canbe easily made as the clampcompletely rotates aroundthe hub. Smaller diameter Shorter length No bolt holes to alignGrayloc vs. )Weight(pounds)3"Grayloc ConnectorANSI 1500 FlangeAPI 5000 62537121926"Grayloc ConnectorANSI 1500 FlangeAPI 5000 14.25014440736510"Grayloc ConnectorANSI 1500 FlangeAPI 5000 (psi)7

Saves Time and MoneyThe Grayloc connector canbe assembled or disassembledquicker and easier than a flangeconnection. Usually, 3 to 8Grayloc connectors can beassembled/disassembledin the same time as oneflange connection.Versatile DesignThe standard Grayloc assemblyhas two hubs arranged for buttwelding to pipe. However, acomplete line of other pipingcomponents is available formost pipe sizes and serviceconditions. No bolt holes to align Only 4 bolts to tighten (8 -24for a conventional flange) Hubs (socket weld / threaded) Torque required —as much as 70% lowerthan for a RTJ flange Tees and ells NozzlesMaintenance is simple withonly four bolts to remove. Noperiodic re-tightening of boltsis required once the connectoris in service.The necessary inventory ofspare parts is significantlyreduced since the Graylocconnector is sized accordingto pipe size, schedule, andservice. In most instances, onlyone Grayloc connector size isnecessary for each pipe sizeand seal rings can be reused.8Heavy duty connectors foroilfield and other applicationsare available.Other equipment manufacturers(valves, pumps, compressors,vessel, etc.) are licensed tomachine Grayloc hub profile /seats integral to their products.

How to Select Grayloc ConnectorsHub Material Selection ChartANSIGroup No.DesignationSteel1.1CarbonGrayloc Selection Chart-20 F. to 700 F.Forging(1)A105ANSI Flange SeriesA350-LF21.231 2 NiA350-LF31.4CarbonA350-LF1C-1 2 MoA182-F1 2 Cr-1 2 MoA182-F21.51.711.9600 1 GR 51 GR 51 GR 51 GR 43 41 GR 71 GR 71 GR 51 GR 41 GR 411 GR 111 GR 111 GR 71 GR 51 GR 511 211 2 GR 1411 2 GR 1411 2 GR 1411 2 GR 1111 2 GR 1121 4 Cr-1MoA182-F221.135Cr-1 2 MoA182-F5A182-F5aA182-F922 GR 202 GR 202 GR 202 GR 142 GR 11A182-F30421 221 2 GR 2521 2 GR 2521 2 GR 2521 2 GR 2021 2 GR 20A182-F304H33 GR 273 GR 273 GR 253 GR 233 GR 20A182-F31644 GR 404 GR 344 GR 344 GR 314 GR 2355 GR 525 GR 465 GR 465 GR 405 GR 3166 GR 626 GR 626 GR 526 GR 466 GR 34A182-F34788 GR 828 GR 768 GR 678 GR 528 GR 46A182-F347H1010 H 9710 H 9410 H 8410 H 7210 H 62A182-F3481212 M 12012 M 11212 M 10212 M 82X12 M 72X14 GR 120X14 GR 321H2.518Cr-10Ni-CbA182-F348H14X14 GR 13016X16 GR 140B564-N0880018X18 GR 170Alloy C276B574-N1027620X20 GR 180Alloy 625B564-N0662524X24 GR 220Alloy .5Alloy 600B564-N066003.6Alloy 8003.8.1 GR 4Grayloc SizeA182-F111.1016Cr-12Ni-2Mo4500A182-F121Cr- 2 Mo2.22500211 4 Cr-1 2 Mo18Cr-8Ni1500112.1900NominalPipe SizeAdditional sizes available upon requestEXAMPLE2" ANSI 1500 2 GR20 GraylocA182-F53A182-F55Pipe SizeGrayloc Clamp Size(1) Standard Grayloc materials referenced inthis catalog.Grayloc Ring Sizeto Match Pipe IDANSI Pressure Ratings Ceiling ValuesTemperature, F600900150025004500-20 to 76529404905882570011351705284047308515All Thread StudClampButt Weld HubNotes to Grayloc Selection Chart:1.Corrosion allowance: 1/32" for 1" nominal and 1/16" forlarger pipe sizes.2.Connectors listed in the Grayloc Selection Chart exceedthe ANSI ceiling pressure ratings. Actual ratings areavailable upon request.3.Ratings are based on carbon steel clamps.Seal RingSphericalFace Nut9

Part Numbers / DimensionsButt Weld HubsGrayloc hubs are usually made of the samegeneric material as the other system componentsthey connect. Standard hub materials are SA105carbon steel and SA182-F316 stainless steel, butthey can be manufactured from most machinablemetals, including all of the carbon, low alloy,austenitic stainless steels, MONEL*, INCONEL*,titanium and zirconium alloys.Sealing surfaces on carbon steel and low alloysteel weld hubs and fittings are protected byelectroless nickel coating. The welding beveland all part tolerances are in accordance withANSI B16.5.ABED25 FC* MONEL and INCONEL are trademarks of Special Metals Corp.Nominal Sched.PipeorSizeWeightHubSizePart NumberApprox.Carbon Stl. Stainless Stl. PipeODAPipeIDBCDimensions (Inches)D(1)EFDepthofRecess(2) 3130.3130.3130.313.

Grayloc vs. Flanges W.P. Diameter Length Weight Size Connection (psi) (inches) (inches) (pounds) 3" Grayloc Connector 6,593 6.875 6.750 37 ANSI 1500 Flange 3,705 10.500 9.250 121 API 5000 Flange 5,000 10.500 8.625 92 6" Grayloc Connector 6,359 12.000 9.500 144 ANSI 1500 Flange 3,705 15.500 13.500 407 API 5000 Flange 5,000 15.500 14.250 365 10" Grayloc Connector 5,368 17.625 12.325