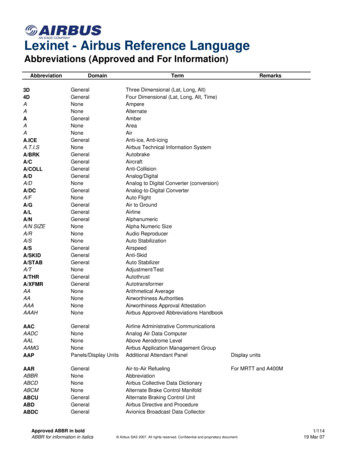

Transcription

GENERAL PRODUCTSExperts in heattransfer since 1923

Founded in 1923, Aerofin is a leading manufacturerof finned tube heat exchanger coils and heat transferequipment and accessories, such as processgas coolers/heaters, transformer oil coolers,fan/coil units, face and bypass coils, frames forcoil removal capabilities, and airside transitions.For nearly 100 years, Aerofin has been anindustry leader in supplying fin-tube heatexchangers and other heat transfer equipment.WhoWe Are.Aerofin products serve a variety of industriesincluding HVAC, fossil fuel power generation,nuclear power generation, industrialprocess, pulp and paper, automotive, andpetrochemical. Applications are evaluatedusing the latest Windows-based performanceand sizing software, which accommodatesnearly any heat transfer medium. Coils aredesigned and fabricated to virtually anysize and configuration using a wide array ofconstruction materials. Additionally, all productscan be designed and constructed to thestringent requirements of the ASME code.Aerofin has the specialized knowledge andexperience to design and fabricate heatexchangers to meet the most rigorousperformance and durability requirements.

Industrial Process - PetrochemicalHvac - Pulp & Paper - AutomotiveFossil Fuel Power GenerationNuclear Power GenerationStarting with the broadest fin surface capabilitiesin the industry, Aerofin offers three plate finsurfaces (flat, star, and wave) and a wide arrayof spiral wrapped fin surfaces (edgewound,L-foot, embedded, extruded, and welded).Each of these may be produced using a varietyof materials to meet specific application needssuch as (but not limited to) aluminum, copper,carbon steel, and stainless steel.Aerofin also offers a wide choice of tubematerials. From copper and copper-nickel tubesutilizing brazed joint construction to carbonand stainless steel tubes with welded jointFAST FACTS First Nuclear application in 1966 ASME Section VIII U-Stampholder since 1953 Over 25 products AHRI certifiedconstruction, Aerofin has the ability to meet themost severe requirements. Even materials suchas Aluminum and AL-6XN are no problem forour experienced welders.Our capabilities and experience also allow formany different styles of header designs to fityour specific needs and application. Whether itis a standard pipe header allowing for maximumflexibility in the coil design, or a plugged boxheader where each tube can be cleanedindividually, or a completely removable headerplate for maximum cleanability, Aerofin candesign and manufacture what you need. Worldwide installations 165,000 sq. ft facilityin Lynchburg, VA Plate and Spiral fins available Full-time ANI on site

HVACIntegral Reheat CoilChilled water cooling coils designedto dehumidify as well as cool air.Evaporator CoilCopper tube and Aluminum fin evaporatordesigned for face split control on dualcircuited refrigeration applications.Steam Distributing CoilSteam Distributing (non-freeze) coilsdesigned with tube in a tube construction.Aeromix Face &Bypass CoilHot water or steam preheat coils with bypassdampers in both vertical and horizontal designs.

COMMERCIAL / REPLACEMENTSplit-Fit CoilCooling coil with modularconstruction allowing easyinstallation in tight spaces, withCopper fin, Copper-Nickel tubes,and Copper-Nickel headers.Water CoilStandard water coil construction withCopper tube and Aluminum fin. Constructionshown with copper tubes and aluminumfins but can be built with a variety ofmaterial choices to suit the application.Flex Steam CoilSteam coils designed with independent,curved tubes allowing the coil toexpand and contract internally,accounting for thermal expansion whilemaintaining connection locations.Spiral Fin Water CoilWater coil constructed withCopper tube and spiral fin allowingfor variable tube spacing

INDUSTRIALBare Tube CoilBare tube construction for applications whereusing fins could cause severe clogging.Oil CoolingPlug box header construction allows foreasy cleaning of each individual tube.Removable HeaderCoil with SolderCoated FinsRemovable Carbon Steel Headers onboth ends of the coil, constructed withsolder coated Copper tube and fins.Stainless SteelWater CoilWelded tube construction using StainlessSteel tubes and headers used in corrosiveenvironments to prolong the life of the coil.

Large ReturnBend Steam CoilTriple-circuited steam coilutilizing 1” stainless steeltubing and copper plate fins.Steam CoilTransition UnitTransition with multiple coilsdesigned with the capability to adda coil for additional capacity.Heavy Duty MultipleCoil Transition UnitDuct access panels and removable coredesign to facilitate cleaning and maintenancewith an ASME code stamped transition.Motor CoolerCoils and transitions designed tocool high horsepower motors.

POWER GENERATIONSteam Coil withHousingCarbon Steel welded joint constructionwith Aluminum spiral wrappedfins in a Carbon Steel frame.Slide-Out HousingStainless Steel frame designedfor easy removal of coils.Turbine Inlet Air CoilLarge coils used to cool intakeair of gas turbines.Combustion PreHeating Steam CoilsBank of three coils designed to bestackable used to pre-heat combustionair at coal fired power plants.

NUCLEARASME-NPT StampedExternal FramesDual water coils with Copper tube,Copper spiral fin and Stainless Steelheaders designed to be removable froman NPT-stamped Stainless Steel frame.AutomaticBackwash StrainerThese self-cleaning particle strainers canprovide cost effective continuous protectionfor downstream equipment and can be builtnew or existing units can be refurbished.Shell & Tubeheat exchangerShell & Tube heat exchangerwith Copper-Nickel tubesand Carbon Steel shellcoated on the interior.Removable Header CoilRemovable Stainless Steel headers onboth ends of the coil, constructed withCopper tube and Copper plate fins.

Custom unitsSprayguard MoistureEliminatorsSprayguard controls the discharge ofmoisture from coils without restricting airflow.Custom BrazingCustom brazed Copper-Nickelreturn bends meeting a customerspecific requirement.Hydrogen CoolerHydrogen coolers employ water to coolthe hot hydrogen gas produced insideof large-scale turbine generators.Extreme Duty CoilCoils designed and built towithstand rigorous shock andvibration requirements.

Knock Out TankStainless Steel knock out tankused for moisture separation.Piping SkidFabricated piping skids with all the requiredcomponents for steam and water coils.Air CoolerUnits where structures, fans, andmotors are added to the coil whenmore than just a coil is needed.Transformer OilHigh temperatures of transformeroil reduces efficiency and causespremature failure, these coolersreduce operating and capital costs.

Founded in 1923, Aerofin is a leading manufacturer of spiral and platefin heat exchanger coils and related heat transfer equipment such asprocess gas coolers/heaters, transformer oil coolers, air coolers, faceand bypass coils, external frames, and airside transitions.Aerofin’s home office and manufacturing plant has been located in Lynchburg,Virginia since 1966. With a facility size of over 165,000 square feet, Aerofin isable to supply any custom finned tube heat transfer product required.Phonelocation(800) 237-63464621 Murray Place P.O. Box 10819 Lynchburg, VA 24506email & Webinfo@aerofin.com www.aerofin.com

curved tubes allowing the coil to expand and contract internally, accounting for thermal expansion while maintaining connection locations. Spiral Fin Water Coil Water coil constructed with Copper tube and spiral fin allowing for variable tube spacing Water Coil Standard water coil construction with Copper tube and Aluminum fin. Construction