Transcription

MOLEX COPPER FLEXIBLECIRCUIT SOLUTIONSCIRCUITS DESIGNEDWITH A RANGE OF CAPABILITIESMaximum Performance for Demanding ApplicationsFlex and Rigid Flex (Typical)Layer Count1 to 8 LayersStandard Panel Sizes (Others Available)Taiwan250 by 540mm250 by 600mmBase MaterialRigid and Flex IPC-6011 Subspecifications/1 Adhesive and /11 AdhesivelessPolyimide Flex and Epoxy-Glass Rigid MaterialsStiffenersThermal-Set or Pressure-Sensitive AdhesiveFR4PolyimideAluminumStainless SteelShieldingEtched Copper, Silver Ink, Shielding FilmHole SizeDrilled: 0.20mm MinimumLaser-Drilled Holes AvailableAspect Ratio6:1SoldermaskCoverlay FilmLPIThermal/UV Cured InksInkjet/Silkscreen Legend OptionsWhite, Yellow, BlackFinish PlatingOSPElectroless Nickel/Immersion Gold (ENIG)Electroless Nickel/Electroless Palladium/Immersion Gold(ENEPIG)Electrolytic/Hard GoldElectrolytic TinImmersion SilverFinished Copper Trace/SpaceOuter Layers35μm Copper – 125μm Trace/Space70μm Copper – 203μm Trace/SpaceInner Layers12μm Copper18μm Copper35μm Copper70μm Copper––––The Molex ApproachAt Molex, we take a multidimensional approach to developcomplete, integrated solutions that turn your ideas into reality.With the industry’s broadest line of printed electronics and theexpertise to work through your mechanical rigors, we can adviseyou on the best fit for your needs, balancing cost, performance,durability, weight and other requirements.50μm Trace/Space75μm Trace/Space125μm Trace/Space178μm Trace/SpaceQuality and TestingIPC-6013 Class 3Learn whether a Molex copper flexible circuit is right foryour end application, and start designing your solution today.Visit lBend Radius Calculator, Environmental, RF, OpticalMechanical, Surface and Metallurgical Analysis, ThermalAnalysis and Imaging, SEM, X-Ray Analysis, EMIElectricalImpedance Calculator, Crosstalk, Skew, Insertion Loss,Return Loss, Eye DiagramCertificationsISO 9001:2008ISO 14001:2004TS 16949IPC 600/610 CertifiedULV94-0AssemblyThrough Hole, SMT, BGA, Press-Fit, Mechanical HardwarePerimeter Tolerances (millimeters)FeatureSteel Rule DieChemical Milled DieHole to Edge .254 .254Hole to Hole .254N/ACutline .254 .127Cutline to Hole .381 .254Outline Dimensions .254 .127Trace to Edge .254 .127Laser Profile .051 .051 .051 .051 .051 .051Hard Tool DieCNC Drill .051 .051 .127 .051 .051N/A .051 .102CNC Rout .127Order No. 987650-0481 Rev. 7USA/250/MIB/KC/2017.11 2017 Molex

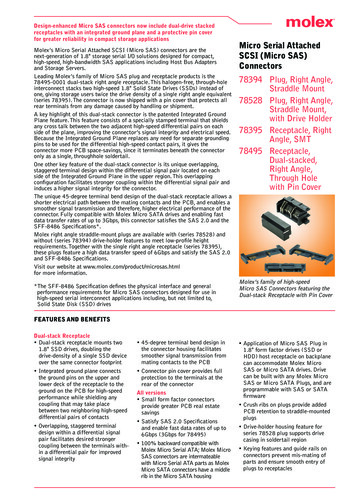

INNOVATIVECOPPER FLEX CIRCUITSMolex Flexible Printed Circuit Technologyis the answer for your most challenginginterconnect applications.We are your total solution for flexible printed circuitrybecause we design and manufacture both the Flex andthe connectors. A flexible printed circuit (FPC or Flex)is an ultra-reliable technology. An FPC can be thebest solution for creating products that are complex,small, lightweight or have harsh environmentalconditions. Flex can be designed to meet a wide rangeof temperature and environmental extremes.This custom solution has a variety of applications.Flex circuits are excellent for designs with highdensity circuitry, and for dynamic applications suchas hinge and drawer devices.Flex circuits make electronic interconnection bothsimpler and more reliable. FPC interconnects areoften used in applications where high signal speed,power distribution, heat, flexibility or spacesavings are issues. Molex can provide your totalinterconnect e are several advantages that flexible printedcircuits have over other interconnect devices: S ignal Integrity — The material used in theconstruction of Flex minimizes signal loss,maintaining high-speed integrity. T hermal Management — Flex does not requirecooling from both sides. It also dissipates heatquickly. Reduces assembly time Multi-layer Double-sided Typically 2 or more layers Double-sided Tight line and space widths Multi-layer Simplify design to meet application requirements whileminimizing costs Connector customization to meet applicationrequirements Early engagement with complete design formanufacturing to streamline production releaseand builds Molex assembly expertiseMultiple manufacturing locations Low-cost geography manufacturing Single, double, multi-layer and rigid flex; up to 8 layers US and Taiwan design centers Impedance control design and manufacture China, Taiwan and Mexico manufacturing facilities B etter thermal characteristics than standardrigid board constructions Value-add assembly: through hole, SMT, BGA, press-fitand mechanical hardware ISO 14001, ISO 9001 and TS 16949-certified facilities Typically 3 or more layersDesign the flex assembly with expertise inelectrical, mechanical, reliability andmanufacturing properties Double-sided Tight line and space widths Multi-layer Multi-layer Large number of interconnect options Multidisciplined engineering support Impedance control-O ptimize electrical, mechanical, flexibilityand manufacturing requirements to meetapplication needs Low signal loss Surface mount on both sides R igid flex Press-fit connector capability Combination of flexible polyimide and rigid FR4-S ynergistic design approach to Flex Impedance control Double-sided Coiling design Multi-layer High speed Extensive background in mechanical designand manufacturing-M inimize points of flex stress; provide long-termreliability products E limination of connectors and cables forimproved reliabilityResilientFlex Molex flex circuit and connector manufacturingexpertise One-stop shop for flex assemblies Typically 2 or more layers High-density routingRigid FlexChallenge our customers to ensure that the flexinterconnect is not overdesigned Disaster recovery backup Reduces weightHigh-SpeedAssembliesDesign and manufacture customerinterconnect solutionsFull range of flex circuit and assembly technologies ZIF jumpers availableHigh-DensityAssembliesA complete source for flex and rigid flex circuit design,development, manufacturing and assembly One supplier – complete assembly B etter thermal characteristics than standardrigid board constructions Space Reduction — Flex is able to occupy threedimensions. It can be bent around packaging andeven over itself in order to fit into a much smallerdevice enclosure. W eight Reduction — Flex is significantly thinnerand lighter than traditional circuit boards; productsusing Flex will naturally be lighter. Single-sided Reduces weight I mpedance Control — Flex promotes a robustdesign pitch due to the close proximity of circuitryand ground planes/shields. T emperature Resistance — Materials used in theconstruction of Flex have closely matching thermalexpansion rates. This causes Flex to be suitablefor hot and cold temperatures as well as largetemperature fluctuations. V irtually unlimited variety of interconnectoptions Excellent thermal managementJumpersFLEX TYPESLocations Design Centers:St. Paul, MN; Taipei, TW Flex Circuit Manufacturing:Taipei, TW Assembly Fabrication:N aperville, IL; Taipei, TW; Guadalajara, MX;Dongguan, PRCMOLEX DELIVERS: Standards certification supportDesign engineering supportIndustry leader in signal integrity designProven Molex reliability Specialize in high-speed design and materials support Full signal integrity modeling and testing capabilities Internally developed impedance calculator based onmanufacturing parameters and material selectionIn-house value-addcapabilities

MOLEX COPPER FLEXIBLECIRCUIT SOLUTIONSCIRCUITS DESIGNEDWITH A RANGE OF CAPABILITIESMaximum Performance for Demanding ApplicationsFlex and Rigid Flex (Typical)Layer Count1 to 8 LayersStandard Panel Sizes (Others Available)Taiwan250 by 540mm250 by 600mmBase MaterialRigid and Flex IPC-6011 Subspecifications/1 Adhesive and /11 AdhesivelessPolyimide Flex and Epoxy-Glass Rigid MaterialsStiffenersThermal-Set or Pressure-Sensitive AdhesiveFR4PolyimideAluminumStainless SteelShieldingEtched Copper, Silver Ink, Shielding FilmHole SizeDrilled: 0.20mm MinimumLaser-Drilled Holes AvailableAspect Ratio6:1SoldermaskCoverlay FilmLPIThermal/UV Cured InksInkjet/Silkscreen Legend OptionsWhite, Yellow, BlackFinish PlatingOSPElectroless Nickel/Immersion Gold (ENIG)Electroless Nickel/Electroless Palladium/Immersion Gold(ENEPIG)Electrolytic/Hard GoldElectrolytic TinImmersion SilverFinished Copper Trace/SpaceOuter Layers35μm Copper – 125μm Trace/Space70μm Copper – 203μm Trace/SpaceInner Layers12μm Copper18μm Copper35μm Copper70μm Copper––––The Molex ApproachAt Molex, we take a multidimensional approach to developcomplete, integrated solutions that turn your ideas into reality.With the industry’s broadest line of printed electronics and theexpertise to work through your mechanical rigors, we can adviseyou on the best fit for your needs, balancing cost, performance,durability, weight and other requirements.50μm Trace/Space75μm Trace/Space125μm Trace/Space178μm Trace/SpaceQuality and TestingIPC-6013 Class 3Learn whether a Molex copper flexible circuit is right foryour end application, and start designing your solution today.Visit lBend Radius Calculator, Environmental, RF, OpticalMechanical, Surface and Metallurgical Analysis, ThermalAnalysis and Imaging, SEM, X-Ray Analysis, EMIElectricalImpedance Calculator, Crosstalk, Skew, Insertion Loss,Return Loss, Eye DiagramCertificationsISO 9001:2008ISO 14001:2004TS 16949IPC 600/610 CertifiedULV94-0AssemblyThrough Hole, SMT, BGA, Press-Fit, Mechanical HardwarePerimeter Tolerances (millimeters)FeatureSteel Rule DieChemical Milled DieHole to Edge .254 .254Hole to Hole .254N/ACutline .254 .127Cutline to Hole .381 .254Outline Dimensions .254 .127Trace to Edge .254 .127Laser Profile .051 .051 .051 .051 .051 .051Hard Tool DieCNC Drill .051 .051 .127 .051 .051N/A .051 .102CNC Rout .127Order No. 987650-0481 Rev. 7USA/250/MIB/KC/2017.11 2017 Molex

INNOVATIVECOPPER FLEX CIRCUITSMolex Flexible Printed Circuit Technologyis the answer for your most challenginginterconnect applications.We are your total solution for flexible printed circuitrybecause we design and manufacture both the Flex andthe connectors. A flexible printed circuit (FPC or Flex)is an ultra-reliable technology. An FPC can be thebest solution for creating products that are complex,small, lightweight or have harsh environmentalconditions. Flex can be designed to meet a wide rangeof temperature and environmental extremes.This custom solution has a variety of applications.Flex circuits are excellent for designs with highdensity circuitry, and for dynamic applications suchas hinge and drawer devices.Flex circuits make electronic interconnection bothsimpler and more reliable. FPC interconnects areoften used in applications where high signal speed,power distribution, heat, flexibility or spacesavings are issues. Molex can provide your totalinterconnect e are several advantages that flexible printedcircuits have over other interconnect devices: S ignal Integrity — The material used in theconstruction of Flex minimizes signal loss,maintaining high-speed integrity. T hermal Management — Flex does not requirecooling from both sides. It also dissipates heatquickly. Reduces assembly time Multi-layer Double-sided Typically 2 or more layers Double-sided Tight line and space widths Multi-layer Simplify design to meet application requirements whileminimizing costs Connector customization to meet applicationrequirements Early engagement with complete design formanufacturing to streamline production releaseand builds Molex assembly expertiseMultiple manufacturing locations Low-cost geography manufacturing Single, double, multi-layer and rigid flex; up to 8 layers US and Taiwan design centers Impedance control design and manufacture China, Taiwan and Mexico manufacturing facilities B etter thermal characteristics than standardrigid board constructions Value-add assembly: through hole, SMT, BGA, press-fitand mechanical hardware ISO 14001, ISO 9001 and TS 16949-certified facilities Typically 3 or more layersDesign the flex assembly with expertise inelectrical, mechanical, reliability andmanufacturing properties Double-sided Tight line and space widths Multi-layer Multi-layer Large number of interconnect options Multidisciplined engineering support Impedance control-O ptimize electrical, mechanical, flexibilityand manufacturing requirements to meetapplication needs Low signal loss Surface mount on both sides R igid flex Press-fit connector capability Combination of flexible polyimide and rigid FR4-S ynergistic design approach to Flex Impedance control Double-sided Coiling design Multi-layer High speed Extensive background in mechanical designand manufacturing-M inimize points of flex stress; provide long-termreliability products E limination of connectors and cables forimproved reliabilityResilientFlex Molex flex circuit and connector manufacturingexpertise One-stop shop for flex assemblies Typically 2 or more layers High-density routingRigid FlexChallenge our customers to ensure that the flexinterconnect is not overdesigned Disaster recovery backup Reduces weightHigh-SpeedAssembliesDesign and manufacture customerinterconnect solutionsFull range of flex circuit and assembly technologies ZIF jumpers availableHigh-DensityAssembliesA complete source for flex and rigid flex circuit design,development, manufacturing and assembly One supplier – complete assembly B etter thermal characteristics than standardrigid board constructions Space Reduction — Flex is able to occupy threedimensions. It can be bent around packaging andeven over itself in order to fit into a much smallerdevice enclosure. W eight Reduction — Flex is significantly thinnerand lighter than traditional circuit boards; productsusing Flex will naturally be lighter. Single-sided Reduces weight I mpedance Control — Flex promotes a robustdesign pitch due to the close proximity of circuitryand ground planes/shields. T emperature Resistance — Materials used in theconstruction of Flex have closely matching thermalexpansion rates. This causes Flex to be suitablefor hot and cold temperatures as well as largetemperature fluctuations. V irtually unlimited variety of interconnectoptions Excellent thermal managementJumpersFLEX TYPESLocations Design Centers:St. Paul, MN; Taipei, TW Flex Circuit Manufacturing:Taipei, TW Assembly Fabrication:N aperville, IL; Taipei, TW; Guadalajara, MX;Dongguan, PRCMOLEX DELIVERS: Standards certification supportDesign engineering supportIndustry leader in signal integrity designProven Molex reliability Specialize in high-speed design and materials support Full signal integrity modeling and testing capabilities Internally developed impedance calculator based onmanufacturing parameters and material selectionIn-house value-addcapabilities

INNOVATIVECOPPER FLEX CIRCUITSMolex Flexible Printed Circuit Technologyis the answer for your most challenginginterconnect applications.We are your total solution for flexible printed circuitrybecause we design and manufacture both the Flex andthe connectors. A flexible printed circuit (FPC or Flex)is an ultra-reliable technology. An FPC can be thebest solution for creating products that are complex,small, lightweight or have harsh environmentalconditions. Flex can be designed to meet a wide rangeof temperature and environmental extremes.This custom solution has a variety of applications.Flex circuits are excellent for designs with highdensity circuitry, and for dynamic applications suchas hinge and drawer devices.Flex circuits make electronic interconnection bothsimpler and more reliable. FPC interconnects areoften used in applications where high signal speed,power distribution, heat, flexibility or spacesavings are issues. Molex can provide your totalinterconnect e are several advantages that flexible printedcircuits have over other interconnect devices: S ignal Integrity — The material used in theconstruction of Flex minimizes signal loss,maintaining high-speed integrity. T hermal Management — Flex does not requirecooling from both sides. It also dissipates heatquickly. Reduces assembly time Multi-layer Double-sided Typically 2 or more layers Double-sided Tight line and space widths Multi-layer Simplify design to meet application requirements whileminimizing costs Connector customization to meet applicationrequirements Early engagement with complete design formanufacturing to streamline production releaseand builds Molex assembly expertiseMultiple manufacturing locations Low-cost geography manufacturing Single, double, multi-layer and rigid flex; up to 8 layers US and Taiwan design centers Impedance control design and manufacture China, Taiwan and Mexico manufacturing facilities B etter thermal characteristics than standardrigid board constructions Value-add assembly: through hole, SMT, BGA, press-fitand mechanical hardware ISO 14001, ISO 9001 and TS 16949-certified facilities Typically 3 or more layersDesign the flex assembly with expertise inelectrical, mechanical, reliability andmanufacturing properties Double-sided Tight line and space widths Multi-layer Multi-layer Large number of interconnect options Multidisciplined engineering support Impedance control-O ptimize electrical, mechanical, flexibilityand manufacturing requirements to meetapplication needs Low signal loss Surface mount on both sides R igid flex Press-fit connector capability Combination of flexible polyimide and rigid FR4-S ynergistic design approach to Flex Impedance control Double-sided Coiling design Multi-layer High speed Extensive background in mechanical designand manufacturing-M inimize points of flex stress; provide long-termreliability products E limination of connectors and cables forimproved reliabilityResilientFlex Molex flex circuit and connector manufacturingexpertise One-stop shop for flex assemblies Typically 2 or more layers High-density routingRigid FlexChallenge our customers to ensure that the flexinterconnect is not overdesigned Disaster recovery backup Reduces weightHigh-SpeedAssembliesDesign and manufacture customerinterconnect solutionsFull range of flex circuit and assembly technologies ZIF jumpers availableHigh-DensityAssembliesA complete source for flex and rigid flex circuit design,development, manufacturing and assembly One supplier – complete assembly B etter thermal characteristics than standardrigid board constructions Space Reduction — Flex is able to occupy threedimensions. It can be bent around packaging andeven over itself in order to fit into a much smallerdevice enclosure. W eight Reduction — Flex is significantly thinnerand lighter than traditional circuit boards; productsusing Flex will naturally be lighter. Single-sided Reduces weight I mpedance Control — Flex promotes a robustdesign pitch due to the close proximity of circuitryand ground planes/shields. T emperature Resistance — Materials used in theconstruction of Flex have closely matching thermalexpansion rates. This causes Flex to be suitablefor hot and cold temperatures as well as largetemperature fluctuations. V irtually unlimited variety of interconnectoptions Excellent thermal managementJumpersFLEX TYPESLocations Design Centers:St. Paul, MN; Taipei, TW Flex Circuit Manufacturing:Taipei, TW Assembly Fabrication:N aperville, IL; Taipei, TW; Guadalajara, MX;Dongguan, PRCMOLEX DELIVERS: Standards certification supportDesign engineering supportIndustry leader in signal integrity designProven Molex reliability Specialize in high-speed design and materials support Full signal integrity modeling and testing capabilities Internally developed impedance calculator based onmanufacturing parameters and material selectionIn-house value-addcapabilities

MOLEX COPPER FLEXIBLECIRCUIT SOLUTIONSCIRCUITS DESIGNEDWITH A RANGE OF CAPABILITIESMaximum Performance for Demanding ApplicationsFlex and Rigid Flex (Typical)Layer Count1 to 8 LayersStandard Panel Sizes (Others Available)Taiwan250 by 540mm250 by 600mmBase MaterialRigid and Flex IPC-6011 Subspecifications/1 Adhesive and /11 AdhesivelessPolyimide Flex and Epoxy-Glass Rigid MaterialsStiffenersThermal-Set or Pressure-Sensitive AdhesiveFR4PolyimideAluminumStainless SteelShieldingEtched Copper, Silver Ink, Shielding FilmHole SizeDrilled: 0.20mm MinimumLaser-Drilled Holes AvailableAspect Ratio6:1SoldermaskCoverlay FilmLPIThermal/UV Cured InksInkjet/Silkscreen Legend OptionsWhite, Yellow, BlackFinish PlatingOSPElectroless Nickel/Immersion Gold (ENIG)Electroless Nickel/Electroless Palladium/Immersion Gold(ENEPIG)Electrolytic/Hard GoldElectrolytic TinImmersion SilverFinished Copper Trace/SpaceOuter Layers35μm Copper – 125μm Trace/Space70μm Copper – 203μm Trace/SpaceInner Layers12μm Copper18μm Copper35μm Copper70μm Copper––––The Molex ApproachAt Molex, we take a multidimensional approach to developcomplete, integrated solutions that turn your ideas into reality.With the industry’s broadest line of printed electronics and theexpertise to work through your mechanical rigors, we can adviseyou on the best fit for your needs, balancing cost, performance,durability, weight and other requirements.50μm Trace/Space75μm Trace/Space125μm Trace/Space178μm Trace/SpaceQuality and TestingIPC-6013 Class 3Learn whether a Molex copper flexible circuit is right foryour end application, and start designing your solution today.Visit lBend Radius Calculator, Environmental, RF, OpticalMechanical, Surface and Metallurgical Analysis, ThermalAnalysis and Imaging, SEM, X-Ray Analysis, EMIElectricalImpedance Calculator, Crosstalk, Skew, Insertion Loss,Return Loss, Eye DiagramCertificationsISO 9001:2008ISO 14001:2004TS 16949IPC 600/610 CertifiedULV94-0AssemblyThrough Hole, SMT, BGA, Press-Fit, Mechanical HardwarePerimeter Tolerances (millimeters)FeatureSteel Rule DieChemical Milled DieHole to Edge .254 .254Hole to Hole .254N/ACutline .254 .127Cutline to Hole .381 .254Outline Dimensions .254 .127Trace to Edge .254 .127Laser Profile .051 .051 .051 .051 .051 .051Hard Tool DieCNC Drill .051 .051 .127 .051 .051N/A .051 .102CNC Rout .127Order No. 987650-0481 Rev. 7USA/250/MIB/KC/2017.11 2017 Molex

using Flex will naturally be lighter. Design and manufacture customer interconnect solutions Molex flex circuit and connector manufacturing expertise Connector customization to meet application requirements Molex assembly expertise One supplier - complete assembly Full range of flex circuit and assembly technologies One .