Transcription

HIGHWAY CERTIFIED TECHNICIAN PROGRAMTRAINING MANUALConstructionEarthworks

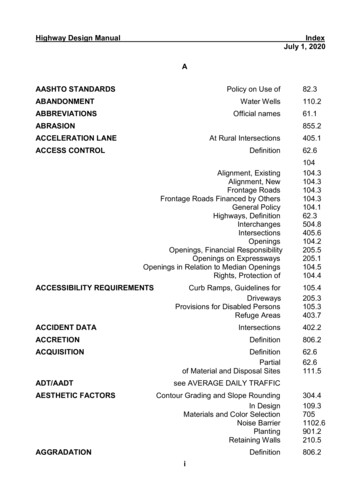

Table of ContentsChapter One -- Right-Of-Way PreparationPreliminary Investigation . Clearing and Grubbing . . .Removal of Structures and Obstructions .Building and Foundation RemovalInspection and Removal of AsbestosBridge RemovalPipe and Sewer RemovalPavement and Miscellaneous RemovalChapter Two -- Soils Identification and ClassificationMaterials . . .2-4Origin and Geology of SoilsSoil ProfilesSoil Composition and TextureSoil ClassificationField Identification and Classification of SoilsRock and Shale Embankment . . .2-14Principal Rock TypesIndiana GeologyRockShale, Shale and Soft Rock Mixtures, or Soft RockOther Embankment and Fill Materials . BorrowB BorrowStructural BackfillRock Backfill2-161-11-21-2

Aggregate Materials . . 2-16Aggregate BasesSubbaseAggregate Pavement or ShouldersSynthetic Materials . 2-17Coal Combustion By-ProductsCrushed GlassRecycled Concrete PavementRecycled Foundry SandChapter Three -- ExcavationCommon Excavation . Submitting SamplesPreparing the IT 530Rock Excavation .Exploratory drillingRock Pre-SplittingExplosivesPrimary BlastingRestrictionsFinished GradeUnclassified Excavation .Waterway ExcavationClass Y ExcavationClass X ExcavationWet ExcavationDry ExcavationFoundation Excavation, UnclassifiedDisposal of Excavated Material . .Suitable MaterialUnsuitable MaterialExcess MaterialBorrow . .Contractor Responsibilities . .Preparing a Borrow Pit . .Peat Excavation . Treatment of Existing FillsTreatment by Removal3-13-33-53-63-73-83-83-9

Treatment by DisplacementPeat DisposalChapter Four -- Excavation Construction RequirementsGeneral Preparation . General Requirements . .Temporary Erosion Control . Lifts . .Equipment . . .HaulingSpreadingCompacting4-14-34-34-44-4Chapter Five -- Embankment ConstructionRock Embankment . Lift RequirementsCompaction MethodsShale and Soft Rock Embankments .Lift and Compaction RequirementsEmbankments on Hillsides and Slopes .Embankment over Existing Roads . .Treatment of Existing Roadbeds .Compaction Control . Settlement Control .5-15-25-35-35-45-55-6Chapter Six -- Measurement and Earthwork CalculationsContract Quantity Payment .Measured Quantity Payment Measurement and Earthwork Calculations . .Cross Sections . Volumes .6-16-26-26-26-3Chapter Seven -- Subgrade ConstructionConstruction Requirements .Fine Grading .Density Testing Proofrolling .Subgrade Treatments .Chemical Modification of Soils .Moisture Control .Drainage .Measurement and Payment .Summary .7-27-27-37-47-47-57-67-77-77-7

Chapter Eight -- FinishingShoulders Ditches Slopes .Earth Graded Roads Final Trimming and Cleaning .Measurement and Payment .8-18-18-18-28-28-3Chapter Nine -- Special Fill and BackfillB Borrow Fill and Backfill .MaterialsFlowable Mortar SubstitutionConstruction RequirementsMechanical CompactionEmbankment for BridgesB Borrow Around BentsAggregate for End Bent BackfillUnbalanced BackfillSpandrel FillingMethod of MeasurementBasis of PaymentFlowable Backfill . ProportioningFlowAverage Penetration ResistanceMixing EquipmentPlacementLimitation of OperationsMethod of MeasurementBasis of Payment9-19-5Chapter Ten -- Aggregate BasesAggregate Base Preparation of SubgradeTemperature LimitationsSpreadingCompactingChecking and Correcting BasePrimingMethod of MeasurementBasis of PaymentSubbase Preparation of subgradeTemperature LimitationsSpreading10-110-2

CompactingChecking and Correcting Base and SurfaceMethod of MeasurementBasis of PaymentAggregate Pavements or Shoulders . Preparation of SubgradeTemperature LimitationsSpreadingCompactingChecking and Correcting BaseDust PalativeMethod of MeasurementBasis of Payment10-4Chapter Eleven – Light Weight DeflectometerOverview . 11-1Using the Light Weight Deflectometer . 11-2Chapter Twelve – Dynamic Cone PenetrometerOverview . .12-1Components .12-2Use of the DCP 12-5Chapter Thirteen -- Family of Curves and One-Point Proctor ProceduresMaximum Dry Density 13-1Family of Curves . 13-1One-Point Proctor 13-2Example Problem 13-2This material is to be used for training purposes only. Some of the procedures, field tests, and otheroperating procedures as described within these pages may be different than actual on-siteprocedures. Therefore, application should not be made without consideration of specificcircumstances and current INDOT standards and policies.

1 Right-of-Way PreparationPreliminary InvestigationClearing and GrubbingRemoval of Structures and ObstructionsBuilding and Foundation RemovalInspection and Removal of AsbestosBridge RemovalPipe and Sewer RemovalPavement and Miscellaneous Removal

CHAPTER ONE:RIGHT-OF-WAY PREPARATIONWhether the work requires widening of an existing pavement section or theconstruction of a new roadway section through a new undisturbed right of way,certain preliminary investigations are required. The PE/PS obtains right of waygrants for all parcels of property purchased for the new work. These alsoinclude grants for temporary right of ways. From the construction plans, allright of way is staked so that the limits of ownership are clearly visible and areasof temporary ownership for construction are known. All INDOT employees andthe Contractor are required to be aware of the limits so that no disputes ariseover work activities outside our property or destroying or disturbing privateproperty. Any work on the right of way has some involvement with public orprivate utilities.PRELIMINARY INVESTIGATIONDuring the completion of the plans, INDOT has already notified all public utilitiesand all pipe line owners or other parties affected so that they may plan to moveand relocate their existing facilities. Delays caused to the Contractor by publicutility companies are reason for time extension and may cause contracts to beextended into another construction season.Existing survey section corners and other survey controlled points and benchmarks are required to be referenced for establishment when the contract iscompleted. The County Surveyor is contacted to obtain the proper location ofall section survey references.Another area of importance is the investigation of existing undergrounddrainage. Farm field tiles placed by farmers are required to be outletted or1-1

continued across the project limits so the drainage is uninterrupted. Legalcounty tiles and ditches are required to be maintained and preserved. ThePE/PS coordinates with the County Surveyor or County Engineer to assure thatall legal county drainage has been located.If the Contractor is required to assist in the investigation of undergrounddrainage by excavation, this excavation is paid for as set out in Section 203.1-1

CLEARING AND GRUBBINGWhen the Contractor arrives at the job-site, one of the first orders of business isto clear the right-of-way in preparation for construction. This work consists ofthe removal and disposal of all vegetation and debris within the limits ofconstruction which is in the way of the construction work. Any items within theright-of-way that are designated to remain in place are not to be disturbed ordamaged by the Contractor.Trees that are encountered within the construction limits may be removed. Ifthe tree stump is cut off level with the ground and is a minimum of 3 ft belowthe final subgrade, the stump may be left in place. If trees are completelyremoved, the roots from the stump are required to be grubbed from the groundaround the old stump. Any holes created in the embankment area are requiredto be backfilled satisfactorily up to the level of the existing ground prior tostarting the new embankment. Burning perishable items may only be done iflocal laws, ordinances, and the contract permit burning. Perishable materialssuch as brush, stumps, and sod are removed from the right-of-way and disposedof at a location approved in advance by INDOT. This approval includes a plan forsite restoration after the contract, and a plan for prevention of streamsedimentation. Written permission to dispose of perishable materials isrequired to also be obtained from the property owner before beginning thedisposal operation (Section 201.03).The measurement and payment of clearing of right of way is a somewhatcomplicated process. Payment may be by the acre, by a lump sum, by length, orby individual units. If tree removal is paid for by an individual unit, the tree ismeasured at a height of 24 in. above the ground. Any tree less than 4 in. indiameter is classified as brush and no payment is made.REMOVAL OF STRUCTURES AND OBSTRUCTIONSMost contracts require removal of structures and obstructions. This includesthe removal and disposal of buildings, fences, structures, old pavement,abandoned pipe lines, and any other obstructions that are not designated in thecontract to remain in place.1-2

BUILDING AND FOUNDATION REMOVALA Contractor is not allowed to begin removing a building without writtenauthority from INDOT.For buildings or houses that are1-2

required to be removed, the Contractor removes the buildings and thefoundations or basement walls to an elevation 1 ft below original ground. Alldebris and trash that is accumulated in a basement or foundation is removed.Any floor drains encountered are plugged, and any basement floors are broken.All public utilities into the building are to be shut off prior to beginning ofdemolition. The Contractor is responsible for notifying the utility companiesinvolved. Basements are backfilled with B Borrow in accordance with Section203.Wells, cisterns, septic tanks, and other tanks are cleaned and backfilled in anapproved manner. Cisterns, septic tanks, and other tanks that cannot besatisfactorily backfilled are removed. All abandoned wells are sealed andbackfilled in accordance with Indiana code.INSPECTION AND REMOVAL OF ASBESTOSThe contract documents will contain information on if the building containsasbestos. All State, Federal and Local regulations are required to be followed incleaning up the hazardous materials.BRIDGE REMOVALClearing of the right-of-way may include the removal of bridges, culverts, andother drainage structures. Bridge foundations are removed to the existingstream bed, and those portions outside the stream bed are removed 1 ft belowthe original ground. The removal of a reinforced concrete arch includes theremoval of all of the pavement and backfill of the arch.Blasting should only be used in the demolition of bridges if allowed by Localordinances. When a portion of a bridge structure is removed to widen anexisting structure, care is taken not to damage the portion of the existingstructure to remain in place. If specified, broken up concrete from bridgeremoval may be used as riprap on the contract.1-3

PIPE AND SEWER REMOVALMaterials not specified to be salvaged become the property of the Contractor.Sanitary and storm sewers no longer in use are removed from under theroadway and shoulders.1-3

PAVEMENT AND MISCELLANEOUS REMOVALWhen the removal includes concrete pavement, sidewalks, curbs, and othermiscellaneous concrete items, this concrete may be broken into pieces andused as riprap on the contract or disposed of off the right-of-way. Pavementremoval includes the concrete pavement and all HMA overlay courses onexisting public roads, streets, and alley pavements. Parking lots anddriveways are not considered pavement removal. When a portion ofpavement is removed, the limits of removal are marked and sawed alongthese limits to assure a smooth line of removal. Any portion that is damagedoutside the removal lines is replaced at the Contractor’s expense. Sawing ofpavement to be removed is not paid for directly, but is included in the cost ofpavement removal.

2 MaterialsMaterialsSoil Composition and TextureSoil ClassificationField Identification and Classification of SoilsRock and Shale EmbankmentPrincipal Rock TypesIndiana GeologyRockShale, Shale and Soft Rock Mixtures, or Soft RockOther Embankment and Fill MaterialsBorrowB BorrowStructural BackfillRock Backfill

Aggregate MaterialsAggregate BaseSubbaseAggregate Pavements or ShouldersSynthetic MaterialsCoal Combustion By-ProductsCrushed GlassRecycled Concrete PavementRecycled Foundry Sand

CHAPTER TWO:MATERIALSAll materials used in the construction of highway embankments, fills,subgrades, and subbases originate from the Earth. Most of these materialsare natural in origin, i.e. they are the result of geologic processes that occurnaturally as opposed to synthetic materials which are the result of industrialprocesses (i.e. slag, flyash). This chapter focuses on the natural earthmaterials.Earth materials consist of two types: soil and ro

This material is to be used for training purposes only. Some of the procedures, field tests, and other operating procedures as described within these pages may be different than actual onsite - procedures. Therefore, application should not be made without consideration of specific circumstances and current INDOT standards and policies. 1 Right-of-Way Preparation . Preliminary Investigation .