Transcription

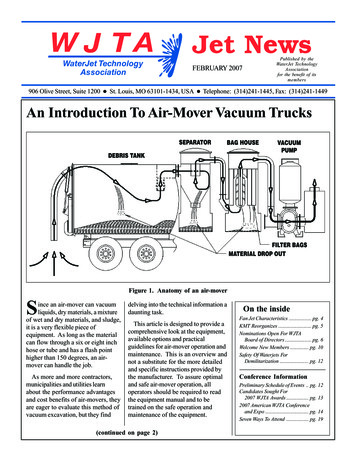

FEBRUARY 2007Published by theWaterJet TechnologyAssociationfor the benefit of itsmembers906 Olive Street, Suite 1200 l St. Louis, MO 63101-1434, USA l Telephone: (314)241-1445, Fax: (314)241-1449An Introduction To Air-Mover Vacuum TrucksFigure 1. Anatomy of an air-moverSdelving into the technical information adaunting task.As more and more contractors,municipalities and utilities learnabout the performance advantagesand cost benefits of air-movers, theyare eager to evaluate this method ofvacuum excavation, but they findThis article is designed to provide acomprehensive look at the equipment,available options and practicalguidelines for air-mover operation andmaintenance. This is an overview andnot a substitute for the more detailedand specific instructions provided bythe manufacturer. To assure optimaland safe air-mover operation, alloperators should be required to readthe equipment manual and to betrained on the safe operation andmaintenance of the equipment.ince an air-mover can vacuumliquids, dry materials, a mixtureof wet and dry materials, and sludge,it is a very flexible piece ofequipment. As long as the materialcan flow through a six or eight inchhose or tube and has a flash pointhigher than 150 degrees, an airmover can handle the job.(continued on page 2)On the insideFan Jet Characteristics . pg. 4KMT Reorganizes . pg. 5Nominations Open For WJTABoard of Directors . pg. 6Welcome New Members . pg. 10Safety Of Waterjets ForDemilitarization . pg. 12Conference InformationPreliminary Schedule of Events . pg. 12Candidates Sought For2007 WJTA Awards . pg. 132007 American WJTA Conferenceand Expo . pg. 14Seven Ways To Attend . pg. 19

Safety Committee SolicitsComments OnImprovements ToRecommended PracticesThe WJTA Safety Committeehereby solicits commentsregarding improvements to thepublication, Recommended Practicesfor the Use of Manually OperatedHigh Pressure WaterjettingEquipment. While RecommendedPractices is reviewed periodically atthe biennial conferences of theWaterJet Technology Association, yourcomments and suggestions forimproving the publication are invitedand welcome anytime.Please address your comments andsuggestions to: Safety Committee, c/oWJTA, 906 Olive Street, Suite 1200,St. Louis, MO 63101-1434, phone:(314)241-1445, fax: (314)241-1449,e-mail: wjta@wjta.org, web site:www.wjta.org.WJTA AdministrationChairman of the BoardJohn Wolgamott(970)259-2869President/Jet News EditorGeorge A. Savanick, Ph.D.(952)432-7594TreasurerLarry Loper(800)289-7447Vice-PresidentPat DeBusk(281)842-8000An Introduction To Air-Mover Vacuum Trucks, from page 1Anatomy of An Air-MoverAn air-mover is referred to by anumber of names such as a wet/dryvacuum truck or even by the names ofmajor air-mover manufacturers suchas Supersucker manufactured bySuper Products LLC or FederalSignal’s Guzzler . A typical airmover in today’s market has a highvacuum 27-28 inch dual lobe or trilobe high air flow (5000-6000 cfm)vacuum pump. It also has a 16-18cubic yard tank, cyclone separator andbaghouse with filter bags.An air-mover uses a combination ofvacuum and air flow to conveymaterial. It uses just enough vacuumto lift the material into the air flowthen let the air flow carry the material.To understand how to operate andmaintain an air-mover, it is essential tolearn about the air flow and filtrationof the equipment. Most air movershave four (4) stages of filtration toremove material from the air flow.Figure 1 (below and on page 1) showsthe air flow of a typical moderndesigned air-mover.Secretary(position open)2005-2007 DirectorsLydia M. Frenzel, Ph.D.(512)392-2210Hugh B. Miller, Ph.D.(520)621-4689Mohamed Hashish, Ph.D.(253)850-3500Carl Olsen(253)872-2300Bill McClister(713)307-2142Forrest Shook(248)624-5555Emeritus MembersAndrew F. Conn, Ph.D.(410)532-3452Thomas J. Labus(262)245-9702Thomas J. Kim, Ph.D.(401)874-5991Fun-Den Wang, Ph.D.(303)279-9415Association ManagersMark S. Birenbaum, Ph.D. l Kenneth C. Carroll(314)241-1445Page 2the center of the separator (seeFigure 2).Figure 2.The air flow leaves the cycloneseparator and goes to the third stageof filtration, the baghouse. Thebaghouse normally contains acryliccoated bags to handle wet or drymaterial. The bags filter out materialgreater than one micron as air flowsthrough the bags. From the baghouse,the air flows through a final filterscreen (stage 4) then through thevacuum pump and out the exhaustsilencer.Performance EnhancingOptionsFigure 1.Note the air flow going through thehose or tube into the debris tankwhere the air flow slows downallowing most of the material to dropinto the tank. (stage 1) From the tank,the air flows into a cyclone separator(stage 2) where the air flow spinsallowing centrifugal force to separatematerial from the air as the air exitsTo enhance air-mover performance,there are a number of optionsavailable to meet application-specificneeds.Hydraulic BoomThis is an ideal tool for vacuumingmaterial out of a trench or sewer, orwhen it is necessary to reach over awall or fence. It allows the user to(continued on page 7)WJTA on the web: www.wjta.orgFebruary 2007

Fan Jet CharacteristicsShimizu* recently published apaper on the subject of structureand erosive characteristics of fan jets.Here are the highlights.material. The erosiveintensity is fairly evenwhen the jet operatesimmediately downstreamof the liquid sheet andthen gradually becomesuneven as the distanceincreases. The erosivepower of a moving fanjet is also the highestimmediately downstream ofthe liquid sheet. Shown in thepicture is the topography of adamaged mild steel specimenby a moving fan jet at 300MPa and 400 mm/min, witha standoff of 20 mm.* Shimizu, S. (2006) Structure and erosivecharacteristics of water jet issuing from fan jetnozzle, in Peter Longman (Ed.), Proceedingsof the 18th International Conference on WaterJetting, Gdansk, Poland, September 2006, pp337-345.Fan jets were produced with nozzleslike the one shown in the picture. Thisnozzle has a conical convergent inletsection with a 84 convergent angle.The outlet face of the nozzle has a 52 triangular notch. In the center is anelliptic hole with major/minordiameters of 0.43 mm/ 0.33mm (for anominal diameter of 0.33 mm nozzle).Instantaneous photographs of thefan jets, with pressure varying from 70to 300 MPa, were taken from twodirections with an exposure time of 1.5microseconds. The jet shown in thepicture was at pressure 300 MPa. Ithas a spreading angle ofapproximately 24 . Below a region oftransparent liquid sheet is a regionwith streak structures of waterdroplets, where practical coatingremoval takes place.A stationary fan jet produces a linesegment type of damage on the targetPage 4Article reprinted with permission from theQuality Waterjet Newsletter, December 5,2006, published by QualJet LLC,www.qualjet.com.Jet Edge Releases New PrecisionWaterjet Cutting Product BrochureJet Edge, Inc., a leadingmanufacturer of ultra-highpressure waterjet and abrasivejetsystems for precision cutting,coating removal and surfacepreparation, recently released a newbrochure highlighting its precisionwaterjet cutting products.The new brochure features JetEdge’s ultra-high pressure intensifierpumps which are rated for 60,000psi (4,100 bar), as well as itsprecision cutting systems, whichinclude an expandable high-railgantry, a mid-rail gantry and anabrasive machining center. Thebrochure also highlights Jet Edge’sAquaVision Di motion controller andprecision cutting accessories thatinclude cutting heads, abrasivedelivery, removal and recyclingsystems, and a closed loop polisher.To request a brochure, call 1-800JET-EDGE (538-3343) or e-mailsales@jetedge.com.The Jet News is published by the WaterJet Technology Association(WJTA) and is a benefit of membership in the Association. 2007 Jet News. All rights reserved. Reproduction in any form forbidden without express permission.WJTA on the web: www.wjta.orgFebruary 2007

KMT ReorganizesDue to the recent acquisitions of RPT and H2O Jet,as well as the new joint-venture KMT SpindleTechnology, KMT introduces a new organization basedon four business areas. In connection with the neworganization, KMT also presents a new managementstructure. The new structure was effective January 1,2007.KMT will be organized in four Business Areas asfollows:KMT Waterjet, includes:-KMT Waterjet Systems, Baxter Springs, USAKMT Aqua-Dyne, Houston, USAKMT McCartney, Baxter Springs, USAKMT H2O, Olympia, USAKMT Precision Grinding, includes:-KMT UVA, Bromma, SwedenKMT Lidköping, Lidköping, SwedenKMT NanoGrinder, Lidköping, SwedenKMT LMV, Lidköping, SwedenKMT Spindle Technology, Wafangdian, ChinaKMT Robotic Systems, includes:- KMT RPT, Auburn Hills, USA- KMT Cutting Systems, Ronneby, SwedenKMT Sheet Metal Working, includes:- KMT Ursviken, Ursviken, Sweden- KMT Herber, Värnamo, SwedenIn connection with this change, KMT introduces a newGroup Management consisting of:Lars Bergström, Chief Executive OfficerJoakim Roslund, Chief Financial OfficerPer-Olof Jungqvist, Technical DirectorDuane Johnson, President Business Area KMTWaterjetKevin McManus, President Business Area KMTRobotic SystemsJohan Westberg, President Business Area KMTPrecision GrindingLars Bergström (CEO), President Business Area KMTSheet Metal WorkingFor more information, please contact Lars Bergström,CEO, Karolin Machine Tool AB, Telephone: 46 8 594211 50 or e-mail: lars.bergstrom@kmtgroup.comPage 5

Nominations Open For WJTA Board Of Directorsominations for the WaterJet Technology Association(WJTA) Board of Directors are now open. The duties ofthe directors are truly challenging and rewarding.NThe terms of office of Craig Anderson, Pat DeBusk, LydiaFrenzel, Ph.D., Larry Loper, Forrest Shook, and JohnWolgamott will expire in August 2007. In addition, the recentresignation of Dr. David Summers from the board has resultedin a seventh open position. Therefore, nominations are soughtfor seven (7) board members. Six (6) board members will beelected to serve a four-year term of office beginning August17, 2007. The candidate receiving the seventh highest numberof votes will be elected to complete Dr. David Summers’unexpired term of office and will serve the remaining two yearsof the four-year term ending August 2009.The WJTA bylaws provide that no more than one of theelected board members may be from the same company ororganization. Therefore, board members may not benominated from the same company or organization alreadyrepresented on the board by individuals whose terms expire in2009, including the Colorado School of Mines (Hugh B. Miller,Ph.D.), Flow International Corporation (Mohamed Hashish,Ph.D.), OMAX Corporation (Carl Olsen), and VeoliaEnvironmental Services (Bill McClister).According to the WJTA bylaws, anyWJTA member in good standing (2006membership dues paid) may submit anomination(s). A nominee who has notpaid his/her dues by March 31, 2007,shall be declared ineligible to run foroffice in the 2007 election. Thedeadline for making nominations isMarch 31, 2007. Your nomination(s)should reach the WJTA office no laterthan March 31, 2007.To submit a nomination(s),complete the Nomination Form andreturn, along with biographicalinformation and a brief statement ofyour nominee’s mission and visionfor WJTA, to:Nominations/Elections ProceduresIn accordance with the bylaws of the WaterJet TechnologyAssociation, revised in 2002, nominations and elections to theBoard of Directors include the following procedures:l At least two calls for nominations to the board ofdirectors will be published in the Jet News. The first callfor nominations appears in this issue. Nominationswill be accepted through March 31, 2007.l An official ballot listing the eligible nominees and a briefbiographical sketch for each individual will then beforwarded by mail to all eligible voting members ofthe Association on May 28, 2007. Signed and executed ballots must be mailed to the Association’soffice for tallying by June 25, 2007.l The names of newly elected board members will beannounced in the Jet News and on the WJTA web site.Only WJTA members in good standing (2006 membershipdues paid) may submit a nomination(s). A nominee who hasnot paid his/her dues by March 31, 2007, shall be declaredineligible to run for office in the 2007 election.WaterJet TechnologyAssociationNomination FormName Of Nominee TitleAddressCity StateCountry Postal CodeTelephoneIn US/Can ( ) Outside US/Can [ ] ( )(area code)[country code] (city code)FaxIn US/Can ( ) Outside US/Can [ ] ( )(area code)[country code] (city code)Attach biographical information with a brief statement ofyour nominee's mission and vision for WJTA.Name Of Nominator TitleAddressWJTA Administrative Office906 Olive Street, Suite 1200St. Louis, MO 63101-1434phone: (314) 241-1445fax: (314) 241-1449.Remember, nominations must bereceived no later than March 31,2007.City StateCountry Postal CodeTelephoneIn US/Can ( ) Outside US/Can [ ] ( )(area code)In US/Can ( ) Outside US/Can [ ] ( )(area code)Page 6[country code] (city code)FaxWJTA on the web: www.wjta.org[country code] (city code)February 2007

An Introduction To Air-Mover Vacuum Trucks, from page 2Body Pressurization/ Auxiliary VanePumpPneumatic UnloadingWhen an application requires liquidsto be blown out of the body, a vanepump can be added to pressurize thebody. Typically this is set at amaximum of 13 psi. The vane pumpcan also be used as an auxiliaryvacuum pump so it can operate as aliquid vacuum.An air-mover can be equipped witha pneumatic unloading option to

KMT will be organized in four Business Areas as follows: KMT Waterjet, includes: - KMT Waterjet Systems, Baxter Springs, USA - KMT Aqua-Dyne, Houston, USA - KMT McCartney, Baxter Springs, USA - KMT H2O, Olympia, USA KMT Precision Grinding, includes: - KMT UVA, Bromma, Sweden - KMT Lidköping, Lidköping, Sweden - KMT NanoGrinder, Lidköping, Sweden