Transcription

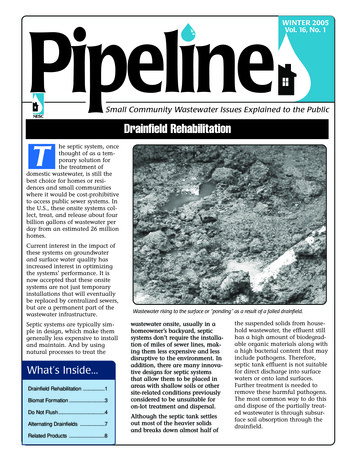

WINTER 2005Vol. 16, No. 1Small Community Wastewater Issues Explained to the PublicDrainfield RehabilitationThe septic system, oncethought of as a temporary solution forthe treatment ofdomestic wastewater, is still thebest choice for homes or residences and small communitieswhere it would be cost-prohibitiveto access public sewer systems. Inthe U.S., these onsite systems collect, treat, and release about fourbillion gallons of wastewater perday from an estimated 26 millionhomes.Current interest in the impact ofthese systems on groundwaterand surface water quality hasincreased interest in optimizingthe systems’ performance. It isnow accepted that these onsitesystems are not just temporaryinstallations that will eventuallybe replaced by centralized sewers,but are a permanent part of thewastewater infrastructure.Septic systems are typically simple in design, which make themgenerally less expensive to installand maintain. And by usingnatural processes to treat theWhat’s Inside.Drainfield Rehabilitation .1Biomat Formation .3Do Not Flush.4Alternating Drainfields .7Related Products .8Wastewater rising to the surface or “ponding” as a result of a failed drainfield.wastewater onsite, usually in ahomeowner’s backyard, septicsystems don’t require the installation of miles of sewer lines, making them less expensive and lessdisruptive to the environment. Inaddition, there are many innovative designs for septic systemsthat allow them to be placed inareas with shallow soils or othersite-related conditions previouslyconsidered to be unsuitable foron-lot treatment and dispersal.Although the septic tank settlesout most of the heavier solidsand breaks down almost half ofthe suspended solids from household wastewater, the effluent stillhas a high amount of biodegradable organic materials along witha high bacterial content that mayinclude pathogens. Therefore,septic tank effluent is not suitablefor direct discharge into surfacewaters or onto land surfaces.Further treatment is needed toremove these harmful pathogens.The most common way to do thisand dispose of the partially treated wastewater is through subsurface soil absorption through thedrainfield.

Drainfield RehabilitationSeptic systems were never intendedfor lifetime use without maintenance. Neglecting maintenanceof system components only leadsto failures. When properlydesigned, installed, and maintained, septic systems have aminimum life expectancy of20 to 30 years.The U.S. EnvironmentalProtection Agency (EPA) OnsiteWastewater Treatment SystemsManual (2002) defines systemfailure as “a condition where performance requirements are notmet.” Typically, failures aredeclared when wastewater isobserved on the surface of theground or is backing up into thehousehold plumbing.When a septic system fails, it canpollute nearby water resourcesand endanger public health.Children are most susceptible tothese health problems becausethey very often come into contactwith the contaminated areas.Pipeline is published quarterly by theNational Environmental Services Centerat West Virginia University,P.O. Box 6064, Morgantown, WV 26506-6064Pipeline is funded through a grant from theU.S. Environmental Protection AgencyWashington, D.C.Steve Hogye—Project OfficerMunicipal Support DivisionOffice of Wastewater ManagementRick Phalunas — Interim Division ManagerMarilyn Noah — EditorJennifer Hause — Technical AdvisorEd Winant PE — Technical AdvisorJohn Fekete — Senior Graphic DesignerJamie Bouquot — Graphic DesignerPermission to quote from or reproduce articles inthis publication is granted when due acknowledgement is given.Please send a copy of the publication in which informationwas used to the Pipeline editor at the address above.an equal opportunity/affirmative action institutionISSN 1060-0043The contents of this newsletter do not necessarily reflect the views and policies ofthe U.S. Environmental Protection Agency, nor does the mention of trade namesor commercial products constitute endorsement or recommendation for use.Printed on recycled paperThere's really not all that muchthat is going to go wrong withthe septic tank itself as long as itis watertight and pumped on aregular basis. (Table 1 givesapproximate pumping frequencies.). However, what usually failsis the soil absorption system.The soil absorption system, ordrainfield, is an arrangement ofperforated pipes or chambersburied underground that channelthe pre-treated wastewater—theliquid discharge (effluent) fromthe septic tank—out over a largearea of the soil. The effluent thenmoves slowly down through thesoil to become naturally purifiedbefore returning to the aquifer.The drainfield acts as a naturalfilter for effluent by absorbingthe organic materials, reducingor removing bacteria and viruses,and removing some nutrients.Table 1.Estimated septic tank pumping frequencies in years.These figures assume there is no garbage disposalunit in use. If one is in use, pumping frequency mayneed to be increased.Household Size(number of 509.14.22.61.81.31.0900 11.05.23.32.31.71.31000 12.45.93.72.62.01.51250 15.67.54.83.42.62.01500 18.99.15.94.23.32.61750 22.1 10.76.95.03.93.12000 25.4 12.48.05.94.53.72250 28.6 14.09.16.75.24.22500 31.9 15.6 10.27.55.94.8The most obvious sign of drainfield failure is surfacing effluent.If the soils can no longer acceptthe effluent being delivered, theeffluent will either rise to theground surface, or ‘blow out’ atthe end of the last trench. Eitherof these two events should alertthe homeowner that there is aproblem.(Source: Pennsylvania State University CooperativeExtension Service.)The reason the soil can no longeraccept the pre-treated effluent ismost often because of the biomat.As the effluent or pre-treatedwastewater enters the drainfield,bacteria in the soil begin to thriveon the new food source. As thesebacteria grow, they form a thickslimy colony called the biomatthat restricts the flow of effluentto the surrounding soil. (See sidebar on page 3.)Causes of failureCauses for failure are many andvaried—ranging from impropersiting, design, or construction,to the simple overuse of watergenerating appliances. It is vitalthat the exact cause for thefailure is determined beforeattempting any remediationto the system.The suggested process for correcting system failure is to gatherinformation about the system,determine the cause of failure,and design the corrective action.These steps will be discussed indetail in this issue of Pipeline.Drainfeld failure can be caused bymany things, including excessiverainfall, tree roots interfering withthe drainlines, or vehicles drivingover the system and crackingpipes. But the two most commoncauses are: hydraulic and biological overloading. Hydraulic overloading occurs when too muchwater is sent to an under-designedsystem. Biological overloading isthe result of too much organicmatter in the effluent.The initial design of a system isbased on soil and site characteristics, including depth to groundwater or bedrock. Part of the designincludes the system’s capacity thattakes into account the number ofpeople living in the home.2PIPELINE – Winter 2005; Vol.16, No.1National Environmental Services Center (800) 624-8301 or (304) 293-4191

Drainfield RehabilitationCapacity is usually based on thenumber of bedrooms in the home,but this may not be an accurateway to determine flow generation.Extra people or the addition of ahot tub, for instance, can quicklycreate more wastewater than thesystem and drainfield can handle.The addition of appliances, suchas garbage disposals and dishwashers, can greatly change thequality of the wastewater sent tothe system. These appliancessend increased amount of solidsto the system, possibly causingbiologic overloading. Use theseappliances in moderation, keeping in mind that a garbage disposal is not a waste receptacle.Many local and state regulatoryauthorities require onsite systemsto be sized larger to handle theadditional load from such appliances as a garbage disposals.Check with your local healthdepartment or permitting authority to see if this is the case in yourarea. Telephone numbers of suchagencies are normally listed inthe government or blue pages ofthe local telephone directory.Septic system failure can alsoresult from: Overloading with water.Homeowners should avoid putting too much water into thesystem at one time; staggerlaundry loads throughout theweek rather than having a‘wash day’ where you might doall the laundry within a 24-48hour period. Divert your hottub away from your onsite system when draining it. Discarding decay-resistantmaterials into the system suchas grease, sanitary napkins,and other solids. Allowing tree roots to clog ordestroy the absorption system. Compacting soil over the drainfield. Avoid driving or parkingvehicles over the drainfield.Biomat FormationAs the effluent is discharged intothe soil absorption system, bacterial growth develops beneaththe distribution lines where theymeet the gravel or soil. This layeris known as the clogging mat,clogging zone, biocrust, and biomat. This biomat (biological mat)is a black, jelly-like layer thatforms along the bottom and sidewalls of the drainfield trench. Thisclogging zone reduces infiltrationof the wastewater into the soils.The biomat is composed ofanaerobic microorganisms (andtheir by-products) that anchorthemselves to soil and rock particles. Their food is the organicmatter in the septic tank effluent.Less than one centimeter to several centimeters thick, the biomatacts as the actual site for effluenttreatment.The biomat forms first along thetrench bottom near the perforations where the effluent is discharged, and then up alongtrench walls. It is less permeablethan fresh soil, so incomingeffluent will move across the biomat and trickle along the trenchbottom to an area where there islittle or no biomat growth. (Seegrowth pattern diagram below.)Biomats tend to restrict the flowof effluent through the drainfield,but are crucial because they filterout viruses and pathogens. Asthe biomat develops, the soilinfiltration rate decreases. Oncethe hydraulic loading rateexceeds the soil infiltration rate,ponding starts. At some pointwastewater will either back upinto the home or break out on tothe soil surface.Biomat formation cannot, andshould not, be prevented, butseptic tank filters, proper organicloading, and proper maintenanceof the septic tank can slow therate at which it forms. Septictank filters prevent excess suspended solids from flowing intothe drainfield and can be retrofitted to existing systems.Other maintenancethat should be performed on the septic system includeshaving the systeminspected and thetank pumped at regular intervals.Pumping the tankallows it to bettersettle out solids,also reducing theorganic load to thedrainfield. (The Fall2004 Pipeline provides detailedguidelines for septicsystem maintenance.)3PIPELINE – Winter 2005; Vol.16, No.1National Environmental Services Center (800) 624-8301 or (304) 293-4191

Drainfield Rehabilitation Age of the system. Septic systems are designed for an operational life of 20 to 30 years. Ifyou have an aging system, itmay be time to inspect andreplace it.The Correction ProcedureWhen an onsite system fails it isimportant to gather specificinformation about the system inorder to diagnose the problemand determine the appropriatecorrective action.Initial data gathering Visual observation of the failureshould be made to confirm theproblem. All system componentsshould be inspected, and anymechanical components (suchas float switches and flow diverters) should be tested by a qualified/certified system inspector.Do Not Flush. Coffee grounds Dental floss Disposable diapers Kitty litter Sanitary napkins Tampons Cigarette butts Condoms Fat, grease, or oil Paper towels Unused household cleaningsolutions or pharmaceuticalsOr hazardous chemicals such as: Paints Varnishes Thinners Waste oils Photographic solutions PesticidesThese items can overtax or destroy the biological digestion taking place within your system.4PIPELINE – Winter 2005; Vol.16, No.1 A complete history of operationand maintenance of the systemshould be reviewed. Frequently,a study of the past three to fiveyears of operation and maintenance will reveal a possibleproblem. The correction maybe as simple as pumping thetank or cleaning a tank filter. Obtain a copy of the originalpermit and any updates. Thispermit will contain a layout ofthe system from a site survey ordrawings of the original design. Determine approximate loading rates from the originaldesign and permit. Soil test results should bereviewed. If soil test results arenot included in the permit, soilsamples should be taken todetermine the soil profile and tolocate any soil boundaries thatmay be present. The age of system should also be determined. Obtain a complete report of thesymptoms of failure. For example, surfacing effluent abovethe drainfield suggests that thesoil may be overloaded, eitherwith too much total water orthat the water has inappropriate amounts of organic matterthat has clogged the soil pores.Additionally, if the failure isseasonal, wet weather conditions are likely to be the cause. Determine the amount ofwastewater entering the system.Using data from the dwelling’swater meters, actual flow (evenif estimated) is then comparedto the design loadings. This willyield a good approximation ofhow much wastewater is entering the wastewater system.Leaking plumbing fixtures willskew this number causing morewater to enter the system. Thus,all leaking fixtures must berepaired.Determining the causeFrom the information gatheredthrough the above steps, ideasabout the potential causes offailure should come to light. Itmight be necessary to do someadditional steps to test the ideabefore any corrective actions aretaken. Wastewater metering ortesting, equipment testing andmonitoring, or additional soiltesting might help more clearlydefine the cause of the systemfailure.Repair permits may be requiredbefore any corrective actionbegins. Contact your local healthdepartment or permitting agencyto find out what is required toobtain such a permit.Remediation techniquesThere are various repair or remediation techniques that may beconsidered, depending on theinvestigation into the causes offailure as described above, economic considerations, and theflexibility of the local permittingentities. State and local statutesvary as to what technologies arepermitted. Homeowners mustwork closely with their localhealth departments or permittingauthorities to make the bestchoice for their individual situation.Short-term solutionsIf the neighborhood is soon toreceive public sewerage, it mightbe practical to use a short-termtechnique such as water conservation. But conservation andother management techniquesare only part of most solutions.Drainfield failure must be considered a serious health hazard andas such, should be taken care ofwith long-term goals in mind.Sometimes the overloaded drainfield can recover if a strict policyof water conservation is observedby the homeowner. After pumping the septic tank and replacingwater-guzzling appliances withmore efficient ones, repairingleaking fixtures, staggering showers and clothes washing times toreduce the output of effluentIf the soil around the piping isallowed to dry out, it may beable to function properly onceagain. This method obviouslyrequires a good deal of home-National Environmental Services Center (800) 624-8301 or (304) 293-4191

Drainfield Rehabilitationowner commitment. It usuallytakes a 30 percent reduction inwater use to allow the drainfieldto recover.In cases of physical damage, system restoration may only requirethe leveling of the distribution boxor repairing crushed or brokenpipe. If tree roots are interferingwith the operation of the soilabsorption field, they can beremoved. Broken or deterioratedbaffles in the septic tank can allowsolids to go to the drainfield; theseshould be replaced or repaired.There are now some new technologies that may provide temporary relief to drainfield failure.The first is “jetting,” a procedurethat utilizes special pumps toinject high-pressure water into thedrainlines to break up silt depositsand other solids, coupled withpowerful vacuum lines that suckthe broken-up solids out of thelines before they can settle again.If the problem stems from poor orcompacted soil, hope may comein the form of another new-technology solution known as “soilfracturing.” Highly specializedequipment uses a pneumatichammer to drive narrow probesdown into the soil of the drainfield, typically to a depth ofbetween three and six feet.Air is then forced into the soil ata controlled rate, which fracturesthe hard soil and creates tinyopen channels through it. Next,polystyrene pellets are injectedinto the newly aerated soil,which keeps the passages open sothe soil will not simply compactagain. This technology has metwith mixed results and is onlyapproved by certain states. It isvery important to check withyour local health officials to findout what similar process (if any)is approved for your situation.Some of these more extreme procedures may provide some temporary relief for a failing systemthat is soon to be replaced orconnected to a municipal system.PIPELINE – Winter 2005; Vol.16, No.1Damaged, waterlogged areas in the lawn over the drainfield indicate drainfield system failure.In many states, the process fallsbetween the regulatory crackswhether or not it is a repair andrequires a repair permit.Long term solutionsIn some cases, corrective measures are not enough; a new soilabsorption system must be constructed. New soil absorptionsystems can be placed either inan isolated area so the oldsystem is not disturbed in theprocess or in between the existingtrenches if there is adequateroom. These additional lines areconsidered part of an alternatingdrainfield system.A diversion valve is installed sothat in the future it will be possible to direct the flow from theseptic tank to either of the soilabsorption systems. After the newdrainfield is in place, the flow isdiverted from the old field thatwill slowly rejuvenate itself andbe available for use in the future.The rejuvenation process takesabout two years and involvesnaturally occurring organisms,which decompose the cloggingmat that has formed and returnthe absorptive system to nearoriginal capacity. (The old drainfield can recover faster if a septicTable 2Signs of impending drainfieldfailure: Sluggish drains and toilets in thehome Odor of sewage in the houseand/or outdoorsSigns that drainfield failurehas occurred: Sewage backing up into the home Ponding in the yard above ornear the drainfield Soil sinking or collapsing overany part of the systemtank pumper can open the fieldand remove as much of theponded wastewater as possible.)After a replacement system hasbeen installed, a homeownershould switch back to the olddrainfield after two years, andthen switch back and forthbetween the two systems annually.This will result in a continuousNational Environmental Services Center (800) 624-8301 or (304) 293-41915

Drainfield Rehabilitationless than 10-15 mg/L, comparedto typical septic tank effluentwith suspended solids in therange of 100-250mg/L).Figure 1Interlacing Drainfield Systemuse and rejuvenation cycle forboth drainfields and should prevent future failures. An observation tube in each drainfield maybe used to monitor the conditionof the drainfields and can helpthe homeowner determine thefrequency of alternating betweenthe two fields.If an adequate area for a newsystem does not exist and the oldsystem is a trench system with atleast six feet of undisturbed soilbetween the trenches, it is possible to install new replacementtrenches interlaced between theold ones. However, the plumbingfor the new and old system mustbe entirely separate so that whenone is in operation the other hasthe opportunity to completely dryout. (See Figure 1.)Another option to reduce theorganic load on the drainfield isby adding an advanced treatment system such as an aerobictreatment unit or a sand filter.Two previous issues of Pipelinedescribe these two technologies:Sand Filters (Summer 1997) andHome Aerobic Treatment Units(Winter 1996).Sand filters and aerobic treatment units (ATUs) are systemsthat use natural processes to treatwastewater and are frequentlyused to renovate biologicallyclogged, failing septic tank-soilabsorption units.6PIPELINE – Winter 2005; Vol.16, No.1Typically, sand filters are used asthe second step in wastewatertreatment after the septic tankwhere solids in raw wastewaterhave been separated out.Constructed of a bed of sandabout two or three feet deep andoften contained in a liner, sandfilters receive the partially treatedeffluent in intermittent doses.The effluent slowly tricklesthrough the media and is collected in an underdrain and flows tofurther treatment and/or disposal.Sand filters are very effective atremoving high levels of suspended solids and are capable of handling heavy hydraulic loads.These two qualities make themparticularly useful in cases ofdrainfields that have been overloaded either hydraulically orbiologically.Aerobic treatment units are similar to septic tanks in that theyuse natural processes to treatwastewater, but unlike septictreatment, the ATU processrequires oxygen. ATUs use amechanism to inject and circulate air inside the treatmenttank. Bacteria that thrive inoxygen-rich environments workto break down and digest thewastewater inside the aerobictreatment unit.Aerobically treated effluent isdefined as effluent exiting aproperly operating ATU or sandfilter. This additional step reducesthe amount of total suspendedsolids (suspended solids value ofIn situations where the soilabsorption units have failed dueto an excessive biomat formation, aerobic effluent reduces thesymptoms. (Several states allowsystems that are failing due toclogging biomat to be renovatedusing aerobically treated effluent,provided the site meets separation requirements between theaggregate/soil interfaces and limiting conditions of high watertable or bedrock.)ReferencesU.S. Environmental ProtectionAgency Onsite WastewaterTreatment Systems Manual, 2002.EPA/625/R-00/008.A Manual for Managing SepticSystems, Sussex County PlanningDept. and New Jersey DEP & E,February, 1994. (#WWBKOM41)Winneberger, John H., et al.“Biological Aspects of Failure ofSeptic-Tank Percolation Systems”University of California, Berkeley,August 1960. (#L000436)Converse, James C. and E. JerryTyler. “Aerobically TreatedDomestic Wastewater toRenovate Failing Septic Tank-SoilAbsorption Fields.” 8th NorthwestOn-site Wastewater TreatmentShort Course and EquipmentExhibition Proceedings, 1995.(#L004343)Stuth, William L. and MatthewM. Lee. “Recovery of FailingDrainfields and a Sand MoundUsing Aerobic Effluent.” 9thNational Symposium onIndividual and SmallCommunity Sewage Systems,2001. (#L006854)“NSFC Q&A: Drainfield Cloggingand Rehabilitation.” Small FlowsQuarterly, Spring 1999; Volume13, No. 2., page 20.Items with # codes areavailable from the NESC at(800) 624-8301.National Environmental Services Center (800) 624-8301 or (304) 293-4191

Drainfield RehabilitationAlternating Drainfields Provide Relieffor a Failing SystemWhen Dr. Todd Crocco saw wet,smelly sewage surfacing in hisfront yard, he knew that he hada problem. His 10-year-old septicsystem was failing. Crocco, aMorgantown, West Virginia resident, contacted the NationalEnvironmental Services Center.When engineering scientists EdWinant, Jennifer Hause, andAndrew Lake visited Crocco’shome to assess the situation, theydetermined that the serial drainfield was failing. Winant saidthat serial drainfields are common in West Virginia where theground is sloped.“You are only using one trench ata time, because once a trenchhas failed, it’s not treating anymore water. When there isnowhere else for it to go, it comesto the surface,” Winant said. “Aserial drainfield is always goingto fail eventually.”NESC engineers found that thebest solution to Crocco’s problemwas an alternating drainfield. Asecond drainfield was installedwith three separate lines withdistribution boxes to evenly distribute the flow. Modificationswere made to the first drainfieldby replacing the overflows withgravity manifold and distributionboxes.A layout of the second drainfield. A serial drainfield consists of aseries of trenches. The first trenchcomes out of the septic tank andhas an overflow pipe that leadsfrom the first trench downhill tothe second trench. The pipeshave holes in the bottom, andwhen water comes into the pipe,it seeps out the bottom. Whenthe trench becomes clogged, thewater cannot seep out anymoreand goes to the top of the pipeand into the overflow. The firsttrench must be completely filledup before water flows into thesecond trench and so on.“The water comes out of my tankand goes to a splitter valve. I runit to one field for two years, andthen I can take off the cap, turnthe valve, and send it to theopposite field for another twoyears,” Crocco said. “The valve isbelow grade. You can’t see it, andI can mow over top of it.”The National EnvironmentalServices Center helps individualsand small communities all overthe U.S. If you have a wastewaterproblem or question, contact ourtechnical assistants at (800) 6248301 or visit our Web site formore information on our servicesat www.nesc.wvu.edu.7PIPELINE – Winter 2005; Vol.16, No.1National Environmental Services Center (800) 624-8301 or (304) 293-4191

NESC Products related to Drainfield RehabilitationPSMA Protocol: Inspecting On-lotWastewater Treatment SystemsIn this video, a Pennsylvania SeptageManagement Association certified inspectorexplains what an inspection entails, takingthe viewer through a Pennsylvania Level 1inspection of a septic system. This includessystem components, equipment used toperform the inspection, signs of a workingsystem, and direct and indirect indicationsof deterioration or failure. Depending uponthe results, the inspection report mayinclude corrective measures and a cost estimate for system repair or replacement. Thevideo also discusses sand mounds as alternatives to conventional septic systems.WWVTPE49 . 25.00Water Conservation: Managing OurPrecious Liquid AssetThis video illustrates practical ways to savewater. How to install low-flow fixtures in anew bathroom and how to retrofit existingbathroom fixtures.WWVTPE33 . 13.50Funding Decentralized WastewaterSystems Using the Clean Water StateRevolving FundThe Clean Water State Revolving Fund(CWSRF) is a low-interest or no-interestfunding source for installing, repairing, andupgrading decentralized wastewater systems in small-town, rural, and suburbanareas. This fact sheet discusses how theCWSRF operates, including eligible projectsand who may qualify. Success stories fromOhio, Maine, Pennsylvania, and Minnesotadescribe how these states have used theCWSRF.WWFSFN07 .Free“Septic System Owner’s Guide.”This guide—available from our sister organizationthe National Environmental TrainingCenter for Small Communities—helpshomeowners understand how a septic system works, how to operate the system efficiently and effectively, how to maintain thesystem and how information and recordsabout the septic system should be kept. Thisguide is designed for homeowners, but canbe used by trainers to educate homeowners,home builders, and realtors in the operationand maintenance of septic systems.TRBKPE11 . 4.00EPA Fact SheetsHigh-Efficiency ToiletsWWFSGN190. 1.00Water EfficiencyWWFSGN111. 0.20These products may be ordered by calling us at (800) 624-8301.ADDRESS SERVICE REQUESTEDNational Environmental Services CenterWVU Research CorporationWest Virginia UniversityP.O. Box 6064Morgantown, WV 26505-6064NONPROFITORGANIZATIONU.S. POSTAGE PAIDPERMIT NO. 34MORGANTOWN, WV

PIPELINE - Winter 2005;Vol.16, No.1 National Environmental Services Center (800) 624-8301 or (304) 293-4191 Drainfield Rehabilitation Capacity is usually based on the