Transcription

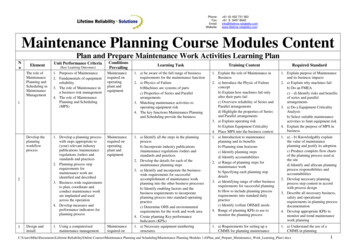

Phone:Fax:Email:Website: 61 (0) 402 731 563 61 (8) 9457 ability.comMaintenance Planning Course Modules ContentPlan and Prepare Maintenance Work Activities Learning PlanNoElement(Key Learning Outcomes)ConditionsPrevailingLearning TaskThe role ofMaintenancePlanning andScheduling inMaintenanceManagement1. Purposes of Maintenance2. Fundamentals of equipmentreliability3. The role of Maintenance ina business risk management4. The role of MaintenancePlanning and Scheduling(MPS)Maintenancerequired onoperatingplant andequipment1. a) be aware of the full range of businessrequirements for the maintenance function2. a) Physics of Failureb)Machines are systems of partsc) Properties of Series and Parallelarrangements3. Matching maintenance activities tooperating equipment risk4. The key functions Maintenance Planningand Scheduling provide the businessDevelop theplanningworkflowprocess1. Develop a planning processwith steps appropriate to(your) relevant industrypublications /maintenanceregulations /orders andstandards and practices2. Planning process steprequirements formaintenance work areidentified and described3. Business-wide requirementsto plan, coordinate andconduct maintenance workare implanted and usedacross the operation4. Develop measures andperformance indicators forplanning processMaintenancerequired onoperatingplant andequipmentDesign andinstall1. Using a computerisedmaintenance managementMaintenancerequired on1. a) Identify all the steps in the planningprocessb) Incorporate industry publications/maintenance regulations /orders andstandards and practices2. Develop the details for each of themaintenance planning steps3. a) Identify and incorporate the businesswide requirements for successfulaccomplishment of maintenance workplanning into the other business processesb) Identify enabling factors and thebusiness requirements to incorporateplanning process into standard operatingpracticec) Determine OHS and environmentalrequirements for the work and work area4. Create planning Key performanceIndicators (KPIs)1. a) Necessary equipment numberingstructures123Unit Performance CriteriaTraining ContentRequired Standard1. Explain the role of Maintenance inBusiness2. a) Introduce the Physic of Failureconceptb) Explain how machines fail onlyafter their parts failc) Overview reliability of Series andParallel arrangementsd) Highlight the properties of Seriesand Parallel arrangements3. a) Explain operating riskb) Explain Equipment Criticality4. Place MPS into the business context1. a) Introduction to maintenanceplanning and its benefitsb) Planning time horizonsc) Identify planning stepsd) Identify accountabilities2. a) Range of planning steps formaintenance workb) Specifying each planning stepdetails3. a) Identifying range of other businessrequirements for successful planningb) How to include planning processrequirements into standard dailypracticec) Identify /collate OHS&E needs4. Range of planning KPIs to use tomonitor the planning process1. Explain purpose of Maintenanceand its business impacts2. a) Explain why machines failb) Do an FMEAc) – d) Identify risks and benefitsof series and parallelarrangements3. a) Do a Equipment CriticalityAnalysisb) Select suitable maintenanceactivities to limit equipment risk4. Explain the purpose of MPS inbusiness1. a) Requirements for setting up aCMMS for planning maintenance1. a) Understand the use of aCMMS in planning1. a) – b) Knowledgably explainthe value of maintenanceplanning and justify its adoptionc) Produce complete flow chartsof the planning process used atthe sited) Identify and allocate planningprocess responsibilities andaccountabilities2. Develop necessary planningprocess step content in accordwith process design3. Describe all necessary business,safety and operationalrequirements in planning processdocumentation4. Develop appropriate KPIs tomonitor and trend maintenancework planningC:\Users\Mike\Documents\Lifetime Reliability\Online Courses\Maintenance Planning and Scheduling\Maintenance Planning Modules 1-6\Plan and Prepare Maintenance Work Learning Plan1.docx1

Phone:Fax:Email:Website: 61 (0) 402 731 563 61 (8) 9457 ability.comMaintenance Planning Course Modules ContentPlan and Prepare Maintenance Work Activities Learning PlanNoElementplanningsupportsystemsUnit Performance Criteria(Key Learning Outcomes)system (CMMS)2. Provide procurement andstores management3. Provide necessary planningreports and documents4. Develop complete Job Plansto do the work5. Install a suitable documentmanagement method6. Install a suitable recordsmanagement method7. Install a user friendlytechnical library8. Provide work budgeting andcost monitoring/control9. Generate managementinformation and reports10. Monitor planning processperformanceConditionsPrevailingLearning Taskoperatingplant andequipment2.3.4.5.6.7.8.9.10.4Identify,specify andconfirm jobrequirements1. Task requirements aredetermined or confirmedand clarified to ensurecorrect interpretation of taskrequirements andspecifications.2. Requirements andspecifications are analysedand priorities set inaccordance with PlanningMaintenancerequired onoperatingplant andequipmentb) CMMS field naming and conventionsc) Providing CMMS content for planningrequirementsa) Specifying parts, materials and servicesb) Purchasing and delivery requirementsc) Stores management basicsd) Inventory control basicsDevelop documents /reports and make themavailable to othersDevelop Job Plans in a suitable formCollate and manage the full range ofdocuments required by the planningprocessesCollate and manage the full range ofrecords required by the organisational, legaland regulatory processesDeveloping and cataloguing an engineeringand technical libraryRequirements for estimating job task costsand identifying actual expenditurea) Determining and create the necessarymanagement reports and their contentTrack and present scheduling process KPIs1. a) Contact work Requestor to understandthe work request and problem historyb) Rewrite work request with full detailsc) Review automatically computergenerated work requests for validity2. a) Scope-out full extent of work perstandardised Job Scope Listb) Identify work specifications and workquality standardsTraining Content2.3.4.5.6.7.8.9.10.1.2.workb) Identify necessary industrypublications /maintenance regulations/orders and standards and practicesa) – b) Purchase order subject matterc) Stores management requirementsd) Inventory control fundamentalsNecessary planning documents andreportsRequirements and content necessaryfor Job Plansa) Documents required and generatedby the planning processesb) Storage of documentsa) Records and information generatedby work done on plant and equipmentb) Storage of recordsNecessary technical informationneeding to be readily availableMaintenance job costing to 10%accuracyThe range of content and the use ofmanagement reportsPlanning process KPIs and trendinga) Work Request job information andproblem history requirementsb) Maintenance work order reviewedand adjusted with requirementsa) Contents and coverage ofmaintenance job scope-outb) – c) Selecting and collating workstandards and engineering standardsd) Setting Operational risk based jobRequired Standard2.3.4.5.6.7.8.9.10.b) Provide the necessary CMMSdatabase contentsa) Specify appropriate parts,materials and services correctlyb) Provide all necessary detailsfor purchasing and deliveryc) Manage a maintenance partsstored) Establish inventory controlsDevelop all necessary planningdocuments, reports and formsCreate a comprehensive andcomplete Job PlanEstablish a documentmanagement systemEstablish a records managementsystemEstablish and catalogue atechnical libraryCost a work order accuratelyDevelop all necessarymanagement reportsPresent and track KPIs1. Review work request andautomatically generated workorder content and makenecessary corrections2. a) Fully scope a job from start tocompletionb) – c) Define minimum workquality standards andengineering standardsC:\Users\Mike\Documents\Lifetime Reliability\Online Courses\Maintenance Planning and Scheduling\Maintenance Planning Modules 1-6\Plan and Prepare Maintenance Work Learning Plan1.docx2

Phone:Fax:Email:Website: 61 (0) 402 731 563 61 (8) 9457 ability.comMaintenance Planning Course Modules ContentPlan and Prepare Maintenance Work Activities Learning PlanNoElementUnit Performance Criteria(Key Learning Outcomes)ConditionsPrevailingLearning TaskSOPs.3. Resources are identified andobtained in order tocomplete task.4. Identified difficulties orproblems are resolved.5. Requirements for site safetyplan3.4.5.5Plan all stepsto completeeach task in1. Task is interpreted andrelevant steps are identifiedto ensure efficient conductMaintenancerequired onoperating1.c) Identify engineering requirements andstandards for the physical assetd) Set Job Priority based on operationalimpacte) Managing backlog of workf) Identifying opportunity maintenanceg) Identify all contents of the work packassociated with the joba) Specify all necessary equipment,resources, parts and manning required tocomplete the work and recommissionb) Identify if resources and manningrequired are internal or externalc) Order parts and materials in a timelymannerd) Using Contracted Servicese) Identify potential resource and manningconstraints and time issuesf) Identify plant and/or equipment accessissuesa) Resolve requirements to access the plantand/or equipmentb) Resolve availability of parts andmaterialsc) Resolve availability of internal andexternal resourcesa) Identify requirements for safe access bypersonnel and equipment to conduct theworkb) Identify requirements to conduct thework safely from start to enda) Create a comprehensive work order fromthe work requestTraining ContentRequired Standardprioritye) Managing work backlogf) – g) Assemble complete work pack3. a) Identifying equipment, resources,parts and manningb) Determine skills required toconduct the job tasksc) Purchasing requirements for partsand materialsd) Minimum requirements for a jobwork packe) Procuring and managingContracted Servicef) Ensuring availability of equipment,resources, parts and manningg) Recognising risks to the successfulcompletion of the work4. a) Addressing issues and risks in amanner suitable to the operationb) Confirming changes of intent withparties and people affected5. a) Job safety analysis and assessmentb) Protecting operating assets fromaccidental damagec) Putting job safety analysisoutcomes into the job pland) – e) Prioritise backlog work tomatch operational riskf) – g) Develop and build thewhole work pack3. a) Identify all necessaryresources, manning, parts, andplant access requirementsb) Specify quantities of resourcesto be allocated for the work4. Identify potential problemsarising during the work anddevelop appropriate plans toaddress the situations if theyoccur5. a) Identify safety issues andhazards for men and equipmentwhen doing the workb) Plan and prepare all necessarypersonnel and equipment assetprotection1. a) Key job and problem historyinformation listed on the work order1. a) Develop the full job plan for awork orderC:\Users\Mike\Documents\Lifetime Reliability\Online Courses\Maintenance Planning and Scheduling\Maintenance Planning Modules 1-6\Plan and Prepare Maintenance Work Learning Plan1.docx3

Phone:Fax:Email:Website: 61 (0) 402 731 563 61 (8) 9457 ability.comMaintenance Planning Course Modules ContentPlan and Prepare Maintenance Work Activities Learning PlanNo6ElementUnit Performance Criteria(Key Learning Outcomes)ConditionsPrevailingthe jobof work to meetspecifications in accordancewith (your) relevantindustry publications/maintenance regulations/orders and standards andpractices.2. Steps are planned inconjunction with the workof other personnel to allowachievement of practicaloutcomes, in accordancewith relevant (your)industry publications/maintenance regulations/orders and standards andpractices.3. Human factors are allowedfor in planning of steps.plant andequipmentDo work andreviewperformancefor feedback1. Work activity is organisedwith other involvedpersonnel, allowing forrelevant human factors andusing relevantcommunication processes toensure safe and appropriatesequencing of tasks.2. All necessarydocumentation related tojob planning and progress iscompleted, and recorded inMaintenancerequired onoperatingplant andequipmentLearning TaskTraining ContentRequired Standardb) Develop a Job Plan listing the majoractivities to do the work and recommissionequipmentc) Identify skills and competencies requiredto do all tasksd) Collate necessary parts and materials liste) Identify applicable equipment data andjob documentation needed to properly dotasksg) Establishing proof tests for job plan stepsf) Write accuracy controlled tasks ordevelop accuracy controlled job procedure2. a) Identify required interactions acrossdepartments and across trade disciplinesb) Confirm all appropriate resources andmanning are availablec) Confirm all necessary documents andengineering information is available3. a) Identify human factors that could causecomplications to Job Plan activitiesb) Address human factor issues and clarifyresolutions to adopt when the work is done1. a) Develop planning bar chartsb) Communicate and inform relevantpeople of planning progressc) Chair and conduct planning meetingsd) Collect and collate parts and materialsfor planned jobse) Liaise with external resources andContracted Servicesf) Inform Scheduler and Maintenance CrewSupervisor of the fixed week planned workg) Create and produce work backlog reportsb) Contents of a Job Planc) Developing Job Plan stepsd) Necessary details noted on the JobPlan including work coordinatione) Estimating standard time for tasksg) Using proof tests and check sheetsto control work qualityf) Develop accuracy controlled tasksand an accuracy controlled procedure2. a) Coordinating across groups ofpeople with different agendasb) Coordinate with external resourcesc) Coordinate with Suppliersd) Coordinate with Storese) Coordinate with Equipment Owner3. a) Explain human error and impact inmaintenance workb) Explain the ‘dirty dozen’ HumanFactors and how to address each oneb) Planning preparation for HumanFactors issuesb) Provide all relevant industrypublications /maintenanceregulations /orders and standardsand practices.c) Set work quality acceptancecriteria2. Ensure job steps are coordinatedto remove wasted time andresources3. Design the work activities, workflow and documentation contentto prevent Human Factor issuesleading to problems1. a) Communication methods andplanning information transfer toolsb) Communicating up and down theorganisationc) Organising and conductingPlanning meetingsd) Stores and inventory managementand control for planned worke) Working with and informingContracted Servicesf) Working with the Scheduler andCrew Supervisor1. a) Work coordination tools andmethods are deployed sopersonnel at all levels throughoutthe operation are aware of theimpact of a job on their workb) External resources andservices are coordinated and keptinformed of job progressionthrough backlog2. a) Work Pack fully compiled andall necessary information anddocuments to complete the jobC:\Users\Mike\Documents\Lifetime Reliability\Online Courses\Maintenance Planning and Scheduling\Maintenance Planning Modules 1-6\Plan and Prepare Maintenance Work Learning Plan1.docx4

Phone:Fax:Email:Website: 61 (0) 402 731 563 61 (8) 9457 ability.comMaintenance Planning Course Modules ContentPlan and Prepare Maintenance Work Activities Learning PlanNoElementUnit Performance Criteria(Key Learning Outcomes)accordance with (your)relevant industrypublications /maintenanceregulations /orders andstandards and practices.3. Performance feedback issought to confirm outcomesare in agreement with taskrequirements andspecifications.4. All necessarydocumentation relevant tothe task is completed andstored.ConditionsPrevailingLearning Taskh) Create, produce and distribute resourcesplanning reportsi) Monitor work order backlog duration2. a) Confirm all necessary documents andstatutory records are present in the workpack3. a) Chair and conduct ‘lessons learned’meetings to improve planning processb) Review planning KPIs performance atplanning meetingsc) Present monthly reports and KPI charts1. a) Record relevant work history inappropriate databasesb) Record statutory and regulatedequipment historyc) Store necessary records for the life ofthe equipment4. d) Archive old work ordersTraining Content2.3.1.4.g) – i) Creating and using a range ofplanning reportsa) Review job preparation readinessand work pack content is completea) Learning from bad and goodworkplace outcomesb) – c) Management reportingrequirementsa) – b) Maintaining informationdatabasesc) Statutory recording requirementsd) Archiving history and equipmentrecords requirementsRequired Standardwithout interruption are presentb) All requirements to collect joband equipment condition historyare in Work Pack3. a) Planning process, jobcoordination and Work Packdocumentation are improvedb) Job Plan task times reduce andwork quality accuracy improves4. a) Work and cost history,technical and engineeringinformation, and job planningdatabases are kept constantly upto-dateb) Documents and records arecontrolled and managedNOTE: Some course content coverage is extracted from the following Australian NTIS training units:1MEA103APlan and organise work activitiesPart of Aero-skills Training Package2UTGNGS003APlan and organise work activitiesPart of Gas Industry Training PackageC:\Users\Mike\Documents\Lifetime Reliability\Online Courses\Maintenance Planning and Scheduling\Maintenance Planning Modules 1-6\Plan and Prepare Maintenance Work Learning Plan1.docx5

C:\Users\Mike\Documents\Lifetime Reliability\Online Courses\Maintenance Planning and Scheduling\Maintenance Planning Modules n1.docx 2 Maintenance Planning Course Modules Content Plan and Prepare Maintenance Work Activities Learning Plan N o Element Unit Performance Criteria (Key Learning Outcomes)