Transcription

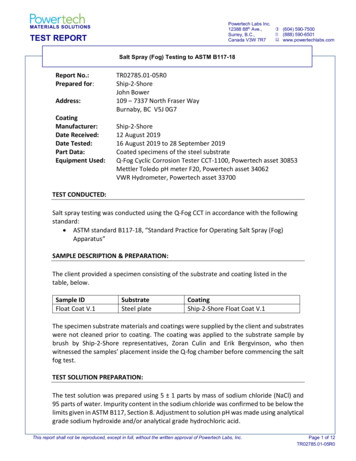

Powertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7MATERIALS SOLUTIONSTEST REPORTSalt Spray (Fog) Testing to ASTM B117-18Report No.:Prepared for:Address:CoatingManufacturer:Date Received:Date Tested:Part Data:Equipment Used:TR02785.01-05R0Ship-2-ShoreJohn Bower109 – 7337 North Fraser WayBurnaby, BC V5J 0G7Ship-2-Shore12 August 201916 August 2019 to 28 September 2019Coated specimens of the steel substrateQ-Fog Cyclic Corrosion Tester CCT-1100, Powertech asset 30853Mettler Toledo pH meter F20, Powertech asset 34062VWR Hydrometer, Powertech asset 33700TEST CONDUCTED:Salt spray testing was conducted using the Q-Fog CCT in accordance with the followingstandard: ASTM standard B117-18, “Standard Practice for Operating Salt Spray (Fog)Apparatus”SAMPLE DESCRIPTION & PREPARATION:The client provided a specimen consisting of the substrate and coating listed in thetable, below.Sample IDFloat Coat V.1SubstrateSteel plateCoatingShip-2-Shore Float Coat V.1The specimen substrate materials and coatings were supplied by the client and substrateswere not cleaned prior to coating. The coating was applied to the substrate sample bybrush by Ship-2-Shore representatives, Zoran Culin and Erik Bergvinson, who thenwitnessed the samples’ placement inside the Q-fog chamber before commencing the saltfog test.TEST SOLUTION PREPARATION:The test solution was prepared using 5 1 parts by mass of sodium chloride (NaCl) and95 parts of water. Impurity content in the sodium chloride was confirmed to be below thelimits given in ASTM B117, Section 8. Adjustment to solution pH was made using analyticalgrade sodium hydroxide and/or analytical grade hydrochloric acid.This report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 1 of 12TR02785.01-05R0

Powertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7MATERIALS SOLUTIONSTEST REPORTSalt Spray (Fog) Testing to ASTM B117-18TEST PROCEDURE:The test specimen was loaded into the test chamber in the orientations shown in Figure1. The specimens were supported on inert racks in the salt spray chamber; the flat panelspecimens were oriented at an angle of 20 5 inclined from vertical.The test parameters are shown below, in Table 1.Table 1: Test parametersParameterDurationStart DateEnd DateChamber TemperatureCollected Solution pHCollected Solution ConcentrationValue1000 hours16 August 201928 September 201935 C 2 CpH 6.5 to 7.2 (at 23 C 3 C)5 1 part by mass NaCl to 95 1 partdistilled waterChamber temperature, collected solution specific gravity, collection rate, and collectedsolution pH were measured every 24 hours, or up to a maximum of 96 hours when thetime period spanned a weekend or holiday.The condition of the specimen was documented by photograph at the followingapproximate intervals: 100, 336, and 500 hours.This report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 2 of 12TR02785.01-05R0

Powertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7MATERIALS SOLUTIONSTEST REPORTSalt Spray (Fog) Testing to ASTM B117-18Float Coat V.1Figure 1: Float coat V.1 specimen inside the Q-fog chamber before starting the testThis report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 3 of 12TR02785.01-05R0

Powertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7MATERIALS SOLUTIONSTEST REPORTSalt Spray (Fog) Testing to ASTM B117-18TEST DATA:See Appendix A for the test record.All parameters except for collected solution pH were within the standard specificationfor the duration of the test. Collected solution pH remained near-neutral, but particulardaily measurements were marginally below the specified pH range (minimum values of6.0-6.3 versus 6.5-7.2). As per ASTM B117, reservoir pH adjustments were made tocompensate when the collected solution pH was found to be out of specified range.TEST RESULTS:Test results relate only to the item tested. No acceptance criteria were provided by theclient. Photographs of the specimens before and during testing are provided below inFigures 2.The specimens did not sustain corrosion, pitting, or metal loss after exposures of up to336 hours. Evidence of corrosion was observed on the Float Coat V.1 specimen (Figure 2D) after exposures of approximately 500 hours and longer.This report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 4 of 12TR02785.01-05R0

Powertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7MATERIALS SOLUTIONSTEST REPORTSalt Spray (Fog) Testing to ASTM B117-18A) As-receivedB) 100 hoursC) 336 hoursD) 500 hoursFigure 2: Float Coat V.1 specimen, in the as-received condition and after exposure tosalt spray testing for 100, 336, and 500 hours.This report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 5 of 12TR02785.01-05R0

Powertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7MATERIALS SOLUTIONSTEST REPORTSalt Spray (Fog) Testing to ASTM B117-18Prepared and Tested By:Reviewed By:Shima KarimiEIT, Materials SolutionsKristen Porter, P.Eng.Materials Engineer, Materials SolutionsRevision HistoryRevision 02019-10-21New DocumentThis report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 6 of 12TR02785.01-05R0

Powertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7MATERIALS SOLUTIONSTEST REPORTSalt Spray (Fog) Testing to ASTM B117-18APPENDIX A.SALT FOG (SPRAY) TEST RECORDThis report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 7 of 12TR02785.01-05R0

MATERIALS SOLUTIONSTEST REPORTPowertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7Salt Spray (Fog) Testing to ASTM B117-18This report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 8 of 12TR02785.01-05R0

MATERIALS SOLUTIONSTEST REPORTPowertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7Salt Spray (Fog) Testing to ASTM B117-18This report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 9 of 12TR02785.01-05R0

MATERIALS SOLUTIONSTEST REPORTPowertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7Salt Spray (Fog) Testing to ASTM B117-18This report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 10 of 12TR02785.01-05R0

MATERIALS SOLUTIONSTEST REPORTPowertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7Salt Spray (Fog) Testing to ASTM B117-18This report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 11 of 12TR02785.01-05R0

MATERIALS SOLUTIONSTEST REPORTPowertech Labs Inc.12388 88th Ave., (604) 590-7500 (888) 590-6501Surrey, B.C., www.powertechlabs.comCanada V3W 7R7Salt Spray (Fog) Testing to ASTM B117-18This report shall not be reproduced, except in full, without the written approval of Powertech Labs, Inc.Page 12 of 12TR02785.01-05R0

Salt Spray (Fog) Testing to ASTM B117-18 Prepared and Tested By: Shima Karimi EIT, Materials Solutions Reviewed By: Kristen Porter, P.Eng. Materials Engineer, Materials Solutions Revision History Revision 0 2019-10-21 New Document . MATERIALS SOLUTIONS TEST REPORT Powertech Labs Inc. 12388 88 th Ave., Surrey, B.C., Canada V3W 7R7 (604) 590-7500 (888) 590-6501