Transcription

Quick Reference CatalogTower partsV2. 11/2020

Your contact informationManitowoc Crane Care

OverviewSummaryWhy choose the genuine part?Consumables GreasesGrease pumpAutomatic grease nipplesMotorized lubricationOilsPaintsVarious consumablesSet of fixing angles for L mastSet of fixing angles for K mast 101416182022262830 3638404244485052545658596062646668Safety Slewing ring fixing boltsHydraulic tensionerSlewing ring seal kitSupport plate screw jacks protectionDaytime and night Hazard lightingOperating cameraAnemometerGiant Vision displayMC 602Cab indicatorsCab-IN: interior crane driver liftingTCL : exterior crane-driver liftingAntirotation assemblyDouble cable pulling gripJib lifting beamTechnical instructionsThorough examination

OverviewSummaryOptions Support platesCab heatingTiraxRemote ControlsBatteries and chargers for remote controlsCrane Control System Options (CCS)CCS Tool KitWalkie-Talkie 7274767880828384

Why choose the genuine part?Control - Manufacturer warrantyOnly the manufacturer has an overall view ofthe product and, by means of its technicalproficiency, it guarantees total compatibility.Generic aftermarket parts meet just a fewbasic criteria and can modify thecharacteristics of the machine.

Why choose the genuine part?Advantages of the genuine part: Safety, Manufacturer warranty, Service life, Cost control, Traceability, Quality technical support.Risks of the adaptable part: Modification of the crane characteristics, Safety problems with serious risks to peopleand equipment, Premature wear of other components, Increased maintenance costs and equipmentdowntime, Cancellation of the manufacturer's warranty, Annulation de la garantie constructeur, No appeal possible against the manufacturer.

ContentsNotes

ContentsConsumables

GreasesGreases selected specificallyby Manitowoc, respectingthe precise specificationsdefined for each use.10

GreasesStandard quality for slewing ring bearings G2 type:E-01032-51*Cartridge 400 gH-01032-54Screw Cartridge 400 g84066032Can 5 kgG-01032-53High-quality for slewing ring bearings GM type**:T-61032-74*Cartridge 400 gJ-61032-65Screw Cartridge 400 g84066033Can 20 kgU-61032-75Aerosol for slewing ring gears and teeth P type**:P-01032-60*Aerosol 400 mlS-01032-63Specially selected for fish joints by pins ATD type**:N-61032-23*Can 1 kgT-61032-05Can 5 kg84066107Specially selected for topping up greasein reducer gear S00 type :H-12032-52*Tube 250 g82016145Can 5 kgJ-12032-53Can 50 kgK-12032-54Specially selected for topping up greasein reducer gear G0 type :K-12032-08*Can 1 kgL-12032-32Can 18 kgP-12032-12*Material code not sold**Essential in the inspection vehicles!11

ATD Grease* for fish jointsGrease, specially designed inorder to increase the lifetime ofthe mast assembling by pins.Making fitting and dismantling ofthe pins easier.Very strong adhesiveforce on the metallicsurfaces, ensuringlong conservation ofthe protecting andlubricating film.Excellent thermalstability : can be usedfrom -25 C to 50 Cand can be storedfrom -40 C to 60 12To be used at each assembly

ATD Grease* for fish jointsSpecially selected for fish joints by pins:ATD typeCan 1 kgT-61032-05ATD typeCan 5 kg84066107To be used at each assembly13

Grease pump*Easy to use, convenient and efficient, this pumpwill be essential to make your greasing operationevery day!SUPPORTMAGNÉTIQUEThis greasing system is easy and clean,No hands contact with the grease,Optimal ergonomics thanks to the magnetic support,Compatible with traditional or screw cartridgesEssential in the inspection vehicles!14

Grease pump*Kit content:1 Pump, 1 Adapter for screw cartridges,10 Sealing lids for traditional cartridges,1 User guide84066027Consumables:Traditional cartridge:G2 type400 gH-01032-54GM type400 gJ-61032-65AdapterBox of 24 pieces84066028G2 type400 g84066032GM type400 g84066033Screw cartridge:Sealing lids84066029Essential in the inspection vehicles!15

Automatic grease nipplesInstalled instead of greasenipples, it will extend thelifetime of your slewing ringsensuring an efficient greasingby releasing accurate andregular quantities with aspecially selected grease.16

Automatic grease nipplesFor range GME and GMA.Complete Grease Cartridge*:Including refill with batteriesJ-01458-97Refills*with batteries:120 cm³ (3 months)Sold per 4Q-62505-40250 cm³ (6 months)Sold per 4H-62505-56Reinforced connection:Refill 250 cm³K-01458-98Reducing adapters:M 8*125W-75375-57M 10*100Q-75375-51M 10*150V-75375-56Elbow fittingV-75375-56For range GME only.Grease cartridge electrochemical:125 cm³ delivered without batteries84031284For old GMA (HD / GTMR).Retrofit kit:Automatic grease cartridge J-01458-97and reducing adapters are not includedN-51458-02* Essential in the inspection vehicles!17

Motorized lubricationThis system allows thelubrication of the bearingrace and the teeth of yourslewing ring with only onegrease type.18

Motorized lubricationRing lubrication kits:(4 grease cartridges are included in each kit)Kit 4 Internal Greasing PointsK-21995-45Kit 6 Internal Greasing PointsL-21995-46Kit 8 Internal Greasing PointsM-21995-47Kit 12 Internal Greasing PointsA-21995-59Grease gun:N-64435-77Grease cartridge:GM type cartridge 400 gJ-61032-65Tooth lubrication kits:Kit pinion M10S-21995-52Kit pinion M12U-21995-54Kit pinion M16V-21995-55CSS cranesPower-supply option8400452219

OilsQuality oils, respecting precise specifications,selected for a maximum lifetime of your equipment.All our oils are not misciblewith other brands.Hydraulic oil for telescoping hydraulic units:E Standard TypeE-12032-26*Can 5 litres84108903Can 25 litresG-12032-28F Type (Extremeweather conditions)B-01032-48*Can 5 litres84108902Can 25 litresD-01032-50Can also be used for braking devicesHydraulic oil for hydraulic units Hup, IGO, HD cranes:I TypeP-61032-47*20Can 5 litres84108904Can 25 litresQ-61032-48

OilsOil for reduction gears – RCS Type:Q-12032-13*Can 5 l.W-61032-77Can 25 l.S-12032-15Oil for reduction gears – HR Type:H-61032-87*Can 5 l.84055632Can 25 l.84108905Oil for reduction gears – HRA Type:Q-61032-94*Can 5 l.84055662Can 25 l.84108906Oil for reduction gears - RSC Type:S-61032-96*Can 5 l.84055634Can 25 l.T-61032-97Oil for reduction gears – RSY TypeC-61032-36*Can 5 l.84055633Can 25 l.M-61032-91Oil for reduction gears construction hoistTCLCan 5 l.84055313* Material code not sold21

PaintsProducts of quality selected fora longer lifetime of your cranes.22

PaintsPrimer:Primer beige aerosol400 ml82021847PrimerCan 23,7 Kg84062805Primer hardenerCan 3,7 kg84062806Paint thinner X400Can 5 lF-11034-99Thinner primerCan 25 lB-68034-24Lacquer thinnerPU/THESCan 25 l84077707Solvent:Hardener for polyurethane lacquer PU/THES :Can 5 kg84012719Yellow paint SPU FIN THES:For cranes suppliedafter 1992Can 13,5 kg84061724Red paint SPU FIN THES:Can 13,5 kg84061724Paint for daytime hazard lighting:RedCan 13,5 kg84061399WhiteCan 13,5 kg84061397* Essential in the inspection vehicles!23

PaintsPOTAIN grey lacquer*:Aerosol400 mlZ-67034-18GL: for cranessupplied after 1992Can 25 kgW-67034-16PU/THES: for cranessupplied after 2000Can 13,5 kg84061420POTAIN galvanised lacquer*:Aerosol500 ml82013254POTAIN sand lacquer GL / SP:For cranes prior to1992Can 25 kgF-01034-82POTAIN yellow lacquer 92*:Aerosol400 ml82028322Aerosol150 mlE-11034-98Polyurethane lacquerCan 13,5 kg84061397400 ml82001191White lacquer:Blue lacquer:Aérosol* Essential in the inspection vehicles!24

ContentsNotes25

Various consumablesProducts selected by ManitowocCrane Care for usual and regularmaintenance of your equipment.26

Various consumablesLubricant ropes*:LC TypeAerosol 400 mlP-61032-70Anti-seize compound*:Aerosol 400 mlK-01035-78Aerosol 400 mlE-01035-27anti-seize agent*:Anti-seize paste copper:Tube 200 grL-15031-98Bottle 75 mlR-12035-36Anaerobic fixation:Cyanoacrylate adhesive*:Bottle 20 grH-12035-05Repair kit glass bonding:Tube 412 gr82020617Roll 6 mV-02031-32Mastic adhesive:D8Insulating adhesive tape*:Set 10 insulating adhesive tapesB-61031-43* Essential in the inspection vehicles!27

Set of fixing anglesfor L mastDiscover our full rangeof sets of fixing anglesfor L mast, with or without pin!You have pins in stockand you want to reuse them?Order only a set of bare fixing anglesand economize the price of pins!28

Set of fixing anglesfor L mastP12B :B-77109-81*Fixing angleswithout pins84063457Kit pins shafts**84063462Fixing angleswithout pins84063458Kit pins shafts**84063463Fixing angleswithout pins84063459Kit pins shafts**84063463Fixing angleswithout pins84063460Kit pins shafts**84063464P12C :Z-30110-90*P12D / P16A :P-75110-31*P12E / P20A :A-22101-39*P12ER / P16E / P21A :N-82662-81*Fixing angleswithout pins84063461Kit pins shafts**84063464P20A/ P21A SP :Q-23101-11**Fixing angleswithout pins84107953Kit pins shafts**84107954Please note, the old equipped code can no longer be ordered anymore!** Kit containing 8 pins 4 shafts 4 safety-pins29

Set of fixing anglesfor K mastFor more flexible management of yourequipment, we propose equipped fixingangles in the form of a kit.1 kit of 4 unequipped fixing angles1 fishplate kit301 pin kit

Set of fixing anglesfor K mastP41A :U-61109-57*Unequipped fixing angles setW-61109-59Fishplate kit84070143Pin kit84070146Unequipped fixing angles setW-61109-59Fishplate kit84070143Pin kit84070147Unequipped fixing angles set82031909Fishplate kit84070144Pin kit84070148Unequipped fixing angles set82031909Fishplate kit84070144Pin kit84070149Unequipped fixing angles set82028835Fishplate kit84070144Pin kit84070150Unequipped fixing angles set82028835Fishplate kit84070144Pin kit84070151P41A Tirax :V-61109-58*P61B :82031776*P61B Tirax :82031775*P62B :82028042*P62B Tirax :82028041**Please note, the old equipped code can no longer be ordered anymore!31

Set of fixing anglesfor K mastP800B :82019608*Unequipped fixing angles set82025958Fishplate kit84070144Pin kit84070152Unequipped fixing angles set82025958Fishplate kit84070144Pin kit84070153Unequipped fixing angles set82014499Fishplate kit84070145Pin kit84070154Unequipped fixing angles set82014499Fishplate kit84070145Pin kit84070155Unequipped fixing angles set84071651Fishplate kit84070145Pin kit84070154Unequipped fixing angles set84071651Fishplate kit84070145Pin kit84070155P800B Tirax :82019609*P850A :H-20680-29*P850A Tirax :B-18680-61*P854A :84071645*P854A Tirax :84071646*32*Please note, the old equipped code can no longer be ordered anymore!

ContentsNotes

ContentsNotes

ContentsSafety

Slewing ring fixing boltsChoose bolts specially selected,adapted to your crane with atraceable serial number stampedon the bolt head.36

Slewing ring fixing boltsLet regularly check or change your boltsfor slewing ringFollow the manufacturer’s recommendations:* Verification of the tightening of the slewing ring bolts everyyear, following the instructions in Chapter 65E “Slewing ringfixing bolts” or paragraph “Slewing ring fixing bolts” ofyour catalog that comes with the crane.* Systematic preventive exchange of the slewing ring boltsuntreated every 8 years or after 16000 hours of operation ofthe machine.* Systematic preventive exchange of the slewing ring boltstreated every 12 years or after 24000 hours of operation of themachine.* Systematic exchange of the slewing ring bolts by change ofthe slewing ring of the crane, unless specific instructions fromManitowoc.37

Hydraulic tensionerfor slewing ring boltsHydraulic tensioner is essentialtool for tightening hydraulictension bolts on slewing ring.38

Hydraulic tensionerfor slewing ring boltsManitowoc offers two different types oftensioners for M20 to M27 bolts with a singlehigh-pressure hand pump.Tensioners:For boltsM20, M22 and M2482017093For boltsM2782017094High pressure hand pump*:U-64435-37Hydraulic oil LHMF300*:Can 5 l.84062679* Two-stage high pressure (150MPa), equipped with oilpressure gauge rapid connector, self-closing-highpressure hose length 3m.To use this material, please refer to the maintenance section ofyour crane manual which defines precisely the general rules fortightening your slewing ring bolts.39

Slewing ring seal kitThis slewing ring seal kit is for usewith GMA-GME cranes of the Potain brand.You order the entire assemblyand only replace those items used.You therefore always have everythingyou need for your operations.40

Slewing ring seal kitProtection of the bearing tracks andmaintenance of grease in the travel path.Slewing ring seal kit:84034143Composed slewing ring 5031-02Cyanoacrylate adhesive**:Bottle 20 grH-12035-05lidded box:84034044* seals with lengths of 2 x 7 meters.** 2 bottles41

Support platescrew jacks protectionThe protection bellows preservesthe screw thread from dust and concrete.Compatible with chassis ZC4230, ZD4230,ZD463 et ZX6830.The protection bellows:84058203The setting of support plates remains easy evenafter several construction sites usages.The assembly is possible on a crane in operation.42

Notes43

Daytime and night Hazardlighting for tower cranesThe LED night hazard lighting medium intensityis dedicated for a day and nighttime, the securepower of which is integrated in an externalstainless steel enclosure.In accordance with ICAO medium intensity typeA and B, FAA L864/L865 flashing lights.44

Daytime hazard lightingfor tower cranesCharacteristics:This hazard lighting included: 1 flashead bi-color (6 projectors red 2000 Cd / white 20000Cd), aluminium body, 1 power control panel with batteries, 6 m cable, Automatic day/night switch with photocell, Easy installation and maintenance.Connecting cable between hazard lighting and control panel(additional cable)Daytime hazard lighting:84017772GMA, GMR and GTMR cranes:Order 40 m cable*84036587*For longer lengths, please get in touch withyour usual contact.45

Night hazard lightingfor tower cranesThe hazard lighting allows — thanks tothe proposed light range — to meet therequirements of the ICAO and the FAA fora daytime, night or mixed hazard lighting.The approval of the system by the localauthority of commercial aviationis under the supervision of the customer.46

Night hazard lightingfor tower cranesCharacteristics: Box: system of protection IP55Dimensions: 415 X 600 X 300 mm2 batteries 12 V 90 AhNight Hazard lighting:Complete set is composed: 820183263 red, low-intensity obstruction lights of type A,3 inox light supports,1 complete control panel with batteries of at least 100hours discharge time,200 m cable.The various light types*:Continuous red light of low luminous intensity: Type A 10 Cd IP 6682018334 Type B 35 Cd IP 6682019122*Other lights can be proposed on request.Control panel with batteries:82018329Supply voltage: 110V to 400V compatible 50 à 60Hz,Light output voltage: 24V DC,Possible discharge time of 15 (type B light) to 100 hours (typeA light) in continuous operation.Light support:Sold alone:8201833647

Operating cameraDriving assistance: Work safely,while improving the productivity!Optimal view allowingto not depend only oninstructionstransmitted orally.Accurate vision of the loadposition, of the hook and theunloading area.Reliable radio link with perfectpicture in real time.48

Operating cameraFor distributing cranes:Camera kit84060746Package containing camera, batteries,radio link and accessories, LED screen 12’’and auto-contact pack.Optional solar panel:Mounted on the trolley together with thebattery pack: automatic power supply ofthe camera without any manualintervention.J-85985-58For luffing jib cranes:Camera kit84060747Package containing camera, feed, cablelink and tilting support, LED screen 12’’.49

Dialog Wind AnemometerCompulsory in order towarn about the risk ofoverturning of cranes orinvoluntary movement ofthe load in high winds, thisis indispensable to safety*.*For any request, please get in touchwith your usual contact.50

Dialog Wind AnemometerSturdy and reliable: Digital system,Tested and certified by the CETIAT,Complete basic assembly including:sensor alarm block main display cablesH-68416-10Sensor:J-68416-11Cup holder set:Z-68416-25Indicator:N-68416-15Alarm nal display box (wire link, cable 60m)For cranes with collector, we propose a solutionwith radio repeaterPack including sensor alarm block main display repeater displayF-71406-5451

Giant Vision display for all brandsand types of tower cranesGiant Vision display indicates the windspeed on a large led screen.Limits the amplified danger of accidentsduring extreme weather conditionsVisible by all people on the site up to 50meters, all times of day and nightCrane without CCS52CCS Crane

Giant Vision display for all brandsand types of tower cranesCrane without CCSXXL wind display:84002612Complement:For any request, please get in touchwith your usual contact.CCS CraneXXL wind display:84042786Switch box:84043689Crane foot display, software version V1.5.5.For any request, please get in touchwith your usual contact.MR Refresh (MRXX8) crane *:*For any request, please get in touchwith your usual contact.53

MC602 System anticollisionMC602* more user friendly, able tocommunicate with the previous Top TracingI and Top Tracing II systems.This new system allows to prevent thedanger of collision between the cranes, butalso to limit the crane working zone inorder to avoid forbidden overslewing ofbuildings, aerial lines.DisplayComputer*For any request, please get in touchwith your usual contact54

Notes55

Cab indicatorsMake your cranes comply with the articleR.233-20 of the labour code : requires themounting of efficient and performanceindicators in the cab.56

Cab indicatorsCab indicator kit "Dialog Visu":Standard assembly includingdisplay, interface block,connecting cable and rail DIN.H-47113-50This kit will be completed with an additional set (connectingcable, sensors ) to be defined according to the crane type, itsinitial composition of the existing safety devices.For any request, please get in touchwith your usual contact.Anemometer option:WindU-02670-48Anemometer sensor, cable and support allow the readingof speed wind on cab indicator.External signaling kit:Wind signaling kitP-68416-16Adaptor connects to visuN-63522-90Option repeater on crane foot:Repeater kit windQ-68416-17SupplyU-68416-21Bloc can visuQ-72406-2157

New interior crane-driver lifting equipmentNew interior crane-driver liftingequipment for Potain mast sections,compatible with all K mast sections(1,6 m, 2 m et 2,45 m) with newand old access.Option to retrofit the existing mastsections to change these into Cab-INmast sections: contact us. Installation of the crane-driver liftingequipment is carried out at the same time asthe crane and alongside the access ladders No extra transport and storagecosts as the Cab-IN stayspermanently in the masts.Optimal management of the mastsection fleet, compatible with: All current mast section bases(fixing angles, chassis and crossshaped bases).Potain Cab-INcrane-driver lifting equipmentcomplete visibilityArrival/departure platformPotain K mastsAccess ladderswith back loops Arrival/departure platforms enclosure. Upper and lower sensors on the lift cab for safetywhen in use. 360 visibility from the crane-driver liftingequipment interior for inspecting the mast sections. Drive unit maintenance from the inside of the cranedriver lifting equipment.58

Tower Crane Lift (TCL ) :the motorized external constructionhoist ergonomicThe new model TCL is developed anddistributed for your all Potain towercranes.Fits all K mast sections on tower cranes(for other masts or mixed masts, pleasecontact us).Reversible cab (opening door left or right)In compliance with applicable standardsand recommendations*Mastswith rackEasily adaptable equipment for reducedfitting time: Fitted on the exterior of the mastsection, using the crane orindependently with an optionalderrick. No modification of the mastsections is required. Lightweight and adaptable anchorageparts, identical for all mast sections.Large gap between anchorages, forreduced fitting time. Fast connection of the galvanized rack mast sectionsusing captive screws. A retrofit kit is also available for the classic TCL. Compliant with the crane lift standard EN 81-43. In France: in accordance with recommendation R.495.From January 1, 2019, motorized access is mandatory ifthe crane cab requires an ascent of more than 30 m.59Suitable anchorageLift for crane operatorAccess

Antirotation AssemblyThis system is an additional brake mountedbetween the gearbox and the slewing motor.It aims to limit the “autogiration” or“uncontrolled spinning” of the slewing part ofthe crane when left in weathervane and isexposed to abnormal wind effects on site.The device is set up specifically for eachconfiguration of crane and at each site. At eachdismantling of the crane, it is compulsory todisable the system or remove it.The adjustment values are defined by thetechnical support of Manitowoc Crane Care.60

Antirotation AssemblyThe antirotation assembly is composed of« antirotation » Mechanism, electrical panel,electrical panel bracket.Antirotation assembly:For flanges 200 mm (SL1)82007096For flanges 250 mm (LP2)8200709761

Double cable pulling gripwith swivel*Reinforce safety when changing cables.These new generation cable pulling grips with centralswivel are ideal for safewire rope replacement.They meet the obligations of European regulations, inparticular the "Machinery" Directive 2006/42/EC.*Usable for cables with no ends.62

Double cable pulling gripwith swivel*Rope 258406355425/308406356430/3584063565*Usable for cables with no ends.63

Jib lifting beamReinforce safety on your siteby using a lifting beam.Handling and shifting craneelements are delicateexercises which can causeaccidents.In order to minimize thedanger and to improve safetyon your site, Manitowocproposes a jib lifting beam.64

Jib lifting beamJib lifting beam:For round bar of 40 mm to 170 mm.Max. load per lifting beam: 17500 daN.Weight per lifting beam: 30 kg.84003496Advantages:Secures the slinging operation, especially for double tie barlines. The beam separates the chains allowing room for the tiebars to lift without catching the chains.65

Technical instructionsSystematically supplied with the newcranes, they are carried out in perfectaccordance with the crane composition.They also can be supplied on request."The company manager must put at the disposal ofqualified persons which are in charge of the inspections,tests and proofs to be carried out, the requireddocuments such as the manufacturer's instructions,conformity declaration or certificate, the reports of theprevious inspections and the maintenance log-book ofthe machines".Extract of the decree of March 1st, 2004 (J.O. N 77 ofMarch 31,2004, page 6189, text N 25) Article 3,b.66

Technical instructionsCranes manufactured after 1992:For GMA cranesC-62985-29For GME cranesE-62985-31Cranes manufactured in 1992 or prior to 1992:For GMA cranesD-62985-30For GME cranesF-62985-32The complete sets of manuals in form of a USB stick:For cranes manufactured after 199284070396Neutral maintenance booklet for tower cranes:Neutral maintenance bookletV-85985-9267

Thorough examinationThe objective of thorough examination is avoid a craneaccident. We classify the risk in 4 areas :1. Collapse of the crane,2. Collapse of the load,3. Uncontrolled movement,4. Safety of operators (crane operators, planners, technicians).Manitowoc owns specific stock of mechanical itemsdedicated to thorough maintenance examination of oldtower cranes for brands Potain, BPR, Cadillon and BKT:* Reducer,* Drum,* Motor,* Brake,* Transmission / Gearbox.The thorough examination of tower cranes is definedby law on 3 March 2004concerning thorough examination of tower cranes* This technical maintenance can be performby our Manitowoc technicians68

Notes69

Notes

ContentsOptions

Support platesMade from composite material,light and strong, They are abetter substitute for woodenplates which are usually usedfor wedging cranes or othermobile cranes.Support plates exist in rectangular models,round and planks.72

Support platesRectangular models – Set of 4 plates:1000*750*50 mm1000*1200*60 mm1000*1200*80 mm38 kg/plate72 kg/plate96 kg/plateZ-82985-60W-82985-58D-83985-22Square models – Set of 4 plates:600*600*40 mm600*600*60 mm600*600*80 mm750*750*50 mm800*800*40 mm800*800*50 mm800*800*60 mm1000*1000*50 mm1400*1400*100 mm15 kg/plate21,5 kg/plate28,5 kg/plate28 kg/plate25,5 kg/plate32 kg/plate38 kg/plate50 kg/plate200 re model – Set of 2 plates:400*400*50 mm8 kg/plateS-86985-70Round models - Set of 4 plates:ØØØØØØØ700 - 50 mm800 - 50 mm900 - 40 mm900 - 60 mm1000 - 80 mm1200 - 60 mm1200 - 80 86985-55W-85985-248200347503142474Planks– Set of 4 plates:1200*330*80 mm32 kg/plateB-84985-2473

Cab heatingA quality heating device,specially selected for crane cabs.Cab heating:Power : 2000 WSize : 253*253*164 mmWeight : 5.5 kgLow noise level : 50 dBVentilation function for the summerRoom thermostat control74Q-15418-19

ContentsNotes75

Tirax 80Tirax is a tool, which allows toinsert and to extract mast pins*(1,6 m, 2 m or 2,45 m) withouteffort, in safety and near silent.* Requires use of special pins equipped with gripping heads76

Tirax 80Complete tirax:Tool consisting of a hydraulic cylinderof traction with gripping jaws.D-44384-51Supplied by portable hydraulic unitconnected by sleeved hoses.77

Remote controlsEspecially adapted to your cranes,either recent or old ones and takinginto account the features of each ofthe mechanisms.78

Remote controlsTell us the model and serial number of yourcrane, and we will indicate the part numberand price of the remote control which suits.4 remote-control ranges are proposed:PRB1:For small cranes (and overhead travelling cranes)PRC:For ranges GMA: HDT and GTMRPRS or PRM:For ranges GME: MD, MDT and MRV3 and CCS:For ranges GME: MD and MDTComposition kit remote-control:-1 transmitter ( PRB, PRC, PRM or PRS),-1 receiver (connector included),-1 charger,-2 batteries.79

Batteries and chargersfor remote controlsDCWe offer 3 types of batteriesand chargers for remotecontrols depending of yourcrane generation.BA80

Batteries and chargersfor remote controlsCharger 110 / 220 V P8:Voltage 9,6 VDF-63418-87AD-63418-85Battery 9,6 V / 1,2 Ah:150*60*20 mmCharger 110 / 220 V / 300 MAh:Voltage 9,6 VCA-63418-59BZ-63418-58CN-63418-94Battery 9,6 V / 0,6 Ah:60*60*20 mmCharger 110 / 220 V:Voltage 3,6 VBattery 3,6 V / 2,75 Ah:50*60*20 mmB8408605281

CCS options84028029Software Version 1.5r7.Software upgrade possible*Defined according to your crane*Software Version 1.5r7.Software upgrade possible*Remote control84038397Recorder8402803184010450*For any request, please get in touchwith your usual contact82

Crane Control Systemtool kit (CCS)Cranes equipped of Crane Control System(CCS) technology require specific tools torealize maintenance.CCS tool kit:This backpack, pratical and ergonomic,included all essential toolingtroubleshooting CCS cranes (20 toolings,accessories, connections kit, contacts )84054165All the elements contained in this kit*are also available for sale separately:*For further information on the content of this kit (tool details,references, use ), Please refer to ‘CCS Tools Catalogue’(included on tool kit or available upon request )83

Walkie-talkieFor a true communication betweencrane driver and slinger, our walkietalkies offer guarantee of optimumproductivity.This model was selected by ourown after sales service that usesit regularly in its interventions oncranes.Our kit is included:- 2 transmitters - receivers- 2 rechargeable batteries NiMH- 1 dual charger (2 USB micro connexions)- 2 belt clips.Kit walkie-talkie:Power 500 mW, allows to communicateup to 10 km distance, 18h battery life. 84 82005259

ContentsNotes85

ContentsNotes

Documentation andContents on linegiveawaysManitowoc Direct is theultimate resource center forall the sales and marketinginformation you’ll need foryour Manitowoc GBYou can find our giveawaysalso on our website:http://www.manitowoc-shop.eu

Regional headquartersAmericasMilwaukee,Wisconsin, USATel: 1 920 684 6621Fax: 1 920 683 6277Europe and AfricaDardilly, France - TOWERSTel: 33 (0)4 72 18 20 20Fax: 33 (0)4 72 18 20 00APACShanghai, ChinaTel: 86 21 6457 0066Fax: 86 21 6457 4955Shady Grove,Pennsylvania, USATel: 1 717 597 8121Fax: 1 717 597 4062Wilhelmshaven,Germany - MOBILETel: 49 (0) 4421 294 0Fax: 49 (0) 4421 294 4301SingaporeTel: 65 6264 1188Fax: 65 6862 4040Middle East and IndiaDubai, UAETel: 971 4 8862677Fax: 971 4 8862678/79Parts officesFranceManitowoc Crane CareFrance SASTel (FR): 33 (0)4 72 81 51 51Tel (EN): 33 (0)4 72 81 51 50GermanyManitowoc Crane GroupGermany GmbHTel: 49 (0) 21 73 8909-0ItalyManitowoc Crane GroupItaly SrlTel: 39 174 26 166PolandManitowoc Crane GroupPoland Sp. z o.oTel: 48 22 843 3824PortugalManitowoc Crane GroupPortugal LdaTel: 35 1 22 96 98 840RussiaManitowoc Crane GroupCISTel: 7 495 641 23 59The NetherlandsManitowoc Crane Group

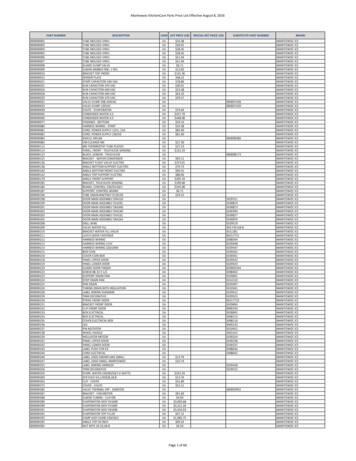

Generic aftermarket parts meet just a few basic criteria and can modify the characteristics of the machine. Control -Manufacturer warranty. Advantages of the genuine part: . by Manitowoc, respecting the precise specifications defined for each use. 10. Greases Standard quality for slewing ring bearings G2 type: