Transcription

The Permanence and Care of Color PhotographsChapter 1414. Envelopes and Sleeves for Films and PrintsRecommendationsEnclosure Materials: Recommended: Uncoated transparent polyester(e.g., DuPont Mylar D and ICI Melinex 516). Alsosuitable are uncoated polypropylene (e.g., Hercules T500 film) and certain nonbuffered 100%cotton fiber papers (e.g., Atlantis Silversafe Photostore). Probably satisfactory is high-densitypolyethylene (recommended as the best available low-cost material for amateur photofinishingapplications). Should be avoided: Low-density polyethylene(e.g., Print File, Vue-All, and Clear File notebookpages and sleeves); cellulose acetate (e.g., KodakTransparent Sleeves); polyvinyl chloride [PVC](e.g., 20th Century Plastics vinyl notebook pages);surface-treated polypropylene (believed acceptable for slide pages, however); conventional glassine; acid-free glassine; kraft paper and most othercommon types of paper; matte polyester (e.g.,DuPont Mylar EB-11); and synthetic paper-likematerials (e.g., DuPont Tyvek).Enclosure Design: Recommended: Top-flap sleeves (preferably madeof uncoated transparent polyester; as a secondchoice, uncoated polypropylene is probably acceptable). These sleeves allow films and printsto be inserted and removed without sliding againstthe enclosure surfaces, thus avoiding scratches(available from Talas Inc. and Light Impressions). Acceptable: High-density polyethylene sleevesof the types often used in amateur photofinishing(commonly referred to as “sleeving material”).Although they require that negatives slide againstthe plastic surfaces during insertion and removal,high-density polyethylene sleeves appear to haveminimal tendency to cause scratches and haveotherwise proven to be generally satisfactory forapplications that require low-cost enclosures. For additional protection: All sleeved films andprints, either singly or in groups, should be storedin high-quality, top-flap paper envelopes for protection from dust and physical damage, and toallow marking with rubber stamps, pens, etc.Envelopes, sleeves, and other enclosures for long-termstorage of photographs must meet three fundamental requirements:1. The design of an enclosure — and the surface characteristics of the materials used to make it — must notcause scratches and abrasion to films and prints duringstorage and use. This requirement is not met by mostcurrently available photographic enclosures because itis necessary to slide films and prints against the enclosure material during insertion and removal.2. Materials and adhesives used to make the enclosuresmust not be hygroscopic (attracting moisture from thesurrounding air), nor contain any chemicals that couldcause, or contribute to, fading or staining of black-andwhite or color photographs during the intended storageperiod. In museum collections, most photographs willbe kept for hundreds or thousands of years. Unstablematerials, including poor-quality paper, glassine, andpolyvinyl chloride (PVC), may over the years produceharmful decomposition products, stick to emulsions,exude gooey plasticizers, or cause other types of damage to photographs.3. To provide adequate physical protection during the lifeof a photograph, the materials used to make an enclosure must retain sufficient physical strength and tearresistance for as many years as the photograph insideis to be kept. Because a photograph is likely to beretained even after the image has significantly deteriorated, the enclosure material should have aging characteristics which are at least as good as the photograph’spaper or plastic support material.The requirements for enclosure materials suggest thatthe relatively few plastics and high-quality nonbuffered papers suitable for making print and film bases logically couldalso be used to make filing enclosures. If the material isnonreactive and stable enough to be used as a photographicsupport material, it should be equally satisfactory as anenclosure material.When storing comparatively unstable films, such as colornegatives made with Kodak Kodacolor II and Vericolor II,pre-1989 Agfacolor XRS and XRG, and pre-1992 3MScotchColor films (which are significantly less stable indark storage than current Kodak Vericolor III and 400,Ektar, and Kodak Gold Plus; Fujicolor Super HG, Super G,Reala, and Fujicolor Professional 400 and 160; and KonicaSuper SR, GX, Super DD, and XG films), the permanenceThis document originated at www.wilhelm-research.com on June 6, 2003 under file name: HW Book 14 of 20 HiRes v1.pdf 485

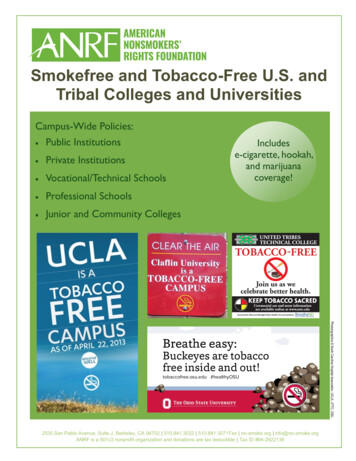

Thomas Beecher, a staff member at the Library of Congress in Washington, D.C., and Beverly W. Brannan, curator ofdocumentary photography in the Prints and Photographs Division of the library, examine color transparencies in the LookMagazine collection. The Look collection was donated to the library after the magazine ceased publication in 1971. Thetransparencies and negatives are still in their original, less-than-ideal sleeves and envelopes, although the films likely willbe put in new, higher-quality enclosures at some point in the future. Films and prints in most institutional and privatecollections, however, are destined to remain in their original enclosures for as long as they are kept. To avoid cumulativedamage to photographs caused by unsuitable filing materials, it is essential to use safe and long-lasting enclosures right atthe outset. (Since this photograph was taken in 1979, the color transparencies in the Look collection have been moved tothe library’s cold storage facility in nearby Landover, Maryland.)requirements for the enclosure material are in generalless stringent than they are for the longer-lasting colorfilms — and, of course, for black-and-white negatives.Likewise, enclosures for older, less stable color printssuch as those made with Ektacolor 37 RC and 74 RC paper,need not be of the same high quality as is required forstorage of the much longer lasting Konica Color, Ektacolor, Agfacolor, and Fujicolor papers introduced during1984–1985, or for storage of the most stable types of prints,including Ilford Ilfochrome (called Cibachrome, 1963–1991),Kodak Dye Transfer, and Fuji Dyecolor color prints, andblack-and-white prints, which, when kept in the dark, havethe potential to remain in good condition for many hundreds and perhaps even thousands of years. UltraStablePermanent Color prints and Polaroid Permanent-Color pigment prints, which are extremely stable both on displayand in dark storage, of course also require very long-lasting storage enclosures.But regardless of how good or poor the inherent imagestability of a particular film or print may be, the enclosurematerial should not in any way contribute to, or speed up,the deterioration of the image or of the base material. As apractical matter, most photographers and collecting institutions will want to use the same type of enclosure foreverything in their collections — and this means that onlythe very best, most stable enclosures will suffice.Avoiding Scratches and Other DamageCaused by EnclosuresA fundamental requirement in the design of any photographic enclosure is that a film or print can be inserted orremoved without sliding it against the surfaces of the enclosure material. Sliding a negative in and out of an enclosure will, over time, almost certainly result in scratches;the longer a negative or color transparency is kept — orthe more valuable it is — the more likely it is that it will berepeatedly accessed and printed. The more it is handled,the more likely it is to be scratched or otherwise physicallydamaged.This document originated at www.wilhelm-research.com on June 6, 2003 under file name: HW Book 14 of 20 HiRes v1.pdf 486Chapter 141979Envelopes and Sleeves for Films and Prints

The Permanence and Care of Color PhotographsAs any photographer knows who has laboriously attemptedto retouch an enlargement printed from a scratched 35mmnegative, every possible precaution should be taken to avoideven minor surface scratches on negatives. Scratches ontransparencies are especially troublesome because theywill show up on prints as black lines which must be chemically bleached before they can be retouched with spottingdyes — a time-consuming and difficult task. Although theenclosure material itself may be soft enough not to scratchdelicate gelatin emulsions, particles of dust and grit inevitably become sandwiched between the enclosure and filmsurfaces. As film is dragged across even a tiny particle ofgrit, the emulsion or base can be scratched. Stiff plasticenclosure materials are particularly prone to cause gritrelated scratches. In this author’s experience, PVC enclosures are the most likely to cause scratches on films asthey are slid in and out; among plastic materials, highdensity polyethylene appears to have the least tendency tocause scratches during use.Charges of static electricity which can develop as a filmor print is inserted and removed from a plastic enclosure— especially in low-humidity conditions — cause an attraction between the film and enclosure, increasing the likelihood of scratches.An enclosure should be designed so that it can be openedlike a book, allowing a film or print to be lifted out withouttouching the enclosure material. This non-sliding requirement alone eliminates from consideration most of the envelopes, sleeves, and notebook filing pages currently onthe market.Enclosures for negatives, unmounted transparencies,and prints are discussed in this chapter. Although information on PVC, polypropylene, and other plastics used tomake 35mm slide pages is included in this chapter, discussion of the practical aspects of these products is found inChapter 18, Handling and Preservation of Color Slide Collections.Types of EnclosuresPhotographic enclosures have been made with manydifferent paper and plastic materials, and supplied in avast number of configurations. They can be divided intotwelve groups:1. High-density polyethylene sleeve for automatic negative sleevers. Many professional labs, photofinishers,and mini-labs return 35mm negatives in plastic sleeveswhich are made with edge-sealed negative compartments side-by-side in a row, with one end of each compartment open. Nearly all sleeves of this design aremade of translucent, high-density polyethylene, andmost are manufactured in Japan. Often imprinted withthe name of the photofinisher, the sleeves are now themost common kind of negative enclosure — in the U.S.alone, many millions are used every week. Negativesare cut — most commonly to 4-frame lengths — andinserted into the sleeves with manually operated orhigh-speed automatic machines. With negatives inside,the sleeves are folded accordion-fashion and placed incustomers’ print envelopes. Negative strips can alsobe cut with scissors and manually inserted into theChapter 14sleeves. When made of high-density polyethylene (lowdensity polyethylene is not recommended), the sleevesappear to be reasonably satisfactory if kept in aphotofinisher’s envelope, standard paper letter envelope, or other enclosure to prevent contamination withdust and dirt. The naturally “slippery” and non-clinging surface of high-density polyethylene is much lesslikely to cause scratches on films than most other typesof enclosure plastics. High-density polyethylene sleevesare obviously superior to the open-end yellow paperfolders in which negatives are returned to customersby Kodalux photofinishing labs; with an entire roll ofnegatives cut to random lengths stuffed into each folder,the Kodak folders offer little protection to individualnegatives.2. Plastic sleeve with uncemented top flap. Usuallymade of transparent uncoated polyester, polypropylene,or cellulose triacetate, this sleeve can be opened like abook to allow the film or print to be lifted out, avoidingthe possibility of scratches. Both ends are open andadhesives are not used. Used in combination with highquality top-flap paper envelopes (No. 8 below), this isthe recommended design for most applications. Stableand chemically inert uncoated polyester is the bestmaterial with which to make these sleeves; “matte”surface polyester such as DuPont Mylar EB-11, whichis impregnated with abrasive silicon dioxide, should beavoided. It is absolutely essential that the sleeve havevery tight and crisp folds to minimize the chances of afilm accidentally sliding out of either end of the closedsleeve during handling. Top-flap polyester sleeves usedin combination with high-quality top-flap paper envelopes provide the best protection of any currently available filing system. (See Figure 14.1.)3. Plastic sleeve heat-sealed around uncut roll films.Similar in appearance to plastic negative tubes, thesesleeves consist of two transparent plastic strips (mostcommonly made of heat-sealable polypropylene) thatare sealed on both edges around uncut roll films withspecial heat-sealing equipment; for protection from dustand scratches during handling in the lab, films are usually sleeved immediately after processing. The cut endsof the sleeves are not sealed and remain open. Thesleeves are most commonly used with 120 and 220 rollfilms but are also applied to 35mm films when customers request that a lab return rolls uncut. The rolllength sleeves with film inside are generally cut withscissors into lengths of the desired number of frames.For protection from dust, cut lengths of sleeved filmshould be stored in paper envelopes. Once films areremoved from the sleeves, this author recommends thatthe sleeves be discarded and films placed in top-flappolyester or uncoated polypropylene sleeves, also keptinside of paper envelopes. In recent years, hot-sealsleeves have become popular in professional processing labs, especially for housing transparency roll films.Automatic heat-sealing equipment and plastic sleevingmaterial are supplied by Climax, Ltd. and other firms(see Suppliers at the end of this chapter). At the timethis book went to press, no information was availableThis document originat

(available from Talas Inc. and Light Impressions). Acceptable: High-density polyethylene sleeves of the types often used in amateur photofinishing (commonly referred to as “sleeving material”). Although they require that negatives slide against the plastic surfaces during insertion and removal, high-density polyethylene sleeves appear to have