Transcription

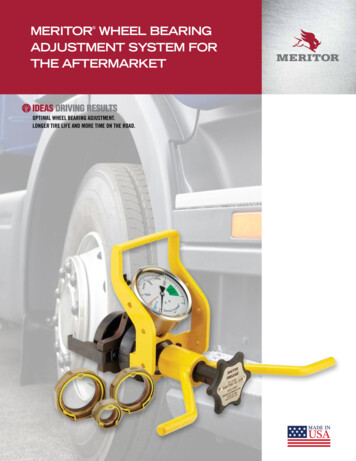

MERITOR WHEEL BEARINGADJUSTMENT SYSTEM FORTHE AFTERMARKET OPTIMAL WHEEL BEARING ADJUSTMENT.LONGER TIRE LIFE AND MORE TIME ON THE ROAD.

Meritor and Temper.Together to Provide a Superior BearingAdjustment Solution.With more than 100 years of axle-manufacturingexperience, Meritor has consistently brought advancedaxle technologies to the marketplace. Whetherdesigning and manufacturing from the ground up orpartnering with another industry leader, our goal isto provide fleets and end users with products thatdeliver maximum operating efficiency and premiumperformance. And now, Meritor Aftermarket is teamingup with Temper to offer Doctor Preload and TemperLoc spindle nuts – a superior bearing adjustmentsystem for wheel-end management, longer tire life andless downtime. That’s an idea that really does drive results.“I’m a firm believer in the Doctor Preload andTemper-Loc nut system. It’s helped us cutrecap use by one-third over two years andreduce inside tire edge wear-out by 90%.Our wheel ends run truer and run longer.”Russ Van Beek, Heyl Truck LinesAkron, Iowa“I use the system on roughly100 trailers and it’s keepingpreload on the wheel bearings.It has been a good additionto my fleet.”John Herbst, Owner, J&R TransportDickeyville, WIFounded in 1969, Temper is a leading engineeringand manufacturing company in precision assembliesand equipment for industrial products. The companyintroduced its first product – Temper Load Rings – in1970 to offer better bearing adjustment for a widevariety of industrial applications. Today, Tempercontinues to pioneer technologies that provide completesolutions for heavy vehicle applications, including theDoctor Preload and Temper-Loc bearing adjustmentsystem.Doctor Preload and Temper-Loc bearing adjustmentsystem is designed and manufactured in the U.S.A.“Setting the proper pre-load can’t beanything but good. That’s why we’veinvested in Doctor Preload and Temper-Locspindle nuts. I’m glad I spent the moneyon this system and it’s working well on allmy trailers.”Brock Ackerman, K & B TransportationSouth Sioux City, Nebraska“We believe in the product and it’s doing exactly whatit promised to do – keeping a consistent preload on thewheel bearings and contributing to good-to-better tirewear. The system has been a valuable addition to ourmaintenance operation. On our two most recent ordersof new trailers, we insisted that the OEMs installTemper-Loc nuts, which puts us on the right trackwith properly managed bearing settings.”Roy Hegland, Fleet Maintenance Supervisor, Midwest Motor ExpressBismarck, ND

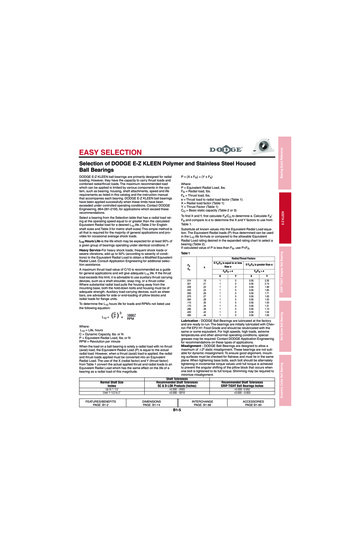

Better Bearing Management Through Preload.Load on bearings, including preload, is measured in“pounds-force” or lbf. SAE recommended practiceJ2535 stipulates the optimal settings for drive andtrailer axle wheel bearings to be between 500 and1,000 lbf, and between 250 and 500 lbf for steeraxle wheel bearings. With these settings, bearings,seals and other wheel-end components providemaximum performance.Optimum wheel-end management begins with optimalwheel bearing adjustment. According to the Societyof Automotive Engineers (SAE), the optimal setting forwheel bearings is a light preload.What is preload? Preload is simply defined as ameasured “tight” bearing setting in which all of therollers in the tapered roller bearings are kept undera slight force, or load. This preload condition keepsvibration and angular movement in the wheel end to aminimum during operation, reducing potential bearingwear and other wheel-end problems.Without preload, there is space or “clearance” betweenthe bearing components and the bearings are said tohave end play (also referred to as a “loose” bearingsetting). Excessive end play can result in extreme wearon bearings, spindles, tires, and wheel seals. It can alsocause anti-lock braking system (ABS) faults.IMPORTANT WHEEL-END PERFORMANCE GAINSINCREASINGWheel-End PerformanceDoctor Preload setting range(SAE J2535)Conventional practice end play(degraded performance)0PRELOADPounds.004END PLAYInches.008.012.016

Optimal Preload with the DoctorPreload Tool.Doctor Preload, when used in conjunction withTemper-Loc spindle nuts, is the ideal wheel-endbearing adjustment solution. The system sets thebearings to precise preload settings with a quick,simple, reliable and repeatable process.Features and Benefits:n Measured, precise, repeatable settings to optimalpreload for more time on the road Improved tire life Optimal bearing, spindle and wheel seal life Decreased ABS faultsn Adjusts wheel-end bearings to meet SAE J2535recommended preload settingsSpecificationsDoctor Preload ToolPart NumberUse with Temper-Loc NutAxle SpindleApplicationMER415005MER614723TP TrailerMeritor (TP), Dana, Eaton (P22), Fruehauf, ProparTN TrailerMeritor (F, H, RL, RQ, TK, TKL, TKLD, TL, TLD, TN, TND, TO, TQC, TQD)Dana Spicer (D20, D21, D22, DD22, K21, K25,K30)Eaton (C, C2, CD, CD2, CE, ESA225J, EST, EST225J, EST230J, ETA230C, ETA225D,ETA225J, H23L, H25R, HCE, HJ, HJE, LA15, T18C, 20L-77, 22L, 22R, J, JE, JH, 23L,23R, 25R)Hendrickson (HN)Ingersoll (A22T)Standard Forge (A25, A26, 17,000 lbs, 18,000 lbs trade)Meritor (F, H, RL, RQ, TK, TKL, TKLD, TL, TLD, TN, TND, TO, TQC, TQD)Dana Spicer (D20, D21, D22, DD22, K21, K25, K30)Eaton (C, C2, CD, CD2, CE, ESA225J, EST, EST225J, EST230J, ETA230C, ETA225D,ETA225J, H23L, H25R, HCE, HJ, HJE, LA15, T18C, 20L-77,22L, 22R, J, JE, JH, 23L,23R, 25R)Hendrickson (HN)Ingersoll (A22T)Standard Forge (A25, A26, 17,000 lbs, 18,000 lbs trade)MER415003*MER614743Axle ApplicationsMER415084MER614743TN Trailer withAluminum HubsMER415002MER614836FF SteerMeritor (FD900, FD901, FD961, FE900, FE903, FF900, FF901, FF921, FF931,FF932, FF933, FF941, FF942, FF943, FF944, FF952, FF961, FG941)Spicer (1100S)MER415347MER614837FE SteerMeritor (FE931)Eaton (EFA12FA, EFA12FA, EFA13FS, E12001, FE931, 12K, 13.2K)Ford Sifco 12KFord 6KMER415004MER614973R DriveMeritor (TR), Eaton (P22), Ford, Rainstar* Note: Not compatible with Conmet aluminum hubs for TN trailer axles. Contact our Customer Care team for more information.

Precise Positioning With Temper-LocSpindle Nuts.Temper-Loc precision single-locking nut systemprovides bearing adjustment with pinpoint accuracy;each Temper-Loc nut is manufactured to ultra-tightmachining tolerances. The nut system sets optimalwheel-end preload maximizing tire life and vehicleuptime. With its unique chamfered mounting face,Temper-Loc is the exclusive spindle nut used inconjunction with the Doctor Preload bearingadjustment tool.Features and Benefits:n Heat-treated nut face for superior strengthn Fingertip control retainer ring for ease of placementand positioningn EasyView verification of positive lockingSpecificationsTemper-LocNut ner Ring xle SpindleApplicationThreadDiameterThreadsPer InchTool Socket SizeOuter BearingMER644723TP Trailer3.480”124-13/16” - 8 pointHM518445 / HM518410MER644743TN Trailer2.625”163-3/4” - 8 pointHM212049 / HM212011448-4836MER644836FF Steer1.500”122-1/2” - 6 point3782 / 3720MER614837448-4837MER644837FE Steer1.500”182-1/2” - 6 point3782 / 3720MER614973449-4973MER644973R Drive3.250”124-3/8” - 8 point580 / 572

Six Simple Steps. Countless Benefits.1. Attach Doctor Preload tool to end threads of theaxle. Use a sweeping motion to guide the load armsaround the locknut while engaging the key locatorin the keyway. Engage the thread with two turns ofthread with the end of the axle.4. Finger-tighten the Temper-Loc nut against thebearing; align the closest dot on the nut to the keylocator indicator mark.2. S eat the bearing rollers. Tighten T-handleto load the bearings until the gaugepointer is in green “Roll In Zone.”Roll the wheel three revolutions.5. Remove the Doctor Preload tool.atorcoDloPredreloator PcoetDurmpleter yoly coRegis ay. Simp tails andoddetool t istrationcopygith a to:ewremthorethis finvoicsend originalruof yonc.tor, I HighwayMeriDixie0427975 e, KY 41 ancnmFlore eter FreePAttn:3. To set the bearings, loosen T-handle slowly untilgauge pointer points to “Set Drive/Trailer Axle” or“Set Front Axle” accordingly.6. Install the Temper-Loc nut retainingring and check for correct retainerinstallation.panComcContaStreeCity:DaEN

ionatstrireglo toDaProduct Protection You Expect.Customer Support You Deserve.:Dateode:Zip Came:ny Nme:ct Na:dresset Ad:State:reone:nfirme Phto coaytimde:ssudresill beil Adess wE-Maaddrilaber:: E-mNumNotePartloober:Tloadl Numr PreSeriatolcoooDTloadr PreDoctom:d FrohasePurc:)Datevoicehasey of inpoPurccachse att(Pleaationegistrof rceiptEach tool is shipped with aregistration card. Registrationmust be completed forwarranty eligibility of DoctorPreload tool and Temper-Locnut system.forantyr war.osespurpDoctor Preload tools are covered by a 1-year warrantyfrom the sale date to the end user. Temper-Loc nutsare covered by a 3-year warranty from the date ofinstallation. Documentation of tool sale date and nutinstallation details (including date of installation) mustaccompany warranty claim submission. The DoctorPreload tool and Temper-Loc nut system must beregistered for warranty eligibility.Our highly trained Customer Care team is your sourcefor complete support. Call them at 888-725-9355(in Canada, call 800-387-3889). Or visitMeritorPartsOnline.com – our industry-leading onlinecatalog, ordering and tracking system – with real-timeaccess to complete parts information resources.

As a world leader in providing aftermarketsolutions for the global commercial vehicle andindustrial markets, Meritor is committed to providing our customers with innovative aftermarketideas that deliver the results you need to get thejob done faster, better and more efficiently.Temper, Doctor Preload, Temper-Loc, and EasyView are registered trademarks of Temper Corporation.Product models, brands and names depicted herein are the property of their respective owners and are not in any way associated with Meritor, Inc., or its affiliates.Meritor Heavy Vehicle Systems, LLC7975 Dixie HighwayFlorence, Kentucky 41042 USA888-725-9355 U.S.800-387-3889 CanadaMeritorPartsOnline.commeritor.com 2015 Meritor, Inc.Litho in USA, SP-1520Issued 01-15 (47865/11900)

MERITORDOCTOR PRELOAD TOOLS and TEMPER-LOC NUTSSTORE SUGGESTED STOCK LEVELSJanuary 2015PART MER614973B12DESCRIPTIONFF Steer ToolTN Trailer Tool - Cast HubR Drive ToolTP Trailer ToolTN Trailer Tool - Aluminum HubFE Steer ToolTP Trailer NutTP Trailer NutTN Trailer NutTN Trailer NutFF Steer NutFF Steer NutFE Steer NutFE Steer NutR Drive NutR Drive 1200008161236LARGE11111054132441081848003684

MERITORDOCTOR PRELOAD TOOLS and TEMPER-LOC NUTSU.S. LIST PRICEPART R644973DESCRIPTIONFF Steer ToolTN Trailer Tool - Cast HubR Drive ToolTP Trailer ToolTN Trailer Tool - Aluminum HubFE Steer ToolTP Trailer NutTP Trailer NutTN Trailer NutTN Trailer NutFF Steer NutFF Steer NutFE Steer NutFE Steer NutR Drive NutR Drive NutTP Trailer Lock RingTN Trailer Lock RingFF Steer Lock RingFE Steer Lock RingR Drive Lock RingJanuary 2015LIST PRICE 1,561.89 1,561.89 1,700.67 1,642.06 1,757.36 1,561.89 76.06 71.42 58.92 55.33 53.33 50.08 60.50 56.81 66.39 62.33 18.25 14.14 12.78 14.50 15.92

Doctor Preload Bearing Adjustment Tools&Temper-Loc Spindle Nuts

Who is Temper Companies? Founded in 1969 in Fonda, NY by John Rode Focused on Bearing Adjustment in Multiple Industries– Marine, Fuel Systems, Aircraft Engines, & CommercialVehicles (millions sold annually)– Designed Load Rings to Provide Precise Bearing Loads Exclusive Distribution Agreement with Meritor inNorth America22

MERITOR and TEMPER PRODUCTS ADD VALUEINDUSTRY ISSUE: Increased brake life demands longer-life wheel end components. Fleets experiencing wheelend issues including ABS faults, wheel seal and bearing premature failures and reduced brake shoe life.MERITOR SOLUTION: Doctor Preload and Temper-Loc Nut System for optimum long-life wheel-endperformance.Doctor Preload, when used inconjunction with Temper-Loc spindlenuts, is the ideal wheel-end bearingadjustment solution. The system setsthe bearings to precise preload settingswith a quick, simple, reliable andrepeatable process limiting future wheelend issues.Features and BenefitsDoctor Preload Measured, precise, repeatable settings to optimal preload for more time on the road Improved tire life Optimal bearing, spindle and wheel seal life Decreased ABS faults Adjusts wheel-end bearings to meet SAE J2535 recommended preload settingsCompetitive AnalysisStemco ProTorq nuts are one-piece locknuts but, do not help maintain preload.Meritor ValueThe Doctor Preload and Temper-Loc spindle nut system provide optimal preload for more time on the road.Fleets and end users no longer need to worry about the results of excessive end play such as extreme wearon bearings, spindles, tires, and wheel seals or possible anti-lock braking system (ABS) faults. The systemhelps avoid costly downtime, improves tire life and increases productivity.ConMet Preset hubs are veryexpensive.Temper-Loc Spindle Nuts Heat-treated nut face for superior strength Fingertip control retainer ring for ease of placement and positioning EasyView verification of positive locking

Tapered Roller Bearings Overview An Assembly of Loose Parts Rollers not Aligned Applied Force Aligned Rollers andImproved Performance Our Program Improves the Life ofRoller Bearings and Wheel Ends!4

Why Has the Industry Used End-Play? Technology and Maintenance Council (TMC)– RP618 – Wheel Bearing Adjustment Procedures– Held up as the standard In reality, it is a procedure for a multi-part jam nut Why End Play and Not Preload for Class 8 Wheel Ends?1. There is no method to measure preload in wheel endbearings until the introduction of Doctor Preload bearingadjustment tools2. “Pre Set” options are very expensive5

The Basis for Preload Settings Truck and Bus Wheel Committee– Members include engineers of bearing and sealmanufacturers– Reports to Brake and Stability Control Steering Committee Developed Recommended Practice (SAE J2535)– “Setting Preload in Heavy-Duty Wheel Bearings”– Bearing and seal manufacturers agree on preload targets6

Preload Benefits Reduced tire costs– Improved mileage due to elimination of edge wear– Small investment per wheel end– ROI within six months Reduced wheel seal leaks and failures– Eliminates axial movement of seal components Longer bearing life and fewer wear issues Reduced ABS faults7

Why Our Solution? Doctor Preload Bearing Adjustment Tools– Establishes Light Preload to Improve Wheel End Performance– Quick, Easy and Repeatable Process (Adjusts & Measures atthe Same Time)– Final Load Settings Reduced from .008” to less than .002”– Takes Torque Out of The Equation (Preload Cannot BePredicted Using Torque) Easy-to-Install Temper-Loc Single-Piece Spindle Nuts– Holds Bearings in Preload When Installed with the Tool– Won’t Back OffAffirms Optimal Bearing and Seal Performance at Light PreloadBearing Settings Rather Than “Loose” End Play Settings8

Commercial Opportunity Fleet Conversions (Tractors, Trailers, and Dollies)––––Every Shop Needs a Set of Doctor Preload ToolsEvery Wheel End Needs a Temper-Loc NutThe ROI on Tires Self Funds the ConversionThe Benefits Don’t Happen Unless the Wheel End isConverted to Preload9

Doctor Preload & Temper-Loc Product Offering Product Offering– 6 Bearing Adjustment Tools (Doctor Preload)– 5 Temper-Loc Spindle NutsSP - 152010

Doctor Preload Bearing Adjustment ToolsDr. Preload Tool PartNumberMER415005Use with Temper LocNutAxle ApplicationsTP TrailerMeritor TP, Dana, Eaton (P22), Propar, FruehaufMER614743TN TrailerDana Spicer (D20,D21,D22,DD22,K21,K25,K30),Hendrickson (HN),Ingersoll ,LA15,T18C,20L77,22L,22R,J,JE,JH,23L,23R,25R), ,TQD),Standard Forge (A25,A26, 17,000lbs.,18,000lbs. trade)MER415084MER614743Dana Spicer (D20,D21,D22,DD22,K21,K25,K30),Hendrickson (HN),Ingersoll T230J,TN Trailer w/ Aluminum T18C,20LHubs77,22L,22R,J,JE,JH,23L,23R,25R), ,TQD),Standard Forge (A25,A26, 17,000lbs.,18,000lbs. trade)MER415002MER614836FF 44,FF952,FF961,FG941) Spicer (1100S)MER415347MER614837FE SteerMeritor (FE931), Eaton ord Sifco 12K,Ford 6KMER415004MER614973R DriveEaton (P22), Ford, Rainstar, Meritor (TR)MER415003MER614723Axle Spindle Application11

Temper-Loc Spindle Nuts Only Temper-Loc Spindle Nuts Can be used with DoctorPreload adjustment tools– Special Chamfered Face to Accommodate the Tool– Cannot use Stemco’s ProTorq with Doctor PreloadTools Temper-Loc Can replace Stemco Pro-Torq nuts(see chart below) TN & TP Nuts Approved for Production Meritor TrailerAxlesTemper Loc NutReplacementAssemblyReplacesRetainer RingNumberStemco NumberNumberAxle SpindleApplicationThread Threads PerDiameterInchTool Socket SizeOuter BearingMER614723447-4723MER644723TP Trailer3.480"124-13/16" - 8 pointHM518445 / HM518410MER614743447-4743MER644743TN Trailer2.625"163-3/4" - 8 pointHM212049 / HM212011MER614836448-4836MER644836FF Steer1.500"122-1/2" - 6 point3782 / 3720MER614837448-4837MER644837FE Steer1.500"182-1/2" - 6 point3782 / 3720MER614973449-4973MER644973R Drive3.250"124-3/8" - 8 point580 / 57212

Tool & Nut Program Details Doctor Preload Tools– Packaged in a Temper box with a Meritor label– In the Box: Tool calibration certificate How to use the tool instructions Warranty registration card Temper-Loc Nuts & Retainer Rings– “12-packs” – 12 Nuts, Retainer Rings, and Installation Instructions Packaged in a Temper box with a Meritor label Bulk Packs Designed for fleets doing conversions– Single-Nut Pack – 1 Nut, Retainer Ring, and Installation Instruction Packaged in a Meritor box with a Meritor label Designed For over-the-counter sales– Retainer rings will be available – can only be used with Temper-Loc nuts Packaged in a Meritor box with a Meritor label 2 Retainer rings per box13

Pricing & Warranty Program Pricing: (Suggested Dealer Net)– “12-packs” (part numbers end in “B12”) Up to 16% below Stemco ProTorq– Single pack boxes Up to 8% below Stemco Pro-Torq Warranty:– Doctor Preload Tools 1 Year After Sale - Must Register Tool Using Provided Registration CardThe Doctor Preload tool registration card must be completed, with copy ofpurchase invoice, and returned to Pete Freeman, Florence– Temper-Loc Nuts 3 Years From Date of Installation (must provide supporting documentation)14

Sales Support Training videos on Bullpen (Jan 2015) Demo Stands with Tools and Nuts for Training Trucks (Jan 2015) Product brochure – SP-1520 (Dec 2014)––––What is preloadFleet testimonialsProduct description / features & benefitsWarranty statement15

Questions?

Quick Start Instructions for Doctor Preload FOR USE WITH DOCTOR PRELOAD TOOLS FOR DRIVE AXLESR SPINDLESTEMPER AXLE PRODUCTS CORPORATIONALL PRODUCTS INVENTED AND MADE IN USA!WWW.DOCTORPRELOAD.COMNOTE: USE DOCTOR PRELOAD ONLY WITH CONVENTIONAL WHEEL ENDS.REMOVE ALL BEARING SPACERS FROM PRE-ADJUSTED HUB ASSEMBLIESBEFORE ADJUSTING WITH DOCTOR PRELOAD. DO NOT ATTEMPT TO ADJUSTA UNITIZED HUB ASSEMBLY USING THE DOCTOR PRELOAD SYSTEM. USEDOCTOR PRELOAD ONLY WITH TEMPER-LOC SPINDLE NUTS. To preventserious eye injury, always wear safe eye protection when you perform vehicle maintenance orservice. Park the vehicle on a level surface. Block the wheels to prevent the vehicle from moving.Support the vehicle with safety stands. Do not work under a vehicle supported only by jacks.Jacks can slip and fall over. Serious personal injury and damage to components can result.Before Starting Bearing Adjustment:Inspect all wheel end components. Repair any damage to the spindle threads so that the Temper-Loc spindle nutis able to thread completely onto the spindle.Prepare the Wheel End for Bearing Adjustment:Always be sure the hub is fully seated before adjusting with Doctor Preload. Thread the correct size Temper-Locnut onto the spindle. Using a bar and socket, tighten the Temper-Loc nut to drive the hub solidly against the axle.Loosen the nut one half turn. Finally, hand tighten the nut until it first touches the face of the outer bearing.Six Simple Steps:1) ATTACH DOCTOR PRELOAD TO THE END THREADS OF THE SPINDLE: Using a downward sweeping motion, guidethe two spring-loaded load arms around two flats of the nut (not over any of the “points” of the nut) whileengaging the keyway locator in the keyway. Use the end tabs on the load arms to control the load arms. Engagethe spindle adapter thread on the spindle with three turns of the star-handle.Check to be sure the tips of the load arms are properly located around the edge of the backface of the TemperLoc nut and that they make contact with the outer bearing cone. See the diagram below.Top View of Spindle with Doctor PreloadMounted and Properly Aligned.(Continue Instructions on Reverse Side)

2) SEAT THE BEARING ROLLERS: Tighten the T-handle by turning it clockwise. Load the bearings until the needlepointer on the Doctor Preload gage reaches the green ‘Roll-in Zone.’ Spin the hub at least 3 full turns in anyone direction to seat the bearing rollers.The load may drop slightly when rolling in the bearings – this isnormal. If the needle pointer drops out of the “Roll-in Zone”, tightenthe T-handle until it returns to the “Roll-in Zone” and spin the hubthree full turns again. Repeat until the needle pointer stays in the“Roll-in Zone.” Do not spin the hub again after this step.The load arms and the keyway locator should NOT be in contactwith the Temper-Loc nut or any part of the hub during this step. Ifthis occurs, remove Doctor Preload and start over by fully seatingthe hub as described in “Prepare Wheel End for BearingAdjustment” above. Do not hand tighten the Temper-Loc nutagainst the bearing while the needle pointer is in the green “Roll-InZone”. Caution: Applying excess force (moving the needle pointerabove the “Roll-In Zone”) can damage the Doctor Preload tool.3) SET THE BEARINGS: Loosen the T-handle by turning it counterclockwise slowly until the needle pointer on theDoctor Preload gage reaches ‘Set Drive/Trailer Axle.’ Do not go past the set point; if the set point is overshot,go back to Step 2 and repeat in order to seat the bearing rollers.4) LOCK IN THE BEARING SETTING: Hand tighten the Temper-Loc nut to align the furthest possible index dot withthe hash mark on the keyway locator and/or the load arms. When hand tightened, if the hash mark lines up inthe space between two dots, loosen the nut a fraction of the space to align the next dot with the hash mark.5) REMOVE DOCTOR PRELOAD FROM THE SPINDLE: Completely loosen the T-handle by turning itcounterclockwise until the load shown on the gage drops to zero. Hold the gage-guard handle to support theweight of the tool, and then loosen the star-handle by turning it counterclockwise. When the tool is detachedfrom the spindle, gently rotate Doctor Preload until the two load arm tips are positioned over two flats of thenut and pull straight back so that the load arms and keyway locator will slide back around the nut.6) INSTALL THE RETAINER RING: First install the EasyView center tab of the retainer ring in the Temper-Loc nut,engaging the key in the keyway at the same time. See below. Push in on each end finger tab, one at a time, to fiteach tab into the nut groove.Retainer Tab entering groove.Retainer Tab secured in groove.ALWAYS INSPECT THE FINAL ASSEMBLY. Ensure that there is a yellow retainer ring inserted in the nut. CHECK THAT ALLTHREE EasyView TABS AND THE LOCKING TEETH OF THE KEY ARE FULLY SEATED IN THE NUT. The EasyView notches of allthree tabs must be completely hidden in the groove of the nut. Failure to inspect the installation thoroughly could resultin component failure and bodily injury. Jan 2015 Temper Axle Products CorporationBulletin # TP10120

Quick Start Instructions for Doctor Preload FOR USE WITH DOCTOR PRELOAD TOOLS FOR TRAILER AXLESTN AND TP SPINDLESTEMPER AXLE PRODUCTS CORPORATIONALL PRODUCTS INVENTED AND MADE IN USA!WWW.DOCTORPRELOAD.COMNOTE: USE DOCTOR PRELOAD ONLY WITH CONVENTIONAL WHEEL ENDS.REMOVE ALL BEARING SPACERS FROM PRE-ADJUSTED HUB ASSEMBLIESBEFORE ADJUSTING WITH DOCTOR PRELOAD. DO NOT ATTEMPT TO ADJUSTA UNITIZED HUB ASSEMBLY USING THE DOCTOR PRELOAD SYSTEM. USEDOCTOR PRELOAD ONLY WITH TEMPER-LOC SPINDLE NUTS. To preventserious eye injury, always wear safe eye protection when you perform vehicle maintenance orservice. Park the vehicle on a level surface. Block the wheels to prevent the vehicle from moving.Support the vehicle with safety stands. Do not work under a vehicle supported only by jacks.Jacks can slip and fall over. Serious personal injury and damage to components can result.Before Starting Bearing Adjustment:Inspect all wheel end components. Repair any damage to the spindle threads so that the Temper-Loc spindle nutis able to thread completely onto the spindle.Prepare the Wheel End for Bearing Adjustment:Always be sure the hub is fully seated before adjusting with Doctor Preload. Thread the correct size Temper-Locnut onto the spindle. Using a bar and socket, tighten the Temper-Loc nut to drive the hub solidly against the axle.Loosen the nut one half turn. Finally, hand tighten the nut until it first touches the face of the outer bearing.Six Simple Steps:1) ATTACH DOCTOR PRELOAD TO THE END THREADS OF THE SPINDLE: Using a downward sweeping motion, guidethe spring-loaded load arms around the nut while engaging the keyway locator in the keyway. Engage thespindle adapter thread on the spindle with three turns of the star-handle.Check to be sure the tips of the load arms are properly located around the edge of the backface of the TemperLoc nut and that they make contact with the outer bearing cone. See the diagram below.Top View of Spindle with Doctor PreloadMounted and Properly Aligned.(Continue Instructions on Reverse Side)

2) SEAT THE BEARING ROLLERS: Tighten the T-handle by turning it clockwise. Load the bearings until the needlepointer on the Doctor Preload gage reaches the green ‘Roll-in Zone.’ Spin the hub at least 3 full turns in anyone direction to seat the bearing rollers.The load may drop slightly when rolling in the bearings – this isnormal. If the needle pointer drops out of the “Roll-in Zone”, tightenthe T-handle until it returns to the “Roll-in Zone” and spin the hubthree full turns again. Repeat until the needle pointer stays in the“Roll-in Zone.” Do not spin the hub again after this step.The load arms and the keyway locator should NOT be in contactwith the Temper-Loc nut or any part of the hub during this step. Ifthis occurs, remove Doctor Preload and start over by fully seatingthe hub as described in “Prepare Wheel End for BearingAdjustment” above. Do not hand tighten the Temper-Loc nutagainst the bearing while the needle pointer is in the green “Roll-InZone”. Caution: Applying excess force (moving the needle pointerabove the “Roll-In Zone”) can damage the Doctor Preload tool.3) SET THE BEARINGS: Loosen the T-handle by turning it counterclockwise slowly until the needle pointer on theDoctor Preload gage reaches ‘Set Drive/Trailer Axle.’ Do not go past the set point; if the set point is overshot,go back to Step 2 and repeat in order to seat the bearing rollers.4) LOCK IN THE BEARING SETTING: Hand tighten the Temper-Loc nut to align the furthest possible index dot withthe hash mark on the keyway locator and/or the load arms. When hand tightened, if the hash mark lines up inthe space between two dots, loosen the nut a fraction of the space to align the next dot with the hash mark.5) REMOVE DOCTOR PRELOAD FROM THE SPINDLE: Completely loosen the T-handle by turning it counterclockwiseuntil the load shown on the gage drops to zero. Hold the gage-guard handle to support the weight of the tool, andthen loosen the star-handle by turning it counterclockwise. When the tool is detached from the spindle, gentlypull Doctor Preload straight back, and the load arms and keyway locator will slide back around the nut.6) INSTALL THE RETAINER RING: First install the EasyView center tab of the retainer ring in the Temper-Loc nut,engaging the key in the keyway at the same time. See below. Push in on each end finger tab, one at a time, to fiteach tab into the nut groove.Retainer Tab entering groove.Retainer Tab secured in groove.ALWAYS INSPECT THE FINAL ASSEMBLY. Ensure that there is a yellow retainer ring inserted in the nut. CHECK THAT ALLTHREE EasyView TABS AND THE LOCKING TEETH OF THE KEY ARE FULLY SEATED IN THE NUT. The EasyView notches of allthree tabs must be completely hidden in the groove of the nut. Failure to inspect the installation thoroughly could resultin component failure and bodily injury. Jan 2015 Temper Axle Products CorporationBulletin # TP10121

Quick Start Instructions for Doctor Preload FOR USE WITH DOCTOR PRELOAD TOOLS FOR TN AXLES*TN-AH* Tools for TN SPINDLES*For Use with Certain Aluminum TN Spindle Trailer HubsTEMPER AXLE PRODUCTS CORPORATIONALL PRODUCTS INVENTED AND MADE IN USA!WWW.DOCTORPRELOAD.COMNOTE: USE DOCTOR PRELOAD ONLY WITH CONVENTIONAL WHEEL ENDS.REMOVE ALL BEARING SPACERS FROM P

wear and other wheel-end problems. Load on bearings, including preload, is measured in "pounds-force" or lbf. SAE recommended practice J2535 stipulates the optimal settings for drive and trailer axle wheel bearings to be between 500 and 1,000 lbf, and between 250 and 500 lbf for steer axle wheel bearings. With these settings, bearings,