Transcription

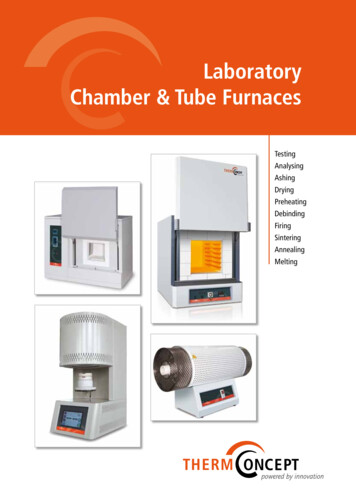

LaboratoryChamber & Tube ndingFiringSinteringAnnealingMelting

Laboratory Chamber & Tube FurnacesExperts in FurnacesTHERMCONCEPT develops, designs and manufactures furnaces andsystems for a broad range of production and research applications. Manyin our workforce have decades of experience in furnace engineering. Theexpertise we have amassed is deployed on a day-to-day basis in order toplan and realise your ideal furnace solution.EngineeringOur highly-skilled development engineers and designers, hardware andsoftware professionals, technicians and mechanics create cost-efficientand reliable furnace solutions. Direct contact with users enables us todesign furnaces that are practical to use. Our aim is to deliver crucialtechnical and financial benefits.Fast and flexibleMany applications can be achieved with our extensive range of standardfurnaces. The advantages for you are proven, fully-developed models,excellent value for money and quick delivery times. Of course, we alsosupply customised furnaces specially designed to meet your specificapplication. In close consultation with you, we develop a furnace systemwhich meets your challenging tasks both reliably and economically.Global Sales and Service NetworkTHERMCONCEPT furnaces and systems are proven in daily use at satisfiedcustomers in many countries worldwide. Our international distributionnetwork ensures that our customers receive individual support, rapidresponses and expert local service.THERMCONCEPT powerd by innovationFurnaces and industrial heat treatment systems made byTHERMCONCEPT are synonymous for top quality proven technology ractical and service-friendly design customer-specific and application-based solutions maximum thermal efficiency and value for money eco-friendly materials professional service.THERMCONCEPT is your partner for high-performance furnaces andsystems for wide-ranging and challenging applications in production andresearch.2

ContentsMuffle furnaces and chamber furnaces 1100 to 1400 CLaboratory chamber furnaces1100 / 1200 / 1300 C4Compact muffle furnaces1100 C6Muffle furnaces1100 / 1200 C7Ashing furnaces1100 / 1200 C8Chamber furnaces with ceramic muffle1000 / 1100 / 1150 C9Furnaces for asphalt tests600 C10Laboratory furnaces with weighing system1200 C11Special laboratory furnaces12Furnace accessories13Chamber furnaces with 5-side heating1300 / 1400 C14Annealing furnaces and accessories1300 C16High temperature furnaces1400 / 1500 / 1600 C18High temperature furnaces (1 - 20 litres)1500 / 1600 / 1750 / 1800 C19High temperature furnaces (16 - 70 litres)1600 / 1750 / 1800 C201100 - 1800 C21Tube furnaces1200 C22Modular tube furnaces1100 / 1300 C24Split tube furnaces1100 / 1500 C25High temperature tube furnaces1400 / 1500 / 1600 C26High temperature tube furnaces1700 / 1800 C27High temperature chamber furnaces 1400 to 1800 CElevator furnaces 1100 to 1800 CElevator furnacesTube furnaces (horizontal/vertical) 1100 to 1800 CSpecial tube furnaces28Tube furnace accessories29Drying cabinets, High temperature ovens 250 – 850 CDrying cabinets with natural or forced air convection250 / 300 C30Vacuum drying cabinets200 C31High temperature ovens450 / 650 / 850 C32High temperature ovens750 C33Customized furnaces34Furnaces and plants for production36Exhaust air purification plants38Process control and documentation40Professional service42The product range at a glance433

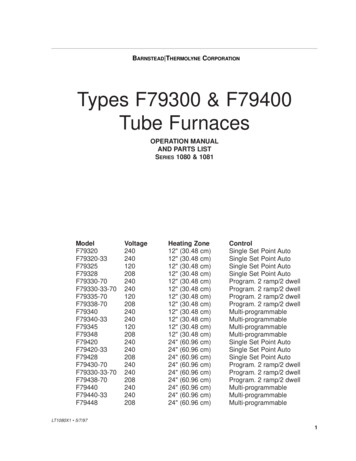

Laboratory Chamber FurnacesT max 1100 C, 1200 C and 1300 C Very high temperature uniformity inside the furnace chamber Double-walled housing with rear-ventilation to ensurelow outer-casing temperatures Parallel-guided door moving up-wards with hot insulation surface tothe rear, away from operator Insulation made of high grade ceramic fibre with low thermal mass Door collar made of strong fire bricks Wear-resistant fire brick insulation in the furnace bottom Delivery includes ceramic bottom plate Heating elements on ceramic supporting tubes, mounted in front ofthe insulation for free heat radiation Powerful heating elements in both sides providing fast heating rates Heating elements controlled by solid state relays for very precisetemperature control, wear-free and noiseless Exhaust pipe in the rear wall (KLS 45/. in the ceiling)Technical Data4ModelT maxInner dimensionsVolumeOuter dimensionsPowerVoltageKLS 05/111100210 x 200 x 1506550 x 580 x 6502,0230 V 1/NKLS 10/111100200 x 250 x 20010560 x 640 x 7202,7230 V 1/NKLS 15/111100220 x 300 x 23015560 x 640 x 7204,0400 V 3/NKLS 30/111100280 x 380 x 28030590 x 690 x 7904,0400 V 3/NKLS 45/111100300 x 500 x 30045660 x 810 x 8206,0400 V 3/NKLS 05/121200180 x 200 x 1405550 x 580 x 6502,0230 V 1/NKLS 10/121200200 x 250 x 20010560 x 640 x 7204,0400 V 3/NKLS 15/121200220 x 300 x 23015560 x 640 x 7204,0400 V 3/NKLS 30/121200280 x 350 x 28027590 x 690 x 7904,5400 V 3/NKLS 45/121200300 x 500 x 30045660 x 810 x 8206,0400 V 3/NKLS 05/131300200 x 250 x 1407550 x 580 x 6502,5230 V 1/NKLS 10/131300200 x 250 x 1809560 x 640 x 7204,0400 V 3/NKLS 15/131300230 x 300 x 23016590 x 690 x 7904,0400 V 3/NKLS 30/131300270 x 350 x 27026590 x 690 x 7906,0400 V 3/NKLS 45/131300300 x 500 x 30045660 x 810 x 8206,0400 V 3/N[ C][mm]Width x Depth x Height[l][mm]Width x Depth x Height[kW][V]

Laboratory Chamber FurnacesWide range of furnacesThermconcept laboratory chamber funaces are available in sizes from5 litres to 45 litres (see Technical Data page 4). The inner dimensions andmaximum operating temperatures are adapted to the needs of laboratories. Our range of furnaces also includes models with a Voltage of 230 V.Special dimensions and sizes in between are of course available uponrequestAccessoriesDue to many different accessories and extras our laboratory chamberfurnaces can be adapted to individual needs and applications: Vent with fan or with catalytic converter Adjustable temperature limiter to protect furnace and chargeacc. EN 60519-2 Protective gas connection at the rear side Quartz protection tubes for heating elements Pre-heating of process air Parallel-guided swing door Further accessories see page 135

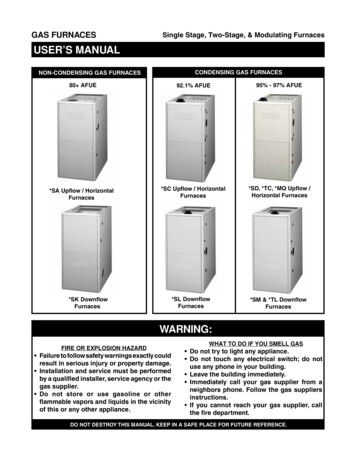

Compact muffle furnacesT max 1100 C Compact muffle furnaces with outstanding price-performance ratio Suitable for many applications in laboratories Compact outer dimensions and design to minimize space requirements Powder-coated, double-walled housing with long service life Insulation complete made of high-grade fibre material with low thermal mass for short heat-up times High quality heating wire with long service life Heating wire mounted in quartz glass tubes, protected against mechanical damages and waste gases, service friendly design Heating elements switched by solid state relais for precise furnacecontrol, wear-free and noiseless Exhaust pipe in the furnace ceilingTechnical Data6ModelT maxInner dimensionsVolumeOuter dimensionsPowerVoltageKLE 03/111100130 x 180 x 1303400 x 450 x 4501,0230 V 1/NKLE 05/111100160 x 200 x 1605430 x 470 x 4801,5230 V 1/NKLE 09/111100190 x 250 x 1909460 x 520 x 5102,0230 V 1/NKLE 15/111100220 x 300 x 22015490 x 570 x 5403,0230 V 1/N[ C][mm]Width x Depth x Height[l][mm]Width x Depth x Height[kW][V]

Muffle FurnacesT max 1100 C and 1200 C Universal muffle furnaces for ambitious laboratory applications Compact design for minimum space requirements Stainless steel casing, long service life, extremelyresistant Resistant fibre module as inner chamber, high mechanical durability, short heating cycles, low powerconsumption Door collar made of strong fire bricks to protect insulation against mechanical damages High-quality heating elements, long service life Heating wire embedded in ceramic plates with goodprotection against damages, service-friendly andcost-effective Heating elements controlled by solid state relays for veryprecise temperature control, wear-free and noiseless Exhaust pipe in the rear wallAccessories: Vent with fan Vent with fan and catalytic converter Adjustable temperature limiter to protect furnace andcharge acc. EN 60519-2 Further accessories see page 13Technical DataModelT maxInner dimensionsVolumeOuter dimensionsPowerVoltageWeightKL 03/111100180 x 140 x 1003380 x 415 x 4001,2230 V 1/N20KL 05/111100230 x 170 x 1305430 x 445 x 4252,4230 V 1/N35KL 09/111100230 x 240 x 1709430 x 515 x 4653,0230 V 1/N45KL 15/111100250 x 340 x 17015450 x 615 x 4653,5230 V 1/N50KL 03/121200180 x 140 x 1003380 x 415 x 4001,2230 V 1/N20KL 05/121200230 x 170 x 1305430 x 445 x 4252,4230 V 1/N35KL 09/121200230 x 240 x 1709430 x 515 x 4653,0230 V 1/N45KL 15/121200250 x 340 x 17015450 x 615 x 4653,5230 V 1/N50[ C][mm]Width x Depth x Height[l][mm]Width x Depth x Height[kW][V][kg]7

Ashing furnacesT max 1100 C and 1200 C Similar to chamber furnaces KLS (page 4), but specially adapted forashing of organic probes Pre-heating of cumbustion air through ceramic inlet-channels in thefurnace bottom Heating wire mounted in quartz glass tubes, protected against mechanical damages and waste gases, service friendly design Large exhaust outlet in the furnace ceiling and stainless steel stackwith a height of 350 mm on top of the furnace Double-walled housing with rear-ventilation to ensure low outercasing temperatures Very good temperature uniformity in the furnace chamber Parallel-guided door moving up-wards with hot insulation surface tothe rear, away from operator Insulation made of high grade ceramic fibre with low thermal mass Door collar made of strong fire bricks Wear-resistant fire brick insulation in the furnace bottom Delivery includes ceramic bottom plate Heating elements on ceramic supporting tubes, mounted in front ofthe insulation for free heat radiation Powerful heating elements in both sides providing fast heating rates Heating elements controlled by solid state relays for very precise temperature control, wear-free and noiselessAccessories: Parallel-guided swing door Adjustable over-temperature protection of furnace and chargeacc. EN 60519-2 Further accessories see page 13Technical Data8ModelT maxInner dimensionsVolumeOuter dimensionsPowerVoltageKLS 05/11/ASH1100210 x 200 x 1506550 x 580 x 6502,0230 V 1/NKLS 10/11/ASH1100200 x 250 x 20010560 x 640 x 7203230 V 1/NKLS 05/12/ASH1200180 x 200 x 1405550 x 580 x 6502,0230 V 1/NKLS 10/12/ASH1200200 x 250 x 20010560 x 640 x 7204,0400 V 3/N[ C]*Height 350 mm for exhaust stack[mm]Width x Depth x Height[l][mm]Width x Depth x Height*[kW][V]

Laboratory chamber furnaceswith ceramic muffleT max 1000 C, 1100 C and 1150 C Chamber furnaces with integrated ceramic muffle, high mechanical and chemical resistance Furnaces designed especially and recommended for ambitiouslaboratory applications with aggressive waste gases Suitable for assay of precious metals or ashing of organicsubstances Delivery including ceramic muffle Heating elements wound around outside the ceramic muffle,heating on all 4 sides for high temperature uniformity insidethe chamber Heating elements protected against aggressive waste gasesatmospheres Heating elements controlled by solid state relays for veryprecise temperature control, wear-free and noiseless Exhaust pipe in the rear wall KLS 07/11/M with double-walled housing and rear ventilationto ensure low outercasing temperatures, parallel-guided doormoving up-wards with hot insulation surface to the rear, awayfrom operator, insulation made of high grade ceramic fibrewith low thermal mass, collar made of fire bricks to ensurehigh wear resistance against mechanical stressKLS 07/11/M KLS 03/10/M and KLS 02/11/M with userfriendly swing doorwith multilayer insulation made of high grade fibreAccessories: Adjustable temperature limiterto protect furnace and chargeacc. EN 60519-2 Further accessoriessee page 13KLS 02/11/MKLS 03/10/MTechnical DataModelT maxInner dimensionsVolumeOuter dimensionsPowerVoltageWeightKLS 03/10/M1000140 x 200 x 1103320 x 350 x 4101,5230 V 1/N20KLS 02/11/M1100100 x 140 x 1002320 x 350 x 4101,5230 V 1/N20KLS 07/11/M1150210 x 280 x 1107550 x 580 x 6502,7230 V 1/N60[ C][mm]Width x Depth x Height[l][mm]Width x Depth x Height[kW][V][kg]9

Laboratory chamber furnacefor asphalt tests according ASTM D 6307-98T max 600 C Chamber furnace especially developed for analysis of asphalt at 540 Caccording to ASTM D 6307-98 With integrated balance for weight loss determination, software andinterface for data storage, max. probe weight is 2500 gr. Thermal after burner, mounted to the exhaust on top of the furnace, forcleaning of waste gases emerging from the probe Very high temperature uniformity in the furnace chamber Double-walled housing with rear-ventilation to ensure low outer-casingtemperatures Swing door with electrical locking at process temperature above 150 C Insulation made of high grade ceramic fibre with low thermal mass Door collar made of strong fire bricks Wear-resistant fire brick insulation in the furnace bottom Powerful heating elements in both sides providing fast heating rates, forfast heat-up in approx. 35 min to 540 C Heating elements on ceramic supporting tubes, mounted in front of theinsulation for free heat radiation Heating elemants covered with quartz glass tubs for protection Heating elements controlled by solid state relays for very precise temperature control, wear-free and noiseless According to norm with automatic switch off after test has been finishedTechnical Data10ModelT maxInner dimensionsVolumeOuter dimensionsPowerWeightKLS 30/06/BIT600300 x 300 x 30027605 x 595 x 515 / 11304400 V 3/N[ C][mm]Width x Depth x Height[l][mm]Width x Depth x Height[kW][V]

Laboratory furnaces with weighing systemT max 1200 C Laboratory chamber furnaces with integrated weighing system formeasuring and documentation of mass loss at different temperatures Balance mounted underneath the furnace and connected with indentor and charge tray inside the furnace Switchgear mounted in

Special tube furnaces 28 Tube furnace accessories 29 Drying cabinets, High temperature ovens 250 – 850 C Drying cabinets with natural or forced air convection 250 / 300 C 30 Vacuum drying cabinets 200 C 31 High temperature ovens 450 / 650 / 850 C 32 High temperature ovens 750 C 33 Customized furnaces 34 Furnaces and plants for production 36 Exhaust air purification plants 38 .